Flexible Application of Tracked Mobile Crusher in Mining on Complex Terrain

This comprehensive article explores the exceptional value of tracked mobile crushers when deployed in challenging mining environments such as rugged mountains, uneven pits, and remote sites. As a pivotal piece of modern mining technology, these machines fundamentally transform limitations associated with traditional stationary crushing plants through their unique mobility, robust terrain adaptability, and integrated crushing solutions. The discussion delves into how they address specific topographic obstacles, enhance overall mining efficiency, optimize operational costs, and ensure worksite safety. By analyzing practical application scenarios and technical advantages, this piece serves as a thorough reference for professionals seeking efficient crushing strategies in demanding conditions, highlighting how mobility translates into tangible benefits across various mining phases.

Core Challenges and Crushing Needs in Mining on Complex Terrain

Complex geological and topographical conditions impose severe tests on the material crushing phase within mining operations, where conventional approaches often fall short. The inherent difficulties of uneven ground, limited access routes, and environmental extremes demand equipment that can perform reliably without extensive site preparation. These challenges not only escalate costs but also pose significant risks to personnel and machinery, necessitating innovative solutions that prioritize flexibility and resilience. Understanding these hurdles is the first step toward appreciating the transformative role of advanced mobile crushing technology in such settings.

Difficult Road Conditions and Equipment Accessibility Issues

Mining sites located in mountainous or hilly regions frequently feature narrow, winding paths that are unsuitable for heavy fixed crushers or even wheeled vehicles. The lack of proper infrastructure means that transporting bulky equipment to the desired location becomes a logistical nightmare, often requiring costly road construction or helicopter assistance. Tracked mobile crushers overcome this by leveraging their self-propelled capabilities, which allow them to traverse rough landscapes independently. Their low ground pressure and robust undercarriage enable movement across soft soil or rocky outcrops where other machinery would struggle or fail entirely.

Beyond mere mobility, the ability to access remote areas directly impacts project timelines and feasibility. Delays in equipment deployment can halt entire mining operations, leading to financial losses and missed production targets. The tracked design ensures that crushers can be driven directly to the extraction point, minimizing the need for auxiliary transport and reducing dependency on external infrastructure. This autonomy is crucial in regions with seasonal weather changes, where roads may become impassable due to rain or snow, further emphasizing the importance of all-terrain proficiency in maintaining continuous operations.

Dispersed Workfaces and High Costs of Material Transportation

When mining operations span multiple scattered pits or veins, the traditional model of centralized crushing necessitates long-distance haulage of raw materials. This process involves numerous truck journeys that consume substantial amounts of fuel, increase wear on vehicles, and contribute to higher labor expenses. The cumulative effect of these transportation activities can constitute up to 50% of total operational costs in some cases, making efficiency paramount. Tracked mobile crushers address this by enabling on-site processing, which drastically shortens the distance between excavation and crushing stages.

Moreover, the economic implications extend beyond direct fuel savings to include reduced carbon emissions and lower maintenance requirements for transport fleets. By positioning the crusher adjacent to each workface, operators can process material immediately after extraction, streamlining the workflow and enhancing resource utilization. This approach not only cuts costs but also minimizes the environmental footprint of mining activities by limiting the number of heavy vehicles traversing sensitive landscapes. The strategic placement of mobile units thus supports sustainable practices while improving profitability.

Site Space Constraints and Equipment Layout Difficulties

Complex terrain often offers limited flat areas for setting up extensive fixed crushing plants, which typically require large foundations, conveyors, and auxiliary structures. The scarcity of suitable land compels operators to make compromises that can hinder productivity or force them to undertake expensive earthmoving projects. Tracked mobile crushers eliminate this dilemma through their compact, integrated designs that consolidate multiple functions into a single unit. This consolidation allows for operation in confined spaces without sacrificing performance or safety standards.

Additionally, the flexibility in layout reduces the time and capital invested in site preparation, as no permanent installations are needed. Operators can quickly position the crusher on available level ground, even if it is temporary or sloped, thanks to adjustable stabilizers and intelligent leveling systems. This adaptability is particularly valuable in terrains like narrow valleys or steep hillsides, where every square meter of space must be optimized. Consequently, mining projects can proceed with minimal disruption to the natural topography while maximizing equipment efficiency.

Harsh Environmental Demands on Equipment Stability

Operating in environments with dust, extreme temperatures, or significant gradients places exceptional demands on crushing machinery, requiring enhanced durability and reliability. Standard equipment may suffer from accelerated wear, frequent breakdowns, or safety hazards under such conditions, leading to unplanned downtime and increased repair costs. Tracked mobile crushers are engineered with reinforced components and advanced sealing systems to withstand these challenges, ensuring consistent performance despite external factors. Their robust construction includes features like dust-proof bearings and temperature-resistant hydraulics that maintain functionality in adverse settings.

Furthermore, stability on uneven surfaces is critical to prevent accidents and maintain crushing accuracy. Modern tracked crushers incorporate sophisticated monitoring systems that detect tilt angles and automatically adjust operations to avoid instability. This capability allows them to work safely on slopes of up to 15 degrees or more, depending on the model, without compromising output quality. The integration of such technologies not only prolongs equipment lifespan but also safeguards operators by reducing the risk of rollovers or mechanical failures in precarious locations.

How Tracked Mobile Crushers Overcome Complex Terrain

Tracked mobile crushers are specifically designed to tackle the obstacles presented by difficult mining landscapes, combining innovative engineering with practical functionality. Their unique attributes enable them to perform reliably where other machines cannot, transforming previously inaccessible areas into productive sites. This section examines the key design elements that contribute to their success, from locomotion systems to power management, illustrating how each component plays a role in conquering topographic challenges. The synergy between these features results in a machine that is both agile and powerful, capable of meeting the rigorous demands of modern mining.

Crawler Track System Delivering Superior Ground Pressure and Climbing Ability

The crawler track assembly distributes the machine's weight over a larger surface area compared to wheeled counterparts, resulting in lower ground pressure that prevents sinking in soft or muddy terrain. This design allows the crusher to move across unstable ground like sand, gravel, or wet soil without getting stuck, maintaining traction even on slippery surfaces. Additionally, the tracks provide exceptional climbing capabilities, enabling the unit to ascend gradients as steep as 25 degrees in some configurations, which is essential for navigating hilly mining sites. The continuous track motion ensures smooth progression over obstacles like rocks or ditches, reducing jolts that could damage internal components.

Moreover, the track system enhances stability during crushing operations by providing a broad, secure base that minimizes vibration and shifting. This is achieved through robust steel frames and precision-engineered rollers that absorb shocks from uneven ground. Operators can rely on consistent performance whether working on a slight incline or flat surface, as the tracks adapt to variations in topography without requiring manual adjustments. The durability of these systems is evidenced by their ability to endure thousands of hours in abrasive environments, underscoring their suitability for long-term mining projects in remote locations.

Integrated Design Enabling On-the-Spot Crushing Convenience

Tracked mobile crushers combine the crusher, feeder, and screening units into a single cohesive system mounted on one chassis, eliminating the need for multiple separate machines and complex setup procedures. This integration allows for immediate operation upon arrival at a site, as no assembly or disassembly is required beyond basic positioning and leveling. The streamlined design reduces the footprint of the crushing operation, making it ideal for confined spaces where traditional plants would be impractical. Key components like the hopper and conveyor systems are optimized for seamless material flow, minimizing bottlenecks and maximizing throughput.

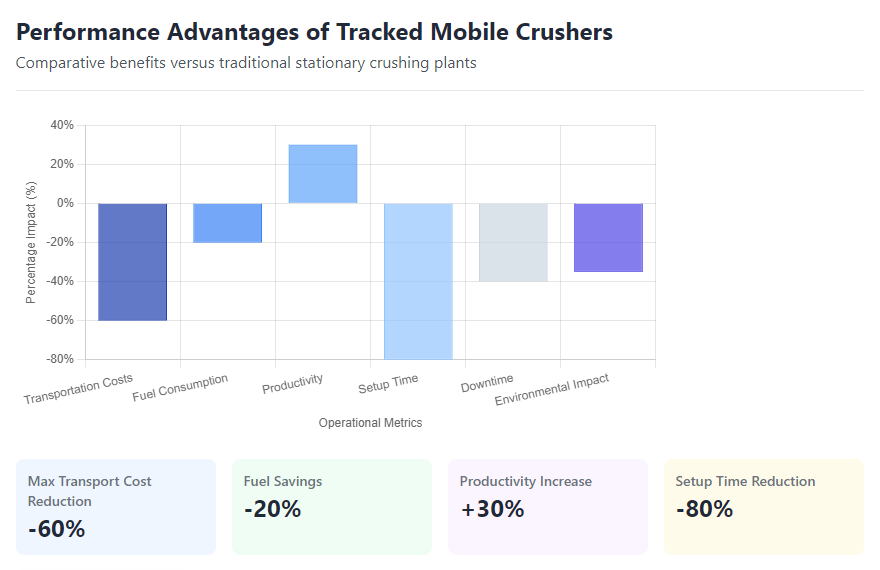

Furthermore, the unified structure simplifies transportation between sites, as the entire unit can be moved as one entity rather than requiring dismantling and reassembly. This portability is crucial for mining companies that operate across multiple pits or engage in exploratory drilling, as it enables rapid redeployment in response to changing resource locations. The efficiency gains from reduced setup times can lead to productivity increases of up to 30% in some operations, highlighting the economic benefits of this approach. By consolidating functions, tracked crushers deliver a plug-and-play solution that enhances operational agility.

Hydraulic Drive and Intelligent Control Systems Ensuring Precise Movement and Positioning

Hydraulic systems provide the power for both locomotion and crushing functions, offering smooth, variable speed control that allows for precise maneuvering in tight spaces. Operators can adjust the machine's position with millimeter accuracy using joystick controls or automated programs, facilitating optimal alignment with excavation faces or discharge points. Intelligent control panels monitor parameters like engine load and track tension, automatically making corrections to maintain efficiency and prevent overloads. This level of precision is vital when working near drop-offs or in crowded work zones where safety margins are narrow.

Additionally, advanced software enables features like remote monitoring and diagnostics, allowing technicians to assess machine health from a central office. Real-time data on factors such as fuel consumption, production rates, and component wear help optimize performance and schedule maintenance proactively. The integration of GPS and mapping technologies further aids in navigation across large, unfamiliar sites, ensuring that the crusher follows the most efficient routes. These smart systems not only improve operational accuracy but also reduce the skill threshold required for effective machine management, making advanced crushing technology accessible to a broader range of operators.

Powerful Engine Systems Guaranteeing Continuous Operation in Remote Areas

Equipped with high-capacity diesel engines, tracked mobile crushers generate their own electricity, eliminating reliance on external power grids that are often unavailable in isolated mining regions. These engines are designed for fuel efficiency and low emissions, complying with international standards like Tier 4 Final to minimize environmental impact. With power outputs ranging from 200 to 500 horsepower depending on the model, they provide sufficient energy to drive both the crushing mechanism and auxiliary systems simultaneously. This self-sufficiency ensures uninterrupted production even in the most secluded locations, where infrastructure development is not feasible.

Moreover, modern engines incorporate features like automatic idle shutdown and eco-mode settings that reduce fuel consumption during periods of low activity. The ability to operate independently for extended durations reduces the logistical burden of transporting fuel or maintaining power lines, which can be prohibitively expensive in rugged terrains. Some models also offer optional hybrid configurations that combine diesel with electric power for even greater efficiency. This reliability is critical for meeting production targets in demanding schedules, as downtime due to power issues can have cascading effects on downstream processes like material handling and processing.

Specific Applications of Tracked Mobile Crushers in Various Complex Mining Scenarios

The versatility of tracked mobile crushers allows them to be deployed across a wide spectrum of mining environments, each with distinct characteristics and requirements. From steep slopes to deep pits, these machines demonstrate their adaptability by delivering consistent performance in contexts that would challenge conventional equipment. This section outlines practical use cases where mobile crushing technology has proven particularly effective, highlighting how it addresses site-specific issues while enhancing overall operational coherence. By examining these applications, readers can gain insights into the strategic advantages of incorporating mobility into mining workflows.

Primary Crushing in Mountainous and Steep Slope Quarries

In alpine or hilly quarries, tracked mobile crushers can be driven directly to the rock face following blasting activities, enabling primary crushing at the source. This proximity eliminates the need for primary haulage of large, uncrushed boulders, which is both dangerous and inefficient on inclines. The crushed material can then be conveyed to secondary processing stations or stockpiles via integrated belts, reducing the number of truck trips required. This method not only speeds up production cycles but also enhances safety by minimizing vehicle movement on precarious roads.

Additionally, the ability to work on gradients allows operators to exploit mineral deposits that were previously considered uneconomical due to access issues. For instance, in quarries with elevation differences exceeding 100 meters, mobile crushers can relocate between benches without requiring extensive ramps or roads. This flexibility supports continuous extraction despite topographic constraints, maximizing resource recovery from challenging formations. The use of jaw crushers in these setups ensures robust performance against hard materials like granite or basalt, delivering consistent particle size reduction for downstream milling.

Step-by-Step Crushing in Deep Open-Pit Mines

As open-pit mines deepen over time, the distance between extraction levels and surface processing plants increases, leading to higher transportation costs and longer cycle times. Tracked mobile crushers can descend into the pit and follow the advancing mine faces, crushing ore directly at each level before it is hoisted to the surface. This approach integrates seamlessly with continuous mining systems, where conveyors replace trucks for vertical material handling. The result is a more efficient flow of materials that reduces energy consumption and operational complexity.

Furthermore, the mobility of these units allows them to shift between different production zones within the pit, adapting to changing geology or operational priorities. For example, if a particular bench yields higher-grade ore, the crusher can be repositioned to prioritize that area without disrupting overall schedules. This dynamic response capability is enhanced by real-time data sharing with other equipment like excavators and drills, creating a synchronized production environment. The economic benefits include lower per-ton processing costs and extended mine life due to improved resource utilization.

Flexible Solutions for Multi-Site, Small-Batch Exploratory Mining

Exploration phases often involve testing multiple small deposits to assess their commercial viability, requiring equipment that can be moved frequently without significant setup costs. Tracked mobile crushers are ideal for this purpose, as they can be transported between sites on low-loaders or even self-drive short distances on permissible roads. Once on location, they quickly begin processing samples, providing valuable data on ore characteristics and potential yields. This agility enables mining companies to evaluate prospects more efficiently, reducing the time and expense associated with traditional exploration methods.

Moreover, the ability to handle varying material types and volumes makes these crushers suitable for pilot projects or low-volume production runs. Operators can adjust settings like feed size and crushing pressure to match specific ore properties, ensuring optimal recovery rates. The compact design also minimizes site disturbance, which is important in environmentally sensitive areas or regions with strict permitting requirements. By facilitating rapid, low-impact operations, mobile crushers support sustainable exploration practices that align with modern regulatory standards.

Resource Recovery in Tailings Ponds and Waste Rock Dumps

Historical mining operations often left behind large quantities of tailings or waste rock that contain residual minerals, which can now be reprocessed using advanced technologies. Tracked mobile crushers are deployed directly onto these deposits, crushing the material to liberate valuable elements for further treatment. This application not only extracts additional resources but also helps remediate contaminated sites by reducing the volume of hazardous waste. The mobility of the crusher allows it to cover extensive areas efficiently, processing material where it lies without requiring relocation.

Additionally, the use of mobile units in recycling applications supports circular economy principles by turning waste into usable products like construction aggregates or industrial fillers. For instance, crushed tailings can be repurposed for road base or cement production, generating revenue while minimizing environmental liabilities. The integration of screening attachments enables separation of different material sizes on-site, enhancing the value of the end products. This approach is particularly relevant in urban mining contexts, where space constraints and community concerns favor compact, self-contained equipment like impact crushers for secondary reduction.

Key Technologies and Performance Advantages Optimized for Complex Terrain

To meet the unique demands of complex mining environments, tracked mobile crushers incorporate a range of specialized technologies that enhance their functionality and reliability. These innovations address issues such as stability, wear resistance, and operational safety, ensuring that the equipment performs optimally under adverse conditions. This section details the engineering solutions that set these machines apart, explaining how each contributes to improved outcomes in challenging settings. From advanced chassis designs to automated control systems, these features collectively enable tracked crushers to deliver superior results where it matters most.

Advanced Chassis Structure and Center of Gravity Design Ensuring Operational Stability

The chassis of a tracked mobile crusher is constructed from high-strength steel with reinforced cross members and bogies that distribute loads evenly across the track system. This design lowers the center of gravity, reducing the risk of tipping when operating on slopes or uneven ground. Engineers use computational modeling to optimize weight distribution, ensuring that the machine remains stable even during dynamic activities like crushing or turning. Hydraulic outriggers or leveling jacks provide additional support when stationary, further enhancing safety and precision.

Moreover, the chassis incorporates flexible suspension elements that absorb shocks from rough terrain, protecting internal components from damage and maintaining alignment between critical parts. This durability is essential for longevity in abrasive environments where constant vibration and impact loads are common. The robust construction also allows for heavier crushing chambers and larger feed openings without compromising mobility, enabling higher throughput capacities. These structural advantages translate into consistent performance metrics, such as maintaining target discharge sizes despite external disturbances, which is crucial for meeting product specifications in aggregate or mineral processing.

Pre-Screening and Metal Detection Systems Minimizing Blockages and Damage Risks

Integrated pre-screening modules separate fine materials and debris from the primary feed before it enters the crushing chamber, reducing the volume of processed material and preventing clogging. This step is especially important in mining applications where ore may contain soil, clay, or other contaminants that could impede crusher efficiency. Metal detectors identify tramp iron or other metallic objects that might cause catastrophic damage to rotors or liners, automatically triggering diversion mechanisms to remove them from the stream. These systems enhance operational continuity by minimizing unplanned stoppages for clearing jams or repairing broken components.

Additionally, the use of pre-screening improves the quality of the final product by ensuring a more uniform feed size distribution, which optimizes crusher performance and energy consumption. For example, removing undersized particles early allows the crusher to focus on reducing larger rocks, increasing throughput and reducing wear on consumable parts. The integration of these auxiliary systems demonstrates how modern tracked crushers are designed as comprehensive solutions rather than standalone machines. This holistic approach results in higher overall equipment effectiveness and lower total cost of ownership over the machine's lifespan.

Remote Control and Automation Systems Enhancing Safety and Efficiency

Remote operation capabilities allow controllers to manage the crusher from a safe distance using wireless consoles or cabin-mounted interfaces, reducing exposure to hazards like dust, noise, or falling debris. Automated functions include programmed start-up sequences, load management, and self-diagnostic checks that ensure optimal operating conditions without constant human intervention. These features are particularly valuable in unstable areas such as pit edges or steep slopes, where direct operator presence could be dangerous. The ability to monitor and adjust parameters remotely also facilitates faster response to changing site conditions, improving overall productivity.

Furthermore, automation enables data collection for performance analytics, helping operators identify trends and optimize processes over time. For instance, algorithms can adjust crushing pressure or speed based on real-time feedback from sensors monitoring material hardness or moisture content. This level of precision ensures consistent product quality while maximizing energy efficiency. The convergence of automation with mobility represents a significant leap forward in mining technology, enabling smarter, safer operations that require fewer personnel on-site. As a result, companies can achieve higher output with reduced risk, aligning with industry trends toward digitalization and automation.

Efficient Dust Suppression and Noise Reduction Systems Meeting Environmental Standards

Tracked mobile crushers are equipped with integrated water spray systems that suppress dust at key points like feed hoppers and discharge conveyors, maintaining air quality and visibility. These systems use minimal water through atomized nozzles that create fine mists, effectively capturing airborne particles without saturating the material. Noise reduction measures include acoustic enclosures around engines and crushers, as well as vibration-damping mounts that lower sound emissions to comply with regulatory limits. These features are critical for operating near residential areas or in regions with strict environmental protections.

Moreover, the environmental benefits extend to reduced water consumption and contamination risks compared to traditional methods that rely on open spraying or chemical suppressants. The closed-loop design of many dust control systems recycles water where possible, minimizing waste and conserving resources. Compliance with standards like the European Union's Machinery Directive ensures that these crushers can be used globally without legal impediments. By addressing ecological concerns proactively, tracked mobile crushers support sustainable mining practices that balance economic objectives with social and environmental responsibilities, often incorporating cone crusher technologies for finer, controlled outputs with lower noise profiles.

Core Strategies for Achieving Efficient Operations and Cost Optimization

Adopting tracked mobile crushers involves more than just acquiring new equipment; it represents a shift in operational philosophy that prioritizes flexibility and efficiency. This section explores the strategic approaches that maximize the benefits of mobile crushing, from cost reduction to process integration. By understanding how to leverage these machines within broader mining workflows, operators can unlock significant value while mitigating common pitfalls. The discussion covers economic considerations, logistical planning, and lifecycle management, providing a roadmap for realizing the full potential of this technology in complex terrains.

Significant Reduction in Material Transportation Costs Delivering Direct Economic Benefits

By processing material directly at the extraction point, tracked mobile crushers eliminate the need for primary haulage of unprocessed ore or rock, which is typically the most expensive phase of material handling. Studies indicate that transportation can account for 30-60% of total operating costs in mining, so minimizing these expenses has a profound impact on profitability. The savings stem from reduced fuel consumption, lower maintenance for trucks, and decreased labor requirements for driving and loading. Additionally, shorter haul distances translate into faster cycle times, allowing more material to be moved within the same timeframe.

Furthermore, the economic advantages extend to indirect cost savings such as reduced road maintenance and lower insurance premiums due to fewer vehicle accidents. The ability to crush on-site also enables operators to handle lower-grade deposits that were previously uneconomical because of high transport costs. This expands the resource base and prolongs mine life, contributing to long-term sustainability. The strategic deployment of mobile crushers thus serves as a catalyst for overall operational improvement, aligning financial goals with practical realities in challenging landscapes.

Rapid Relocation and Setup Times Maximizing Equipment Utilization

Tracked mobile crushers can be moved between work sites in a matter of hours, compared to days or weeks for disassembling and reassembling fixed plants. This agility allows mining companies to respond quickly to changing production demands or newly discovered resource zones. Once on location, setup involves simple steps like unfolding conveyors and activating stabilizers, minimizing downtime between moves. High utilization rates are achieved by keeping the crusher active across multiple projects or phases, rather than sitting idle during transitions.

Moreover, the quick setup facilitates just-in-time production models where crushing occurs only when needed, reducing stockpiling requirements and associated costs. For example, in seasonal mining operations, equipment can be deployed during favorable weather windows and relocated during off-periods. This flexibility also supports contract crushing services, where mobile units are leased to different clients for short-term projects. The overall effect is a higher return on investment through increased productive hours and reduced capital tied up in underutilized assets, often leveraging high crushing capacities to offset mobilization expenses.

Seamless Integration with Upstream Excavators and Downstream Conveying Systems

Tracked mobile crushers are designed to interface directly with excavators or loaders via adjustable feed hoppers that accommodate varying dump heights and angles. This direct feeding eliminates the need for intermediate equipment like primary crushers or apron feeders, streamlining the material flow from excavation to size reduction. Discharge conveyors can be linked to longer belt systems for transport to secondary processing or storage, creating a continuous production line. The synchronization of these elements reduces handling steps and minimizes potential points of failure.

Additionally, modern control systems enable communication between the crusher and other machinery, allowing for coordinated operations that optimize overall efficiency. For instance, the crusher can signal the excavator to adjust feeding rates based on current load, preventing overloads or empty running. This integration is particularly beneficial in large-scale operations where multiple units work in tandem, as it ensures balanced production across the site. The holistic approach to system design underscores how mobile crushers act as central hubs within broader material processing networks, enhancing coherence and reliability.

Lifecycle Cost Analysis and Investment Return Assessment

While the initial purchase price of a tracked mobile crusher may be higher than that of a fixed plant, the total cost of ownership over its lifespan often proves lower due to operational savings. Lifecycle analysis considers factors like fuel efficiency, maintenance intervals, repair costs, and resale value to provide a comprehensive financial picture. For example, the ability to avoid infrastructure investments like concrete foundations or permanent shelters reduces upfront capital expenditure. Similarly, the flexibility to relocate equipment extends its useful life by allowing deployment in new projects as old ones conclude.

Moreover, calculating return on investment involves quantifying benefits such as increased production rates, reduced downtime, and lower transportation expenses. A typical payback period for a mobile crusher in a complex terrain application ranges from 12 to 24 months, depending on utilization and local cost structures. The long-term economic viability is further supported by the machine's adaptability to evolving technologies, such as retrofitting with newer engines or control systems. This forward-looking perspective ensures that investments remain profitable despite changes in market conditions or regulatory requirements, solidifying the role of mobile crushing in modern mining economics.

Equipment Selection, Safe Operation, and Maintenance Guidelines

To ensure optimal performance of tracked mobile crushers in complex terrain, careful attention must be paid to selection criteria, operational protocols, and upkeep routines. This section provides practical advice on choosing the right machine for specific conditions, implementing safety measures, and maintaining reliability over time. By adhering to these guidelines, operators can mitigate risks, extend equipment lifespan, and achieve consistent results. The recommendations are based on industry best practices and engineering principles, tailored to address the unique challenges of mobile crushing in demanding environments.

Selecting the Appropriate Crusher Host Type Based on Material Characteristics and Capacity Requirements

The choice of crusher type depends on factors such as rock hardness, abrasiveness, moisture content, and desired output size. For primary crushing of hard, abrasive materials like granite or iron ore, a tracked mobile jaw crusher is often preferred due to its compressive action and robust construction. Softer or less abrasive materials may be better suited to impact crushers, which use high-speed rotors to fracture particles through impact. Capacity needs dictate the size of the crusher, with larger models handling over 500 tons per hour in some configurations, while smaller units serve niche applications.

Additionally, considerations like feed size distribution and product shape requirements influence selection. For instance, cone crushers produce more cubical particles ideal for concrete aggregate, whereas jaw crushers generate more flaky outputs suitable for base layers. Consulting manufacturer specifications and conducting material tests help match the machine to the application, ensuring efficient operation and minimal wear. The integration of screening options further customizes the setup, allowing for closed-circuit operations that recirculate oversize material. This meticulous selection process lays the foundation for successful implementation in varied topographic settings.

Safe Operating Procedures and Risk Prevention in Complex Terrain

Operating tracked mobile crushers on slopes or unstable ground requires strict adherence to safety protocols to prevent accidents like rollovers or collisions. Procedures include conducting pre-shift inspections of the terrain for hazards such as loose rocks, hidden voids, or excessive gradients. Operators must be trained in emergency response measures, including how to use fire extinguishers, first aid kits, and communication devices in remote locations. The implementation of proximity warning systems and cameras enhances situational awareness, especially in blind spots around the machine.

Furthermore, risk assessments should identify potential issues like overhead power lines, underground utilities, or environmental sensitivities that could affect operations. Establishing exclusion zones around the crusher during operation protects personnel from flying debris or moving parts. Regular safety drills and certification programs ensure that teams remain prepared for unforeseen events. These measures not only comply with occupational health and safety regulations but also foster a culture of vigilance that reduces incident rates. The combination of technical safeguards and procedural rigor creates a secure working environment even in the most challenging conditions.

Wear Parts Management and Replacement Strategies for High-Abrasion Environments

In mining applications, components like jaw plates, concaves, and blow bars experience rapid wear due to constant contact with abrasive materials, necessitating proactive management. Implementing a tracking system for wear parts helps monitor their lifespan and schedule replacements before failure occurs, avoiding unplanned downtime. Stocking critical spares on-site or through reliable suppliers ensures quick availability when needed, minimizing production interruptions. The use of advanced materials such as manganese steel or ceramic composites extends service intervals by resisting wear more effectively.

Moreover, optimizing operational parameters like feed rate and closed-side setting can reduce unnecessary stress on wear parts, prolonging their usability. Regular inspections using thickness gauges or visual checks detect early signs of deterioration, allowing for planned maintenance during scheduled stops. Documenting wear patterns over time aids in predicting future needs and budgeting for replacements. This systematic approach to parts management not only controls costs but also maintains consistent product quality by ensuring that crushing chambers remain within design tolerances. The reliability of the entire operation hinges on effective wear management, especially in remote sites where delays can be costly.

Daily Inspection and Periodic Maintenance Essentials for Travel and Hydraulic Systems

The crawler tracks require daily checks for tension, damage, and wear on pads and rollers to ensure safe mobility and prevent derailment. Cleaning accumulated mud or debris from the undercarriage prevents corrosion and reduces friction that could lead to overheating. Hydraulic systems need regular monitoring of fluid levels, hose integrity, and filter conditions to maintain pressure and avoid leaks that could impair functionality. Following manufacturer-recommended service intervals for oil changes and component lubrication is crucial for long-term reliability.

Additionally, periodic maintenance includes calibrating sensors, testing safety devices, and updating software to keep the crusher operating at peak efficiency. Keeping detailed maintenance logs helps track service history and identify recurring issues that may indicate deeper problems. Training maintenance staff in specific procedures for tracked equipment ensures that repairs are performed correctly and safely. This disciplined upkeep regimen not only prevents breakdowns but also preserves the machine's resale value by demonstrating diligent care. The investment in routine maintenance pays dividends through reduced repair costs and higher availability, making it a cornerstone of successful mobile crushing operations.

Future Development Trends and Technological Innovations

The evolution of tracked mobile crushers continues as manufacturers integrate emerging technologies to enhance performance, sustainability, and user experience. This section explores anticipated advancements that will shape the next generation of equipment, from energy solutions to digital integration. Understanding these trends allows mining companies to plan for future upgrades and stay competitive in a rapidly changing industry. The focus is on innovations that address current limitations while opening new possibilities for efficient resource extraction in complex terrains.

Hybrid and New Energy Technologies Reducing Carbon Emissions

Hybrid powertrains combining diesel engines with electric batteries are gaining traction, allowing crushers to operate silently and emission-free during stationary crushing while using diesel for mobility. This configuration reduces fuel consumption by up to 20% in some cases, lowering operating costs and environmental impact. Fully electric models powered by onboard batteries or external grid connections are also under development, targeting zero emissions during use. The adoption of renewable energy sources like solar panels for auxiliary power further supports decarbonization goals in mining.

Moreover, the shift toward alternative fuels such as hydrogen or biofuels promises to eliminate greenhouse gas emissions entirely in the long term. These technologies require adaptations in engine design and fuel storage, but offer the potential for sustainable operation without compromising power. Regulatory pressures and corporate sustainability initiatives are driving investment in these areas, accelerating their commercialization. The integration of energy recovery systems, such as capturing brake energy from tracks, adds to overall efficiency. These innovations align tracked mobile crushers with global efforts to combat climate change while maintaining operational excellence.

Artificial Intelligence and Machine Learning Enabling Predictive Maintenance and Smart Scheduling

AI algorithms analyze data from sensors monitoring vibration, temperature, and performance metrics to predict component failures before they occur, enabling proactive maintenance. Machine learning models optimize crushing parameters in real time based on material characteristics, maximizing throughput and minimizing energy use. Smart scheduling systems coordinate the movement of multiple crushers across a site, ensuring balanced workloads and reducing idle time. These capabilities reduce human error and enhance decision-making, leading to more efficient operations.

Furthermore, AI-driven analytics provide insights into long-term trends, helping planners optimize equipment deployment and resource allocation. For example, predictive models can forecast wear rates based on historical data, allowing for just-in-time parts ordering. The integration of AI with other digital tools like IoT platforms creates a cohesive ecosystem where all equipment communicates seamlessly. This digital transformation not only improves productivity but also reduces the skill gap by providing operators with intelligent assistants. The future of mobile crushing lies in these smart technologies that make complex processes more manageable and predictable.

5G Technology and Remote Immersive Control Deepening Integration

The high bandwidth and low latency of 5G networks enable real-time transmission of high-definition video and sensor data from crushers to remote control centers. This allows operators to manage machines from thousands of kilometers away with minimal delay, improving safety by removing personnel from hazardous sites. Immersive control interfaces using virtual or augmented reality provide a lifelike experience, enhancing situational awareness and precision. These technologies are particularly beneficial in extreme environments like deep pits or radioactive areas, where human presence is limited.

Additionally, 5G facilitates the connection of multiple devices within a site, creating a networked environment where data flows freely between excavators, crushers, and conveyors. This interoperability supports autonomous operations where machines coordinate their actions without human intervention. The reliability of 5G in remote locations is improving with the deployment of satellite-based solutions, ensuring connectivity even in isolated regions. The convergence of telecommunications and heavy machinery represents a paradigm shift in mining, enabling more flexible and responsive operations. This trend toward remote and automated control will redefine the role of human operators in the years to come.

Modular and Customizable Designs Adapting to Extreme Special Conditions

Future tracked mobile crushers will feature modular components that can be swapped out to match specific requirements, such as different crushing chambers for varying material types. Customization options will include adjustable track widths for stability on soft ground or enhanced cooling systems for hot climates. Manufacturers are developing designs that can be easily upgraded with new technologies, extending the usable life of the equipment. This flexibility allows mining companies to tailor crushers to unique site conditions without commissioning entirely new machines.

Moreover, modularity supports rapid repair and maintenance by enabling the replacement of entire assemblies rather than individual parts. For instance, a damaged hydraulic system could be swapped for a pre-assembled module in hours instead of days. The ability to reconfigure crushers for different applications—such as switching from primary to secondary crushing—adds versatility that maximizes utility across project phases. These advancements reflect a growing emphasis on user-centric design that prioritizes adaptability and ease of use. As mining ventures into more extreme environments, such as arctic regions or high altitudes, customizable tracked crushers will become indispensable tools for success.