High-Performance Stone Crushers

MSW® Group engineers heavy-duty stone crushers (rock & ore crushers) designed to withstand the toughest mining and quarrying environments. Whether processing granite, basalt, or iron ore, our equipment delivers precise material reduction (5mm-150mm) with maximum throughput.

Countries Exported

Patents

Solutions for Different Stone Crushing Applications

NOTICE: The images below are for illustrative purposes only and do not represent actual client projects. (Source: Unsplash)

Types of Stone Crusher

Different stone crushers have different application scenarios. Choosing the right machine can help you complete the task better.

Primary Crushing

Handles the first stage of crushing, reducing large rocks into smaller pieces.

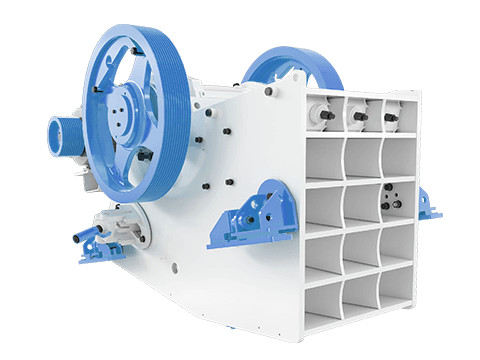

Jaw Crusher

Compressive Crushing: Utilizes compressive force generated by a reciprocating motion between a fixed jaw plate and a movable jaw plate. The material is crushed by progressive compression as it moves downward through the crushing chamber.

Primary Crushing High Reduction Ratio

Learn more >>

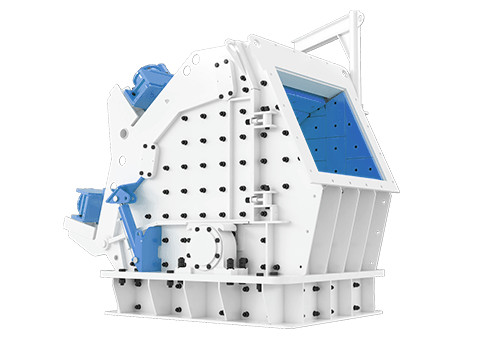

Impact Crusher

Dynamic Impact Crushing: Relies on kinetic energy transfer via high-speed rotors equipped with blow bars or hammers. Material is shattered by direct impact against rotating components or stationary anvils, with fragmentation occurring through particle-on-particle collisions.

High-Speed Impact Cubical Aggregate

Learn more >>

Gyratory Crusher

Conical Compression Crushing: Operates via a conical head gyrating within a concave bowl, generating progressive compression as material moves downward. Combines elements of jaw and cone crushers for ultra-high-capacity primary crushing.

Primary Crushing High Capacity

Learn more >>

Secondary Crushing

Further reduces the size of materials after primary crushing, ensuring uniform particles.

Cone Crusher

Employs interparticle crushing (also called layer compression), where rocks are crushed between a rotating mantle and a concave liner. The eccentric gyratory motion of the mantle creates a compressive force field, inducing fractures along grain boundaries.

Secondary Crushing Hydraulic Adjustment

Learn more >>

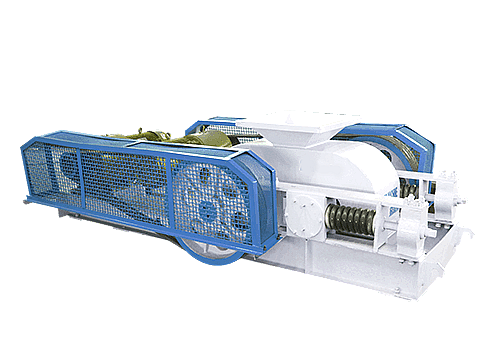

Roll Crusher

Shear-Compression Crushing: Applies shear-compression forces between counter-rotating rolls with textured or smooth surfaces. Material is drawn into the gap (nip angle) and fragmented via tensile failure or surface abrasion.

Double Roll Design Low Fines Production

Learn more >>

Tertiary Crushing

Provides final crushing to refine material into fine particles, often used for sand production.

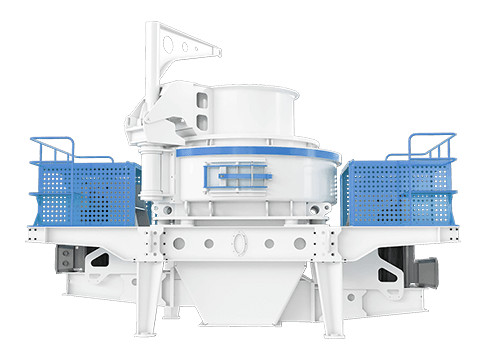

VSI Crusher

Centrifugal Acceleration Crushing: Accelerates material through a high-speed rotor (up to 70 m/s) and projects it against a stationary anvil or rock-lined chamber, exploiting centrifugal force and interparticle collision for fragmentation.

Vertical Shaft Impact Cubical Product Shape

Learn more >>

Fine Crusher

With a simplified structure and convenient maintenance, Fine Crusher delivers high production capacity and a long service life for its hammer heads. It is widely used for crushing granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite, and more.

Precision Crushing Ultra-Fine Output

Learn more >>

And More ...

Hammer Crusher

Dynamic Impact with Grinding: Combines high-velocity hammer strikes (rotating hammers on a horizontal shaft) with material grinding against breaker plates or screens. Fragmentation occurs through impact, attrition, and shear.

High-Speed Hammer Brittle Material Crushing

Learn more >>

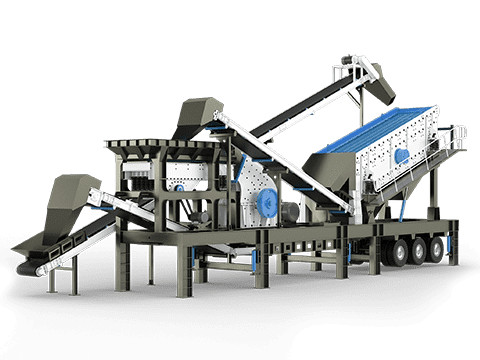

Mobile Crusher

Mobile crushers are advanced crushing machines designed for on-site material processing, offering high mobility and flexibility. They can be easily transported between job sites, making them ideal for construction, mining, and recycling applications.

On-Site Crushing Track / Wheel Mobility

Learn more >>

Why Choose Our Stone Crusher

Customized crusher with reliable price

We offer more than just stone crushers—we provide complete solutions tailored to your specific needs. With years of experience in the industry, we have developed cutting-edge technology and engineering expertise to deliver reliable, high-performance crushers that are built to last. Our commitment to quality and innovation ensures that you receive equipment that maximizes efficiency, minimizes downtime, and reduces operational costs.

Latest Knowledge about Stone Crushers

Read more about stone crushers and related topics written by our experts.

Impact Crusher: Advanced Impact Crushing Solutions for Diverse Industrial Needs

Guide to Impact Crusher + Vibrating Screen Process Flow for Asphalt Pavement Processing

Comprehensive Energy Optimization Guide for Mobile Jaw Crushers at Demolition Sites

Mobile Jaw Crusher: 2025 Global Guide to Sustainable Crushing Technology and Applications

AI Ore Sorting Crusher Revolution: Cutting 30 % Energy with Smart Pre-screening & Targeted Fracture

Stone Crusher Guide: Principles, Optimization & 200% Efficiency Strategies

Contact Us

Don't know how to choose? Need more detail? Contact us to provide you with customized services. Our specialist will be at your service.