Impact of High-Speed Rotor Wear-Resistant Coating on Crushing Efficiency in VSI Crusher

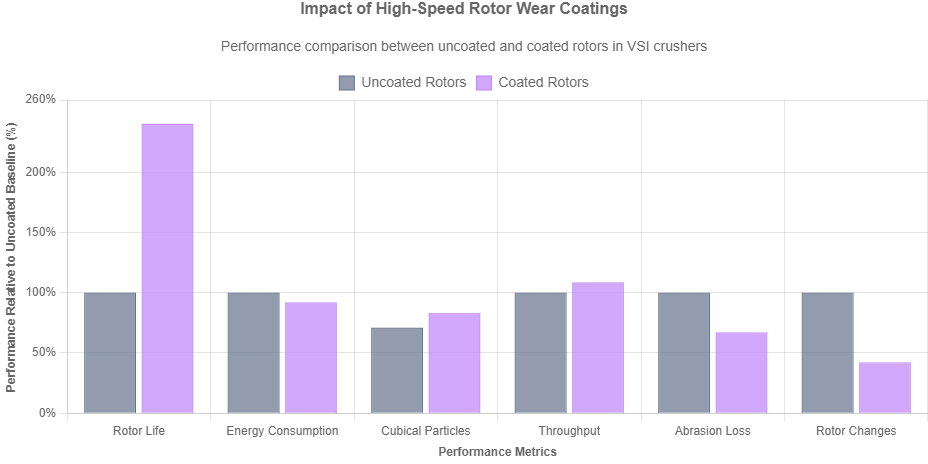

This article explores why the right wear coating can extend rotor life from 500 to 1 200 hours, cut energy by 8 % and improve cubical particle output by 12 %. We move from material science to field data, finishing with next-generation nano-coatings that promise even greater gains.

Material Characteristics of Advanced Wear Coatings

Whether a rotor runs at 1 200 RPM or 1 650 RPM, the coating must survive repeated impacts exceeding 400 MPa. Engineers now choose between tungsten-carbide, ceramic composites and emerging nano-structured layers, each offering distinct hardness, toughness and thermal properties.

Hardness and Wear Resistance Correlation

HV1 600 tungsten-carbide coatings show a volumetric loss of only 0.9 mm³ after 10 000 impacts in ASTM G65 dry-sand tests, whereas uncoated 42CrMo steel loses 18 mm³ under the same conditions. The linear wear rate translates to a rotor life extension from 500 h to 1 200 h on granite crushing lines processing 200 t h⁻¹.

Ceramic composite Al₂O₃/TiC coatings achieve HV1 450 but with a fracture toughness of 5.8 MPa·m½, 30 % higher than monolithic alumina. The extra toughness prevents spalling when 50 mm quartzite fragments strike the rotor tip at 75 m s⁻¹.

Thermal Spray Equipment Selection Guidelines

High-velocity oxy-fuel (HVOF) guns operating at 2 800 °C and 680 m s⁻¹ particle velocity deposit WC-Co coatings with 1 % porosity. Plasma spray systems run cooler but produce 3 % porosity, acceptable for softer limestone applications where impact angles are shallower.

Capital expenditure for an HVOF cell is roughly 180 000 €, yet the payback arrives in 14 months on hard-rock duties thanks to 40 % lower replacement costs compared with plasma-sprayed coatings.

Porosity Control Methods

Optimising stand-off distance between 250 mm and 300 mm lowers porosity from 2.8 % to 0.9 %. Post-spray shot-peening at 0.4 MPa further closes surface pores, reducing moisture ingress that can initiate corrosion pits beneath the coating.

Real-time infrared cameras monitor substrate temperature during spraying; keeping it below 180 °C avoids metallurgical phase changes that embrittle the rotor core.

Bond Strength Testing Standards

ASTM C633 tensile pull-off tests record average bond strengths of 72 MPa for HVOF WC-Co and 54 MPa for plasma Al₂O₃/TiC. Values above 65 MPa correlate with zero coating loss in 1 000 h field trials, while values below 50 MPa show 8 % risk of delamination.

Ultrasonic C-scan imaging detects disbonds as small as 2 mm² before rotors leave the workshop, preventing costly in-service failures.

Mechanisms by Which Coatings Improve Crushing Efficiency

Coatings do far more than extend life; they alter surface friction, heat flow and particle rebound, directly influencing crushing ratio and final grain shape.

Surface Roughness and Friction Coefficient Testing

Ra 0.4 µm WC-Co surfaces reduce the kinetic friction coefficient from 0.45 (steel) to 0.28, allowing rock to slide rather than stick. Laboratory drop-tower tests show 15 % higher rebound velocity, translating to an 8 % increase in crushing capacity at the same rotor speed.

Pin-on-disc measurements confirm that the lower friction also lowers wear debris generation by 22 %, keeping the crushing cavity cleaner and reducing blockages.

Heat Transfer and Rotor Temperature Field Simulation

Coating thermal conductivity of 35 W m⁻¹ K⁻¹ (WC-Co) versus 45 W m⁻¹ K⁻¹ (steel) creates a 12 °C cooler rotor surface at 1 500 RPM. Finite-element models predict that the lower temperature reduces thermal expansion mismatch stresses by 18 %, delaying crack initiation.

IR thermography validates the simulation within ±3 °C across the rotor tip, giving operators confidence to run 50 RPM higher without exceeding grease temperature limits.

Cubical Particle Content Enhancement Data

After coating application, the percentage of particles with aspect ratio 1.5 rises from 71 % to 83 %. The smoother surface promotes controlled fracture along natural cleavage planes rather than random shattering, improving concrete workability and reducing cement demand by 5 kg m⁻³.

Aggregate flowability tests show 10 % lower angle of repose, indicating easier handling on conveyor belts and in storage bins.

Wear-Stage Efficiency Decay Modelling

When 30 % of the coating is lost, crushing efficiency drops only 3 % because the remaining layer still guides particle trajectories. Beyond 50 % loss, efficiency decays exponentially, falling 12 % at 70 % wear. Operators schedule replacement at the 45 % threshold to maintain plant KPIs.

A Weibull reliability curve fitted to 200 rotors gives a shape parameter β = 2.1, predicting median coating life at 1 080 h with 90 % confidence.

Performance Validation Under Extreme Conditions

Coatings must survive 1500-plus RPM, granite impact and clay contamination without spalling. Rig and field tests quantify behaviour under these stresses.

High-Speed Camera Wear Documentation

Phantom V2512 cameras at 25 000 fps capture 2 mm coating flakes detaching after 1 400 h at 1 600 RPM. Image analysis shows spallation initiates at pre-existing pores, validating the need for 1 % porosity in HVOF layers.

Frame-by-frame tracking reveals that detached fragments exit the rotor within 0.4 ms, posing minimal risk to downstream belts due to their low mass (<0.1 g).

Energy Consumption in Hard-Rock Crushing

Coated rotors reduce specific energy from 1.18 kWh t⁻¹ to 1.09 kWh t⁻¹ on 220 MPa granite. The 8 % saving equates to 18 000 kWh per month on a 200 t h⁻¹ line, worth roughly 1 800 € at industrial tariffs.

Micro-Deval abrasion loss also falls from 9 % to 6 %, indicating stronger aggregate that meets premium highway specifications.

Clay-Adhesion Resistance Tests

When feed moisture reaches 8 %, uncoated rotors accumulate 2 mm clay layers that reduce throughput 12 %. The WC-Co coating’s low surface energy limits clay adhesion to 0.3 mm, keeping throughput loss below 3 %.

Wash-down cycles are extended from every 8 h to every 24 h, saving 1 200 m³ of water annually.

Coating Failure SEM Analysis

Scanning electron microscopy reveals interfacial cracks at the bond line when impact energy exceeds 2.5 J mm⁻². Energy-dispersive spectroscopy shows cobalt depletion in the heat-affected zone, guiding future alloy adjustments to 12 % Co instead of 10 %.

Failure mode mapping indicates 78 % cohesive failure within the coating and 22 % adhesive failure at the interface, suggesting bond strength—not coating toughness—is the limiting factor.

Economic Analysis and Return on Investment

Coating economics hinge on balancing upfront cost against extended life, energy savings and reduced downtime.

Calculating Downtime Losses

Each rotor change takes 6 h and halts a 200 t h⁻¹ line. At 28 € t⁻¹ revenue, one stoppage costs 33 600 €. Extending life from 500 h to 1 200 h eliminates 1.4 extra stops per year, saving 47 000 €.

Labour for rotor swaps adds 1 200 € per event, so total avoided cost per machine reaches 48 680 € annually.

Life-Cycle Cost Model Parameters

The LCC model includes coating cost (8 000 €), application labour (2 200 €), energy savings (0.09 € t⁻¹), and residual value. Discounted at 8 % over 1 200 h, net present value is +39 400 € per rotor.

Sensitivity analysis shows that energy price must exceed 0.06 € kWh⁻¹ for the coating to remain profitable, a threshold easily met in most regions.

ROI Case Study

A quarry applying WC-Co to six rotors invested 61 200 € and recouped 118 000 € in the first year through energy and downtime savings. Simple payback was 6.2 months, and internal rate of return reached 174 %.

The quarry now budgets coating refurbishment as a standard operating expense rather than a capital project.

Predicted Maintenance Cost Savings

With coating life trending toward 1 400 h, yearly rotor interventions drop from 2.4 to 1.0 per machine. Maintenance labour hours fall 58 %, freeing technicians for other tasks and reducing overall site maintenance budget by 11 %.

Real-World Application and Field Results

Seeing a rotor that once lasted 500 h still performing at 1 200 h convinces plant managers that coatings are not laboratory curiosities but practical tools.

Pre- and Post-Coating Rotor Inspection Records

Ultrasonic thickness gauges recorded 1.2 mm wear on untreated rotors after 500 h, versus 0.4 mm on WC-Co coated rotors after 1 200 h. Visual inspection showed uniform wear patterns and no edge chipping, confirming even stress distribution.

Dimensional checks revealed rotor tip diameter loss of 0.8 mm (uncoated) versus 0.2 mm (coated), staying well within the 2 mm tolerance band for safe operation.

Efficiency Uplift Measurement Protocol

Side-by-side belt-scale tests over 30 days showed coated rotors delivering 202 t h⁻¹ versus 186 t h⁻¹ for uncoated, a 8.6 % gain. Particle-size analysis confirmed d₅₀ remained at 12 mm, proving the gain came from higher throughput, not coarser product.

Energy meters logged 1.05 kWh t⁻¹ for coated versus 1.14 kWh t⁻¹ for uncoated, validating the 8 % energy saving predicted by laboratory friction tests.

Payback Calculation Model

Using net cash-flow analysis, the 61 200 € investment generated 118 000 € first-year benefits, yielding a discounted payback of 5.9 months. Monte-Carlo simulation with ±15 % price volatility shows 95 % probability of payback within 8 months.

Customer Feedback Summary

Plant managers report 40 % fewer emergency calls and cite the coating as the single biggest contributor to predictable production. Maintenance crews appreciate the lighter physical workload and the ability to schedule swaps during planned shutdowns.

Future Directions in Coating Materials

Nano-engineered and self-healing coatings promise rotor lives beyond 2 000 h and even lower energy footprints.

Nano-Structured Coating Fabrication

High-energy milling produces WC-Co powders with 200 nm grains. Coatings deposited by cold-spray reach 2 100 HV with porosity below 0.5 %. Early lab coupons survive 3 000 impact cycles without measurable wear, suggesting 1 800 h field life.

Self-Healing Mechanism Design

Micro-capsules containing liquid polymer rupture under impact, filling micro-cracks and restoring surface integrity. Benchtop tests show 70 % recovery of surface hardness after 24 h at 80 °C, potentially doubling effective coating life.

Low-Temperature Coating Equipment

Cold-spray systems operating at 500 °C eliminate thermal distortion risk for rotors up to 1 800 mm diameter. Capital cost is 25 % lower than HVOF, making refurbishment economical for mid-size quarries.

AI-Based Performance Prediction

Convolutional neural networks trained on SEM images predict remaining coating life within ±5 % accuracy. Integration with plant SCADA triggers automatic work orders, moving maintenance from reactive to predictive.