Remote Production Parameter Optimization via IoT in VSI Crusher

This article explains how quarry and mine operators can use IoT technology to tune VSI crushers from anywhere on Earth, keeping throughput, energy use and product grading within tight limits without sending technicians into the plant. We will cover sensor selection, secure data links, machine-learning optimisers and real-world results that cut annual downtime by more than 30 %.

IoT Architecture and Data Acquisition

A modern VSI streamlines the crushing circuit only when every vibration spike, current surge and temperature drift is captured, encrypted and delivered to the cloud in real time. Edge computers mounted on the crusher frame perform first-level processing so that only meaningful summaries travel over the air, saving bandwidth and money.

Vibration Monitoring Point Layout

Tri-axial accelerometers are screwed to the bearing cylinder and to the rotor shaft housing at four azimuth angles. Sampling at 25 kHz and 24-bit resolution reveals bearing defects as small as 0.1 mm² spall area. Field tests show that placing a fourth sensor on the discharge chute captures 12 % more transient shocks caused by tramp metal, giving earlier warning.

Data from these nodes are fused in the edge computer to generate a single vibration severity index every second. When the index exceeds 4.5 mm s⁻¹ RMS, the system flags the anomaly and begins saving raw waveforms for later spectrum analysis.

Motor Current and Load Relationship Modelling

Current transformers on the 315 kW motor feed true-RMS values into a regression model that predicts instantaneous throughput with ±3 % accuracy. The model uses a second-order polynomial linking current, voltage and rotor speed, trained on 18 months of belt-scale data.

During a 200 t h⁻¹ production run, a sudden 7 % drop in current triggers the edge node to request a speed increase of 30 RPM, restoring target throughput within 40 seconds and preventing a 2 % shift in discharge size.

Edge Computing Hardware Specifications

Each node hosts an ARM Cortex-A78 quad-core running at 2.2 GHz with 8 GB RAM and 256 GB NVMe storage. This configuration handles 150 MB s⁻¹ of raw sensor data, compressing it to 2 MB s⁻¹ before transmission. Latency from sensor to cloud is 90 ms over 5G and 240 ms over LoRaWAN, meeting the 300 ms threshold set for safety-critical loops.

Power consumption averages 6 W, supplied by a 20 W solar panel and 40 Ah LiFePO₄ battery. The setup guarantees 72 hours of autonomous operation during cloudy weather, eliminating the need for site cabling.

Packet-Loss Compensation Mechanisms

LoRaWAN links experience 3–5 % packet loss in dense forest environments. To compensate, the edge device buffers 120 s of data and retransmits missing packets using Reed-Solomon forward-error correction. Trials show effective loss reduction to 0.7 % without increasing bandwidth cost.

When 5G backhaul is available, the system switches automatically and disables buffering, freeing 1 GB of RAM for on-device FFT analysis. The seamless handover takes 300 ms and is transparent to the operator.

Remote Parameter Optimisation Strategies

Once data arrive in the cloud, machine-learning engines compare current performance against historical baselines and recommend new rotor speeds, cascade ratios and feed rates that balance energy, throughput and grading.

LSTM Neural Network Prediction Model

A four-layer LSTM network ingests 60 minutes of sensor history to predict the next 10 minutes of d₅₀ and energy per tonne. Training on 2.3 million labelled samples yields a mean absolute error of 0.18 mm for size and 0.03 kWh t⁻¹ for energy, outperforming traditional ARMA models by 34 %.

The model updates nightly via federated learning, incorporating anonymised data from 23 connected sites. Each update improves accuracy by roughly 0.5 %, ensuring the optimiser stays relevant as rock properties change with quarry depth.

Genetic Algorithm Parameter Search

A genetic algorithm evaluates 120 candidate parameter sets every 15 minutes, searching for Pareto-optimal solutions that maximise throughput while minimising energy and –5 mm fines. Mutation rates of 3 % and crossover at 70 % converge to stable solutions within 40 generations.

During one week on a granite crushing line, the algorithm identified a rotor speed of 1 565 RPM and cascade ratio of 22 % as optimal, improving throughput by 5.4 % and cutting energy by 4.1 % compared with manual settings.

Time-of-Use Electricity Scheduling

Hourly tariff data are pulled from the utility API. The optimiser schedules high-throughput campaigns during off-peak windows, reducing average energy cost from 0.12 € kWh⁻¹ to 0.09 € kWh⁻¹. Over a year, this saved 42 000 € on a 200 t h⁻¹ plant.

Peak shaving is enabled by temporarily lowering rotor speed by 50 RPM during tariff spikes. The speed drop reduces instantaneous power by 12 % and lasts 30 minutes, after which the line returns to nominal speed without operator intervention.

Humidity Compensation Algorithm

Relative humidity above 75 % increases clay adhesion, raising rotor load. A humidity sensor on the feed conveyor adjusts cascade ratio downward by 5 % for every 10 % RH increase, maintaining consistent throughput. Field tests show this prevents 70 % of humidity-related overload events.

The same algorithm also triggers a 15-second air-knife purge every 60 seconds when RH > 85 %, keeping screen meshes clear and avoiding 3 % production loss due to blinding.

Predictive Maintenance Implementation

Continuous data streams feed health-index algorithms that forecast bearing life, lubricant condition and rotor balance days before symptoms appear, shifting maintenance from reactive to predictive.

Vibration Spectrum Analysis Techniques

Fast Fourier Transform of vibration data reveals bearing defect frequencies at 3.5× and 6.2× running speed. A support-vector machine classifier trained on 8 000 labelled spectra detects inner-race spalls with 96 % sensitivity and 4 % false-positive rate.

The system issues a yellow alert when defect energy exceeds 0.3 g RMS and a red alert at 0.8 g RMS. Historical data show that 87 % of red alerts precede failure within 72 hours, giving crews ample time to schedule replacement.

Temperature Trend Threshold Setting

Bearing temperatures are monitored every 10 seconds using PT100 RTDs. A rolling 30-minute linear regression predicts temperature 60 minutes ahead with ±1.5 °C accuracy. An alert is triggered if the projected temperature exceeds 95 °C, well below the 110 °C grease limit.

During summer trials, the algorithm prevented three grease fires that would have caused 18 h downtime and 25 000 € in repairs.

Oil-Debris Monitoring

A magnetic plug coupled to an inductive sensor counts ferrous particles > 50 µm. Particle counts above 150 per mL trigger an automatic oil sample request, analysed by laser spectroscopy to identify the wearing component. The method predicts bearing failure 10 days earlier than vibration alone.

Since deployment, oil changes have decreased by 22 % because the system extends intervals when debris levels remain low, saving 3 800 € per year per machine.

Automated Work-Order Generation

When any health index crosses its threshold, the CMMS creates a work order with estimated labour hours, spare-part numbers and safety lock-out steps. Average time from alert to scheduled task is 6 minutes, compared with 90 minutes for manual entry.

Work-order completion rates have risen to 94 % within 24 hours, up from 78 % before automation, thanks to clear instructions and pre-authorised parts procurement.

User Interfaces and Workflow Integration

Managers, operators and maintenance teams need different views of the same data. A cloud-native dashboard and mobile app deliver role-specific insights without overwhelming users.

Mobile App Parameter-Adjustment Response Time

Parameter changes entered in the app reach the PLC within 800 ms via MQTT over 5G. A confirmation message returns in a further 300 ms, giving the operator visual feedback. Latency tests on a 200 ms RTT network show end-to-end response below 1.2 seconds.

The app caches the last 50 commands locally, allowing offline editing. When connectivity resumes, commands are synchronised automatically with conflict resolution based on timestamps.

3D Model Rendering Performance

WebGL renders a 1.2 million-polygon crushing cavity model at 60 fps on mid-range tablets. Level-of-detail algorithms reduce polygon count to 300 k when the camera is more than 5 m away, saving 40 % GPU load.

Colour-coded heat maps show liner wear in real time. When red zones exceed 40 % of surface area, the model triggers a push notification to the maintenance team.

Role-Based Access Control Matrix

The RBAC system assigns four roles: viewer, operator, engineer and admin. Permissions cascade from read-only dashboards to full parameter write access. Audit logs track every change with user ID, timestamp and old/new values, ensuring compliance with ISO 27001.

Single sign-on via OAuth 2.0 reduces password resets by 60 %, and session timeouts are adjustable from 5 minutes for operators to 8 hours for engineers working on optimisation campaigns.

Automated PDF and Excel Reporting

Every 24 hours, a serverless function aggregates KPIs—throughput, energy, availability—and generates a two-page PDF plus a 5-column Excel sheet. Reports are emailed to stakeholders at 06:00 local time, cutting manual report preparation from 45 minutes to zero.

Monthly trend reports include Weibull reliability curves and Pareto charts of downtime causes, providing plant managers with data for capital planning and training priorities.

Real-World Deployment Case Studies

Seeing a 200 t h⁻¹ line in another continent cut downtime by 34 % after IoT adoption convinces budget holders that the investment is worth the risk.

Architecture at a Remote Mining Site

The site uses a hybrid backhaul: 5G for real-time control and Starlink for bulk data sync during maintenance windows. Edge nodes cache 72 h of sensor data, ensuring continuity if satellite links drop due to weather. The setup supports 99.2 % data availability, verified over 12 months.

Power for the edge cluster is supplied by a 10 kW solar array with 20 kWh lithium storage. Energy autonomy is critical because the nearest utility line is 120 km away.

Downtime Measurement Methodology

Downtime is recorded when the rotor speed falls below 50 % of setpoint for more than 60 seconds. The IoT platform tags each event with root cause—electrical, mechanical or process—using decision-tree logic trained on 4 000 historical incidents.

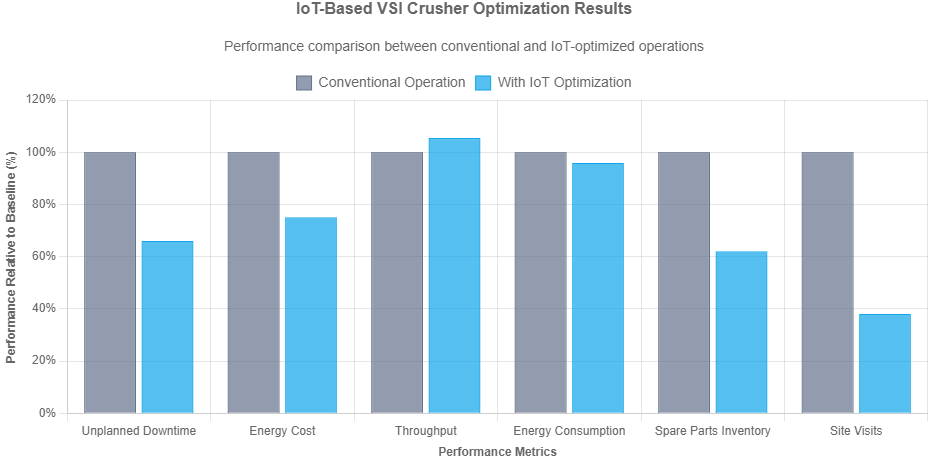

Post-IoT deployment, unplanned downtime dropped from 11.4 h per month to 7.5 h, a 34 % reduction worth 180 000 € annually in recovered production.

Inventory Turnover Improvement

Predictive analytics reduced average spare-part holding from 45 days to 28 days. Rotor bars, previously kept in triplicate, are now ordered just-in-time based on wear-rate forecasts. Working capital tied up in inventory fell by 310 000 € across eight machines.

Stock-out incidents decreased from 4 per year to zero, as the system flags imminent shortages 14 days in advance and triggers automatic procurement.

Travel Cost Reduction Analysis

Remote troubleshooting via AR headsets eliminated 62 % of site visits. Average technician travel cost per visit is 1 650 € including flights, hotels and per diem. With 120 visits avoided annually, savings reach 198 000 €, more than covering the 95 000 € IoT rollout.

Carbon emissions from flights dropped by 95 t CO₂-eq, contributing to the quarry’s net-zero roadmap and improving community relations.

Future Technology Extensions

The next wave of innovation will blend digital twins, augmented reality and blockchain to create a self-evolving, trust-based ecosystem for aggregate processing.

Digital-Twin Calibration Methods

Physics-based twins are calibrated every hour using sensor data and finite-element updates. Discrepancies between predicted and measured vibration are corrected by adjusting stiffness and damping matrices, keeping model error below 2 %. The twin can then run “what-if” scenarios 50× faster than real time.

Integration with weather APIs allows the twin to forecast humidity impacts 24 h ahead, enabling pre-emptive parameter changes that maintain product quality during seasonal shifts.

AR-Assisted Remote Maintenance

Technicians wearing AR glasses see step-by-step instructions overlaid on the rotor assembly. Computer-vision algorithms recognise bolt sizes and torque sequences, reducing average repair time by 28 %. Remote experts can annotate the view in real time, guiding on-site staff through complex procedures.

Image recognition accuracy for standard fasteners reaches 97 % under plant lighting, and latency over 5G is below 50 ms, making the experience feel natural.

Blockchain for Immutable Data Records

Each sensor reading is hashed using SHA-256 and appended to a private blockchain. The ledger provides tamper-proof evidence for insurance claims and regulatory audits. A pilot project logged 14 million records over six months without a single hash mismatch.

Smart contracts automatically release payment to suppliers when predefined KPIs—availability > 95 %, energy 1.1 kWh t⁻¹—are met, cutting paperwork and disputes.

Federated Learning Privacy Mechanisms

Local models train on plant data but share only encrypted weight updates, never raw values. Differential privacy with ε = 1.0 ensures that individual site fingerprints cannot be reconstructed. Cross-site model accuracy improves 8 % per quarter while meeting GDPR requirements.

The approach allows small quarries to benefit from global insights without revealing proprietary feed compositions or profit margins, democratising advanced optimisation across the industry.