Efficient Dynamic Balancing Methods for VSI Crusher Rotors: Selection and Application of On-Site vs. Off-Site Balancing

Maintaining the precise balance of the rotor is fundamental to the smooth operation and longevity of a Vertical Shaft Impact crusher. This guide compares on-site and off-site dynamic balancing techniques, providing a clear framework for selecting the appropriate method based on factors like cost, time, and required precision. It outlines step-by-step procedures for performing effective on-site balancing to minimize operational downtime and protect critical components from vibration-induced damage.

Understanding Rotor Imbalance and Its Consequences

Rotor imbalance occurs when the mass center of the rotating assembly does not align perfectly with its axis of rotation. This common issue generates significant centrifugal forces that increase with the square of the rotational speed, leading to harmful vibrations. In a VSI crusher, which operates at high speeds, even a small imbalance can have destructive effects.

The primary consequences include accelerated bearing fatigue, potential damage to mechanical seals, and stress on the crusher's foundation. These vibrations also lead to higher energy consumption and can cause cracks in structural components. Over time, the financial impact accumulates through unplanned downtime, increased maintenance costs, and reduced equipment lifespan.

Identifying the Common Causes of Mass Distribution Errors

Imbalance often stems from uneven wear of the wear parts, such as the rotor tips and distribution plates. Manufacturing tolerances, improper installation, or the adhesion of material to the rotor surfaces can also disrupt its balanced state. A sudden impact from an uncrushable object can cause immediate and severe imbalance.

The Destructive Chain Reaction of Unchecked Vibration

Vibration transmits destructive energy throughout the entire machine. It not only damages the rotor bearings but can also loosen fasteners, cause misalignment in the drive motor, and lead to premature failure of the crusher's housing and supports. The bearing cylinder is particularly vulnerable to these forces.

Interpreting Vibration Spectra to Isolate Imbalance

Vibration analysis is a key diagnostic tool. A dominant vibration peak at the machine's fundamental rotational frequency, known as 1X rpm, is the classic signature of mass imbalance. This distinguishes it from other faults like misalignment or bearing defects, which produce different harmonic frequencies.

International Standards for Permissible Residual Imbalance

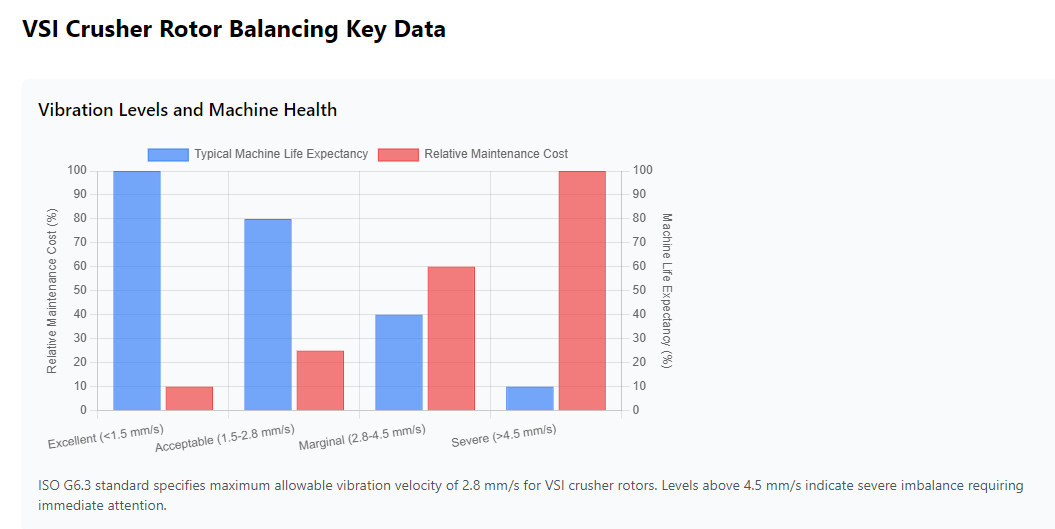

Standards such as ISO 1940-1 provide guidelines for acceptable imbalance levels. For a VSI crusher rotor, a balance quality grade of G6.3 is typically specified. This grade defines the permissible residual imbalance based on the rotor's mass and maximum service speed, providing a clear target for balancing procedures.

Off-Site Dynamic Balancing: Precision Correction in a Controlled Environment

Off-site balancing is performed using a dedicated balancing machine after the rotor assembly has been completely removed from the crusher. This method offers the highest possible accuracy and is considered the definitive solution for correcting inherent imbalance within the rotor itself.

The process involves mounting the rotor on the machine's supports, where it is spun at a controlled speed. Sensors precisely measure the magnitude and angular location of the imbalance. Technicians then add or remove weights at specific locations on the rotor until the vibration levels are reduced to within the acceptable standard.

The Role of the Balancing Machine in Achieving High Accuracy

Modern balancing machines use sophisticated electronics to separate the imbalance into two correction planes, typically at each end of the rotor. This allows for a precise counterbalancing action that neutralizes the unbalanced forces and moments, ensuring smooth operation across the entire rotor length.

Standardized Procedure for Off-Site Correction

The standard workflow includes safe dismantling of the rotor, transportation to the balancing facility, meticulous measurement, correction through calibrated weights, and a final verification run. The rotor is then reinstalled in the crusher, often resulting in a significant reduction in vibration.

When Off-Site Balancing Becomes a Necessity

This method is mandatory after major overhaul events, such as replacing the entire rotor, repairing a damaged rotor shaft, or when a rotor has been subjected to extreme stress. It is the only way to ensure the core rotating component itself is fundamentally balanced before returning to service. This level of repair is common in extensive mining and quarrying operations.

Selecting a Qualified Balancing Service Provider

Choosing a reputable service center is critical. Key factors to consider include the capability of their balancing machines, the experience of their technicians, adherence to international standards, and a proven track record with industrial rotors of similar size and weight.

On-Site Dynamic Balancing: Rapid Correction Without Disassembly

On-site balancing is a field maintenance technique that corrects imbalance while the rotor remains installed in the crusher. It is a highly efficient method for addressing imbalance caused by wear or minor damage, dramatically reducing downtime compared to off-site balancing.

This technique utilizes a portable balancing instrument equipped with a vibration sensor and a phase reference probe. The instrument guides the technician through a process of adding a trial weight, measuring the resulting change in vibration, and calculating the exact weight and position required to counteract the imbalance.

The Principle of Influence Coefficient Method

The core of on-site balancing is the influence coefficient method. By analyzing the vibration vector change caused by a known trial weight, the system calculates the specific correction needed. This empirical approach effectively characterizes the rotor's response without requiring complex mathematical models of the entire structure.

Advantages of Minimizing Crusher Downtime

The most significant benefit is the drastic reduction in machine outage time. Since the rotor does not need to be disassembled and shipped, balancing can often be completed within a few hours. This makes it a cost-effective solution for addressing imbalance issues that arise during routine operation.

Prerequisites for a Successful On-Site Balance Job

Success depends on a correct initial diagnosis. The vibration must be confirmed to be primarily caused by imbalance rather than other issues like resonance, mechanical looseness, or a failing motor bearing. The rotor must also be clean, and accessible for weight placement.

Modern Features of Portable Balancing Instruments

Contemporary balancers are user-friendly, with intuitive software that walks the technician through each step. They can perform single-plane or two-plane balancing, store measurement data for trend analysis, and generate professional reports for maintenance records.

A Decision Framework: Selecting the Appropriate Balancing Method

Choosing between on-site and off-site balancing requires a structured evaluation of the specific situation. The decision impacts not only the immediate repair cost but also the long-term reliability of the equipment.

A practical decision tree starts with assessing the vibration severity. A slight increase in vibration levels noticed during routine monitoring is a candidate for on-site balancing. However, a severe vibration event following an impact or after a major component failure likely necessitates off-site balancing.

Key Factors Influencing the Selection Process

The critical factors are the severity of the imbalance, the available window for downtime, the budget for the repair, and the availability of trained personnel and equipment. The history of the rotor is also important; a rotor that has been repeatedly balanced on-site may have an underlying issue best resolved off-site.

Scenario-Based Guidance for Common Situations

For gradual vibration increase due to normal wear, on-site balancing is the first choice. After replacing all wear parts on the rotor, off-site balancing is recommended to ensure a perfect initial balance. If on-site balancing attempts fail to resolve the issue, it strongly indicates a problem requiring off-site correction.

Conducting a Cost-Benefit Analysis

The analysis must include direct costs like labor and parts, and indirect costs such as production losses during downtime. While on-site balancing has lower direct costs, off-site balancing, despite higher initial expense, may offer a better long-term solution by providing a more fundamental correction, thus preventing recurring issues.

Step-by-Step Guide to Performing On-Site Dynamic Balancing

Executing a successful on-site balance requires a methodical approach to ensure safety and accuracy. Following a standardized procedure minimizes errors and leads to a predictable outcome.

The process begins with comprehensive safety preparations, including locking out and tagging the crusher's power source. The work area must be clear, and all personnel must be aware of the activity. The rotor should be accessible and able to be rotated manually for initial positioning.

Initial Safety Preparations and Machine Isolation

Safety is paramount. The crusher must be completely shut down and isolated from all energy sources using a lockout-tagout system. Verify that the rotor has come to a complete stop before approaching it. This ensures the safety of the personnel performing the balancing operation.

Measuring Baseline Vibration Amplitude and Phase

The vibration sensor is mounted on the crusher's bearing housing, and the photo tachometer is aimed at a reflective mark on the rotor shaft. The machine is started, and the balancer records the initial vibration velocity and the phase angle relative to the fixed mark.

Executing the Trial Weight Run and Calculation

A trial weight of estimated mass is attached to the rotor at a known radius and angle. The crusher is run again, and new vibration readings are taken. The balancer's software uses the vector difference between the initial and trial runs to calculate the optimal correction weight and its exact location.

Installing Correction Weights and Final Verification

The calculated weight is installed, and the trial weight is removed. A final run confirms the success of the procedure. Vibration levels should be significantly reduced, ideally to within the ISO standard limits. This final verification is crucial for ensuring the rotor will operate smoothly.

Implementing a Proactive Rotor Balancing Management Strategy

Moving from reactive repairs to a proactive maintenance philosophy enhances overall equipment reliability. A rotor balancing management program involves planning, monitoring, and standardized practices.

This strategy includes maintaining detailed historical records for each rotor, tracking all balancing activities, wear part replacements, and vibration trends. This data becomes invaluable for predicting maintenance needs and making informed decisions about repairs and replacements.

Establishing a Rotor History Log and Vibration Trend Monitoring

A log should document every intervention, including dates, initial and final vibration readings, weights added or removed, and the technician's name. Regularly scheduled vibration monitoring allows for the creation of trend charts, providing early warning of developing imbalance.

The Practice of Wear Part Kit Replacement and Weight Matching

When replacing wear parts like rotor tips, they should be changed in complete sets. Furthermore, weighing each new tip and selecting a set with minimal weight variation from one another can drastically reduce the initial imbalance introduced during maintenance. This is a key practice for mobile VSI crusher fleets where availability is critical.

Developing a Standardized Balancing Procedure

Creating a detailed Standard Operating Procedure ensures that every balancing job is performed consistently, safely, and effectively. The SOP should cover safety protocols, equipment setup, measurement techniques, and documentation requirements.

Training Personnel to Recognize Early Signs of Imbalance

Operators and maintenance staff should be trained to identify early indicators of imbalance, such as a change in the sound of the crusher or a slight increase in perceived vibration. Early detection allows for planning the balancing activity during a scheduled shutdown rather than an emergency stop.