The Trade-off Between Particle Shape Index and Throughput: A Guide to Core Parameter Configuration for VSI Crushers

This article provides a comprehensive examination of the fundamental trade-off between particle shape index and production throughput in Vertical Shaft Impact crushers. It offers a detailed guide on configuring essential operational parameters to strike an optimal balance for specific industrial objectives, ensuring efficient and high-quality output.

Understanding Particle Shape and Throughput: The Dual Objectives of VSI Crusher Performance

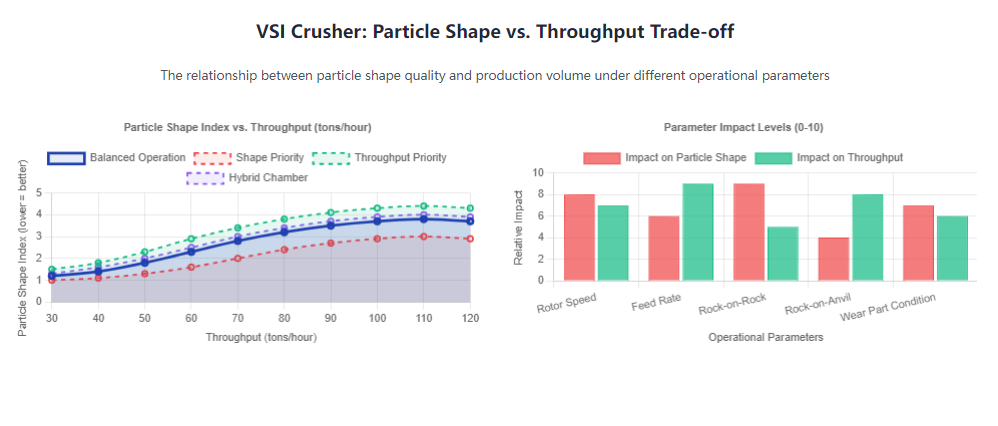

Excellent particle shape and high production throughput represent two primary and often competing goals in the operation of a Vertical Shaft Impact crusher. Achieving a superior cubic particle shape is crucial for enhancing the performance of concrete and asphalt, while maximizing throughput is essential for economic viability in large-scale projects. The inherent conflict arises from the very mechanics of the crushing process itself, where adjustments favoring one metric typically incur a cost on the other.

Defining Superior Particle Shape: An Introduction to the Particle Shape Index

The quality of crushed material is often quantified using a particle shape index, which evaluates characteristics like flakiness and elongation. Cubical particles, with their low shape index, are highly desirable because they interlock more effectively, leading to greater structural strength in concrete and improved durability in road surfaces. Industries reliant on high-grade aggregates establish strict specifications for this index to ensure final product integrity.

Standardized measurement techniques involve analyzing a sample of particles to determine the percentage that deviates from an ideal cubical form. A lower proportion of flaky or elongated particles directly correlates with a higher product value and better performance in downstream applications, making particle shape a critical quality parameter.

The Comprehensive Meaning of Throughput: Beyond Simple Tonnage

Throughput in a crushing context refers not only to the mass of material processed per hour but also to the overall operational efficiency of the system. A high throughput rate reduces the cost per ton of material produced, which is a key economic driver for mining and quarrying operations. However, this metric must be considered alongside energy consumption and the rate of wear on crusher components.

Sustaining a high throughput requires a consistent and well-managed feed system. Fluctuations in feed rate or material characteristics can cause disruptions that lower the effective throughput and increase operational costs, highlighting that throughput is a measure of stable, efficient production.

The Mechanical Conflict: Impact Crushing Versus Compression Crushing

The core of the trade-off lies in the two dominant breaking mechanisms within a VSI crusher. Impact crushing occurs when particles are shattered by high-velocity collisions with the rotor or other particles, a process that effectively produces the desired cubical shape. This mechanism requires a certain energy intensity and space within the crushing chamber to function optimally.

In contrast, compression or interparticle crushing happens when the feed rate is high, causing material to layer and break through pressure between rock particles. While this method can significantly increase throughput, it often results in more irregular and flaky particles. The crusher operator must therefore manipulate conditions to promote one mechanism over the other based on the production goal.

The Role of Feed Material Properties in Shaping Outcomes

The inherent properties of the feed rock, such as its hardness, abrasiveness, and geological structure, significantly influence the relationship between shape and throughput. Hard, competent rocks like granite may require higher energy impact to break into cubic shapes, inherently limiting the achievable throughput compared to softer limestone.

Understanding the feed material's characteristics is the first step in parameter configuration. A comprehensive analysis of the rock's compressive strength and silica content allows for a more predictive approach to setting rotor speed and feed rate, creating a foundation for achieving the desired balance.

Core Parameter One: Precise Control of Rotor Speed

Rotor speed is arguably the most influential parameter for controlling the crushing process in a VSI crusher. The rotational velocity of the rotor directly determines the kinetic energy imparted to the rock particles, governing the breaking force and the resulting product shape. Precise speed control is the primary tool for navigating the trade-off between product quality and production volume.

The Kinetic Energy Principle: Relating Rotor Speed to Breaking Force

The kinetic energy of a particle ejected from the rotor is proportional to the square of the rotor's tip speed. This physical relationship means that a small increase in speed results in a large increase in impacting energy. For instance, increasing the tip speed from 60 meters per second to 70 meters per second can increase the available breaking energy by over 35 percent, which is decisive for shaping hard, abrasive rocks.

Manufacturers provide recommended operating ranges for different material types. For highly abrasive materials, tip speeds may be maintained between 65 and 75 meters per second to ensure sufficient energy for cubical fracture without excessively accelerating wear on the rotor components.

Methods for Adjusting Rotor Speed in Industrial Settings

The most common and flexible method for adjusting rotor speed is through the use of a variable frequency drive connected to the crusher's main motor. This system allows operators to digitally set the motor's rotational speed, which in turn adjusts the rotor speed via the drive belts, enabling fine-tuning without mechanical intervention.

An alternative mechanical method involves changing the pulley sizes on the motor and the crusher. While this is a more permanent adjustment, it is a cost-effective solution for applications where the material type and product specification are consistent over long periods. Proper alignment and belt tension are critical during such modifications to prevent power transmission losses.

Operational Symptoms of Incorrect Rotor Speed Settings

An excessively high rotor speed often manifests as a noticeable increase in crusher vibration and noise levels. The high-energy impacts can generate an excessive amount of fine material, or crusher dust, which may not be desirable for the target product specification and represents an inefficient use of energy.

Conversely, a rotor speed set too low will fail to provide adequate energy for proper rock fracture. This condition typically results in a product with a high proportion of poorly shaped, flaky particles and a lower overall throughput because the crushing chamber cannot clear material efficiently. Monitoring the power draw of the main motor can provide an early indication of such suboptimal operation.

Establishing a Baseline Speed for New Material Types

When processing a new type of feed material, a systematic approach to finding the optimal rotor speed is necessary. This often begins with operating the crusher at a medium speed setting and conducting a series of short tests where the speed is incrementally adjusted while holding the feed rate constant.

After each adjustment, samples of the product are taken and analyzed for particle shape index and gradation. The speed that yields the best compromise between shape quality and production rate for that specific material is then established as the new operational baseline, creating a data-driven setup procedure.

Core Parameter Two: Feed Rate and Feed Characteristics Management

The manner and rate at which material is introduced into the crushing chamber are equally critical as the rotor speed. A stable and appropriately characterized feed stream is the foundation for achieving a predictable balance between particle shape and throughput. Uncontrolled feeding leads to chamber flooding, power surges, and inconsistent product quality.

The Importance of Consistent and Uniform Feed Material

A steady, uninterrupted flow of material into the crusher is paramount for stable operation. Fluctuations in the feed rate cause the power draw of the crusher to oscillate, which prevents the crushing chamber from maintaining an optimal rock-on-rock action. This instability directly translates into variations in the product's particle shape and overall gradation.

Modern crushing plants utilize weighing scales and level sensors on feed conveyors to ensure mass-flow consistency. This constant monitoring allows for automatic adjustments to the feed equipment, creating a closed-loop system that stabilizes the crusher's operation and protects it from detrimental feed surges.

Optimizing Feed Gradation Through Pre-Screening

The size distribution of the feed material has a profound impact on the crushing efficiency. A feed that contains a high percentage of fines can cushion the impacts within the chamber, reducing the effective breaking energy and leading to a lower quality product. Conversely, feed containing only very large rocks can overload the rotor and cause excessive wear.

Implementing a pre-screening stage before the VSI crusher is a highly effective strategy. This screen removes the fine material that has already reached the target size and may also scalp off oversize rocks that could be reduced by a primary jaw crusher first. This ensures the VSI crusher receives a well-graded feed ideal for its shaping function.

Strategies for Handling Damp or Sticky Feed Materials

Moisture and clay content in the feed material present a significant challenge, as they can cause material to adhere to the inside of the feed hopper and the crushing chamber. This buildup reduces the effective volume of the chamber and can eventually lead to clogging, severely limiting throughput and potentially causing mechanical damage.

Several solutions exist for sticky feeds, including installing vibrators or air cannons on the hopper to dislodge material, using liners with a low coefficient of friction, or in extreme cases, applying indirect heat to reduce moisture. For operations consistently handling such materials, a specialized feed system design is a worthwhile investment.

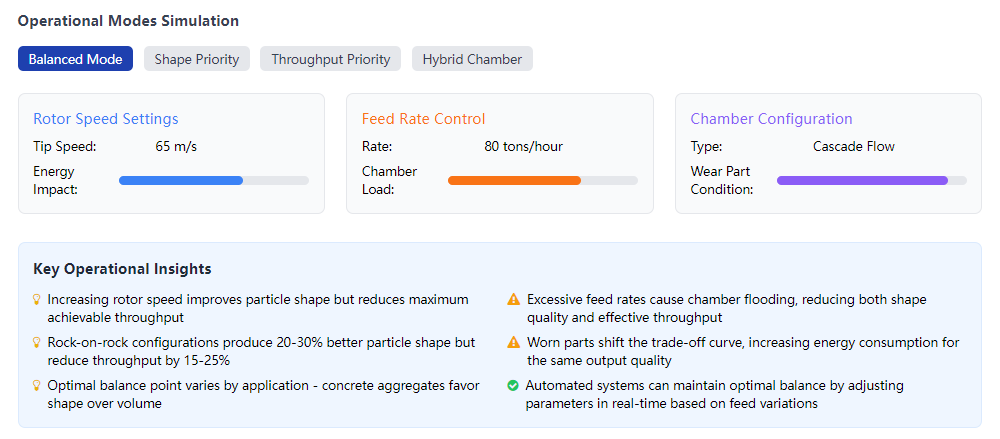

Automated Feed Control Linked to Crusher Power Draw

Advanced VSI crusher systems often integrate an automated control loop that links the feed rate directly to the crusher's main motor power consumption. The control system is programmed to maintain the motor's power draw at a setpoint that corresponds to an optimally loaded crushing chamber.

If the power draw rises above the setpoint, indicating a potential overload, the system automatically reduces the feed rate. Conversely, if the power drops, the system increases the feed to maximize throughput. This dynamic adjustment is a key technology for maintaining the delicate balance between shape and tonnage without constant manual intervention.

Core Parameter Three: Crushing Chamber Design and Wear Parts Configuration

The physical design of the crushing chamber and the configuration of its internal wear parts fundamentally define the crushing action available to the operator. The choice between rock-on-rock and rock-on-anvil configurations, along with the state of wear parts, creates a fixed framework within which the variable parameters of speed and feed rate operate.

Rock-on-Rock Crushing: Maximizing Particle Shape Quality

In a rock-on-rock configuration, the incoming material is accelerated by the rotor and thrown against a stationary bed of previously crushed rock that forms a natural lining within the chamber. This action promotes interparticle impact, which is highly effective at breaking rocks along their natural cleavage planes to produce well-shaped, cubic particles with minimal wear part consumption.

The primary limitation of this method is its capacity. To maintain the rock bed necessary for effective crushing, the feed rate must be carefully controlled. Excessive feed can disrupt the bed, leading to direct impact on the chamber walls and a deterioration in particle shape, illustrating the inherent throughput constraint of this design.

Rock-on-Anvil Crushing: Prioritizing Production Throughput

The rock-on-anvil configuration involves the rotor throwing material directly against stationary metal anvils or aprons located around the perimeter of the crushing chamber. This direct transfer of energy results in very high size reduction efficiency and allows for significantly greater feed rates and throughput compared to the rock-on-rock method.

The trade-off for this high capacity is often a less favorable particle shape. The violent impact against metal surfaces can produce more fractured and elongated particles. This makes the configuration ideal for primary crushing stages or for producing aggregates where shape is less critical, such as for base course layers in road construction.

Hybrid and Cascade Flow Chambers: Seeking an Optimal Balance

Many modern VSI crushers feature hybrid chamber designs that combine elements of both rock-on-rock and rock-on-anvil principles. In a cascade flow design, material is initially impacted against anvils for primary breakage and then cascades into a rock-lined chamber for secondary shaping.

This multi-stage approach within a single machine allows operators to achieve a more favorable balance, offering higher throughput than a pure rock-on-rock system while producing better particle shape than a pure rock-on-anvil system. The specific geometry of the crushing cavity is engineered to guide the material flow for optimal performance.

The Critical Impact of Wear Parts Condition on Performance

The geometry of the wear parts, particularly the rotor tips and the anvils, is precisely designed to guide the material flow and impact angle. As these parts wear, their profiles change, altering the trajectory of the ejected material. This leads to less efficient impacts, a broader product gradation, and a shift in the balance between shape and throughput.

Establishing a regular measurement and replacement schedule for wear parts is essential for consistent performance. Allowing parts to wear beyond their design limits not only reduces product quality but can also lead to unbalanced forces on the rotor, increasing vibration and the risk of damage to the bearing system.

System Integration and Closed-Loop Control for Dynamic Optimization

Moving beyond static parameter settings, the highest level of performance is achieved by integrating the VSI crusher into a smart, automated system. Using sensors and control logic, the crusher can dynamically adjust its operation in real-time to maintain the desired product quality despite variations in feed material, effectively transforming a static trade-off into a dynamic optimization.

Utilizing Online Particle Analysis for Real-Time Feedback

Technologies like digital image analysis systems can be installed on the product conveyor to continuously monitor the particle shape index of the output material. This real-time data is fed directly to the plant's control system, providing immediate feedback on the effectiveness of the current crusher parameter settings.

If the system detects a deviation from the target shape index, it can automatically initiate corrective actions, such as fine-tuning the rotor speed or adjusting the feed rate. This creates a direct feedback loop for product quality that was previously impossible with manual sampling and lab analysis, which involved significant time delays.

Data Fusion from Multiple Sensors for System Health Monitoring

A comprehensive automation system aggregates data from multiple sensors monitoring the crusher's condition. Vibration sensors on the main bearing housing, temperature sensors on the lubrication system, and the main motor's power and current readings together create a detailed digital twin of the machine's operational state.

By analyzing trends in this data, the system can not only optimize for product quality but also predict maintenance needs. For example, a gradual increase in vibration levels might indicate progressing wear on the rotor, allowing for planned maintenance before a failure occurs, thus avoiding unplanned downtime.

Implementing Operational Modes for Different Product Goals

Advanced control systems allow pre-defined operational modes to be selected with a single command. A "Shape Priority" mode would automatically set parameters to favor cubical particle production, perhaps by maximizing rotor speed and carefully moderating the feed rate, even if it means a slight reduction in throughput.

Conversely, a "Throughput Priority" mode would configure the crusher for maximum tonnage, potentially by utilizing a lower rotor speed and a higher, stable feed rate suitable for producing base material. This allows a single plant to easily switch between producing different product specifications to meet market demands.

The Long-Term Economic Benefits of Automation

The initial investment in sensors, instrumentation, and control software for a VSI crusher is justified by long-term gains in operational efficiency. Automated systems maintain consistent product quality, reducing the amount of off-spec material that must be re-crushed or sold at a lower price, thereby minimizing waste.

Furthermore, by ensuring the crusher always operates within its optimal parameters, automation reduces specific energy consumption and slows the rate of wear on components. This extends the service life of expensive wear parts and reduces maintenance costs, contributing to a lower total cost of ownership over the machine's lifespan.

Practical Configuration Strategies for Specific Application Scenarios

Bringing together the principles of parameter control, this section provides actionable strategies for configuring a VSI crusher to meet well-defined industrial goals. The optimal

setup is not universal but depends heavily on the value placed on particle shape versus production volume in the final application of the crushed product.

Strategy for Absolute Particle Shape Priority: High-Performance Concrete Sand

When the primary goal is to produce aggregate for high-strength concrete or asphalt, where particle shape is paramount, the configuration must prioritize the impact crushing mechanism. This involves setting the rotor tip speed to the higher end of the acceptable range for the material, typically between 70 and 80 meters per second, to ensure high-energy impacts.

The feed system must be meticulously controlled to provide a steady, moderate feed rate that maintains a dense rock-on-rock action within the chamber without causing overload. The crusher should be equipped with a rock-on-rock or cascade flow chamber design, and wear parts must be kept in like-new condition to preserve the designed material trajectory.

Strategy for Absolute Throughput Priority: Base Course or Fill Material

For applications such as road base or landfill cover, where volume is the critical economic factor and particle shape is secondary, the crusher should be configured for maximum throughput. A rock-on-anvil chamber configuration is typically selected to handle high feed rates. The rotor speed can be set to a lower, more energy-efficient value that still provides adequate breakage.

The feed rate is maximized to the point just below the crusher's power or mechanical limits. In such a scenario, the use of a robust impact crusher configuration is acceptable, and the focus of maintenance shifts towards maximizing uptime and component life rather than perfect particle geometry.

Strategy for a Flexible Multi-Product Operation

Many aggregate plants need to switch production between different product specifications throughout a day or week. For this flexibility, the crusher should be equipped with a versatile chamber design like cascade flow and be integrated with an advanced automation system. Pre-set recipes for different products can be stored in the control system.

Switching from producing concrete sand to drainage gravel becomes a matter of selecting the corresponding recipe from a control panel. The system then automatically adjusts all parameters, including rotor speed, feed rate, and even crusher discharge size settings if applicable, to achieve the new target specification with minimal transition time and material waste.

Developing a Standardized Procedure for Parameter Adjustment

To ensure consistency and safety, every operation should develop a clear Standard Operating Procedure for adjusting crusher parameters. This SOP should outline the steps for any change, starting with a review of the current product sample and production goal, followed by a systematic adjustment of one parameter at a time while monitoring the crusher's response.

The procedure must emphasize safety, requiring communication with all plant personnel and locking out the control system during manual adjustments if necessary. A well-documented SOP prevents haphazard changes that can lead to equipment damage, poor product quality, and unsafe operating conditions, ensuring that the sophisticated balance between shape and throughput is managed methodically.