Bearing Selection Guide for VSI Crushers: How to Choose Bearing Type and Size Based on Crushing Force and Rotational Speed?

This guide details the methodology for selecting the correct bearings for Vertical Shaft Impact crushers, focusing on withstanding dynamic loads from crushing forces and ensuring reliability under high rotational speeds. It provides a step-by-step process for engineers to choose the appropriate bearing type, size, and configuration for long service life and reduced operational costs.

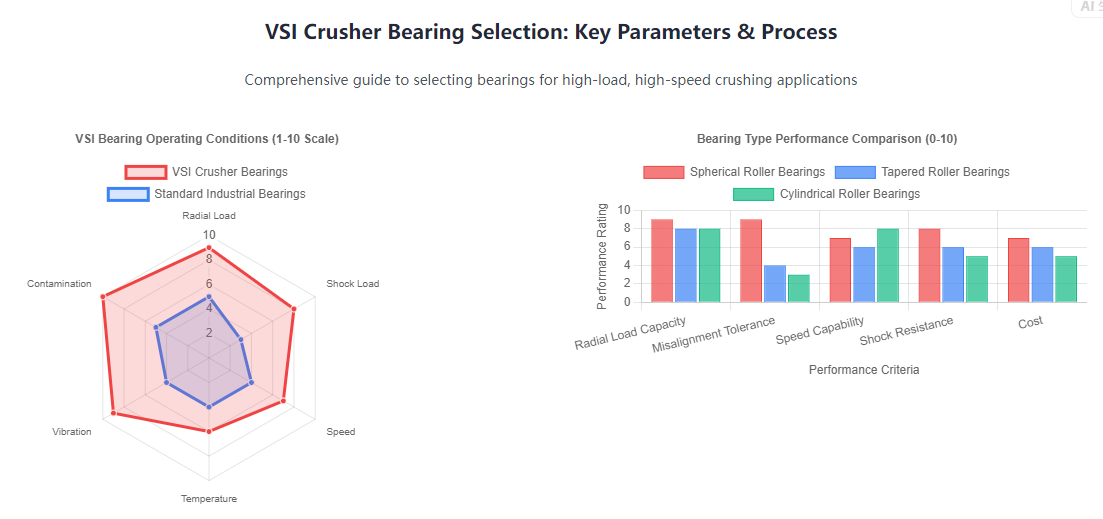

The Extreme Operating Conditions of VSI Crusher Bearings

Bearings in a Vertical Shaft Impact crusher are subjected to one of the most demanding environments in industrial machinery. They must support the high-speed rotor assembly while enduring significant shock loads from the rock crushing process, all within a contaminated atmosphere of dust and variable temperatures. Understanding these challenges is the first step toward a successful bearing selection.

Analyzing the Origin and Nature of Crushing Forces

The primary load on the bearings comes from the crushing forces generated when the rotor accelerates rock particles and impacts them against the chamber walls or anvils. These forces are not smooth or constant; they are dynamic and impulsive, characterized by high peak magnitudes that occur randomly as rocks of different sizes and strengths are processed.

This shock loading creates stress cycles that can cause premature fatigue failure in bearings not designed for such applications. The magnitude of the force depends on factors like rotor speed, feed rate, and rock hardness, making it a variable that must be carefully estimated during the design phase.

The Impact of High Rotational Speed on Bearing Performance

VSI crusher rotors operate at high peripheral speeds to achieve the necessary particle acceleration. These high rotational speeds, often exceeding 1000 revolutions per minute, push bearings toward their operational limits. High speeds generate increased friction and heat within the bearing, which can degrade the lubricant and lead to thermal expansion issues.

The bearing's internal design, including the type of cage and the precision of the rolling elements, must be suitable for high-speed operation to prevent skidding and excessive wear. The limiting speed rating provided by bearing manufacturers is a critical parameter that must not be exceeded in the application.

Additional Challenges from Vibration and Misalignment

Inevitable imbalances in the rotor assembly, combined with uneven feeding of material, introduce vibration and potentially misaligning forces into the bearing system. These conditions impose additional radial and axial loads that are not present in ideal, theoretical calculations, further compounding the stress on the bearing components.

Bearings selected for VSI crushers must therefore have inherent capabilities to accommodate some degree of misalignment. Without this feature, the additional loads caused by shaft deflection can dramatically shorten bearing life and lead to catastrophic failure.

The Consequences of Bearing Failure in a Crushing Application

A bearing failure in a VSI crusher is a serious event that leads to immediate, unplanned downtime, halting production entirely. The financial impact includes not only the cost of lost production but also the expensive repair process, which often involves replacing the damaged bearings, the main shaft, and possibly other adjacent components.

In severe cases, a seized bearing can cause the rotor to lock up, resulting in a drive belt failure or even damage to the motor. This underscores the critical importance of correct initial bearing selection and proper maintenance to ensure overall equipment reliability and minimize total cost of ownership.

Step One: Calculating and Evaluating the Dynamic Loads on the Bearings

The foundation of proper bearing selection is a realistic calculation of the loads it will experience during operation. For VSI crushers, this involves quantifying the complex combination of static and dynamic forces acting on the rotor support points and translating them into an equivalent load for bearing life calculations.

Identifying the Primary Sources of Bearing Load

The loads acting on the crusher's main bearings originate from several sources. The most significant is the crushing force itself, which is transmitted from the rotor to the shaft. Additional loads include the weight of the rotor assembly, the tension from the V-belts driving the rotor, and forces generated by any residual imbalance in the rotating mass.

For a complete analysis, all these forces must be considered in their radial and axial components. The crushing force, in particular, is predominantly radial, but operational conditions can introduce axial components that must be accounted for in the bearing arrangement.

Calculating the Equivalent Dynamic Load for Bearing Selection

To simplify the selection process, the varying loads are combined into a single constant value called the equivalent dynamic load, denoted as P. This value represents a theoretical constant load that would have the same effect on bearing fatigue life as the actual complex load spectrum. The calculation involves applying service factors that account for the severity of shock and vibration.

For VSI crushers, a high shock factor, often between 1.5 and 2.5, is applied to the calculated radial load to account for the impulsive nature of the crushing forces. This conservative approach ensures the selected bearing has a sufficient safety margin for the harsh operating conditions.

A Simplified Model for Estimating Maximum Crushing Force

While detailed force analysis might require specialized software, a practical estimation can be made based on the crusher's drive motor power. The torque transmitted to the rotor can be calculated from the motor power and speed, and this torque, combined with the rotor's geometry, provides an approximation of the tangential force at the tip of the rotor, which relates to the radial force on the bearings.

This simplified method provides a reasonable ballpark figure for initial sizing. For example, a crusher with a 300 kilowatt motor and a rotor diameter of 1 meter operating at 1200 RPM will transmit a significant force that must be accurately estimated to begin the bearing selection process.

Advanced Techniques for Measuring Actual Bearing Loads

For critical applications or new crusher designs, more precise load data can be obtained through direct measurement. Strain gauges applied to the crusher's main shaft near the bearing locations can directly measure the strain caused by operational loads, which is then converted into stress and force values.

This empirical data provides invaluable validation for theoretical models and can reveal load conditions that were not anticipated during the design phase. Although this approach requires significant effort and instrumentation, it leads to the most accurate and reliable bearing selection, optimizing both performance and cost.

Step Two: Selecting the Bearing Type Based on Load and Speed Requirements

Once the operating loads and speeds are understood, the next step is to choose a bearing type whose inherent design characteristics are best suited to withstand these conditions. The bearing must offer high load capacity, accommodate misalignment, and perform reliably at the crusher's operational speed.

Spherical Roller Bearings: The Preferred Choice for VSI Applications

Spherical roller bearings are overwhelmingly the standard choice for VSI crusher main bearings. Their key advantage is the ability to self-align, which compensates for slight misalignments caused by shaft deflection under load or minor installation errors. This feature is crucial for ensuring even load distribution across the roller elements and preventing edge loading, which can cause premature failure.

Furthermore, spherical roller bearings are designed to carry high radial loads and moderate axial loads in both directions, which matches the loading profile of a VSI crusher rotor. Their two rows of symmetrical rollers provide a large load-carrying capacity within a compact dimension.

Understanding Bearing Size Series and Their Impact on Capacity

Bearings are available in different dimension series, which indicate the relative size and load capacity for a given bore diameter. A 23 series bearing, for example, has a wider cross-section than a 22 series bearing with the same bore, giving it a higher radial load rating but potentially a lower speed capability.

Selecting the appropriate series involves balancing the need for high load capacity against the constraints of the available space in the crusher's housing and the required operating speed. For most VSI crushers, a medium or heavy series spherical roller bearing is typically specified to provide the necessary robustness.

The Critical Selection of Bearing Internal Clearance

Bearing internal clearance, the amount of internal play between the rolling elements and the raceways, is a vital selection parameter. Standard bearings are manufactured with a Normal clearance group, but for applications like VSI crushers with significant shock loads and expected heat generation, a larger than normal clearance is required.

A C3 or even C4 clearance group is commonly specified. This extra internal space prevents the bearing from becoming preloaded when the inner ring expands due to frictional heat, which would otherwise lead to rapid overheating and failure. The correct clearance ensures the bearing operates smoothly under the expected temperature gradient.

Alternative Bearing Types for Specialized Configurations

While spherical roller bearings are standard, certain crusher designs might utilize a different arrangement, such as two single-row tapered roller bearings mounted in opposition. This configuration provides very high rigidity and precise shaft positioning but is less forgiving of misalignment and requires more precise adjustment during installation.

The choice between bearing types ultimately depends on the specific crusher design philosophy. The manufacturer's recommendation, based on years of testing and field experience, should always be the primary guide, as the bearing arrangement is integral to the machine's overall performance and reliability.

Step Three: Determining the Required Basic Dynamic Load Rating and Life

With the bearing type selected and the equivalent dynamic load calculated, the specific bearing size is chosen based on its load rating and the desired operational life. International standards provide a formal method for calculating the theoretical fatigue life, which guides the selection of a bearing with adequate capacity.

The Definition and Importance of the Basic Dynamic Load Rating

The Basic Dynamic Load Rating, denoted as C, is a fundamental property of a bearing published in manufacturer catalogs. It represents the constant radial load that a bearing can endure for one million revolutions with a 90% probability of survival. This rating allows for the direct comparison of load-carrying capacity between different bearing sizes and types.

The selected bearing must have a C value that is sufficiently higher than the application's equivalent dynamic load P. The ratio of C to P is the central

factor in the life calculation equation, determining the theoretical lifespan of the bearing under specified operating conditions.

Applying the Standard L10 Life Calculation Equation

The theoretical fatigue life of a rolling bearing is calculated using the ISO 281 standard life equation: L10 = (C/P)^p * (10^6 / (60n)), where L10 is the life in hours, C is the basic dynamic load rating, P is the equivalent dynamic load, n is the rotational speed in RPM, and p is an exponent (10/3 for roller bearings).

For a VSI crusher application, a target L10 life between 30,000 and 60,000 hours is often considered a reasonable design goal. This lifespan balances initial cost with long-term reliability, aiming for several years of operation between major overhauls. Using the equation, the required C value can be back-calculated from the desired life and the known P and n values.

A Practical Calculation Example for a VSI Crusher Bearing

Consider a crusher with an equivalent dynamic load P of 200 kN and a shaft speed n of 1000 RPM. If the target L10 life is 50,000 hours, the required basic dynamic load rating C can be calculated. Substituting into the formula: 50,000 = (C/200)^(10/3) * (1,000,000 / (60*1000)). Solving for C yields a value of approximately 550 kN.

The engineer would then consult a bearing catalog to select a spherical roller bearing with a bore diameter that fits the crusher shaft and a C rating of at least 550 kN. This quantitative approach removes guesswork from the selection process.

Solutions When Standard Bearing Ratings Are Insufficient

In cases where the calculated required C rating is very high and a single standard bearing does not meet the requirement, alternative solutions must be considered. One option is to use two bearings in tandem at each support location, effectively doubling the load-carrying capacity, though this requires a more complex housing design.

Another solution is to explore custom-engineered bearings with enhanced performance characteristics, such as those made from vacuum-degassed steel or featuring optimized roller profiles. While more expensive, these premium bearings can offer significantly higher load ratings and longer life in extreme applications.

Step Four: Bearing Configuration, Fitting, and Lubrication System Design

Selecting the correct bearing is only part of the solution; its performance is equally dependent on how it is integrated into the machine. The design of the housing, the fits on the shaft and in the housing, the lubrication method, and the sealing system all play a critical role in achieving the designed service life.

Selecting and Designing the Appropriate Bearing Housing

The bearing housing must provide rigid and precise support for the outer ring of the bearing. Cast steel housings are typically used for their strength and durability. A common design is the plummer block or pillow block housing, which is often of the split type for easier installation and maintenance.

The housing must be designed to ensure proper alignment of the two bearing positions supporting the rotor shaft. Misalignment between housings will induce parasitic loads in the bearings, drastically reducing their life. The housing also incorporates features for effective sealing and lubrication delivery.

Specifying the Correct Fits for the Shaft and Housing

The fit between the bearing rings and the mating components is crucial. The inner ring, which rotates with the shaft, is typically mounted with an interference fit to prevent creep, which is the slight rotation of the ring on the shaft that can cause fretting damage. The fit is selected based on the load conditions and shaft diameter.

The outer ring, held stationary in the housing, is usually fitted with a slight clearance to allow for axial expansion of the shaft due to thermal growth. However, under heavy loads that might cause the outer ring to rotate, a tighter fit may be necessary. The selection of these fits is a precise engineering decision.

Choosing Between Grease and Oil Lubrication Systems

Lubrication is the lifeblood of a bearing. For VSI crushers, grease lubrication is common due to its simplicity and effective sealing properties. A high-quality, high-temperature grease with extreme pressure additives is required to withstand the heavy loads and operating temperatures.

For very high-speed or heavily loaded applications, oil lubrication may be preferred. Oil can carry away more heat than grease and can be filtered to remove contaminants. Systems can range from simple oil baths to sophisticated circulating oil systems with coolers and filters, offering superior performance at a higher complexity and cost.

Designing a Robust Sealing System to Exclude Contaminants

Preventing the ingress of abrasive dust into the bearing is perhaps the greatest challenge in a crusher application. A multi-stage sealing approach is essential. This often consists of a primary labyrinth seal, which creates a tortuous path for dust, combined with secondary rubber radial lip seals.

In some designs, a positive pressure air purge system is used. This system injects a small flow of clean, filtered air into the seal cavity, creating a slight overpressure that actively prevents dust from entering. Such systems are highly effective in extremely dusty environments and significantly extend bearing life by maintaining a clean lubricant.

Bearing Installation, Maintenance, and Condition Monitoring for Longevity

Even a perfectly selected bearing will fail prematurely if it is not installed correctly, properly maintained, and monitored during operation. Adherence to best practices in these areas is non-negotiable for achieving the full potential of the bearing's design life and ensuring crusher reliability.

Following a Standardized Procedure for Bearing Installation

Bearing installation must be performed with care to avoid damaging the precision components. The use of proper tools is mandatory. Induction heaters should be used to heat the bearing inner ring for mounting onto the shaft, ensuring a smooth, controlled interference fit without the use of force that could brinell the raceways.

Similarly, hydraulic nuts are used to apply precise axial force when pressing bearings onto shafts or into housings. The procedure should specify clean working conditions, verification of fits before assembly, and the correct application of the initial preload or clearance adjustment.

Establishing a Regular Lubrication Maintenance Schedule

For grease-lubricated bearings, a disciplined relubrication schedule must be established based on operating hours, temperature, and the bearing size. The schedule should specify the type of grease, the exact quantity to be added, and the procedure for purging old, contaminated grease from the housing.

Over-lubrication can be as harmful as under-lubrication, as it can cause churning of the grease, leading to overheating. The use of automated single-point lubricators can provide a continuous, metered supply of fresh grease, optimizing the lubrication process and reducing manual labor.

Implementing Vibration and Temperature Monitoring for Early Fault Detection

Condition monitoring techniques are powerful tools for predicting bearing failures before they occur. Vibration analysis is particularly effective. By regularly measuring vibration levels and analyzing the frequency spectrum, technicians can detect early signs of bearing deterioration, such as fatigue spalling or misalignment.

Similarly, continuous temperature monitoring of the bearing housing can provide an early warning of lubrication failure or the onset of excessive friction. Integrating these sensors into the plant's control system allows for alarms to be triggered when pre-set thresholds are exceeded, enabling planned intervention.

Analyzing Failure Modes to Prevent Recurrence

When a bearing does fail, a thorough root cause analysis should be conducted. Examining the failed bearing can reveal the mode of failure—such as fatigue, wear, corrosion, or plastic deformation—which points to the underlying cause, be it contamination, inadequate lubrication, improper installation, or overloading.

Documenting these findings and updating maintenance procedures accordingly creates a feedback loop that continuously improves reliability. This proactive approach to failure analysis transforms unexpected breakdowns into learning opportunities, steadily increasing the meantime between failures for the crusher's critical bearing cylinder components.