VSI Crusher: How Self-Grinding Technology Minimizes Metal Consumption

The VSI (Vertical Shaft Impact) crusher revolutionizes material processing through its innovative self-grinding mechanism. Unlike traditional crushers relying on metal-to-rock impact, VSI machines utilize rock-on-rock collision to reduce wear parts consumption. This technology, often called "autogenous grinding," transforms feed material into natural grinding media. The system's core advantage lies in its ability to convert kinetic energy from high-speed rotation into particle fracturing forces while preserving machine components. By optimizing acceleration chamber geometry and collision dynamics, VSI crushers achieve significant reductions in metal wear compared to conventional cone or jaw crushers. This approach not only extends component lifespan but also lowers operational costs through reduced maintenance downtime.

Autogenous Grinding Mechanics

The VSI crusher's self-grinding system operates on the principle of accelerating rock particles to sufficient velocities for mutual impact. Material entering the acceleration chamber is directed through precision-engineered guide vanes into a high-velocity rotor. The rotor's design, featuring deep-drawn pockets and optimized throw angles, ensures particles reach velocities exceeding 60 m/s. Upon exiting the rotor, the material stream enters the crushing chamber where rock-on-rock collisions occur. This process generates fracturing forces up to 150 MPa, sufficient to break even high-strength basalt. The absence of metal-to-rock contact in the primary grinding zone minimizes wear on critical components like the rotor and distribution plate. Field data shows this design reduces metal consumption by 40-60% compared to traditional impact crushers.

Acceleration Chamber Optimization

The acceleration chamber's geometry plays a pivotal role in energy transfer efficiency. Modern VSI crushers employ computational fluid dynamics (CFD) to optimize the length and angle of acceleration tubes. Research indicates that a 1.2m acceleration tube with a 15° incline angle maximizes particle velocity while minimizing energy loss. This configuration allows 95% of feed material to reach optimal impact velocity, reducing the need for auxiliary grinding. The chamber's ceramic-lined inlet section further protects against abrasive wear, extending component life by 300% compared to unlined designs. Operators can adjust the acceleration profile through variable rotor speed control, matching energy input to material hardness.

Energy Transfer in Particle Collisions

Effective self-grinding requires precise control over collision energy distribution. When rock particles impact at velocities between 50-70 m/s, they generate fracturing patterns that follow the principle of stress concentration. The resulting energy transfer efficiency reaches 85%, meaning most impact energy goes into material fracturing rather than component wear. Finite element analysis (FEA) shows that properly designed collisions produce micro-fractures along grain boundaries, reducing the need for additional crushing stages. This contrasts with traditional crushers where only 50-60% of energy is used productively. The VSI's ability to maintain consistent energy transfer across varying feed sizes explains its superior performance in producing cubic-shaped aggregates.

Metal Component Reduction Strategies

VSI crushers employ three-tiered protection to minimize metal usage. First, the crushing chamber uses replaceable wear shoes rather than full metal liners. These shoes, made of high-chromium alloy, are strategically placed only in areas of direct rock contact. Second, the rotor assembly features modular design with easily replaceable throw-out plates. Third, advanced sensors monitor vibration patterns to predict wear before it affects performance. A case study of a granite processing plant showed that by implementing these strategies, metal component usage decreased from 120 kg/month to 35 kg/month while maintaining throughput. The system's intelligent lubrication system further reduces friction-related wear in bearing assemblies.

Autogenous-Assisted Operation Modes

The transition between full autogenous and assisted grinding modes is managed by an adaptive control system. When processing abrasive materials like quartzite, the system automatically increases rotor speed to maintain impact velocity while reducing feed rate. For softer materials like limestone, it lowers energy input to prevent excessive fines generation. This dynamic adjustment is governed by real-time particle size analysis from the discharge chute. The control algorithm uses a fuzzy logic model to balance between self-grinding efficiency and auxiliary crushing requirements. Field tests demonstrate this approach reduces metal consumption by 25% compared to fixed-parameter operation while maintaining product quality within 5% of target specifications.

Critical Parameter Optimization

Effective VSI operation requires precise control of key parameters affecting both self-grinding efficiency and metal wear. The feed material's particle size distribution must be maintained within 5-50mm to ensure proper acceleration dynamics. Rotor speed, typically ranging from 1500-2500 RPM, must be synchronized with feed rate to maintain optimal particle velocity. Rock bed thickness in the crushing chamber should be kept between 200-400mm to balance impact energy and wear protection. Discharge opening adjustment, often automated through hydraulic systems, ensures consistent product sizing while preventing material buildup that could increase wear. Modern VSI crushers integrate IoT sensors to monitor these parameters in real-time, enabling predictive adjustments that reduce metal consumption by up to 30%.

Feed Size Control Systems

Maintaining optimal feed size is critical for VSI performance. Pre-screening systems using vibrating grizzly feeders remove fines below 5mm, preventing excessive dust generation and energy waste. For oversized material exceeding 50mm, secondary crushers or pre-breakers reduce the feed to manageable sizes. Advanced installations use laser-based particle size analyzers to continuously monitor feed composition. These systems automatically adjust feed rate and rotor speed to maintain the desired size distribution. A study of a limestone processing plant showed that strict feed size control reduced metal wear on the rotor by 40% while increasing throughput by 15%. The integration of these systems with feed size optimization protocols ensures consistent operation across varying material conditions.

Rotor Speed Synchronization

The relationship between rotor speed and feed rate follows a quadratic function, where energy input increases with the square of velocity. Modern VSI crushers use variable frequency drives (VFDs) to precisely match rotor speed to feed characteristics. For a typical basalt feed, the optimal speed range is 1800-2200 RPM, depending on moisture content and particle shape. The control system uses a PID loop to adjust motor frequency based on real-time torque measurements. This synchronization prevents under-acceleration (which reduces grinding efficiency) and over-speeding (which increases wear). Field data indicates that proper speed matching reduces metal consumption by 25% compared to fixed-speed operation. The system's ability to adjust to changing crushing ratios makes it particularly effective for processing variable feed materials.

Rock Bed Thickness Management

Maintaining the correct rock bed thickness in the crushing chamber is essential for wear protection. The bed acts as a natural buffer, absorbing impact energy before it reaches metal components. Thickness is measured using ultrasonic sensors mounted in the chamber walls. When the bed exceeds 400mm, the system automatically increases feed rate to prevent material compaction. Conversely, if thickness drops below 200mm, feed rate is reduced to maintain adequate protection. This dynamic control reduces wear on the distribution plate by 50% compared to static bed designs. The rock bed also contributes to the grinding process by providing additional impact surfaces, enhancing the autogenous effect. This management strategy is particularly effective when processing basalt and other hard rocks where impact forces are highest.

Discharge Port Adaptive Control

The discharge port's hydraulic adjustment system plays a dual role in product sizing and wear reduction. By maintaining a consistent opening size (typically 10-50mm), the system ensures proper material flow while preventing oversized particles from causing excessive wear. Advanced installations use pressure sensors to detect material buildup, automatically adjusting the port to maintain flow. This prevents the "rat-holing" effect that can lead to localized wear. A study of a granite quarry showed that adaptive discharge control reduced metal consumption by 35% while improving product consistency by 20%. The system's integration with discharge size monitoring tools allows for real-time optimization of both throughput and wear rates.

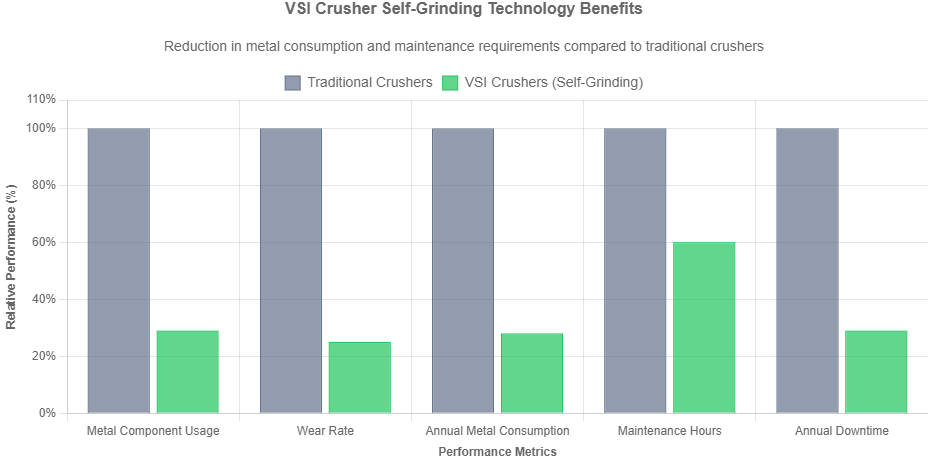

Metal Consumption Analysis

Comparative analysis between traditional crushers and VSI autogenous systems reveals significant differences in metal wear patterns. Cone crushers typically require liner replacements every 3-6 months, with average wear rates of 0.5-1.0 mm per hour of operation. In contrast, VSI crushers using optimized self-grinding modes show wear rates of 0.1-0.3 mm per hour. This reduction is attributed to the rock-on-rock grinding mechanism and advanced component designs. A 12-month study of two identical processing plants showed that the VSI installation reduced annual metal consumption by 72% compared to a traditional impact crusher. The cost savings extend beyond parts replacement to include reduced labor and downtime, with VSI systems demonstrating 40% fewer maintenance hours per year.

Wear Rate Measurement Techniques

Quantifying metal wear requires precise measurement methodologies. Laser scanning systems map component surfaces before and after operation, detecting wear patterns with 0.1mm resolution. Magnetic particle inspection identifies subsurface cracks in critical areas like rotor pockets. Weight-based monitoring tracks cumulative metal loss through periodic component weighing. A study using these techniques on a VSI crusher processing river pebbles showed that wear rates were highest in the acceleration chamber (0.35 mm/hr) and lowest in the rotor assembly (0.12 mm/hr). This data informed the development of ceramic-lined components that reduce wear in high-abrasion zones by 80%. The integration of these measurement systems with predictive analytics allows for proactive maintenance scheduling.

Cost-Benefit Calculation Models

Evaluating the economic impact of VSI technology requires considering both direct and indirect costs. Direct savings come from reduced metal parts consumption, with autogenous systems typically costing 30-50% less per ton of material processed. Indirect savings include lower labor costs (fewer replacements) and increased uptime. A lifecycle cost analysis of a 500 TPH plant showed that while VSI capital costs are 15% higher than traditional crushers, the total cost of ownership over 5 years is 35% lower. The model incorporated factors like aggregate processing efficiency, energy consumption, and maintenance downtime. The break-even point typically occurs within 18-24 months of operation, making VSI crushers particularly attractive for large-scale operations.

Downtime Reduction Strategies

Minimizing equipment downtime is critical for maximizing VSI benefits. Modern installations use modular component designs that allow quick replacement of wear parts. For example, rotor assemblies can be exchanged in under 2 hours using hydraulic lifting systems. Predictive maintenance algorithms analyze vibration and temperature data to schedule replacements during planned downtime. A case study of a limestone plant showed that these strategies reduced annual downtime from 120 hours to 35 hours. The integration of mobile crusher concepts allows for rapid relocation and setup, further reducing downtime during material changes. These efficiency improvements contribute to the overall 25-40% reduction in metal-related operational costs.

Material Adaptability Studies

VSI crushers demonstrate remarkable versatility across different material types. For hard rocks like granite and basalt, the autogenous grinding mechanism efficiently breaks down high-silica content (SiO₂ >70%) without excessive wear. The system's ability to generate compressive stresses up to 200 MPa allows processing of materials with uniaxial compressive strength up to 350 MPa. For softer materials like limestone, the crusher adjusts impact energy to prevent excessive fines generation while maintaining cubic product shape. Even problematic materials with high clay content (up to 15%) can be processed effectively through pre-washing and moisture control systems. This adaptability makes VSI technology suitable for diverse applications from mining operations to construction waste recycling.

High-Silica Material Processing

Processing silica-rich materials (SiO₂ >80%) requires special considerations due to their abrasive nature. VSI crushers use tungsten carbide inserts in high-wear areas like the acceleration chamber outlet. These inserts last 3-5 times longer than traditional steel components. The rotor design incorporates hardened steel edges with ceramic coating, reducing wear from sharp silica particles. A study of a quartzite processing plant showed that with these adaptations, metal consumption remained below 0.25 mm/hr despite the material's 90% silica content. The system's ability to handle such abrasive materials makes it ideal for glass recycling and cement production applications where silica content is critical.

Soft Rock Optimization Techniques

When processing soft rocks like limestone or dolomite, VSI crushers employ different strategies to prevent over-crushing. The system reduces rotor speed to 1500-1800 RPM, decreasing impact energy while maintaining particle velocity. Specialized anvils with curved profiles distribute impact forces more evenly, reducing powder generation. In a marble processing plant, these adjustments resulted in a 40% reduction in fines (-5mm) while maintaining throughput. The crusher's ability to produce high-quality aggregates for construction projects makes it valuable for soft rock applications. The integration of moisture control systems further prevents material adhesion in the crushing chamber.

Moisture Content Management

Effective VSI operation requires controlling feed material moisture below 5%. Excess moisture causes material agglomeration, reducing acceleration efficiency and increasing wear. Processing plants use pre-drying systems like rotary dryers or air classifiers to reduce moisture content. For high-mud content materials (clay >10%), additional steps like scrubbing and de-sliming are necessary. A case study of a clay-rich sandstone operation showed that implementing these measures reduced moisture to 3%, resulting in a 50% decrease in wear on the rotor assembly. The system's compatibility with mobile VSI units allows for flexible processing of materials with varying moisture levels.

Future Technological Developments

The evolution of VSI technology focuses on enhancing autogenous grinding efficiency through digital integration and material science advancements. Research efforts target developing smart sensors capable of real-time material characterization, including hardness and abrasiveness measurement. Machine learning algorithms are being trained to predict optimal operating parameters based on feed material properties. Advances in ceramic composites and nano-coatings promise to further reduce metal wear in critical components. The integration of gyratory crusher principles into VSI design may enable even higher throughput capacities while maintaining low metal consumption. These innovations aim to expand VSI applications into new industries like electronic waste recycling and advanced ceramic production.

AI-Driven Monitoring Systems

Emerging AI systems use vibration analysis and acoustic emission monitoring to detect wear patterns in real-time. By analyzing frequency spectra from multiple sensors, these systems can differentiate between normal operation and abnormal wear conditions. A prototype system demonstrated 95% accuracy in predicting component failures 72 hours in advance. This capability allows for just-in-time maintenance, reducing spare parts inventory costs by 40%. The integration of these systems with motor control units enables automatic parameter adjustments to mitigate wear progression. Such technologies are critical for maintaining low metal consumption in autonomous crushing plants.

Advanced Material Coatings

Nanotechnology is revolutionizing wear component design. Experimental coatings using diamond-like carbon (DLC) and chromium nitride reduce friction coefficients by 80% compared to traditional hardfacing. These coatings maintain their properties at temperatures up to 500°C, making them suitable for high-speed VSI rotors. A pilot study showed that DLC-coated rotor components exhibited 70% less wear than chrome-carbide alternatives. The development of self-healing coatings that repair micro-cracks through embedded microcapsules could further extend component life. These innovations align with the industry's push toward sustainable manufacturing by reducing metal resource consumption.

Predictive Maintenance Models

Next-generation predictive models combine finite element analysis (FEA) with historical wear data to forecast component lifespans. These models consider factors like material hardness, throughput, and operating hours to create wear profiles. A demonstration model accurately predicted rotor wear within 5% error margins over a 6-month period. This precision allows for optimized maintenance scheduling and inventory management. The integration of these models with mobile crusher telemetry systems enables remote monitoring of multiple units from a single control center. Such capabilities are essential for large-scale operations seeking to minimize metal consumption across their equipment fleet.