Sanitary-Ware Polishing Waste: VSI Product as Bauxite Substitute

The ceramic industry generates significant volumes of solid waste from the polishing of sanitary ware, presenting both an environmental challenge and a potential economic opportunity. This article investigates an innovative recycling pathway: using a Vertical Shaft Impact crusher to process this waste into a consistent, fine-grained material that can serve as a partial substitute for bauxite in refractory and abrasive applications. It examines the material's properties, the pivotal role of the VSI crusher in modifying its characteristics, and evaluates the technical and economic viability of this circular economy approach.

Characteristics and Challenges of Sanitary Ware Polishing Waste

Sanitary ware polishing waste is a complex mixture of spent abrasives, ceramic fragments, and binding agents. Its highly abrasive and heterogeneous nature makes traditional disposal methods like landfilling economically and environmentally unsustainable. The primary hurdle for valorization is transforming this inconsistent byproduct into a standardized, high-value raw material with controlled chemical and physical properties.

The waste is predominantly composed of hard minerals like zirconium silicate and alumina, which were originally used as polishing agents. These materials possess high hardness and chemical resistance, making them suitable for demanding applications but also presenting a significant challenge for size reduction equipment due to their extreme abrasiveness. The particle size distribution is typically very wide, ranging from coarse lumps to fine powder, which necessitates effective classification after crushing.

Chemical and Mineralogical Composition Analysis

X-ray diffraction analysis often reveals that the main crystalline phases are zircon and corundum, mixed with amorphous phases from the ceramic body itself. This composition is notably similar to that of low-grade bauxite, which contains alumina along with various silicate impurities, providing a technical basis for substitution in certain contexts.

Inherent Abrasiveness and its Impact on Processing Equipment

The presence of these hard minerals results in a very high Abrasion Index. This property causes rapid wear on conventional crushing equipment like hammer mills or jaw crushers, leading to frequent maintenance downtime and contamination of the product with metallic wear debris from the crusher itself.

Current Disposal Methods and Environmental Pressures

Landfilling is the most common disposal method, which not only consumes valuable space but also represents a loss of potentially useful materials. Increasing environmental regulations and disposal costs are pressuring manufacturers to seek alternative, sustainable solutions for this waste stream.

Variability in Feedstock as a Major Hurdle for Recycling

The waste's composition can vary daily based on the types of products being polished and the specific abrasives used. This inconsistency poses a significant challenge for creating a stable and reliable product that meets industrial specifications, requiring robust processing and potential blending strategies.

The Central Role of VSI Crushers in Material Transformation

The VSI crusher is uniquely suited for this application due to its ability to shape particles and handle highly abrasive materials efficiently. Unlike compression-based crushers, the VSI uses a high-speed rotor to accelerate material and break it through impact, resulting in a cubical and well-graded product.

The rock-on-rock crushing principle, where material is made to impact upon itself within the crushing chamber, is particularly advantageous. This action minimizes wear on the metal components of the crusher by creating a protective layer of the material being processed. Furthermore, the intense inter-particle collisions help to liberate attached binders and homogenize the chemical composition of the output product.

Superior Particle Shape Control for Enhanced Performance

The impact breaking mechanism produces particles with a distinct angular shape and numerous fractured faces. This morphology is highly desirable for use as a refractory aggregate, where interlocking particles provide structural strength, and for abrasive applications, where sharp edges enhance cutting efficiency.

Comparison with Alternative Crushing Technologies

When compared to hammer crushers or roll crushers, the VSI crusher demonstrates a clear advantage in producing a more defined particle shape and a narrower size distribution. Hammer crushers tend to generate more elongated flakes, while roll crushers may not effectively reduce the toughest zirconium silicate grains.

Liberation and Homogenization of Constituent Materials

The violent impact within the VSI crusher helps to break apart composite particles, effectively liberating the valuable abrasive grains from the ceramic matrix. This process also acts as a mixing stage, blending variations in the feed material to produce a more consistent product overall.

Configuring the Crusher for Extreme Abrasion Resistance

To withstand the harsh conditions, the crusher must be equipped with specialized wear parts. Tungsten carbide tips, ceramic composite liners, and high-chromium iron alloys are essential for achieving acceptable service life. The VSI crusher design allows for such robust configurations, making it a durable choice for this demanding task.

Application Pathway One: Refractory Aggregate and Fine Powder

One promising application for the processed waste is as a raw material in refractory products, such as castables and bricks. The key requirements for this use include appropriate chemical purity, high refractoriness, and sufficient mechanical strength of the individual particles.

The alumina and zirconia content in the waste contributes to high-temperature resistance. After processing through the VSI crusher and subsequent classification, the material can be sized to match standard refractory aggregate gradations. It can potentially replace a portion of the bauxite or other aggregates in a formulation, reducing the reliance on virgin mined resources.

Technical Specifications for Refractory Applications

Refractory manufacturers require materials with a consistent melting point, low impurity levels (especially alkalis and iron), and predictable thermal expansion behavior. Laboratory testing is necessary to confirm that the processed waste meets these criteria for the intended service temperature range, which might be suitable for intermediate temperature applications.

Performance Impact on Refractory Castable Properties

Initial laboratory studies involve preparing test specimens according to standard protocols. Key properties evaluated include bulk density, cold crushing strength, porosity, and resistance to thermal shock. The angular particle shape from the VSI crusher can positively influence the packing density and mechanical strength of the final refractory product.

Standardized Testing Methods for Validation

Validation follows established international standards, such as those from the ASTM, which define procedures for measuring refractoriness under load, permanent linear change after firing, and abrasion resistance. Successful passage of these tests is a critical step towards commercial acceptance.

Application Pathway Two: Abrasive and Surface Preparation Media

The processed material also shows potential for use as a blasting or polishing medium. For this application, the particle hardness and sharp, angular shape are primary assets. It could be employed in surface preparation tasks where extreme hardness is not required, offering a lower-cost alternative to synthetic abrasives.

Applications could include cleaning metal surfaces, etching concrete, or texturing stone. The cost advantage over virgin abrasives like aluminum oxide or silicon carbide is significant, creating an opportunity for "waste-to-value" in industries that consume large quantities of surface treatment media.

Key Performance Indicators for Abrasive Media

The effectiveness of an abrasive is measured by its hardness, particle toughness, and particle shape. The waste-derived material would be graded according to standard mesh sizes and tested for its cutting rate on standardized metal test panels and its recyclability within blasting equipment.

Potential Market Sectors and Economic Considerations

Target markets include small-scale metal fabrication shops, construction companies, and monument restoration businesses. The economic viability depends on achieving a production cost that is substantially lower than that of conventional abrasives, while still delivering acceptable performance. The use of a fine crusher like a VSI is central to achieving the required particle morphology.

Addressing Limitations in Hardness and Durability

A primary limitation is that the hardness of the waste material, while high, may not match that of specialized industrial abrasives. This results in a faster breakdown rate during use, which may be acceptable for one-time-use applications or less demanding tasks, but could limit its use in high-recycling blasting systems.

From Laboratory to Industrial Plant: Process Flow Design

Scaling up from successful lab tests to a continuous industrial operation requires a well-designed process flow. The plant design must incorporate pre-treatment, core processing, and post-treatment stages to ensure a consistent and marketable product.

The initial stage involves receiving and pre-processing the waste, which includes removing tramp metal with powerful magnets to protect the crusher and pre-screening to separate oversize debris and fines. The core crushing stage with the VSI crusher is then followed by precise screening and classification to produce different product fractions tailored to specific market needs.

Pre-Treatment: Metal Removal and Primary Screening

A suspended magnet above the conveyor and a drum magnet are essential for extracting ferrous contaminants introduced during the polishing process. A vibrating screen can remove very fine material that may not require further crushing and oversize lumps that could disrupt the crusher's feed.

Core Size Reduction and Shaping with the VSI Crusher

The heart of the process is the VSI crusher, configured for high reduction ratios and optimal particle shape. Operating parameters like rotor speed and feed rate are carefully controlled to maximize the production of the desired cubical particles while managing wear rates.

Post-Processing: Classification and Product Storage

After crushing, the material is passed through a series of vibrating screens to separate it into different size fractions, such as coarse aggregate for refractories or fine grit for abrasives. Each fraction is then stored in silos or bulk bags for dispatch. Efficient aggregate processing principles are directly applicable here.

Comprehensive Economic and Environmental Assessment

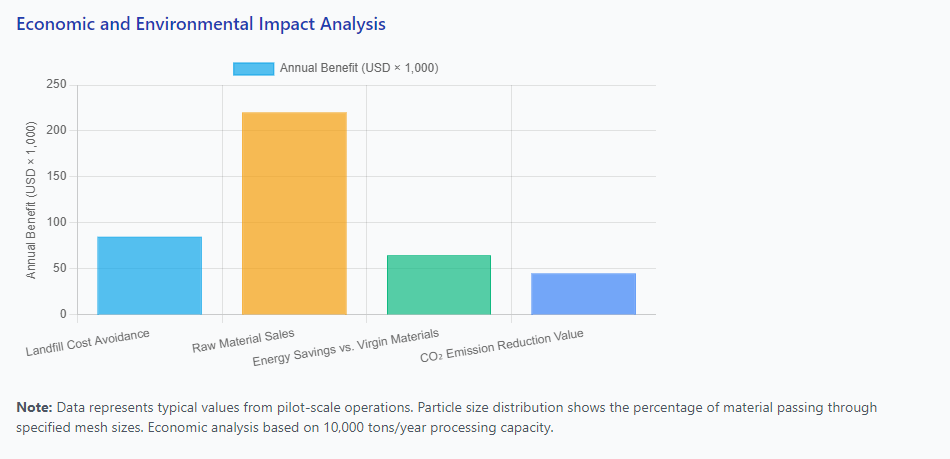

A thorough evaluation must balance the capital and operational costs of the recycling plant against the revenue generated from selling the processed material and the savings from

avoided landfill fees. The environmental benefits add significant value in the context of corporate sustainability goals.

The business case hinges on a stable supply of waste and a clear market demand for the end products. Operational costs are dominated by energy consumption for crushing and the replacement of wear parts on the crusher. Revenue is generated by selling the product at a competitive price against established materials like bauxite or low-grade abrasives.

Capital and Operational Expenditure Analysis

Capital expenditure includes the cost of the VSI crusher, conveyors, screens, magnets, and dust collection systems. Operational expenses involve electricity, labor, maintenance, and wear parts. A detailed cash flow analysis is necessary to determine the payback period and return on investment.

Quantifying Environmental Benefits and Carbon Footprint Reduction

The project contributes to a circular economy by diverting waste from landfill and reducing the need for virgin material extraction. The carbon footprint savings can be calculated by comparing the emissions from landfilling and virgin material production with those of the recycling process, potentially leading to carbon credits or other incentives.

Navigating Policy and Regulatory Incentives

Many regions offer tax benefits, grants, or preferential treatment for industrial waste recycling initiatives. Understanding and leveraging these policies can significantly improve the project's financial viability and accelerate its implementation.