Integration and Optimization of Iron Removal Processes with VSI Crushers in Quartzite Sand Production Lines

This article explores the critical integration of iron removal processes within quartzite sand production lines, focusing on the strategic placement of magnetic separators relative to the Vertical Shaft Impact crusher. It details how proper optimization safeguards the crusher, enhances product purity for high-value industries like glass and solar panel manufacturing, and ensures operational efficiency by addressing both primary and secondary iron contamination sources throughout the production flow.

The Nature and Impact of Iron Impurities in Quartzite Sand

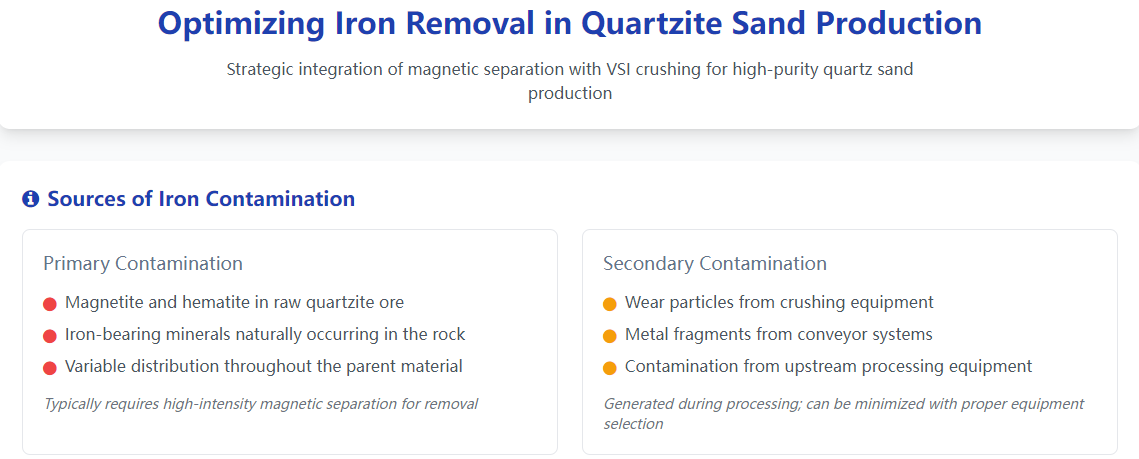

Iron contamination significantly compromises the quality and economic value of quartzite sand. Understanding its origins and effects is the first step toward effective removal. These impurities can originate from the raw ore itself or be introduced during the crushing and handling processes.

The presence of iron, even in minute quantities, can lead to discoloration and reduced performance in final products. For instance, in glass manufacturing, iron content must often be below 100 parts per million to ensure clarity and transparency. Similarly, high-purity quartz sand for photovoltaic cells requires even stricter thresholds, sometimes as low as 30 parts per million, to avoid compromising silicon wafer efficiency.

Primary and Secondary Sources of Iron Contamination

Primary iron is inherent in the quartzite rock, occurring as mineral companions like magnetite or hematite. Secondary iron is introduced through mechanical wear from upstream crushers, such as jaw or cone crushers, and from conveyor systems, adding metallic fragments to the material stream.

Detrimental Effects on High-Value Industrial Applications

Iron impurities cause aesthetic and functional defects. In glass, they impart a greenish tint and reduce light transmittance. In ceramics, they manifest as unsightly black spots, and in silicon production for electronics, they can severely impair electrical properties.

Quantitative Purity Standards for Quartz Sand

Industry specifications provide clear targets. Beyond general guidelines, specific contracts may demand iron oxide content below 0.01%, pushing production lines to employ highly efficient purification methods to meet these stringent requirements.

Mechanical Damage to the VSI Crusher Internals

Beyond product quality, tramp iron poses a direct threat to the VSI crusher. Large metallic pieces can cause catastrophic damage to the rotor, wear plates, and the main shaft, leading to unplanned downtime and expensive repairs. Protecting this core asset is a primary economic driver for pre-crusher iron removal.

Strategic Placement of Iron Removal Stations in the Production Line

Deciding where to locate magnetic separators is a strategic decision that balances equipment protection with final product purity. A multi-stage approach often yields the best results, integrating both pre-crusher and post-crusher removal points.

The configuration is not arbitrary; it must consider the material's granulometry and the nature of the iron contaminants at each stage. A well-designed layout ensures that coarse, strongly magnetic tramp iron is captured early, while finer, weakly magnetic particles are removed after the final crushing stage. This synergy between different separation stages maximizes overall efficiency.

The Role of Pre-Crusher Iron Removal for Equipment Protection

Installing a magnetic separator before the VSI crusher, perhaps after a primary crushing stage, serves as a protective barrier. Its main goal is to intercept large, damaging metal fragments that could originate from upstream equipment or accidental introduction, thereby shielding the crusher's precision components.

The Necessity of Post-Crusher Removal for Final Purity

Despite pre-cleaning, a final iron removal stage after the VSI crusher is indispensable. The intense action of the rotor itself can generate minute metallic wear particles from its own components. This post-crusher stage is critical for capturing this secondary contamination and achieving the desired product specifications.

Implementing a Multi-Stage Cleaning Concept

A robust system often combines a coarse magnetic separator for initial protection with a high-intensity or high-gradient separator for final polishing. This cascading design addresses the full spectrum of iron contaminants efficiently, from large chunks to fine powders. The VSI crusher operates optimally within such a protected and refined process flow.

Synergy with Screening and Classification Systems

Iron removal efficiency is closely linked to particle size. Integrating magnetic separators with screening stations ensures that material is presented to the magnets at an optimal size range, improving capture rates and preventing blinding or overload of the separation equipment.

Selecting the Right Magnetic Separation Technology

Choosing appropriate magnetic equipment is paramount for success. The selection depends on factors like the magnetic susceptibility of the contaminants, material throughput, and the required purity level. Different technologies offer varying strengths and operational costs.

Permanent magnets are often favored for their reliability and low operating costs, requiring no electrical power to generate the magnetic field. Electromagnetic separators, on the other hand, offer adjustable field strength, which can be advantageous for handling varying feed conditions or for achieving very high separation forces for weakly magnetic materials.

Permanent versus Electromagnetic Separators

For most quartzite sand applications, powerful permanent magnets are sufficient and more economical. They provide a constant magnetic field without energy consumption. Electromagnets are typically reserved for situations where the field strength must be frequently adjusted or for removing very feebly magnetic minerals like hematite.

Self-Cleaning Plate Magnets for Fine Material

For post-VSI processing where the sand is fine and dry, plate magnets or magnetic drums are highly effective. These units can be installed above conveyors or incorporated into chutes, automatically expelling captured iron, which minimizes manual maintenance and ensures continuous operation.

Key Parameters for Equipment Sizing

Correct sizing involves calculating the necessary magnetic force based on material burden depth, belt speed, and the mass of the tramp iron to be removed. Undersized magnets will allow contamination to pass, while oversized units represent an unnecessary capital expenditure. The aggregate processing industry has standardized many of these calculations for common applications.

Application of High-Gradient Magnetic Separation

For achieving the highest purity levels, particularly for removing paramagnetic impurities, High-Gradient Magnetic Separators are employed. These devices use a matrix of fine steel wool to create intense field gradients, capable of capturing very fine and weakly magnetic particles that conventional magnets would miss.

Optimizing VSI Crusher Operation to Minimize Iron Contamination

The VSI crusher can be tuned not only for shape and size reduction but also to act as a partner in the iron removal process. Specific operational parameters can significantly reduce the crusher's contribution to secondary iron contamination.

By adopting a rock-on-rock crushing action, where the material feed forms a protective layer on the interior wear parts, metal-to-metal contact is minimized. This autogenous lining drastically reduces the wear rate of metallic components, thereby limiting the generation of new iron particles during the crushing process itself.

Advantages of the Rock-on-Rock Crushing Principle

This method leverages the incoming feed to create a self-renewing protective lining. This results in a much lower wear cost per ton of product and a cleaner output with less metallic wear debris, directly supporting the goals of the downstream iron removal system.

Selecting Highly Wear-Resistant Rotor Components

The choice of material for wear parts like the rotor tips and anvils is critical. Alloys with high chromium content or ceramic composites offer exceptional resistance to abrasion. While these materials may have a higher initial cost, their extended service life reduces both maintenance frequency and the introduction of wear metals into the product stream. The integrity of the rotor is fundamental to this strategy.

Controlling Feed Size and Crusher Throughput

Consistent and appropriately sized feed is crucial. Oversized material can cause violent impacts on the rotor, accelerating wear and potentially causing damage. Operating the crusher within its designed capacity ensures smooth operation and stable product quality, facilitating more efficient iron removal.

Predictive Maintenance through Oil Analysis

Regular analysis of the crusher's lubricating oil can provide early warning of abnormal wear in bearings and gears. Detecting a rising level of ferrous particles in the oil allows for planned intervention before a major failure occurs, preventing a significant contamination event.

Integrating and Automating the Iron Removal System

For consistent results, the individual iron removal units must work in harmony as part of an automated production line. Centralized control allows for monitoring, coordination, and rapid response to any process deviations.

Linking the magnetic separators to the plant's Programmable Logic Controller ensures they activate and deactivate in the correct sequence with the conveyors and crushers. This integration prevents situations where material flows without the protection of the magnets, which could happen during start-up or shutdown sequences if not properly managed.

Automated Cleaning and Tramp Iron Disposal

Modern self-cleaning magnets automatically discharge captured tramp iron into collection bins. Planning for the regular emptying of these bins is a simple but vital part of operational logistics, ensuring the system remains effective and does not become a source of re-contamination.

Centralized Monitoring and Alarm Systems

Integrating the status of all magnetic separators into the plant's SCADA system provides operators with a clear overview. Alarms can be configured for critical faults, such as a magnet losing power or a cleaning mechanism failing, enabling immediate corrective action.

Potential for Online Iron Monitoring

While not yet universal, online analyzers that measure the magnetic susceptibility of the product sand are available. These devices provide real-time feedback on the efficiency of the iron removal process, allowing for automatic adjustments and ensuring consistent product quality.

Data Logging for Continuous Improvement

Recording operational data, including magnet operating hours, cleaning cycles, and product quality samples, creates a valuable database. Analyzing this data over time can reveal trends, predict maintenance needs, and identify opportunities for further process optimization. This holistic view is key to efficient mining and quarrying operations.

Evaluating Efficiency and Committing to Continuous Improvement

The effectiveness of the iron removal system must be quantitatively assessed and continuously refined. A structured approach to measurement and analysis ensures the system meets its objectives and adapts to changing conditions.

The primary metric for evaluation is the iron removal efficiency, calculated by comparing the iron content in the feed and the product. Regular sampling and precise laboratory analysis, using methods like X-ray fluorescence, provide the data needed for this calculation and for verifying compliance with product specifications.

Calculating Iron Removal Efficiency

Efficiency is expressed as a percentage, derived from the formula: (Feed iron content - Product iron content) / Feed iron content × 100%. A well-designed and maintained system should consistently achieve efficiencies above 95% for strongly magnetic contaminants.

Establishing a Routine Sampling and Testing Regime

A statistically sound sampling plan is essential. Samples should be taken from defined points at regular intervals to monitor performance. Laboratory analysis provides the definitive measure of success, beyond what online sensors might indicate.

Scheduled Maintenance of Magnetic Equipment

Permanent magnets can lose strength over time due to mechanical shock or exposure to high temperatures. Electromagnets require checks on electrical connections and cooling systems. A preventive maintenance schedule ensures magnetic fields remain at their specified strength, guaranteeing consistent performance.

Troubleshooting a Sudden Drop in Performance

A rapid decline in removal efficiency can have several causes. Common issues include a overloaded magnet, a damaged or worn-out magnetic element, or a change in feed material characteristics. A systematic checklist helps operators quickly identify and rectify the root cause.