Optimizing Concrete Aggregate Production: A Complete Guide to Adjustable VSI Crusher Configuration

This comprehensive guide explores the c ritical role of Vertical Shaft Impact (VSI) crushers in modern concrete aggregate production. We will examine how

these advanced machines utilize impact crushing technology to create high-quality, cube-shaped aggregates that meet strict industry specifications. The content covers

fundamental working principles, key adjustable parameters, material-specific optimization strategies, and real-world efficiency comparisons. Readers will gain practical insights

into maintenance best practices and discover emerging technologies that are shaping the future of aggregate processing. The information presented here combines engineering

fundamentals with practical application data to provide a thorough understanding of VSI crusher optimization.

ritical role of Vertical Shaft Impact (VSI) crushers in modern concrete aggregate production. We will examine how

these advanced machines utilize impact crushing technology to create high-quality, cube-shaped aggregates that meet strict industry specifications. The content covers

fundamental working principles, key adjustable parameters, material-specific optimization strategies, and real-world efficiency comparisons. Readers will gain practical insights

into maintenance best practices and discover emerging technologies that are shaping the future of aggregate processing. The information presented here combines engineering

fundamentals with practical application data to provide a thorough understanding of VSI crusher optimization.

Modern construction demands consistently high-quality aggregates with specific particle shape characteristics that significantly influence concrete strength and workability. VSI crushers have emerged as the preferred solution for producing premium aggregates between 5-20mm, the most common size range for concrete applications. Unlike traditional compression-based crushers, these machines utilize high-speed impact forces that create particles with optimal cubicity and surface characteristics. Through detailed analysis of operational parameters and their effects on final product quality, this guide provides actionable insights for optimizing entire crushing circuits.

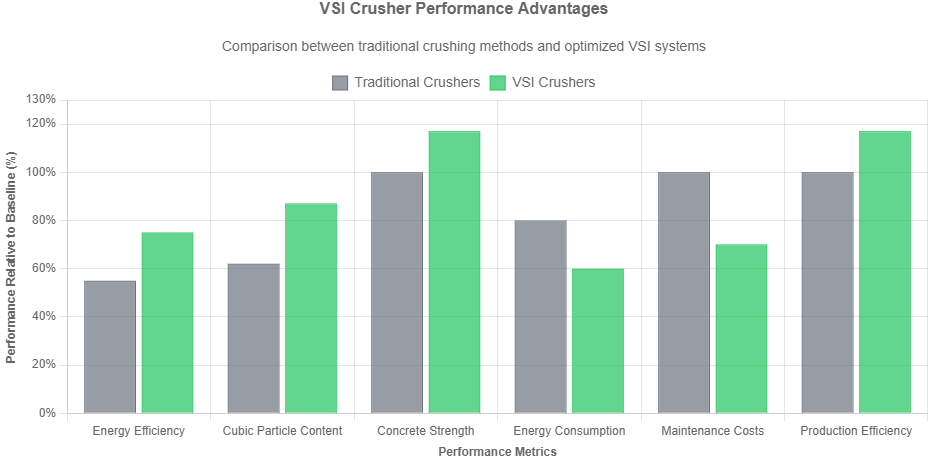

VSI Crusher Working Principles and Concrete Aggregate Production Requirements

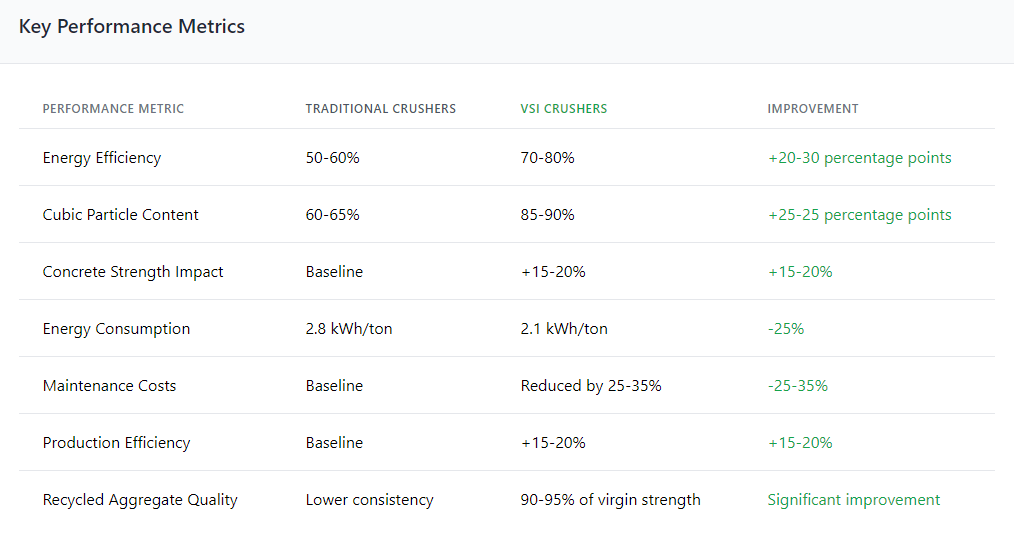

The fundamental operation of VSI crushers centers on accelerating rock particles at high velocity and impacting them either against other particles or against stationary anvils. This rock-on-rock crushing action creates a high percentage of cube-shaped particles while minimizing flaky or elongated grains that compromise concrete quality. The machine's vertical orientation allows for efficient energy transfer, with modern units converting approximately 70-80% of input energy directly into crushing action. This represents a significant improvement over traditional jaw crushers that typically operate at 50-60% energy efficiency for similar applications.

Concrete production requires aggregates meeting strict dimensional standards, with most applications specifying 5-20mm particles with controlled gradation. VSI crushers excel at producing this size range while simultaneously improving particle shape characteristics. The internal configuration of these machines allows operators to fine-tune output based on specific material properties and production requirements. This flexibility makes them indispensable in modern aggregate production plants where consistent product quality directly correlates with concrete performance characteristics.

Core Dynamics of Vertical Shaft Impact Crushing

The crushing process begins when material enters the rotating rotor assembly, which accelerates particles through centrifugal force. Typical rotor tip speeds range between 45-65 m/s, generating sufficient impact energy to fracture even the hardest rocks. The accelerated particles then collide with either the surrounding anvil ring or with other incoming material, creating a highly efficient reduction process. This mechanism produces more uniform particle shapes compared to compression-based crushing methods, making it ideal for concrete aggregate production where particle interlock significantly affects structural performance.

Impact of Aggregate Gradation on Concrete Strength

Proper aggregate gradation directly influences concrete's compressive strength, durability, and workability. Well-graded aggregates with a balanced distribution of particle sizes create a denser concrete matrix with reduced void spaces. VSI crushers provide exceptional control over product gradation through adjustable operational parameters. Research indicates that optimized gradation from VSI processing can improve concrete compressive strength by 15-20% compared to poorly graded materials. The ability to consistently produce aggregates with optimal particle size distribution makes these crushers invaluable for high-performance concrete production.

VSI Advantages in Recycled Aggregate Processing

The construction industry increasingly utilizes recycled concrete aggregates to support sustainability initiatives. VSI crushers demonstrate particular effectiveness in processing recycled materials due to their impact-based crushing action that efficiently separates hardened cement paste from natural aggregates. This process produces cleaner recycled aggregates with improved bonding characteristics for new concrete mixtures. Studies show that VSI-processed recycled aggregates typically achieve 90-95% of the compressive strength obtained with virgin materials, making them suitable for most structural applications.

Limitations of Traditional Jaw Crushers in Comparison

While jaw crushers serve effectively as primary reduction equipment, they exhibit limitations in final aggregate shaping and grading control. The compression-based crushing action typically produces more elongated and flaky particles, which can reduce concrete workability and require higher water-cement ratios. Additionally, jaw crushers offer limited adjustment capability during operation compared to the dynamic parameter control available in modern VSI systems. For final shaping of concrete aggregates, VSI crushers provide superior product quality and operational flexibility.

Key Adjustable Configuration Parameters Analysis

Modern VSI crushers incorporate multiple adjustable parameters that enable operators to optimize performance for specific materials and product requirements. The rotor speed represents perhaps the most significant control variable, with typical operational ranges between 1,000-2,500 RPM depending on machine size and application requirements. Higher rotational speeds generally produce finer products with improved cubicity but increase wear rates and energy consumption. Advanced models feature variable frequency drives that allow seamless speed adjustments during operation, facilitating quick responses to changing feed material characteristics.

Feed configuration presents another critical adjustment parameter, with most VSI crushers offering both central and waterfall feeding options. Central feeding directs material into the center of the rotating rotor, maximizing impact energy transfer for harder materials. Waterfall feeding introduces material around the rotor periphery, reducing wear while maintaining adequate reduction ratios for softer rocks. The optimal feed configuration depends on material abrasiveness, required reduction ratio, and desired product shape characteristics, with many operations switching between modes based on specific production goals.

Mathematical Model of Rotor Speed and Particle Size Distribution

The relationship between rotor speed and resulting particle size distribution follows predictable patterns that can be modeled mathematically. Higher rotational velocities increase particle acceleration, generating greater impact forces that produce finer products. Research indicates that for every 10% increase in rotor speed, the percentage of particles below 5mm increases by approximately 15-18% in typical granite crushing applications. Modern control systems utilize these mathematical relationships to automatically adjust rotor speed based on real-time particle size monitoring, maintaining consistent product quality despite variations in feed material characteristics.

Waterfall Feeding Mechanism for Increased Fines Production

Waterfall feeding configuration significantly influences fines production rates by altering the impact angle and energy transfer efficiency. When material is introduced around the rotor periphery rather than through the center, particles experience more glancing impacts that generate additional abrasion and grinding action. This process typically increases fines production by 20-30% compared to central feeding configurations while reducing wear on the rotor components. Operations requiring higher fines content for concrete sand applications often utilize waterfall feeding to optimize their product mix without additional processing equipment.

Crusher Chamber Design Influence on Fines Content

The geometric configuration of the crushing chamber directly affects material retention time and consequently influences the final product's fines content. Chambers with greater volume capacity allow material to undergo multiple impacts before exiting, increasing reduction ratios and fines generation. Modern VSI designs incorporate adjustable chamber configurations that enable operators to optimize retention times based on specific production requirements. Field data indicates that proper chamber configuration can increase fines production by 25-40% while maintaining desired particle shape characteristics, providing valuable flexibility for meeting varying market demands.

Automatic Discharge Gap Adjustment Systems (APC)

Advanced automatic protection and control systems represent the latest innovation in VSI optimization technology. These systems continuously monitor crusher operation parameters including power draw, vibration levels, and product quality indicators. When abnormal conditions are detected, the system automatically adjusts the discharge setting to maintain optimal performance while protecting the equipment from damage. Modern APC systems can respond to changing conditions within milliseconds, reducing unplanned downtime by up to 45% and maintaining product consistency even with highly variable feed materials.

Optimization Strategies: Classification Control Technology

Effective classification control represents a critical component in optimizing overall circuit performance when using VSI crushers. Implementing pre-screening systems before the crusher removes already-sized material from the feed, reducing unnecessary processing and wear. Post-crushing classification ensures proper separation of final products while returning oversize material for additional reduction. Modern plants utilize multi-deck vibrating screens with precisely sized openings to achieve exact product specifications. The integration of automated sampling and analysis systems provides real-time feedback for process adjustments, maintaining consistent product quality despite variations in feed material characteristics.

Closed-circuit crushing configurations with appropriate classification equipment significantly enhance overall system efficiency. By continuously returning oversize material to the crusher, these systems ensure complete reduction to the desired product size while minimizing energy consumption. Research demonstrates that properly configured closed-circuit operations can improve energy efficiency by 25-30% compared to open-circuit configurations. The integration of advanced control systems that automatically adjust crusher parameters based on classifier performance data further optimizes the process, creating a highly efficient production system capable of maintaining precise product specifications.

Capacity Matching Between Primary Crushing and VSI Stages

Proper capacity balancing between primary crushing equipment and secondary VSI processing ensures optimal plant performance. The primary crusher must provide consistent feed material within the VSI's optimal size range, typically below 50mm for most applications. Underfeeding the VSI reduces production efficiency, while overloading causes quality inconsistencies and increased wear rates. Modern control systems monitor both stages simultaneously, adjusting primary crusher settings to maintain ideal feed conditions for the VSI. Data from optimized plants show that proper capacity matching can increase overall production rates by 15-20% while reducing specific energy consumption by 10-15%.

Pre-Screening Methods for Oversize Particle Removal

Effective pre-screening before the VSI crusher removes already-sized material and prevents oversize particles from entering the crushing chamber. Modern screening technology utilizes vibrating screens with precisely sized openings that separate feed material into multiple fractions. The undersize material bypasses the crusher entirely, reducing wear and energy consumption, while properly sized material proceeds to the VSI for processing. Advanced systems incorporate automated size monitoring that adjusts screen configurations based on real-time feed material analysis, maintaining optimal efficiency even with highly variable input materials.

Online Particle Size Monitoring with Laser Technology

Laser-based particle size analyzers provide continuous, real-time measurement of crushed product characteristics without requiring physical sampling. These systems project laser beams through the material stream, measuring diffraction patterns to determine size distribution with exceptional accuracy. The collected data feeds into the crusher control system, enabling automatic adjustments to maintain consistent product quality. Modern laser analyzers can detect size variations as small as 0.1mm and respond within seconds, ensuring immediate correction of any process deviations. Implementation of this technology typically reduces product specification variations by 60-70% compared to manual sampling methods.

Vibrating Screen Selection and Crushing Efficiency

Proper screen selection significantly influences overall crushing circuit efficiency by ensuring accurate material separation. Screen aperture size, configuration, and vibration characteristics must match the specific application requirements to achieve optimal performance. Modern screening systems feature adjustable parameters that allow operators to fine-tune separation efficiency based on current production needs. Data indicates that optimized screen selection can improve overall circuit efficiency by 20-25% by reducing recirculating loads and minimizing energy consumption. The integration of screen performance monitoring with crusher control systems creates a fully optimized processing circuit that automatically maintains peak efficiency.

Material Adaptability Adjustment Solutions

VSI crushers demonstrate remarkable adaptability to various material types through appropriate configuration adjustments. For extremely hard rocks like granite and basalt, operators typically reduce rotor speed while increasing feed rate to maintain optimal energy transfer efficiency. This configuration minimizes wear while ensuring adequate reduction ratios. Softer materials like limestone permit higher rotor speeds and different chamber configurations that maximize production of specific product sizes. The flexibility to adjust multiple parameters enables operators to optimize performance across a wide range of material characteristics, making VSI crushers suitable for diverse geological conditions and production requirements.

Processing recycled concrete presents unique challenges due to the heterogeneous nature of the material, containing both natural aggregates and hardened cement paste. VSI crushers excel in this application through their impact crushing action that effectively separates these components. Special configurations typically include reduced rotor speeds to minimize excessive fines generation while maintaining adequate liberation of materials. Additionally, integrated metal detection and removal systems prevent damage from reinforcing steel present in recycled concrete. Properly configured VSI crushers can process recycled concrete with efficiency comparable to natural stone while producing high-quality aggregates suitable for most concrete applications.

Wear Plate Material Selection Guide

Selecting appropriate wear plate materials significantly impacts crusher performance and operational costs in different applications. For highly abrasive materials like quartzite or granite, chromium carbide overlays provide exceptional wear resistance, typically lasting 3-4 times longer than standard manganese steel. Less abrasive materials like limestone permit the use of standard manganese components that offer adequate protection at lower cost. Modern composite materials incorporating ceramic inserts provide superior performance in extremely abrasive applications, though at higher initial cost. Proper material selection based on comprehensive wear analysis can reduce maintenance costs by 30-40% while maintaining consistent product quality.

Rotor Speed Efficiency Curve for Hard Rock Crushing

The relationship between rotor speed and crushing efficiency follows a predictable curve that varies based on material hardness. For extremely hard rocks, optimal efficiency typically occurs at 70-80% of maximum rotor speed, balancing impact energy with controllable wear rates. Softer materials achieve peak efficiency at higher rotational velocities, often reaching 90-95% of maximum speed. Modern control systems store efficiency curves for various material types, automatically adjusting rotor speed to maintain optimal performance when material characteristics change. Implementation of these optimized speed profiles typically increases production rates by 15-20% while reducing specific energy consumption by 10-15%.

Cleaning Pre-treatment Process for Clay-Contaminated Materials

Materials with high clay content require special pre-treatment to prevent crusher clogging and maintain product quality. Modern processing plants typically incorporate log washers or scrubbers that mechanically break apart clay clusters before crushing. This process liberates individual particles and removes contaminating clays that could otherwise affect concrete quality. Advanced systems monitor clay content in real-time, automatically adjusting washing intensity based on current feed conditions. Proper clay removal before crushing improves overall efficiency by 25-30% and ensures consistent product quality meeting strict concrete production specifications.

Integrated Metal Contaminant Separation Systems

Metal contamination presents significant challenges in both natural and recycled aggregate processing. Modern VSI installations often incorporate powerful electromagnetic separators that automatically detect and remove ferrous metals from the material stream. For non-ferrous metals, advanced eddy current separators provide effective extraction without affecting the crushing process. These systems typically install before the crusher to prevent damage from metal objects, though secondary separation after crushing ensures complete contamination removal. Implementation of comprehensive metal separation typically reduces crusher maintenance requirements by 40-50% while improving final product quality for sensitive applications like ready-mix concrete production.

Efficiency Improvement Cases in Practical Applications

A comprehensive case study involving a 200-ton-per-hour aggregate production line demonstrates the significant efficiency improvements achievable through VSI optimization. The installation replaced traditional secondary and tertiary crushing stages with a single VSI unit configured for optimal performance. Before optimization, the plant produced aggregates with 65% cubicity rating at an energy consumption of 2.8 kWh/ton. After implementing the recommended configuration changes, cubicity improved to 88% while energy consumption dropped to 2.1 kWh/ton. These improvements translated to annual savings exceeding $150,000 in energy costs alone while producing premium aggregates commanding higher market prices.

Another significant case involved a ready-mix concrete producer struggling with inconsistent concrete workability due to variable aggregate shape characteristics. Implementation of a VSI crusher with advanced control systems eliminated these inconsistencies by maintaining consistent particle shape regardless of feed material variations. The improved aggregate quality reduced water demand by 8-10% while increasing compressive strength by 15%. These improvements allowed the producer to reduce cement content while maintaining performance specifications, resulting in annual material savings exceeding $200,000. The consistent product quality also enhanced the company's reputation, enabling premium pricing for their concrete products.

Large Commercial Concrete Plant Transformation Comparison

A major commercial concrete plant underwent comprehensive transformation by integrating VSI technology into their existing production circuit. Before the upgrade, the plant utilized conventional jaw and cone crushers that produced aggregates with 60-65% cubicity and significant gradation variations. After installing a properly configured VSI system and implementing advanced control strategies, cubicity improved to 85-90% with consistent gradation meeting specification limits. The improvement in aggregate quality reduced cement consumption by 12% while maintaining identical concrete strength characteristics. The $1.2 million investment delivered payback within 18 months through reduced material costs and increased production efficiency.

Technical Pathway for Increasing Cubic Particle Content

Increasing cubic particle content requires optimized impact energy management throughout the crushing process. The most effective approach involves controlling impact velocity and angle to ensure proper fracture patterns that create cube-shaped particles rather than flakes or slivers. Modern VSI crushers achieve this through precise rotor speed control and adjustable impact surface configurations. Implementation of these technologies typically increases cubic particle content from 60-65% to 85-90%, significantly improving concrete performance characteristics. The improved particle shape enhances particle interlock in concrete mixtures, reducing cement requirement while increasing strength and durability.

Motor Power and Actual Energy Consumption Monitoring

Continuous monitoring of motor power consumption provides valuable insights into crusher performance and operational efficiency. Modern systems track power usage in real-time, comparing actual consumption against expected values based on current operating parameters. Significant deviations trigger automatic adjustments or alerts for operator intervention. Implementation of comprehensive power monitoring typically identifies optimization opportunities that reduce energy consumption by 15-20% while maintaining production rates. The data collected also facilitates predictive maintenance by identifying changing power patterns that indicate developing mechanical issues before they cause unplanned downtime.

Application Example of Hydraulic Overload Protection System

Hydraulic overload protection systems automatically detect and respond to uncrushable material entering the crusher, preventing catastrophic damage. When the system detects excessive pressure indicating an overload condition, it immediately opens the discharge setting to release the material before resuming normal operation. Modern systems complete this process within 2-3 seconds, minimizing production interruption while protecting the equipment. Implementation of advanced overload protection typically reduces maintenance costs by 30-40% and prevents approximately 90% of potential damage incidents that would otherwise require extensive repairs and extended downtime.

Best Practices for Maintenance and Monitoring

Implementing comprehensive maintenance protocols significantly extends equipment life and maintains optimal performance in VSI crushers. Regular lubrication system inspections ensure proper oil quality and flow rates to critical components, with advanced systems monitoring oil condition in real-time and alerting operators when maintenance is required. Periodic rotor inspections using advanced measurement techniques identify wear patterns before they affect performance, allowing planned maintenance during scheduled downtime rather than emergency repairs. These proactive maintenance strategies typically increase component life by 30-40% while reducing unplanned downtime by 60-70% compared to reactive approaches.

Modern monitoring technologies provide unprecedented visibility into crusher condition and performance parameters. Vibration analysis systems detect developing bearing issues weeks before failure would occur, allowing planned replacement during routine maintenance periods. Thermal imaging cameras identify overheating components that indicate lubrication problems or misalignment. These advanced monitoring technologies integrate with centralized control systems that automatically adjust operations to compensate for developing issues while maintenance is scheduled. Implementation of comprehensive monitoring typically reduces maintenance costs by 25-35% while increasing equipment availability to 95% or higher.

Early Warning Mechanism for Bearing Temperature Abnormalities

Advanced temperature monitoring systems provide critical early warning of developing bearing issues by detecting abnormal heat patterns before catastrophic failure occurs. Modern infrared sensors continuously monitor bearing temperatures at multiple points, comparing readings against established baselines for current operating conditions. When temperatures exceed predetermined thresholds, the system automatically alerts operators and can initiate controlled shutdown procedures if necessary. Implementation of comprehensive temperature monitoring typically identifies bearing issues 2-3 weeks before failure would occur, allowing planned replacement during scheduled maintenance periods and preventing extensive secondary damage.

Online Rotor Wear Detection Technology

Non-contact wear measurement systems utilizing laser scanning technology provide accurate rotor wear assessment without requiring equipment disassembly. These systems create detailed three-dimensional models of the rotor surface, identifying wear patterns and quantifying material loss with precision exceeding 0.1mm. The collected data enables predictive wear modeling that accurately forecasts remaining component life based on current operating conditions. Implementation of advanced wear monitoring typically extends rotor life by 20-25% through optimized maintenance scheduling and identifies operational adjustments that reduce wear rates while maintaining production efficiency.

Calculation Method for Liner Replacement Cycles

Accurately predicting liner replacement cycles requires comprehensive analysis of multiple factors including material abrasiveness, production rates, and operational parameters. Modern predictive models incorporate real-time data from wear sensors and production monitors to calculate wear rates and forecast remaining liner life with exceptional accuracy. These models typically achieve prediction accuracy within ±5% of actual service life, enabling optimal maintenance scheduling that maximizes component utilization while preventing unexpected failures. Implementation of advanced prediction systems typically reduces liner inventory requirements by 30-40% while ensuring components are replaced at the optimal point in their service life.

Establishing a Fault Code Database System

Comprehensive fault code databases capture and analyze equipment performance data to identify patterns indicating developing issues before they cause failures. Modern systems automatically record all fault occurrences along with relevant operational parameters, creating a knowledge base that improves diagnostic accuracy over time. Advanced pattern recognition algorithms identify subtle correlations between operating conditions and failure modes, enabling proactive adjustments that prevent recurrence. Implementation of sophisticated fault analysis systems typically reduces diagnostic time by 60-70% and prevents approximately 80% of potential failure modes through early detection and corrective action.

Industry Trends and Future Technology Prospects

The aggregate crushing industry increasingly embraces artificial intelligence technologies that optimize operations through machine learning algorithms. These systems analyze vast amounts of operational data to identify patterns and relationships beyond human perception, continuously refining crusher parameters for peak performance. Modern AI implementations typically improve overall efficiency by 15-20% while reducing specific energy consumption by 10-15%. The technology also enables predictive maintenance with unprecedented accuracy, identifying potential issues weeks before they would become apparent through conventional monitoring methods. As computing power continues to increase while costs decrease, AI integration将成为 standard feature in future crushing equipment.

Modular design approaches revolutionize crushing plant flexibility and operational efficiency. Modern modular plants can be reconfigured within hours to accommodate changing production requirements or material characteristics, compared to days or weeks for traditional fixed installations. This flexibility allows operators to quickly respond to market demands or optimize production for specific projects without significant capital investment. Advanced modular designs incorporate plug-and-play components that automatically configure themselves when installed, reducing setup time and eliminating configuration errors. The modular approach typically reduces installation time by 60-70% while providing operational flexibility that increases overall equipment utilization and return on investment.

Machine Learning for Predicting Particle Size Distribution

Advanced machine learning algorithms analyze historical operational data to predict particle size distribution based on current crusher parameters and feed material characteristics. These systems continuously learn from new data, improving prediction accuracy over time and enabling proactive adjustments to maintain consistent product quality. Modern implementations typically achieve prediction accuracy within ±3% of actual size distribution, allowing automatic control systems to make adjustments before quality deviations occur. The technology significantly reduces product variation and improves compliance with strict specification requirements for high-value applications like ready-mix concrete production.

Design of Rapid Rotor Replacement Systems

Innovative rotor designs enable complete replacement within 4-6 hours compared to traditional systems requiring 12-24 hours for the same operation. These rapid replacement systems utilize precision alignment features and integrated lifting points that simplify the process and reduce the potential for errors. Specialized tooling and detailed procedures ensure proper installation without requiring extensive technical expertise. Implementation of rapid replacement technology typically reduces maintenance downtime by 60-70% for rotor-related services, significantly increasing equipment availability and overall production capacity while reducing labor costs associated with extended maintenance activities.

Exploration of Solar-Assisted Drive Solutions

Solar-assisted drive systems supplement traditional power sources with renewable energy, reducing operational costs and environmental impact. Modern implementations typically incorporate high-efficiency photovoltaic panels that generate 20-30% of the crusher's power requirements during peak sunlight hours. Advanced energy management systems seamlessly blend solar and grid power to maintain consistent operation while maximizing renewable energy utilization. Although current technology limits the percentage of total power that can be supplied by solar, ongoing improvements in photovoltaic efficiency and energy storage capabilities promise greater contributions in the future, moving the industry toward more sustainable operations.

VR Technology Role in Operational Optimization Training

Virtual reality training systems provide immersive operational experience without risking equipment damage or production interruptions. These systems recreate actual crushing plant environments with realistic physics and equipment behavior, allowing operators to practice optimization techniques and emergency procedures in a safe virtual environment. Modern VR training typically reduces skill development time by 40-50% compared to traditional methods while ensuring comprehensive understanding of complex operational relationships. The technology also facilitates remote expert assistance, allowing experienced technicians to guide local operators through complex procedures using shared virtual environments, reducing travel costs and response times for critical issues.