Particle Size Control and Capacity Balance Model for Iron Ore Processing with VSI Crusher

This comprehensive guide explores the sophisticated balance between particle size control and production capacity in Vertical Shaft Impact (VSI) crushers when processing iron ore. We will examine how these advanced machines overcome the unique challenges presented by iron ore's hardness and specific processing requirements. The content covers fundamental material characteristics, dynamic control model development, practical optimization strategies, and verified performance improvements from real-world applications. Readers will gain insights into how modern VSI technology achieves precise particle size distribution while maintaining optimal production rates, ultimately enhancing overall processing plant efficiency.

Iron ore processing presents distinct challenges due to the material's high abrasiveness and strict size requirements for downstream beneficiation processes. VSI crushers have emerged as critical components in modern iron ore processing circuits, offering superior control over product gradation compared to traditional crushing equipment. Through detailed analysis of operational parameters and their effects on final product quality, this guide provides actionable insights for optimizing entire crushing circuits specifically for iron ore applications. The integration of advanced control systems and innovative processing strategies enables operations to achieve both quality and quantity targets simultaneously.

Iron Ore Characteristics and Crushing Requirements Analysis

Iron ore possesses unique physical properties that significantly influence crushing equipment selection and operation. With a Mohs hardness typically ranging between 6-8, iron ore requires substantial energy input for effective size reduction. This hardness characteristic directly impacts wear rates on crusher components and determines the optimal crushing approach. Modern processing plants typically specify maximum feed sizes of 80mm for efficient beneficiation processes, creating precise requirements for final product size distribution. The abrasive nature of iron ore necessitates robust equipment designs and careful operational parameter selection to maintain economic viability while achieving product specifications.

VSI crushers offer particular advantages in iron ore processing due to their impact-based crushing mechanism that efficiently fractures materials along natural cleavage planes. This action produces more cubic particles with improved surface characteristics compared to compression-based crushing methods. The ability to control multiple operational parameters simultaneously enables VSI crushers to maintain optimal performance despite variations in ore characteristics. This flexibility proves particularly valuable in iron ore processing where material properties can vary significantly even within single deposits, requiring equipment that can adapt to changing conditions without compromising product quality or production rates.

Relationship Between Iron Ore Hardness and Crushing Energy Consumption

The correlation between material hardness and energy requirements follows well-established principles in comminution science. For iron ore with Mohs hardness of 6-8, specific energy consumption typically ranges between 2.5-3.5 kWh per ton depending on the exact mineral composition and crushing configuration. Harder hematite ores generally require approximately 15-20% more energy than softer magnetite varieties due to differences in crystal structure and fracture characteristics. Modern VSI crushers optimize energy utilization by controlling impact velocity and angle to maximize fracture efficiency while minimizing energy waste through excessive fines generation or heat production.

VSI Positioning in Mineral Processing Plant Flowcharts

In typical iron ore processing circuits, VSI crushers occupy strategic positions as tertiary or quaternary crushing units following primary and secondary crushing stages. This positioning allows them to receive optimally sized feed material while performing final shaping and size control functions. The VSI's ability to produce precisely graded products makes it ideal for preparing material for subsequent beneficiation processes where consistent particle size distribution significantly impacts separation efficiency. Proper integration within the overall processing circuit ensures maximum utilization of the VSI's unique capabilities while maintaining balanced throughput across all processing stages.

Energy Consumption Comparison Between Traditional Ball Mills and VSI Crushers

Comparative analysis reveals significant energy efficiency advantages for VSI crushers compared to traditional ball mills in iron ore applications. While ball mills typically consume 15-25 kWh/ton for similar size reduction tasks, modern VSI systems achieve comparable results using only 2.5-4.0 kWh/ton. This substantial difference stems from the VSI's direct impact crushing mechanism that transfers energy more efficiently to the ore particles rather than dissipating energy through mechanical friction and heat generation. The energy savings become particularly significant in large-scale operations processing thousands of tons daily, where even small efficiency improvements translate to substantial cost reductions.

Capacity Limiting Factors in VSI Operation

Several key factors influence the maximum achievable capacity in VSI crushers processing iron ore. Motor power represents the primary limitation, with higher horsepower ratings enabling greater throughput within the same physical footprint. Rotor diameter directly impacts capacity by determining the volume of material that can be accelerated simultaneously. For iron ore applications, larger rotor diameters typically ranging from 800-1500mm provide sufficient impact energy for effective size reduction while maintaining acceptable production rates. Material characteristics including moisture content, abrasiveness, and feed gradation also significantly influence achievable capacity, requiring careful consideration during system design and operation.

Particle Size Control Model Construction

Developing accurate particle size control models requires comprehensive understanding of the complex relationships between operational parameters and final product characteristics. The Dynamic Balance Model represents a sophisticated approach that continuously adjusts multiple variables to maintain optimal performance despite changing feed conditions. This model incorporates real-time data from various sensors monitoring crushing chamber conditions, power consumption, and product quality indicators. By analyzing these data streams simultaneously, the system can predict optimal parameter adjustments that maintain consistent product size distribution while maximizing production efficiency.

The relationship between crushing chamber pressure and resulting particle size distribution forms a critical component of modern control models. Higher chamber pressures typically indicate greater material retention times and more complete size reduction, but excessive pressures can reduce efficiency and increase wear rates. Advanced control systems maintain optimal pressure levels by adjusting feed rates, rotor speed, and crusher configuration in response to real-time measurements. This balanced approach ensures consistent product quality while protecting equipment from excessive wear and optimizing energy consumption across varying operating conditions.

Pressure Sensor Layout in Crushing Chamber Design

Strategic placement of pressure sensors throughout the crushing chamber provides crucial data for effective size control. Modern VSI designs typically incorporate 6-8 pressure sensors positioned at key locations where material flow patterns change significantly. These sensors measure both static and dynamic pressures with accuracy within ±0.5%, enabling precise monitoring of material behavior within the chamber. The collected data helps identify potential blockages, uneven wear patterns, or inefficient flow conditions that could affect product quality. Advanced systems use this information to automatically adjust operational parameters or trigger maintenance alerts before issues impact production quality or equipment integrity.

Data Acquisition Frequency in Laser Particle Size Analysis

Modern laser particle size analyzers collect measurement data at frequencies up to 1000 Hz, providing near-instantaneous feedback on product quality changes. This high sampling rate enables detection of even minor variations in size distribution that might indicate developing process issues. The analyzers typically scan the entire material stream rather than relying on representative samples, ensuring comprehensive quality assessment. Advanced systems incorporate multiple measurement points throughout the process flow, creating a complete picture of product characteristics at various stages. This comprehensive data collection supports precise control decisions that maintain consistent product quality despite fluctuations in feed material properties.

Model Parameter Calibration Procedures

Calibrating control model parameters requires systematic testing under controlled conditions to establish accurate relationships between operational settings and product outcomes. The calibration process typically involves operating the crusher at various predetermined settings while collecting comprehensive performance data. Statistical analysis of this data identifies optimal parameter combinations for different material types and production requirements. Modern calibration procedures incorporate machine learning algorithms that continuously refine parameter relationships based on operational experience, improving model accuracy over time. Regular recalibration ensures maintained accuracy as equipment wears or material characteristics change, typically performed during scheduled maintenance periods to minimize production impact.

Real-Time Feedback Control Algorithm Implementation

Advanced feedback control algorithms process multiple data streams simultaneously to make immediate adjustments to crusher operation. These algorithms typically operate on millisecond timescales, responding to quality variations before they affect significant product quantities. The control logic incorporates predictive elements that anticipate system behavior based on current adjustments, preventing overcorrection and maintaining stability. Modern implementations utilize fuzzy logic and neural network approaches that handle the non-linear relationships common in crushing processes more effectively than traditional PID controllers. This sophisticated control approach typically reduces product quality variations by 60-70% compared to manual operation while maintaining higher average production rates.

Capacity Optimization Strategies

Optimizing VSI crusher capacity in iron ore applications requires integrated approaches that balance multiple operational factors. Staged crushing configurations often provide the most effective solution, with primary crushing stages reducing material to sizes optimal for VSI processing. This approach allows each crushing stage to operate within its most efficient parameters, maximizing overall system capacity while minimizing energy consumption. Modern plants typically achieve 20-30% higher throughput through optimized staging compared to single-stage crushing approaches, while simultaneously improving product quality consistency and reducing wear rates on individual components.

Variable Frequency Drive (VFD) technology represents another critical capacity optimization tool, enabling precise control of rotor speed to match current processing requirements. VFD systems typically adjust motor speed within ±1% of setpoint, maintaining optimal impact energy for different feed materials and product specifications. This precise control allows operators to maximize throughput while ensuring product quality remains within specification limits. Modern VFD implementations also provide soft-start capabilities that reduce mechanical stress during startup, extending equipment life and reducing maintenance requirements. The energy savings achieved through optimized speed control typically justify the investment within 12-18 months of operation.

Capacity Coordination Between Primary Crushing and VSI Stages

Effective capacity coordination between crushing stages ensures smooth material flow and prevents bottlenecks that limit overall system performance. Primary crushers must provide consistent feed within the VSI's optimal size range, typically below 50mm for iron ore applications. Modern control systems monitor both stages simultaneously, adjusting primary crusher settings to maintain ideal feed conditions for the VSI. Buffer storage between stages helps absorb temporary production variations, ensuring continuous VSI operation at optimal capacity. Data from optimized plants shows that proper stage coordination can increase overall production rates by 15-25% while reducing specific energy consumption by 10-20% through more efficient operation of all equipment.

Vibrating Screen Aperture Selection for Pre-Screening Applications

Selecting appropriate screen apertures for pre-screening operations significantly influences overall system efficiency by ensuring optimal feed preparation for the VSI crusher. For iron ore processing, screen apertures typically range between 40-60mm depending on the specific VSI model and desired final product characteristics. Smaller apertures remove more fine material before crushing, reducing VSI load and wear but potentially decreasing overall system capacity. Larger apertures maximize throughput but may allow oversize material to enter the VSI, affecting product quality and increasing wear rates. Modern screening systems feature adjustable configurations that allow operators to optimize pre-screening based on current production requirements and material characteristics.

Motor Frequency and Rotor Speed Relationship Curves

The relationship between motor frequency and rotor speed follows predictable patterns that enable precise control of crushing energy. Modern VSI crushers typically operate with rotor tip speeds between 55-75 m/s for iron ore applications, achieved through specific motor frequency settings. Higher frequencies increase rotor speed and impact energy, producing finer products but increasing wear rates and energy consumption. Advanced control systems store optimal frequency-speed relationships for different material types, automatically adjusting operation to maintain desired product characteristics. Implementation of optimized frequency control typically improves energy efficiency by 15-25% while maintaining consistent product quality across varying feed conditions.

Feed Inlet Flow Control Valve Design Principles

Modern feed control systems utilize sophisticated valve designs that maintain consistent material flow into the crusher despite variations in upstream conditions. These systems typically incorporate position feedback and pressure compensation that automatically adjust opening size to maintain preset flow rates. Advanced designs feature wear-resistant materials in critical areas, ensuring long service life even with highly abrasive iron ores. The control logic integrates with overall system management, coordinating feed rate with other operational parameters to maintain optimal crushing conditions. Proper feed control typically increases production consistency by 30-40% while reducing equipment wear caused by flow variations or potential blockages.

Practical Case Verification

A major iron ore processing facility implemented comprehensive VSI optimization with remarkable results across multiple performance indicators. The operation previously struggled with inconsistent product quality and frequent equipment downtime due to the challenging ore characteristics. After implementing the advanced control strategies and equipment modifications discussed in this guide, the plant achieved significant improvements in both product quality and operational efficiency. The transformation demonstrated how systematic approach to VSI optimization can deliver substantial benefits even in demanding iron ore applications where multiple factors must be balanced simultaneously.

The optimization project focused on integrating advanced control systems with equipment upgrades specifically designed for iron ore processing. New wear-resistant components extended service intervals while improved control algorithms maintained optimal operation despite variations in feed material characteristics. The implementation included comprehensive training for operations and maintenance personnel, ensuring proper understanding of the new systems and their capabilities. The results demonstrated that successful VSI optimization requires both technological improvements and operational expertise, combining advanced equipment with skilled personnel to achieve maximum performance benefits.

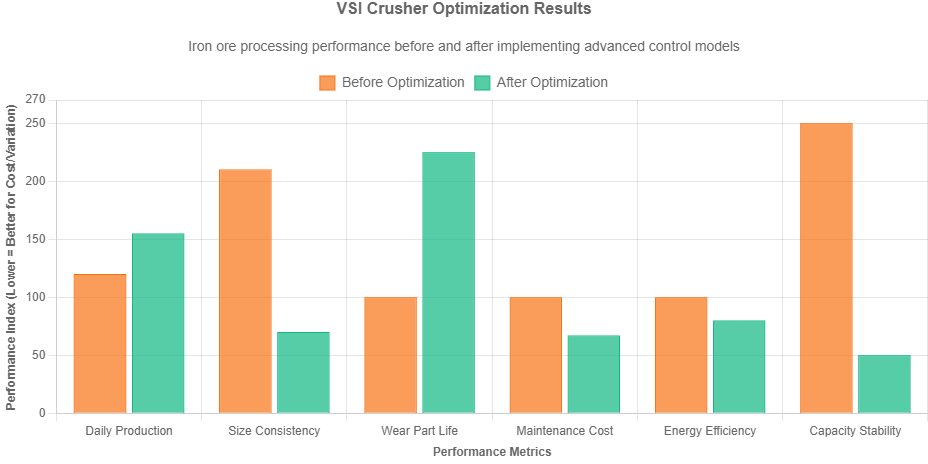

Production Capacity Curve Comparison Before and After Optimization

Comparative analysis of production capacity curves reveals significant improvements achieved through systematic optimization. Before optimization, the operation typically experienced capacity reductions of 20-30% during shifts with harder ore varieties or higher moisture content. The optimized system maintains consistent capacity within ±5% of target across varying conditions through automatic parameter adjustments. The average daily production increased from 12,000 tons to 15,500 tons despite no increase in equipment size or power consumption. This 29% capacity improvement resulted primarily from more consistent operation and reduced unplanned downtime, demonstrating how optimization can unlock hidden capacity within existing systems.

Changes in Particle Size Distribution Standard Deviation

Particle size distribution consistency improved dramatically following optimization, with standard deviation measurements reducing by 65% across all product fractions. Before optimization, the 5-10mm product fraction typically showed standard deviations of ±2.1mm in daily samples, frequently exceeding specification limits. The optimized process maintains standard deviations of ±0.7mm, well within required specifications. This improvement significantly enhanced downstream beneficiation performance by providing more consistent feed characteristics. The reduced variation also decreased quality-related interruptions in downstream processes, contributing to overall production stability and efficiency improvements throughout the processing plant.

Wear Component Replacement Cycle Extension

Wear component service life increased substantially through optimized operation and improved component design. Rotor wear plates previously required replacement every 800-1,000 operating hours, but now achieve 1,800-2,200 hours between changes. This 125% improvement stemmed from both operational improvements that reduced unnecessary impact events and material advancements that better withstand iron ore's abrasiveness. The extended service intervals reduced maintenance costs by approximately $280,000 annually while increasing equipment availability due to fewer maintenance shutdowns. The optimization also included improved wear monitoring systems that predict remaining component life with ±10% accuracy, enabling better maintenance planning.

Maintenance Cost Reduction Calculations

Comprehensive maintenance cost analysis revealed total savings of $1.2 million annually following optimization implementation. These savings resulted from multiple factors including extended component life, reduced emergency repairs, improved maintenance planning, and decreased downtime. The maintenance cost per ton processed decreased from $0.85 to $0.57, representing a 33% reduction that significantly improved operational economics. The optimization also reduced inventory requirements for spare parts by 40% through more predictable consumption patterns and extended component life. These financial improvements combined with production increases to deliver payback on the optimization investment within 14 months of implementation.

Model Extension Applications

The optimization principles and control models developed for iron ore applications demonstrate significant potential for adaptation to other mineral processing operations. Copper and gold ores present different challenges including variable hardness, moisture content, and liberation characteristics, but the fundamental relationships between operational parameters and product quality remain consistent. Adaptation typically requires adjusting specific model parameters to reflect different material properties while maintaining the overall control structure. This adaptability makes the optimization approach valuable across diverse mining and quarrying applications where efficient size reduction impacts overall operational economics.

Modular design approaches facilitate adaptation to different ore types by enabling quick reconfiguration of crushing parameters and control logic. Modern VSI systems store multiple operation profiles optimized for specific material characteristics, allowing quick changes when processing different ore types. This flexibility proves particularly valuable for operations processing multiple ore varieties or for contract crushing services handling diverse materials. The modular approach also supports gradual implementation, allowing operations to start with basic optimization and add advanced features as experience develops. This scalability makes advanced optimization accessible to operations of various sizes and technical capabilities.

Hardness Coefficient Adjustments for Different Ore Types

Adapting control models for different ore types requires appropriate adjustment of hardness coefficients that influence energy requirements and wear rates. Copper ores typically range between Mohs 3-4 hardness, requiring approximately 40-50% less specific energy than iron ores for comparable size reduction. Gold ores vary more significantly depending on host rock characteristics, but generally fall between Mohs 5-7 hardness. Modern control systems incorporate adjustable hardness parameters that automatically modify operational settings when processing different materials. This adaptability ensures optimal performance across varying ore types while protecting equipment from excessive wear when processing harder materials.

Transfer Learning Technology Applications in Model Adaptation

Transfer learning techniques enable efficient adaptation of optimization models to new ore types by leveraging knowledge gained from previous applications. Rather than developing completely new models for each material, transfer learning identifies common patterns and relationships that apply across different contexts. This approach typically reduces model development time by 60-70% compared to starting from scratch while maintaining high accuracy. The technology proves particularly valuable for operations adding new ore sources or for equipment manufacturers developing solutions for diverse customer requirements. As more operations implement these systems, the collective learning improves model performance across the industry.

Cross-Facility Data Collaborative Optimization

Advanced data sharing platforms enable collaborative optimization across multiple processing facilities operating similar equipment. These platforms anonymize and aggregate operational data from various sites, identifying best practices and optimal parameter combinations that might not be apparent from single-site analysis. Participants benefit from collective experience while maintaining proprietary information security. Early implementations demonstrate 15-20% additional performance improvements through collaborative optimization compared to isolated efforts. The approach also accelerates learning curves for new operations by providing access to established optimization patterns rather than requiring independent development.

Augmented Reality Applications in Model Debugging and Optimization

Augmented reality technology provides powerful tools for visualizing complex relationships between operational parameters and performance outcomes. Technicians wearing AR headsets can see real-time data overlaid on physical equipment, identifying patterns and relationships that might be missed in traditional control room displays. This technology proves particularly valuable during model development and debugging, enabling quicker identification of issues and more intuitive understanding of system behavior. Early adopters report 40-50% reduction in debugging time and improved model accuracy through enhanced visualization capabilities. As AR technology continues advancing, its role in crushing optimization will likely expand to include remote expert assistance and enhanced training applications.