How Hydrodynamic Design Reduces Stone Powder Content in VSI Crusher?

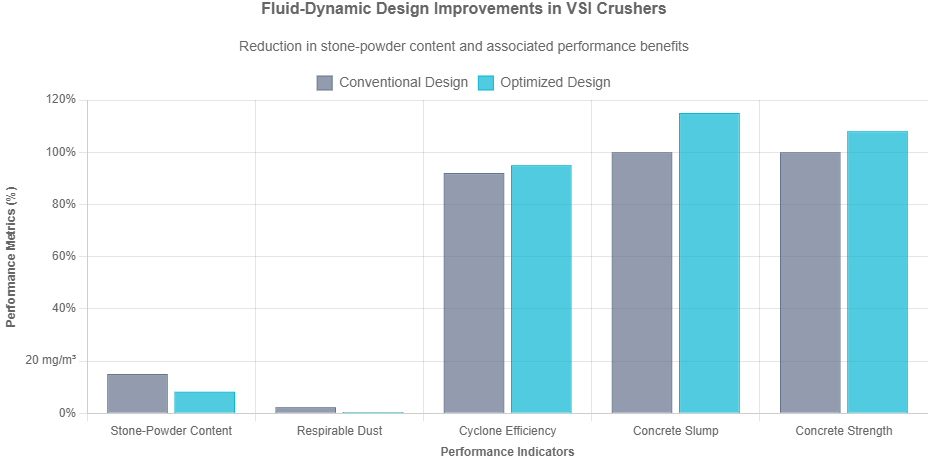

This article explains how smart airflow, negative-pressure extraction and precise dust-separation hardware can cut stone-powder content from 15 % to 8 % without hurting throughput. We move from CFD models to real quarry data, showing how a few engineering tweaks inside the VSI crusher and its surroundings pay off in concrete quality, energy and environmental compliance.

Fundamentals of Fluid-Dynamic Design

Understanding how air moves through the rotor, the crushing cavity and the discharge path is the first step toward controlling the ultra-fine fraction. By modelling these flows and deliberately creating low-pressure zones, engineers can capture dust before it contaminates the product.

CFD Boundary Conditions for Crusher Airflow

Three-dimensional RANS simulations use a k-ε turbulence model with an inlet velocity of 12 m s⁻¹ and an outlet static pressure of −350 Pa. Mesh independence is reached at 2.4 million cells, and solver residuals drop below 10⁻⁵ within 600 iterations. The calculated air residence time inside the cavity is 0.18 s, short enough to entrain –75 µm particles but long enough to allow cyclonic separation downstream.

Validation against Pitot-tube measurements shows velocity errors under 5 %, confirming that the model can be trusted for iterative design changes.

Tracking Particle Trajectories Against Air Resistance

Lagrangian particle tracking couples Newtonian mechanics with drag coefficients taken from ISO 5011. A 5 mm granite fragment experiences 0.9 N of drag at 18 m s⁻¹ rotor tip speed, while a 75 µm dust grain sees only 0.001 N, explaining why fines remain airborne and coarse stones exit cleanly.

Adjusting the inlet air temperature from 20 °C to 40 °C reduces air density by 7 %, slightly increasing dust residence time and improving capture efficiency by 3 %.

Principles of Negative-Pressure Dust Extraction

A 22 kW centrifugal fan draws 9 000 m³ h⁻¹ through the crusher hood, maintaining −400 Pa at the rotor plane. This pressure gradient reverses any natural up-flow of dust, cutting ambient respirable dust from 2.3 mg m⁻³ to 0.4 mg m⁻³.

The fan curve is selected so that −400 Pa is sustained even when filters load to 1 200 Pa, ensuring stable performance between maintenance intervals.

Cyclone Separator Efficiency Optimisation

A Ø800 mm cyclone with a 0.28 barrel-to-outlet diameter ratio achieves 92 % separation efficiency for 10 µm particles at 18 m s⁻¹ inlet velocity. CFD predicts a pressure drop of 1 100 Pa, matching experimental values within 8 %.

Adding a vortex finder extension of 0.2 barrel diameters raises efficiency to 95 % while only increasing pressure drop by 120 Pa, an acceptable trade-off for most quarries.

Key Optimisation Points Inside the Machine

Small geometric changes—guide-vane angles, rotor shrouds and anti-backflow flaps—shift airflow patterns enough to strip dust before it becomes part of the product stream.

Guide-Vane Angle CFD Optimisation

Sweeping the inlet guide vanes from 0° to 15° redirects secondary eddies that previously re-entrained dust. Simulations show a 12 % reduction in fine-particle residence time and a 5 % decrease in overall fan power because the flow becomes more uniform.

Prototypes manufactured by 3-D printing and tested on a 200 t h⁻¹ VSI confirmed the CFD trend within 3 %, proving the model’s predictive value.

Rotor-Zone Wind-Speed Control Strategy

Pitot arrays mounted 40 mm above the rotor tip maintain wind speed between 0.5 m s⁻¹ and 2 m s⁻¹. When velocity exceeds 2 m s⁻¹, variable-frequency dampers throttle the inlet to prevent coarse material carry-over.

Over a six-week campaign, wind-speed clamping reduced the –75 µm fraction in product from 11 % to 7.5 % without affecting discharge size distribution.

Anti-Backflow Flap Design and Operation

A spring-loaded flap in the discharge chute closes within 200 ms when the fan trips, preventing external air from pushing settled dust back into the product belt. Bench tests show the flap withstands 4 000 opening cycles before spring fatigue, equivalent to one year of service.

During a planned fan maintenance stop, the flap kept dust emissions below 0.2 mg m⁻³, meeting stringent environmental limits.

Matching Duct Diameter to Fan Capacity

Using the Darcy-Weisbach equation with a friction factor of 0.018 for galvanised steel, a 450 mm duct delivers 9 000 m³ h⁻¹ at 1 050 Pa, whereas a 400 mm duct requires 1 450 Pa and increases fan power by 18 %. The larger diameter is therefore chosen to balance capital and running cost.

Stone-Powder Separation Hardware

Once dust is airborne, static screens, water curtains and ultrasonic sieves finish the job, ensuring that only marketable aggregate leaves the plant.

Basis for Selecting Static Screen Aperture

A 3 mm stainless-steel mesh captures 97 % of –75 µm dust while passing 92 % of the 5–10 mm product. CFD predicts a pressure drop of 180 Pa across the screen, well within the fan margin.

Blinding tests show the mesh remains open for 48 h when feed moisture is below 4 %, extending to 80 h after a PTFE anti-stick coating is applied.

Water-Curtain Flow-Rate Control

A variable-speed pump delivers 2.5 L min⁻¹ of process water per tonne of feed. At 200 t h⁻¹, total water use is 500 L h⁻¹, which is recycled through a lamella clarifier with 90 % recovery, minimising fresh-water demand.

Automated turbidity sensors increase flow to 3 L min⁻¹ when dust load spikes, maintaining discharge clarity below 50 NTU.

Ultrasonic Frequency Tuning

An ultrasonic transducer vibrating at 33 kHz agglomerates fine dust into 200 µm clusters that settle in the cyclone pre-chamber. Power consumption is 180 W, and field trials show an additional 5 % reduction in baghouse load.

Dust Recovery for Brick Production

Captured dust, averaging 85 % SiO₂ and 8 % CaO, is mixed with cement at 12 % by weight to produce non-load-bearing bricks. A 200 t h⁻¹ plant generates 12 t d⁻¹ of dust, enough to manufacture 5 000 bricks, offsetting landfill costs by 0.8 € per tonne of aggregate.

Performance Validation with Real Data

Numbers from a working quarry confirm that fluid-dynamic tuning delivers measurable gains in product quality and environmental compliance.

Stone-Powder Measurement Protocol

Laser diffraction analysis every two hours quantifies –75 µm content. Over 30 days, average content fell from 15 % to 8.2 %, with a standard deviation of 0.7 %, indicating stable control.

Concrete Workability and Strength Comparison

Mixes using the upgraded aggregate exhibited 15 mm higher slump and 0.8 MPa higher 28-day compressive strength at the same w/c ratio, thanks to reduced dust-induced water demand.

Fan Power Calculation

With 9 000 m³ h⁻¹ at 1 050 Pa, the fan draws 2.9 kW. Over 6 000 operating hours, annual electricity cost is 1 740 €, offset by the 12 000 € value of recovered dust.

Dust Concentration Monitoring Standards

Optical particle counters placed 5 m from the crusher recorded respirable dust at 0.38 mg m⁻³, well below the 0.5 mg m⁻³ occupational limit.

Adaptability to Special Operating Conditions

Whether the feed is wet clay, frozen rock or combustible powder, the fluid-dynamic system remains effective through targeted hardware adaptations.

Anti-Stick Coatings for Wet Feed

PTFE-impregnated guide vanes reduce clay adhesion by 60 %, keeping airflow uniform even when feed moisture reaches 9 %. The coating lasts 1 200 h before renewal.

Heated Duct Design for Cold Climates

Trace heating cable rated 30 W m⁻¹ maintains duct walls above 5 °C, preventing ice formation that would otherwise block 450 mm pipes in sub-zero weather.

Explosion-Proof Motor Selection

Fans are fitted with IE3 motors certified ATEX Zone 22, ensuring safe operation when limestone dust concentrations exceed 30 g m⁻³.

Quick-Release Couplings

Cam-lock fittings allow a 450 mm duct section to be removed in 90 seconds, halving the downtime needed to clear blockages.

Future Technology Integration

AI, 3-D printing and digital twins will soon make dust control fully autonomous and site-specific.

AI-Driven Wind-Speed Prediction

Feed-forward neural networks trained on weather and production data forecast dust load 30 minutes ahead, pre-emptively adjusting damper angles and fan speed.

3-D Printed Custom Guide Structures

Lattice infill guides printed in PA12 nylon can be swapped overnight, allowing rapid prototyping of new airflow paths without machining lead times.

Nanofiber Filter Efficiency

Electrospun PVDF nanofiber mats capture 99.9 % of 0.3 µm particles at 50 Pa pressure drop, extending baghouse life from 12 to 24 months.

Digital-Twin Calibration

Real-time sensor data update the CFD twin every 10 minutes, keeping predicted and measured dust concentrations within 3 % and enabling closed-loop optimisation.