Selecting Roll Crushers for Mining: A Focus on Wear Parts Life and Maintenance Accessibility

Choosing the right roll crusher for a mining operation is a critical decision that extends far beyond initial purchase price and basic capacity specifications. This guide delves into two fundamental factors that directly determine long-term profitability and operational efficiency: the durability of wear components and the ease with which the machine can be maintained on-site. A crusher that boasts superior wear resistance and thoughtful maintenance design minimizes unplanned downtime and reduces the overall cost of processing each ton of material, making it a more valuable asset over its entire lifecycle.

The Extreme Challenges of a Mining Environment

Mining sites present some of the most demanding conditions for industrial machinery. Equipment must operate reliably while contending with factors that rapidly degrade components and test structural integrity. Understanding these challenges is the first step in selecting a crusher built for endurance.

Abrasive Ores and Accelerated Wear

Ores like iron ore and gold quartz are inherently abrasive. As they are compressed between the crusher rolls, they gradually wear away the roll surfaces. This abrasion is a primary factor in determining the service life of wear parts and directly impacts operational costs.

The rate of wear is influenced by the mineral composition of the ore. Materials with high silica content, for example, will wear down components much faster than less abrasive rocks. Selecting a crusher with wear parts designed for specific ore characteristics is therefore essential for economic operation.

Impact Loads from Hard and Large Feed Material

Beyond gradual abrasion, roll crushers are subjected to significant impact forces when large, hard rocks enter the crushing chamber. These sudden shocks travel through the roll shells to the bearings, shafts, and frame, potentially causing damage or fatigue over time.

A robust design is necessary to withstand these forces. This includes using high-strength materials for key components and ensuring the crusher's structure is rigid enough to absorb energy without compromising alignment or performance.

Environmental Factors like Dust and Moisture

Dust is an ever-present challenge in mining, posing a significant threat to lubrication systems and moving parts. Effective sealing around bearings is crucial to prevent abrasive particles from contaminating grease or oil, which can lead to premature failure.

Furthermore, fluctuations in temperature and humidity can affect the performance of hydraulic systems and lubricants. Crushers destined for mining must be equipped with components and systems rated for these variable and harsh conditions.

The Demands of Continuous Operation

Many mining operations run continuously, placing immense stress on equipment. A roll crusher must be engineered for this duty, with components that can withstand constant vibration and loading without excessive wear or the need for frequent adjustment.

This requires not only durable materials but also a design that facilitates easy monitoring and routine maintenance to ensure the crusher remains in optimal condition throughout its long service hours.

Evaluating the Lifespan of Wear Parts

The longevity of consumable components like roll shells is a major contributor to the total cost of ownership. A scientific approach to evaluating wear parts leads to more accurate budgeting and fewer production interruptions.

Roll Shell Material Science

The choice of material for roll shells is a balance between hardness, which resists abrasion, and toughness, which withstands impact. Manganese steel is known for its toughness, while high-chromium iron offers superior abrasion resistance. Advanced composites, such as tungsten carbide overlay, provide an excellent combination of both properties for the most demanding applications.

Consulting with the manufacturer about the best material for your specific ore type is a crucial step. The right choice can extend service intervals significantly, reducing both part replacement costs and associated downtime.

Roll Surface Profile and Its Effect

The profile of the roll surface—whether smooth, corrugated, or toothed—affects both the crushing action and the wear pattern. Smooth rolls provide a compressive crushing action with relatively even wear, while toothed rolls experience more concentrated wear on the peaks and valleys of the teeth.

The optimal profile depends on the desired product size and the characteristics of the feed material. It is important to understand that a more aggressive profile may lead to a faster change in crushing performance as wear progresses.

Linking Manufacturer Claims to Reality

Equipment suppliers provide estimated wear life figures, but these are often based on standard conditions. It is vital to correlate these estimates with the actual abrasiveness and hardness of the ore at your specific site. Providing ore samples to the manufacturer for testing can yield a more accurate prediction of wear part life.

This data-driven approach allows for better planning of spare parts inventory and maintenance schedules, ensuring that operations are not disrupted by unexpected component failures.

Operational Practices to Maximize Life

How the crusher is operated has a direct impact on wear part longevity. Ensuring a consistent and even feed across the width of the rolls prevents localized wear. Properly adjusting the roll gap for the desired discharge size is also critical, as an incorrectly set gap can accelerate wear unnecessarily.

Modern crushers with automated gap adjustment systems help maintain optimal settings, compensating for wear and ensuring efficient operation throughout the life of the roll shells.

Designing for Easy On-Site Maintenance

The ease of performing maintenance tasks directly influences the machine's overall availability. A crusher designed with serviceability in mind can be repaired much faster, minimizing production losses.

Quick-Change Systems for Wear Parts

Many modern roll crushers feature designs that allow for rapid replacement of roll shells. This may involve segmented shells or special locking mechanisms that eliminate the need for complex disassembly. The time saved during a change-out is a direct reduction in downtime and labor costs.

When evaluating crushers, inquire about the standard time required for a roll shell change and the tools needed. A design that simplifies this process is a significant advantage.

Accessibility of Service Points

Routine maintenance tasks like lubrication, inspection, and adjustment should be straightforward. Grease fittings, inspection doors, and adjustment mechanisms should be easily accessible from safe working positions.

Good design minimizes the need for technicians to contort themselves or work in hazardous areas to perform basic checks. This not only improves efficiency but also enhances overall workplace safety.

Handling Major Component Replacements

While less frequent, the potential need to replace major components like a full roll assembly or a bearing must be considered. The crusher's design should facilitate this process, for example, through modular construction that allows sub-assemblies to be removed as a unit.

The site must also have the necessary lifting equipment and space to perform these major tasks safely. Considering these factors during selection prevents major logistical challenges later.

Predictive Maintenance Monitoring

Integrating sensors for condition monitoring is a key feature of modern crushers. Vibration and temperature sensors on bearings can provide early warning of potential problems, allowing maintenance to be planned during scheduled shutdowns rather than reacting to a catastrophic failure.

This shift from reactive to predictive maintenance is a major step forward in improving crusher reliability and maximizing crushing capacity over time.

Comparing Crusher Types and Their Maintenance Needs

Different configurations of roll crushers, such as single-roll and double-roll designs, have distinct maintenance characteristics. Understanding these differences helps match the machine to the site's capabilities.

Single-Roll vs. Double-Roll Crusher Maintenance

Double-roll crushers are common and their maintenance typically revolves around two identical roll assemblies. Single-roll crushers, which crush against a breaker plate, have a different set of wear parts and adjustment mechanisms. The maintenance philosophy and required spare parts inventory will vary accordingly.

The Advantage of Hydraulic Systems

Hydraulics greatly simplify maintenance tasks like adjusting the crushing gap and providing overload protection. A hydraulic system allows for precise, remote adjustment under load, saving time and improving safety compared to manual methods.

The reliability and serviceability of the hydraulic system itself are important factors to evaluate during the selection process.

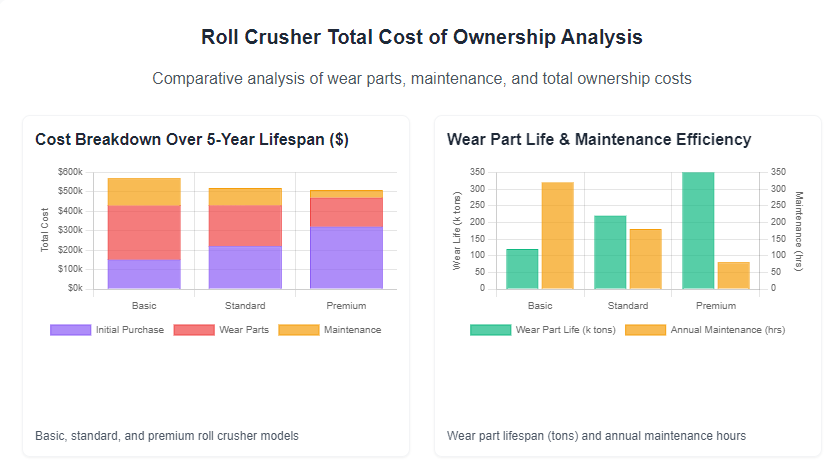

Calculating Total Cost of Ownership

The true cost of a crusher is not just its purchase price, but the sum of all costs over its

operating life. A Total Cost of Ownership analysis provides a clearer financial picture.

The true cost of a crusher is not just its purchase price, but the sum of all costs over its

operating life. A Total Cost of Ownership analysis provides a clearer financial picture.

Wear Cost per Ton Calculation

Dividing the cost of a set of wear parts by the tonnage of material they process gives a clear "cost per ton" metric. This figure is invaluable for comparing different crusher models or wear materials on an economic basis.

Quantifying Downtime Costs

Machine downtime results in lost production. Crushers that are easier and faster to maintain incur lower downtime costs. Estimating the value of lost production during maintenance events is a critical part of any TCO model.

Selecting a roll crusher with a focus on wear life and maintenance accessibility is an investment in long-term, cost-effective operation. By thoroughly evaluating these factors, mining operations can ensure they choose a machine that delivers reliability and low operating costs throughout its service life.