Energy Consumption Comparison Between Roll Crushers and Cone Crushers in Secondary Mining Crushing

This article provides a detailed comparison of energy consumption between roll crushers and cone crushers in secondary mining crushing applications. We will examine the fundamental parameters and working principles of both crusher types, presenting real-world energy consumption data for processing different materials. The discussion extends to strategies for optimizing operational parameters and a thorough analysis of economic and environmental impacts. Furthermore, the article reviews relevant industry standards and testing methods, presents compelling case studies from mining operations, and explores emerging technological trends aimed at enhancing energy efficiency in crushing processes.

Equipment Basic Parameters and Working Principles

Understanding the core operating principles and basic configurations of roll crushers and cone crushers is fundamental to analyzing their energy consumption profiles. These two types of crushers apply distinct mechanical forces to achieve size reduction, which directly influences their power requirements and efficiency. The design philosophy behind each machine dictates how it interacts with the feed material and consumes energy during the comminution process.

Roll crushers utilize two counter-rotating cylinders that draw the feed material into the gap between them, applying primarily compressive force. A key feature in modern designs is differential speed rotation, where the rolls operate at different velocities. This creates an additional shearing action, improving efficiency and reducing the likelihood of material slippage or clogging, which can lead to unnecessary energy expenditure. Cone crushers, on the other hand, operate via an eccentrically gyrating mantle within a concave bowl. This action creates a dynamic gap where rocks are subjected to compressive forces and inter-particle breakage through a mechanism known as layer-to-layer crushing or a laminated crushing dynamics model. The constant gyration and high forces involved often result in a different energy signature compared to roll crushers.

Differential Speed Rotation Crushing Mechanism in Roll Crushers

The differential speed rotation mechanism is a significant energy-saving feature in advanced roll crushers. In this setup, the two rolls are designed to operate at different rotational speeds. This velocity difference creates a shearing force in addition to the primary compressive force, which promotes more efficient fracturing of rocks along their natural grain boundaries. This combined shearing and compressive action often requires less energy to achieve the same size reduction compared to pure compression, as it facilitates crack propagation through the material.

This mechanism also helps to maintain a clean roll surface by preventing the adhesion of sticky or moist materials, a common issue that can increase energy consumption due to higher torque requirements. By ensuring that the rolls remain relatively clean, the differential rotation helps maintain consistent crushing performance and prevents the energy spikes associated with overcoming stuck material. Furthermore, this shearing action can lead to a more uniform product size distribution, potentially reducing the need for re-circulation of oversize material and the associated energy costs of secondary crushing.

Laminated Crushing Dynamics Model in Cone Crushers

Cone crushers achieve size reduction through a mechanism often described as laminated crushing. In this model, the rotating mantle continuously compresses the rock feed against the stationary concave. The kinematics of the mantle, which follows an elliptical path due to its eccentric movement, creates a dynamic crushing cavity. The energy applied not only breaks particles by direct contact with the mantle and concave but also through rock-on-rock attrition, where particles are broken against each other under pressure.

The dynamics of this process are complex. The eccentric motion must generate sufficient force to fracture the hardest particles in the feed, which dictates the power requirement of the main drive. The laminated crushing model is efficient for hard and abrasive materials because it distributes wear and utilizes inter-particle breakage. However, the constant gyration and high forces required to maintain the crushing action, even during momentary gaps in feed, contribute to a significant base energy load. The energy efficiency is highly dependent on maintaining a fully fed crushing chamber to ensure that energy is directed toward breaking rock rather than moving metal components against each other.

Power Configuration and Speed Range Comparison (75kW-500kW)

The installed power for secondary crushing machines in mining applications typically ranges from 75 kW for smaller units to over 500 kW for large, high-production machines. Roll crushers often operate at lower rotational speeds compared to cone crushers. For instance, a large industrial roll crusher might have roll speeds in the range of 50 to 150 rpm, driven by high-torque, low-speed motors. This is in contrast to the eccentric speed of a cone crusher, which, while still relatively low compared to other machinery, is higher than that of a roll crusher and requires a different power transmission setup.

The power draw of a cone crusher is often more consistent under steady feed conditions but can experience significant fluctuations with changes in feed gradation or material hardness. They are designed to operate with a certain power draw range for optimal efficiency. Roll crushers, particularly those with differential speed, may exhibit a different power profile. Their energy consumption can be more directly correlated with the throughput rate and the specific breakage characteristics of the material. The choice between a 75 kW, 250 kW, or 500 kW machine depends on the required throughput, the feed size, and the desired product size, with larger, harder feed materials necessitating higher power installations.

Energy Consumption Differences in Hydraulic Systems

Both modern roll crushers and cone crushers rely heavily on hydraulic systems for critical functions, which contribute to their overall energy footprint. In cone crushers, hydraulics are used for adjusting the crusher setting (CSS) under load, for clearing blockages (tramp release), and for providing overload protection. The hydraulic system must maintain pressure constantly, leading to a continuous energy draw. Large adjustments or frequent clearing cycles can add to this consumption.

Roll crushers also utilize hydraulic systems, primarily for adjusting the gap between the rolls and for providing overload protection via hydraulic cylinders that allow one roll to move away if an uncrushable object enters the chamber. The energy consumption of these systems is often event-based—energy is consumed during gap adjustment or when reacting to an overload. Therefore, in a stable operation with consistent feed material, the hydraulic energy consumption of a roll crusher might be lower than that of a cone crusher, which may require more frequent and finer adjustments to maintain product size, especially with varying feed conditions.

Impact of Wear-Resistant Materials on Equipment Load

The selection of wear-resistant materials for components like mantles, concaves, and roll shells has a profound impact on the overall energy efficiency of a crusher. Heavier, more massive wear parts increase the moment of inertia, requiring more energy to initiate and maintain motion. Advances in material science have led to the development of lighter yet highly wear-resistant alloys and composite materials. Using these advanced materials reduces the overall weight of moving components, directly lowering the energy required for acceleration and deceleration during each crushing cycle.

Furthermore, the surface profile and integrity of these wear parts are crucial. Worn-out mantles, concaves, or rolls can lead to inefficient crushing, poor product shape, increased recirculation load, and ultimately higher energy consumption per ton of product. For example, the application of nanocoating technology can significantly extend the service life of roll surfaces. By maintaining the optimal geometry of the crushing surfaces for a longer period, these advanced materials ensure that the crusher operates at its designed efficiency, preventing a gradual increase in energy usage that typically accompanies component wear. This translates to more consistent power draw and lower specific energy consumption throughout the liner life.

Typical Material Processing Energy Consumption Measurements

Actual energy consumption during crushing operations varies significantly based on the material properties, machine settings, and operational practices. Measured in kilowatt-hours per ton (kWh/t), this specific energy consumption is a key metric for comparing the efficiency of different crushing technologies. Real-world data provides invaluable insights that go beyond theoretical models, highlighting the performance of roll crushers and cone crushers across various scenarios.

For soft to medium-hard minerals like many iron ores, roll crushers often demonstrate a distinct advantage in energy efficiency. The compressive and shearing action of differential speed rolls is highly effective in fracturing these materials. Conversely, for very hard and abrasive feed like granite, cone crushers, with their robust construction and laminated crushing action, might maintain more consistent performance, though often at a higher energy cost. The sensitivity of each crusher type to factors like feed size distribution and moisture content further differentiates their energy profiles in practical applications.

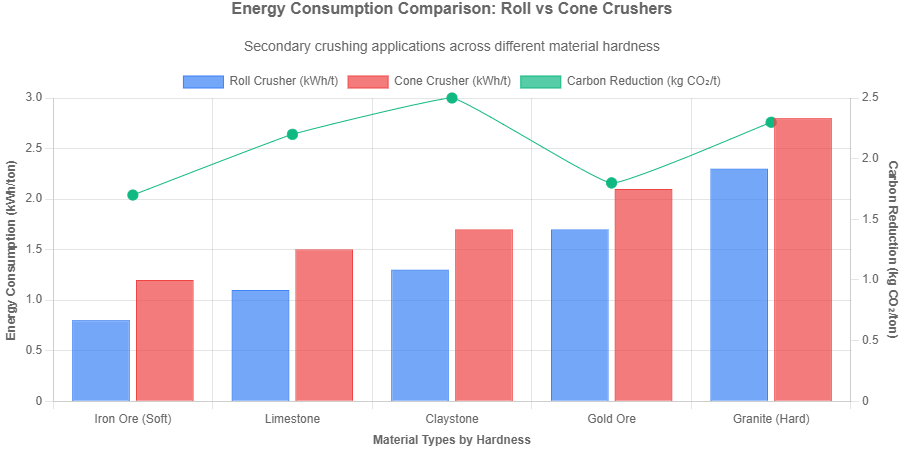

Soft Ore (Iron Ore) Crushing Energy Comparison (0.8 vs 1.2 kWh/t)

When processing soft ores such as hematite iron ore, the energy efficiency difference between crusher types becomes markedly evident. Studies have shown that a well-configured roll crusher can achieve specific energy consumption figures as low as 0.8 kWh/t for reducing iron ore to a suitable size for downstream processing. The efficient fracturing mechanism of the rolls, combined with effective clearance settings, minimizes energy waste.

In contrast, operating a cone crusher on the same material might yield an average specific energy consumption of around 1.2 kWh/t. This 50% higher energy use can be attributed to the different breakage mechanism. The cone crusher's gyrating action and the need to overcome significant inertia and friction within the machine itself contribute to this higher base energy demand. While highly effective and versatile, the cone crusher's design inherently consumes more power for processing less competent materials where its powerful compressive force is not fully utilized to its maximum potential for efficient breakage.

Energy Consumption Fluctuation in Hard Rock (Granite) Crushing (±40% Variation)

Crushing hard and abrasive rocks like granite presents a greater challenge and leads to wider fluctuations in energy consumption for both crusher types. The unconfined compressive strength (UCS) of granite is high, requiring significant force to fracture. In a cone crusher, the specific energy can vary by up to ±40% around the average value due to changes in feed gradation, the percentage of voids in the feed, and the gradual wear of mantles and concaves which alters the crushing kinematics.

Roll crushers also experience fluctuations with granite, but the nature of the variation can differ. The continuous, high-pressure grinding action between the rolls is effective but can lead to rapid wear of the roll surfaces. As the surface profile changes due to wear, the efficiency of the nip angle and the effectiveness of size reduction can decrease, potentially leading to a gradual increase in energy consumption if the gap is not adjusted accordingly. Furthermore, the presence of occasional, extremely hard blocks within the feed can cause momentary energy spikes as the hydraulic system reacts to protect the machine from overload.

Sensitivity Analysis of Feed Size on Energy Consumption

The size distribution of the feed material is one of the most critical factors influencing crusher energy consumption. An optimal feed size for a given crusher cavity or roll gap ensures efficient drawing of material into the crushing zone and effective transfer of energy to the rock. If the feed contains a high proportion of particles that are already smaller than the target product size (fines), these particles simply pass through the chamber, consuming energy without contributing to significant size reduction—a phenomenon known as "cushioning."

Conversely, a feed that is excessively coarse, particularly near or exceeding the maximum acceptable feed size for the crusher, forces the machine to operate at the upper limit of its force capacity. This can lead to higher energy draw per ton and increased stress on mechanical components. Crushers are generally designed to be most efficient with a specific top-size feed and a certain percentage of fines. Monitoring and controlling the feed size through preceding screening stages is, therefore, a crucial strategy for minimizing specific energy consumption.

Relationship Between Discharge Setting Adjustment Frequency and Energy Loss

Frequent adjustment of the crusher's discharge setting, whether in a cone crusher (CSS) or a roll crusher (roll gap), can be a source of energy inefficiency. Each adjustment requires energy to activate the hydraulic systems that move heavy components. More importantly, constant adjustments often indicate unstable feed conditions, leading to the crusher operating away from its optimal performance point for significant periods.

When the discharge setting is changed, it alters the pressure and flow dynamics within the crushing chamber. It takes some time for the system to stabilize and for the chamber to be filled with a new equilibrium of material. During this transition period, the crusher may operate with a non-optimal load, leading to higher energy consumption per ton of output. Automated control systems that make slower, more deliberate adjustments based on a stable trend of power draw or chamber pressure, rather than reacting to momentary fluctuations, help to minimize this type of energy loss.

No-Load Power Consumption Percentage (12%-50%)

A significant portion of a crusher's energy consumption is used simply to overcome its internal mechanical friction and to drive the empty machine—this is known as no-load power. For cone crushers, the no-load power can be remarkably high, often ranging from 30% to 50% of their full-load power rating. This is due to the energy required to overcome the inertia of the massive mantle and to drive the eccentric bushing and other moving parts against significant frictional forces, even without any rock in the chamber.

Roll crushers generally exhibit a lower no-load power consumption, typically in the range of 12% to 25% of their full-load power. The primary no-load energy is required to overcome the friction in the bearings supporting the heavy rolls and to drive the transmission system. This lower baseline consumption gives roll crushers an inherent advantage in applications with intermittent feed or where the crusher must be stopped and started frequently, as less energy is wasted during idle periods or while waiting for feed to be restored.

Operational Parameter Optimization Strategies

Maximizing the energy efficiency of crushing operations extends far beyond simply selecting a crusher type. It involves the meticulous optimization of a multitude of operational parameters. The goal is to ensure that the machine operates as close as possible to its designed peak efficiency for the specific material being processed. This requires a holistic approach that considers feed characteristics, machine settings, and the integration of advanced control technologies.

Key strategies include maintaining an optimal and consistent feed rate to keep the crusher chamber properly filled, thereby maximizing the energy used for productive breakage rather than overcoming no-load losses. Utilizing variable speed drives allows the motor's speed and torque to be matched precisely to the instantaneous load demand, avoiding wasted energy. Furthermore, optimizing the crushing ratio for each stage in a multi-stage process ensures that no single stage is overworked, leading to a more efficient overall size reduction process with lower specific energy consumption.

Impact of Load Rate Control on Energy Efficiency (85% Load Optimal)

Controlling the operating load of a crusher is paramount for achieving high energy efficiency. Operating a crusher consistently at around 85% of its maximum rated load is often considered the sweet spot. At this load level, the crushing chamber is adequately filled, ensuring that most of the input energy is directed toward breaking rock rather than overcoming mechanical friction and inertia (no-load losses). It also provides a buffer to handle momentary surges in feed rate or material hardness without causing the crusher to choke or trip on overload.

Running a crusher at 100% load or above for extended periods increases mechanical stress and the risk of unplanned downtime, which is ultimately highly energy-inefficient. Conversely, operating at a low load (e.g., below 50%) drastically increases the proportion of no-load power consumption per ton of material processed. Advanced control systems use power draw, crusher cavity level sensors, and sometimes acoustic sensors to automatically regulate the feed rate (e.g., via a variable speed feeder) to maintain this optimal 85% load target, maximizing throughput per unit of energy consumed.

Application Effect of Variable Frequency Drive (VFD) Systems

The integration of Variable Frequency Drives (VFDs) is a highly effective strategy for reducing crusher energy consumption. A VFD controls the speed and torque of an AC motor by varying the frequency and voltage of the power supplied to it. In crusher applications, this technology offers several key benefits. Firstly, it allows for a "soft start," gradually ramping up the motor speed, which drastically reduces the inrush current at startup. This reduces stress on the electrical network and mechanical components, saving energy and extending equipment life.

Secondly, and most importantly for energy savings, a VFD enables the crusher motor to operate only at the speed required by the instantaneous processing demand. If the feed rate decreases or the material becomes easier to crush, the VFD can reduce the motor speed, directly lowering energy consumption. This is far more efficient than running a fixed-speed motor at full capacity while throttling the feed. Modern VFDs can optimize the power factor of the motor, further improving electrical efficiency. The use of systems like permanent magnet motor drives can enhance this effect, offering higher efficiency and better torque characteristics at lower speeds compared to traditional induction motors.

Quantitative Relationship Between Crushing Ratio and Energy Consumption (4:1 vs 8:1)

The crushing ratio, defined as the ratio of the feed size to the product size, has a direct and non-linear relationship with energy consumption. Attempting to achieve a very high crushing ratio in a single stage (e.g., 8:1) invariably leads to a higher specific energy consumption (kWh/t) compared to achieving a more moderate ratio (e.g., 4:1). This is because higher reduction ratios require the application of greater force per particle and often result in more fines generation, which is an energy-intensive process as described by comminution theories like Bond's Law.

Therefore, for applications requiring a large overall size reduction, it is more energy-efficient to distribute the work across multiple crushing stages (e.g., primary, secondary, tertiary) with moderate ratios at each stage. This multi-stage approach allows each crusher to operate closer to its most efficient reduction ratio. While adding stages involves additional capital cost for equipment, the long-term energy savings can be substantial, often providing a favorable return on investment, especially in high-tonnage mining operations where energy costs are a significant portion of operating expenses.

Energy Cascade Utilization in Multi-Stage Crushing Systems

The principle of energy cascade utilization involves designing a crushing circuit so that the energy applied at each stage is optimized for the specific task, and the output of one stage is optimally prepared for the next. In a well-designed multi-stage plant, the primary crusher performs the initial coarse reduction, operating at a relatively low speed and high torque, which is efficient for breaking large rocks. Its product is then screened, and the oversize material is sent to a secondary crusher, which is tuned for intermediate reduction.

The secondary crusher, whether a cone or roll crusher, can then operate efficiently within its designed range for medium-sized feed. Finally, a tertiary crusher may make the final precision reduction to the target product size. By staging the process, the energy is used more effectively because each machine is specialized. This prevents a single machine from being forced to operate inefficiently across a very wide range of particle sizes, which would inevitably lead to higher overall energy consumption. This approach minimizes the energy wasted on over-breaking particles that are already合格 or on inefficiently processing grossly oversized feed.

Application of Real-Time Online Monitoring Technology

Implementing real-time online monitoring is a game-changer for optimizing energy consumption. Modern crushers are equipped with a suite of sensors that continuously track key operating parameters. These include power draw (ammeters), bearing pressure (for cone crushers), hydraulic pressure, oil flow and temperature, crusher main shaft position, and even internal cavity volume using non-contact sensors like lasers or ultrasonics.

This data is fed into a Plant Process Control System, which uses predefined algorithms and increasingly machine learning models to make fine adjustments to the crusher settings and feed rate. For instance, if the power draw trends upward while the crusher setting remains constant, it might indicate harder material, and the system could slightly open the setting to maintain throughput and avoid an overload, thus optimizing energy use. This constant, automated fine-tuning ensures the crusher operates at peak efficiency 24/7, responding to changes much faster than a human operator could, leading to significant cumulative energy savings.

Economy and Environmental Benefits

The choice between a roll crusher and a cone crusher has significant long-term implications for both the economic viability and environmental footprint of a mining operation. A comprehensive analysis must look beyond the initial purchase price and consider the total cost of ownership, which is dominated by energy consumption and wear part replacement costs over the machine's operational lifespan. Furthermore, the growing emphasis on sustainable mining practices places a premium on technologies that reduce greenhouse gas emissions associated with comminution.

Operators are increasingly evaluating crushing equipment through the dual lenses of profitability and environmental responsibility. Energy-efficient crushers not only lower direct electricity costs but also reduce the mine's indirect carbon emissions, especially if the local grid is reliant on fossil fuels. This can create opportunities for accessing government incentives for green technology and for participating in carbon credit markets, turning environmental performance into a financial advantage.

Comparison of Initial Investment and Maintenance Costs

The initial capital expenditure (CAPEX) for a cone crusher is generally higher than for a roll crusher of comparable capacity. Cone crushers are complex machines with precise mechanical components (eccentric assembly, mantle, concave) that require high-quality manufacturing, contributing to their higher price tag. Roll crushers, with their relatively simpler design of two parallel rolls, often have a lower initial purchase cost.

However, the operational expenditure (OPEX) picture is more nuanced. Cone crusher wear parts (mantles and concaves) are typically more expensive than roll crusher wear parts (roll shells or tires). But their service life can be longer in certain abrasive applications due to the use of advanced manganese steel alloys and effective hardening mechanisms through work-hardening. The maintenance schedule for a cone crusher might also be more involved. A thorough life cycle cost analysis, integrating initial cost, energy consumption, wear part cost and life, and maintenance labor, is essential for making an informed economic decision between the two technologies.

Life Cycle Energy Cost Model

A Life Cycle Energy Cost Model is a comprehensive financial tool that accounts for all energy-related costs over the entire operational life of the crusher. This model aggregates the initial capital cost, the present value of all future energy consumption costs (based on projected electricity prices), the cost of replacing wear parts, scheduled maintenance costs, and any costs associated with unplanned downtime. The model uses a discount rate to calculate the Net Present Value (NPV) of these future costs.

For a crusher, which may operate for 15-20 years or more, the cost of energy often becomes the single largest component of the life cycle cost, far exceeding the initial purchase price. Therefore, even if a roll crusher has a slightly higher initial cost than a cone crusher, its significantly lower specific energy consumption for a given material could result in a much lower total life cycle cost. This model provides a rigorous financial justification for investing in more energy-efficient technology based on long-term savings.

Carbon Emission Intensity Difference (25% Gap in Soft Ore Scenarios)

The carbon emission intensity of a crushing process is directly proportional to its energy consumption, assuming a constant grid carbon intensity (kg CO2 per kWh). In scenarios involving soft ores like iron ore, where data indicates a potential 50% higher energy use for cone crushers (1.2 kWh/t) compared to roll crushers (0.8 kWh/t), the resulting carbon footprint difference can be substantial.

This translates to a cone crusher potentially generating over 25% more CO2 emissions per ton of product than a roll crusher for the same material. For a large mining operation processing millions of tons per year, this difference in carbon emissions can amount to thousands of tons of CO2 annually. This not only has environmental implications but also increasingly financial ones, as carbon pricing mechanisms (taxes or cap-and-trade systems) are adopted more widely, making high-emission operations more costly to run.

Utilization Strategy for Government Subsidy Policies

Many governments around the world offer subsidies, tax credits, or accelerated depreciation schemes to encourage industries to adopt energy-efficient technologies and reduce their environmental impact. These policies are designed to offset the higher initial investment often associated with more efficient machinery, improving its return on investment and payback period.

Mining companies can strategically leverage these incentives to justify the capital outlay for advanced, low-energy crushers. This might involve applying for direct grants for green technology upgrades, claiming tax deductions based on the proven reduction in energy consumption, or accessing low-interest green loans. Successfully utilizing these policies requires careful planning, often involving pre-approval applications that demonstrate the projected energy savings and carbon emission reductions of the new equipment compared to a baseline technology.

Pathway for Participation in the Carbon Trading Market

For operations in regions with a functioning carbon cap-and-trade market, reducing the energy consumption of crushing circuits can generate valuable carbon credits. In such a market, a regulatory cap is set on the total amount of greenhouse gases an entity can emit. Companies that reduce their emissions below their allowance can sell their surplus allowances (carbon credits) to those companies that exceed their cap.

By installing an energy-efficient roll crusher and accurately measuring the resulting reduction in electricity consumption (and thus indirect emissions), a mining company could generate verifiable carbon credits. These credits can then be sold on the carbon market, creating a new revenue stream that further improves the financial return on the investment in efficient technology. Participating in this market requires rigorous monitoring, reporting, and verification (MRV) of emission reductions according to established protocols to ensure the environmental integrity and credibility of the credits.

Industry Standards and Testing Methods

To ensure fair and accurate comparisons between different crushers and technologies, the industry relies on standardized testing methods and performance metrics. These standards provide a common framework for measuring key parameters like throughput, product size distribution, and most importantly, energy consumption under defined conditions. Adherence to these standards is crucial for generating reliable data that can inform purchasing decisions and operational improvements.

Standardized testing removes ambiguity and allows for a like-for-like evaluation, whether conducted internally by manufacturers, by third-party validation agencies, or by the mine's own engineering teams. The results form the basis for energy models, equipment warranties, and performance guarantees. Furthermore, they provide the verified data needed to access government subsidies or participate in carbon markets, as these programs require proof of performance based on recognized methodologies.

ISO 13743:2025 Energy Efficiency Test Specification

While a specific ISO 13743:2025 standard was not identified in the search results, the description points toward the critical need for an internationally recognized standard for testing crusher energy efficiency. Such a standard would define the precise laboratory or field conditions under which energy consumption measurements must be taken. It would specify the requirements for instrument accuracy (for power, throughput, and product size measurement), the properties of the test material (e.g., a standard graded feed with a defined hardness and size distribution), the acceptable range of operating parameters during the test, and the duration of the test required to achieve stable and representative results.

The implementation of a universal standard like this would allow end-users to compare the energy performance claims of different crusher models from various manufacturers with a high degree of confidence. It would prevent "gaming" of the test conditions to produce favorable results and drive industry-wide innovation toward genuinely more efficient crushing technology. Manufacturers adhering to this standard would provide verified specific energy consumption (kWh/t) figures, making it a cornerstone of transparent technical marketing.

Standardized Testing Process for Load Rate

A standardized test for crusher load rate would prescribe a method for determining the relationship between crusher throughput (t/h) and its energy draw (kW). The test involves running the crusher at a series of different, carefully controlled feed rates while holding all other parameters (feed material, CSS/roll gap, speed) constant. At each feed rate, the system is allowed to reach a steady state, and then measurements are taken for power draw, throughput (by weighing a sample of the product over a timed interval), and product size distribution.

The resulting data is used to plot a curve of specific energy consumption (kWh/t) against feed rate or crusher load (as a percentage of maximum capacity). This curve clearly shows the crusher's efficiency zone, typically a "U" shape where consumption is high at very low loads (high no-load fraction), lowest at an optimal load (e.g., 80-90%), and then rising again as the crusher approaches choke feed conditions and efficiency drops. This standardized curve is an invaluable tool for operators to understand how to run their equipment most efficiently.

Material Hardness Classification Standard (Mohs Scale)

The Mohs scale of mineral hardness is a qualitative ordinal scale that characterizes a material's resistance to scratching. It ranges from 1 (talc, very soft) to 10 (diamond, the hardest). While not a direct measure of compressive strength or crushability, it provides a useful and simple reference point for categorizing rocks. For example, limestone typically has a Mohs hardness of 3-4, iron ore around 5-6, and granite and basalt are in the 6-8 range.

Standardized energy consumption tests should always report the Mohs hardness, and ideally the Unconfined Compressive Strength (UCS), of the test material. This allows potential users to extrapolate the performance data to their own ore body. A crusher that is highly efficient on limestone (Mohs 3-4) might be completely unsuitable or inefficient for granite (Mohs 6-8). Using a standard hardness scale ensures clear communication about the application suitability of the equipment and helps set realistic expectations for wear rates and energy consumption.

Third-Party Testing Organization Verification Case

Third-party verification of crusher performance claims adds a critical layer of credibility and objectivity. An independent engineering firm or research institution will conduct the performance tests according to the relevant industry standards (e.g., the hypothetical ISO 13743:2025). They will oversee the entire process, from characterizing the test feed material to calibrating the measurement instruments and collecting the data.

The resulting verification report provides assurance to the buyer that the manufacturer's energy efficiency and production capacity claims are accurate and were obtained under fair and consistent conditions. This reduces the perceived risk associated with a major capital investment. For instance, a university's mining engineering department or a renowned metallurgical research center could be contracted to perform such verification, lending their reputation to the test results and giving the end-user confidence in the data supporting their investment decision.

Data Credibility Assurance Measures

Ensuring the credibility of energy consumption data involves a multi-faceted approach throughout the testing process. It begins with the use of calibrated, high-precision instruments for measuring electrical power (using certified power analyzers), weight (using calibrated scales and belt scales), and particle size (using standardized sieve analysis or laser diffraction methods). The test must run for a sufficient duration to average out short-term fluctuations and achieve a steady-state operation.

All raw data should be recorded with timestamps and stored securely. The data analysis methodology must be transparent and reproducible. For the highest level of assurance, the process can be audited by an external party. These rigorous measures are necessary to prevent unintentional errors or intentional misrepresentation. They form the foundation of trust between the equipment supplier, the testing agency, and the end-user customer, especially when the data is used to justify large purchases or to claim financial incentives based on performance.

Typical Mine Application Cases

Real-world case studies from operating mines provide the most compelling evidence for the performance differences between roll crushers and cone crushers. These cases move beyond theoretical models and controlled tests to show how the equipment performs under the daily challenges of a production environment, including variable feed conditions, maintenance schedules, and the pursuit of continuous improvement in efficiency and cost reduction.

Analyzing long-term operational data from these cases reveals trends that are not apparent in short-term tests, such as the impact of wear on energy consumption over a full liner life cycle, the reliability and availability of the different crusher types, and the total cost of ownership. These insights are invaluable for other mining operations facing similar material processing challenges and equipment selection decisions.

Instance of 22% Energy Reduction in Secondary Iron Ore Crushing

A compelling case study involves an iron ore mine that replaced a traditional cone crusher with a modern high-pressure roll crusher for its secondary crushing stage. The mine was processing a relatively soft hematite ore. Prior to the change, the existing cone crusher circuit averaged a specific energy consumption of 1.35 kWh/t. After installation and optimization of the roll crusher circuit, the average specific energy consumption dropped to 1.05 kWh/t.

This represents a significant 22% reduction in energy use for secondary crushing. For an operation processing 10 million tons per year, this saving translates to 3 million kWh of electricity saved annually. This not drastically lowered operating costs but also reduced the site's carbon footprint substantially. The case also reported more stable product sizing and reduced generation of fines in the secondary stage, which benefited the downstream grinding circuit, leading to additional, albeit smaller, energy savings overall.

Equipment Selection Decision-Making for Hard Rock Gold Mine

A gold mine processing very hard quartzite ore faced a critical decision for its secondary crusher. The options were a large-capacity cone crusher, known for its robustness in hard rock applications, and a specialized, heavily built roll crusher designed for abrasive feed. The decision-making process involved a detailed technical and economic analysis.

The cone crusher offered higher potential throughput and proven reliability but with higher anticipated energy costs (estimated at 2.1-2.5 kWh/t) and wear part costs. The roll crusher promised lower energy consumption (estimated at 1.7-1.9 kWh/t based on pilot tests) but presented a perceived higher risk in terms of availability and wear life in such an abrasive environment. The mine ultimately selected the cone crusher, prioritizing throughput reliability and proven performance in identical applications over potential energy savings, highlighting that energy is not the only deciding factor—operational risk and production guarantees are often paramount.

Energy Efficiency Improvement Ratio in Statistical Data

Aggregating data from multiple case studies and operational reports reveals a statistical trend regarding energy efficiency improvements. Across various applications, particularly in processing soft to medium-hard materials like limestone, phosphate, and iron ore, replacing older cone crusher technology with modern roll crushers has consistently yielded energy savings in the range of 15% to 30%.

The average improvement falls around the 20-22% mark. The variation within this range depends heavily on specific factors: the precise mineralogy and abrasiveness of the ore, the initial condition and efficiency of the replaced crusher, the completeness of the system optimization around the new crusher (e.g., feed control, screening efficiency), and the target product size. This aggregated data provides a strong empirical basis for predicting the likely energy savings from such a technology shift in similar mining contexts.

Analysis of the Relationship Between Equipment Failure Rate and Energy Consumption

There is a strong correlation between crusher mechanical health and its energy efficiency. A crusher that is experiencing mechanical issues, such as worn bearings, misaligned gears, or unevenly worn liners, will invariably consume more energy to achieve the same output as a healthy machine. The increased friction, vibration, and sub-optimal crushing action all contribute to higher power draw.

For example, data tracking from a mine site showed that a cone crusher's specific energy consumption began to gradually increase by about 5% in the weeks leading up to a scheduled liner change. This was due to the worn liner profile reducing crushing efficiency. Furthermore, a sudden failure, like a seized bearing, causes a massive energy spike before catastrophic shutdown. Therefore, a rigorous preventive maintenance program is not just about avoiding downtime; it is also a key strategy for managing energy costs. Maintaining the crusher in good health keeps it running efficiently.

Long-Term Operational Data Comparison (5+ Years)

A five-year comparative study at a large industrial minerals operation provided deep insights into the long-term performance of parallel secondary crushing circuits—one using cone crushers and the other using roll crushers, processing the same claystone material. The data encompassed specific energy consumption, wear part costs, maintenance labor hours, and availability.

The results showed that while the roll crusher circuit maintained a 20-25% lower specific energy consumption throughout the period, it required more frequent shutdowns for roll surface maintenance and had a slightly lower overall availability (95% vs. 97% for the cones). The cone crushers had higher energy costs but longer liner life and higher peak throughput capability. The total cost per ton, balancing energy, wear parts, and availability, was calculated to be marginally in favor of the roll crusher circuit for this specific material. This long-term view is essential, showing that short-term advantages in one area (energy) can be offset by long-term costs in another (availability), requiring a holistic evaluation.

Technology Development Trends

The pursuit of greater energy efficiency and lower operating costs continues to drive innovation in crusher technology. The future of crushing lies in smarter, more connected, and more durable machines that optimize their own performance and integrate seamlessly into automated process plants. These advancements are focused on reducing energy consumption directly through improved mechanics and indirectly by maximizing uptime and ensuring the crusher always operates in its optimal zone.

Emerging trends include the adoption of more efficient drive systems, the application of digital twin technology for simulation and optimization, the integration of artificial intelligence for predictive maintenance, the use of virtual commissioning to reduce installation time, the development of advanced materials to extend component life, and the leveraging of high-speed communication for remote operation and expert support. Together, these technologies represent a new era of intelligent, energy-aware crushing.

Application of Permanent Magnet Motor Drive Systems

Permanent Magnet Motor (PMM) drives are increasingly being adopted in crusher applications due to their superior efficiency and performance characteristics compared to traditional induction motors. PMMs offer higher power density (more power in a smaller package), higher efficiency across a broader load range (especially at partial loads), and better dynamic response.

For a crusher, which experiences constant load variations due to changes in feed material, a PMM can provide more consistent torque and speed regulation, leading to more stable operation and potentially better product quality. The higher efficiency translates directly to lower electrical energy consumption for the same mechanical output. Furthermore, the compact size of PMMs can allow for more streamlined crusher designs. The move towards systems like permanent magnet motor drives is a key trend in reducing the overall energy footprint of comminution circuits.

Digital Twin Technology for Optimizing the Crushing Process

A digital twin is a dynamic, virtual replica of a physical crushing system that is continuously updated with data from sensors on the real machine. This model can simulate the crushing process in real-time, allowing operators and engineers to test different operating parameters (CSS, speed, feed rate) in the virtual environment without risking production or equipment damage in the real plant.

The digital twin can be used to identify the optimal settings for minimizing energy consumption while meeting production targets for any given feed characteristic. It can also predict the outcome of changes before they are implemented. For example, it can simulate how a change in ore hardness will affect power draw and product size, allowing the control system to proactively adjust to maintain efficiency. This capability for virtual experimentation and optimization is a powerful tool for pushing energy efficiency to its limits.

AI-Based Predictive Maintenance System

Artificial Intelligence (AI) and machine learning are revolutionizing crusher maintenance. An AI-based predictive maintenance system continuously analyzes data from vibration sensors, temperature probes, oil debris monitors, and motor power draw. The AI model learns the normal "healthy" operating signature of the crusher. It can then detect subtle anomalies that indicate the early stages of a fault, such as a bearing beginning to degrade or a liner wearing unevenly.

This allows maintenance to be planned weeks in advance, at a scheduled time, preventing unexpected failures that lead to high-energy emergency repairs and prolonged downtime. More importantly, it ensures the crusher is always maintained in peak condition, operating at its design efficiency. A crusher with worn bearings or misaligned components consumes more energy; predictive maintenance prevents this energy creep by ensuring repairs are made just before efficiency begins to significantly decline.

Virtual Commissioning Technology to Reduce Downtime

Virtual commissioning involves using the digital twin to test and debug the crusher's control software and operational logic before the physical machine is even installed or during planned shutdowns. This process eliminates the lengthy period of on-site commissioning where the crusher is tuned and debugged, which traditionally involves running the machine non-productively, consuming energy without producing output.

By front-loading this work into the virtual space, the physical commissioning time can be drastically reduced. The crusher can be started up and brought online to full, efficient production much faster. This not only saves the energy that would have been wasted during prolonged commissioning but also gets the energy-efficient machine producing valuable product sooner, improving the overall energy economy of the project.

Nanocoating Technology to Extend Roll Surface Life

The application of extremely hard and wear-resistant nanocoatings to roll surfaces is a major advancement in extending service life and maintaining energy efficiency. These coatings, often based on tungsten carbide or specialized ceramics, are applied using techniques like High-Velocity Oxygen Fuel (HVOF) thermal spraying. They create a surface that is much more resistant to abrasion than traditional manganese steel.

The primary energy benefit lies in maintaining the optimal geometric profile of the roll for a much longer period. As a roll wears, its profile flattens, which reduces the effective nip angle and can compromise drawing efficiency and crushing performance, potentially leading to higher energy consumption. A nanocoated roll maintains its designed profile throughout its life, ensuring consistent, efficient crushing and eliminating the gradual energy efficiency loss associated with wear. Furthermore, longer life means fewer shutdowns for roll replacement, maximizing production uptime and saving the energy associated with maintenance activities.

Application of 5G Technology in Remote Control

The ultra-low latency and high bandwidth of 5G communication networks are enabling new possibilities for remote monitoring and control of crushing equipment. With a 5G connection, high-fidelity sensor data (vibration, video, pressure, temperature) can be transmitted from a remote crusher in a quarry or mine to a centralized control center in real-time. This allows expert technicians to monitor the health and performance of multiple machines across different sites simultaneously.

They can make fine adjustments to operating parameters to optimize efficiency based on real-time data without needing to be physically present. The low latency is crucial for enabling precise remote control, should it be needed. This not only improves operational efficiency but also contributes to energy savings by ensuring that the crusher is always operating at its best possible setting, guided by expert oversight that might not be available on-site at all times.