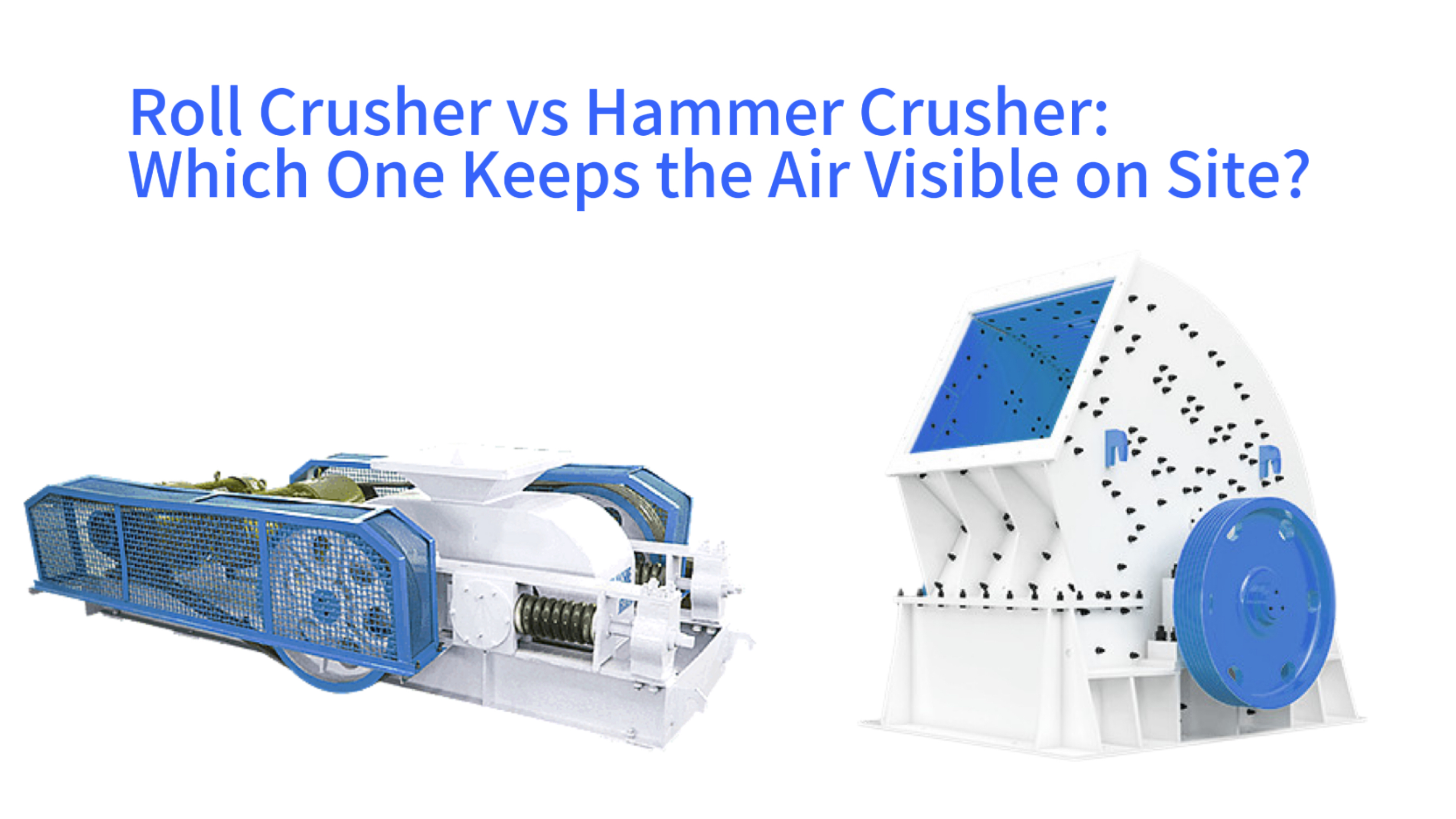

Roll Crusher vs Hammer Crusher: Which One Keeps the Air Visible on Site?

This article provides a comprehensive comparative analysis of the dust generation and control characteristics inherent to two common crushing technologies: the roll crusher and the hammer crusher. Dust emissions present a significant challenge in aggregate production, impacting worker health, equipment longevity, environmental compliance, and overall site safety. The central question addressed is which machine type contributes more effectively to maintaining visible air quality—a tangible indicator of a clean and safe work environment. By examining the fundamental working principles, specific dust generation mechanisms, and the efficacy of associated control strategies, this guide aims to equip site managers, plant engineers, and procurement specialists with the knowledge needed to make an informed selection that prioritizes operational health and environmental stewardship.

Core Analysis Steps for Crusher Dust Control Selection

Analyze Dust Sources

Identify dust types & hazards

Compare Crusher Mechanisms

Evaluate dust generation traits

Evaluate Control Systems

Size & cost of dust collection

Select Optimal Technology

Align with site air quality goals

Implement Best Practices

Maintain low-dust operation

Understanding the On-Site Challenge: The Critical Importance of Crusher Dust Control

The control of fugitive dust at industrial crushing sites transcends mere housekeeping; it constitutes a fundamental operational imperative with wide-ranging consequences. Particulate matter released during the size reduction of rock and mineral aggregates originates from multiple points within the processing chain. The initial crushing stage, however, is often the most prolific and challenging source. These airborne particles, varying in size from coarse grit to respirable fines, create a persistent haze that can severely degrade local air quality. Maintaining visible air, meaning the absence of a discernible dust cloud, is therefore a direct and practical measure of effective dust management. Achieving this state requires an understanding that not all crushing equipment generates or disperses dust in an equivalent manner.

Dust Hazard Classification & Regulatory Limits

| Particle Type | Size (μm) | Health Risk | 8-Hour WEL (mg/m³) |

|---|---|---|---|

| PM10 | ≤10 | Respiratory irritation, asthma | 5.0 (Typical) |

| PM2.5 | ≤2.5 | Lung damage, cardiovascular issues | 1.0 (Typical) |

| Respirable Crystalline Silica (RCS) | ≤4 | Silicosis, lung cancer | 0.05 (Global Standard) |

Economic Impact of Uncontrolled Dust (Annual Cost per Site)

Equipment Maintenance

Cleanup Labor

Regulatory Fines

Unplanned Downtime

The hazards associated with uncontrolled dust are multifaceted and severe. Prolonged exposure to airborne crystalline silica, a common component in many rocks, is a well-documented cause of silicosis, an incurable and potentially fatal lung disease. Beyond direct health risks, dust infiltration accelerates the wear of mechanical components, contaminates lubrication systems, and can cause failures in sensitive electronic sensors and controls. From a safety perspective, reduced visibility increases the likelihood of accidents involving mobile equipment and personnel. Furthermore, visible plumes of dust emanating from a site often lead to regulatory scrutiny, community complaints, and potential fines, damaging a company's social license to operate. Consequently, selecting crushing technology with inherently lower dust propensity is a proactive strategy for mitigating these interconnected risks.

The Physical and Chemical Composition of Crusher Dust

Crusher dust is not a homogeneous substance; its properties vary significantly based on the parent material and the crushing mechanism. The particle size distribution is a critical factor, typically categorized as PM10 (particles with a diameter of 10 micrometers or less) and the more dangerous PM2.5 (2.5 micrometers or less). These finer particles can remain suspended in the air for extended periods and penetrate deep into the lungs. The mineralogical composition further defines the hazard. For instance, dust from granite or sandstone contains high levels of free crystalline silica, posing a greater health risk than dust from pure limestone. The behavior of dust is also influenced by ambient conditions; dry material produces far more airborne and persistent dust than moist material, which tends to agglomerate and settle more quickly.

Regulatory Frameworks and Exposure Limits

Compliance with occupational and environmental health regulations is a non-negotiable aspect of modern crushing operations. Agencies worldwide enforce strict Workplace Exposure Limits (WELs) for respirable dust and crystalline silica. In many jurisdictions, the permissible exposure limit for respirable crystalline silica is set at or below 0.05 milligrams per cubic meter of air as an 8-hour time-weighted average. Environmental regulations also govern the opacity of emissions from point sources, often mandating that visible plumes be minimized. These legal standards provide a quantitative baseline, but many leading companies adopt even stricter internal targets for dust control, recognizing that surpassing compliance enhances worker welfare, community relations, and operational efficiency.

The Economic Rationale for Effective Dust Suppression

Investing in dust control yields measurable financial returns beyond avoiding regulatory penalties. Unchecked dust leads to accelerated abrasion of conveyor belts, bearings, and hydraulic systems, increasing maintenance costs and unplanned downtime. The constant accumulation of dust requires dedicated labor for cleanup and creates a corrosive environment for equipment. Conversely, a cleaner site experiences fewer equipment failures, lower maintenance expenditures, and improved worker productivity and morale, reducing absenteeism. The capital and operational costs of effective dust suppression systems are often offset by these savings, making dust control a sound economic decision rather than merely a regulatory expense.

Community Relations and Environmental Stewardship

The visual and environmental impact of a crushing operation directly affects its relationship with the surrounding community. A site shrouded in dust is a source of nuisance and concern for nearby residents, often leading to complaints and opposition to expansion or renewal of operating permits. Proactive and visible dust management demonstrates corporate responsibility and respect for the local environment. By maintaining clear, visible air on-site, a company builds trust with the community, minimizes conflicts, and secures its long-term operational sustainability. This social license to operate is an intangible but increasingly valuable asset in today's regulated and socially conscious market.

Dust Generation Mechanism of the Roll Crusher: A Low-Velocity, Contained Process

The roll crusher operates on a principle of compression and shear. Two counter-rotating cylinders, or rolls, draw material into the narrowing gap between them. This action applies high pressure, fracturing the material primarily through tensile stress. The process is characterized by relatively low rotational speeds and high torque. The mechanical action is contained and deliberate, with material undergoing a controlled breaking event rather than a violent disintegration. This fundamental mode of operation has profound implications for the nature and quantity of dust produced. The generation of fine particulates is more a result of surface abrasion and slight over-crushing at the point of compression, rather than from high-energy impact.

Roll Surface Design vs Dust Output

| Surface Type | Fragmentation Pattern | Fine Dust Generation | Emission Characteristic |

|---|---|---|---|

| Smooth-Faced | Compression grinding | Higher (15-20% fines) | Localized fallout |

| Toothed/Corrugated | Cleavage splitting | Lower (5-10% fines) | Minor fragment spitting |

Due to its enclosed design and the absence of internal high-speed rotors generating airflow, the roll crusher exhibits a passive dust emission profile. Most dust created remains within the confines of the machine's housing. The primary emission points are typically the feed chute and the discharge area. Any dust that does escape tends to settle quickly due to the lack of propelling force, often accumulating locally rather than forming a drifting plume. This characteristic makes the dust from a roll crusher inherently more manageable and easier to capture with localized ventilation hoods and a smaller baghouse filtration system. The challenge with roll crushers lies less in suppressing violently expelled dust and more in managing the steady, low-velocity fallout from transfer points.

Influence of Roll Surface Design on Particulate Creation

The texture of the crusher rolls directly influences the fragmentation pattern and subsequent dust generation. Smooth-faced rolls rely almost entirely on compression, which can produce a more uniform product but may also generate a higher proportion of fines through a grinding action as material slips before being nipped. Corrugated or toothed rolls, in contrast, engage the material more positively, inducing cleavage and splitting. This can result in a product with a broader size distribution but potentially less uniformly fine dust. However, toothed designs can sometimes cause a slight throwing or spitting of smaller fragments from the point of entry, a different type of localized emission that must be considered in hood design.

Material Feed Uniformity and the Risk of Over-Crushing

A critical operational factor affecting dust output in a roll crusher is the consistency of the feed. An uneven feed, with fluctuations in size or volume, can lead to intermittent overloading or underloading of the nip zone. Underloaded conditions allow smaller pieces to pass through with minimal reduction, while overloaded conditions or large slabs can cause momentary slippage and repeated compression of already-sized material. This over-crushing is a direct and unnecessary source of fine dust. Therefore, maintaining a steady, well-regulated feed using a vibrating feeder or apron conveyor is not only beneficial for capacity but also a key dust minimization strategy, ensuring each particle is subjected to optimal stress only once.

Handling of Damp or Clay-Bound Materials

While moisture generally suppresses dust, sticky materials like clay-bound aggregates pose a unique challenge for roll crushers. These materials can adhere to the roll surfaces, gradually building up and effectively reducing the crusher's diameter and gap. This buildup diminishes crushing efficiency and can lead to unpredictable shearing or chunking of the compacted layer, causing sporadic releases of material and dust. Some roll crusher designs incorporate self-cleaning scrapers or adjustable plows to mitigate this. The intermittent release of built-up material, however, can be a source of sudden, though usually coarse, dust emissions that require consideration in overall site dust management plans.

Dust Generation Mechanism of the Hammer Crusher: A High-Energy, Turbulent System

In stark contrast to the roll crusher, the hammer crusher utilizes dynamic impact as its primary breaking force. A high-speed rotor fitted with pivoting or fixed hammers rotates within a solid housing. Feed material is struck by the hammers with tremendous kinetic energy, shattering upon impact against breaker plates or the housing liners. This process is inherently violent and explosive at the particle level. The high-energy collisions do not merely break rocks; they pulverize a significant portion into fine dust instantly. Furthermore, the rotor assembly acts as a powerful centrifugal fan, creating a substantial flow of air through the machine that carries this newly created dust.

Hammer Crusher Dust Generation Cycle

This internally generated airflow is the defining characteristic of the hammer crusher's dust emission profile. The machine actively pumps dust-laden air from its housing. Emission points are numerous and under positive pressure: the feed inlet, the discharge outlet, and any inspection doors or sealing gaps. The dust is not merely settling; it is being propelled, often forming a visible plume that can travel a considerable distance from the source. Controlling emissions from a hammer crusher therefore requires a system capable of overcoming this internal pressure, capturing high-volume airflows, and filtering an exceptionally high concentration of fine particulates. It represents a fundamentally different, and typically more complex, engineering challenge compared to containing the passive emissions of a roll crusher.

The Amplifying Effect of Grates and Repeated Impact

Most hammer crushers utilize a discharge grate or screen to control final product size. Particles small enough to pass through the grate openings exit the crushing chamber. Those that are too large are retained for further impact. This recycling mechanism ensures product sizing but has a severe downside for dust generation. Material is subjected to repeated high-energy impacts, each event generating more fines. This attrition grinding effect is a major secondary source of dust, particularly of the problematic respirable fraction. While increasing grate opening size can reduce this effect, it also allows larger product to pass, creating a direct trade-off between product specification and dust generation intensity.

Rotor Speed as the Primary Driver of Airflow and Dust Dispersion

The velocity of the hammer tips is a key design and operational parameter, directly linked to both crushing efficiency and dust behavior. Tip speeds often exceed 70 meters per second. The airflow induced by the rotor is approximately proportional to the cube of its rotational speed. A small increase in speed can therefore cause a large increase in the volume of dust-carrying air needing to be managed. This relationship makes the hammer crusher particularly sensitive to operational adjustments. Running the crusher at the minimum speed required to achieve the desired product size is a critical operational practice for minimizing the energy and cost associated with subsequent dust collection.

Case Study: The Silica Hazard in Hard Rock Crushing

The combination of high-impact breaking and induced airflow makes the hammer crusher a high-risk machine when processing silica-bearing rocks like quartzite, granite, or sandstone. The violent impact readily generates vast quantities of respirable crystalline silica (RCS) dust. The internal airflow then efficiently transports this hazardous dust out of the machine and into the work environment. For such applications, the hammer crusher demands not just standard dust collection but a comprehensive containment and filtration strategy designed specifically for high-hazard dust. This often includes ensuring the crusher housing is under negative pressure, using high-efficiency cartridge filters, and implementing rigorous filter maintenance and dust disposal protocols to protect workers from a known carcinogen.

Core Comparative Analysis: Emission Characteristics and Impact on Visible Air

A direct comparison of dust emission characteristics reveals why the two machines have such different impacts on site air visibility. The hammer crusher typically exhibits a significantly higher source strength for fine particulate matter. Studies and practical observations indicate that the mass of PM10 dust generated per ton of material processed can be an order of magnitude greater in a hammer crusher compared to a roll crusher processing similar rock to a comparable product size. This difference stems from the fundamental breakage mechanism: impact shattering versus compressive splitting. The hammer crusher's efficiency at creating fines is, ironically, a major drawback in contexts where dust control is paramount.

Crusher Emission Characteristics Comparison

| Characteristic | Roll Crusher | Hammer Crusher | Difference Factor |

|---|---|---|---|

| PM10 Generation (kg/ton) | 0.1-0.3 | 1.0-3.0 | 10x Higher (Hammer) |

| Emission Type | Gravitational (Localized) | Aerodynamic (Dispersed) | 50m+ Plume (Hammer) |

| Induced Airflow (CFM/ton) | 50-100 | 500-1000 | 10x Higher (Hammer) |

| RCS Emission Risk | Low | High | Critical for Silica Rock |

Beyond the quantity, the dispersal mechanism is pivotal. The roll crusher's emissions are largely gravitational; dust falls out near the source. The hammer crusher's emissions are aerodynamic; dust is injected into the surrounding atmosphere with energy. In the absence of control measures, a hammer crusher will rapidly create a diffuse, hanging dust cloud that reduces visibility across a wide area of the plant. A roll crusher, in the same scenario, will create localized piles of dust beneath transfer points but is less likely to significantly degrade general air visibility. This distinction makes the goal of "visible air" inherently more challenging to achieve with hammer crushers, requiring more robust and energy-intensive countermeasures.

Quantifying the Difference: Emission Factor Trends

Industry emission factors, used for environmental inventorying, underscore this disparity. While specific numbers vary with material and machine configuration, published factors for controlled crushing operations consistently show hammer mills associated with higher particulate emission rates. For example, in certain aggregate processing emission inventories, uncontrolled hammer mill operations may have an emission factor several times greater than that for uncontrolled roll crushers for similar tasks. This quantitative reality reinforces the principle that source reduction—choosing a technology that generates less dust at the point of creation—is the most effective foundation for any dust control program aiming to maintain clear site air.

Downstream Consequences for Material Handling

The dust burden imposed on downstream processes is another critical differentiator. Material discharged from a hammer crusher is often thermally hot and intimately mixed with a high load of fine dust. As this material is conveyed, screened, and transferred, these fines become recurrent sources of secondary dust emissions at every transfer point, chute, and screen deck. In contrast, the product from a roll crusher, being generally cleaner and containing fewer fines, places a lesser dust load on conveying and screening systems. This reduces the complexity and cost of dust control across the entire plant, contributing to a cumulatively cleaner environment and making the overall goal of visible air more attainable.

The Synergistic Impact of Noise and Dust

The environmental footprint of crushing equipment is multi-sensory. The hammer crusher is typically a high-noise machine due to the repeated metal-on-rock impacts and high-speed rotor. This acoustic pollution, combined with a persistent visible dust plume, creates a powerful negative perception for both workers and the surrounding community. The roll crusher, operating at lower speeds and with a crushing rather than impacting action, is generally quieter. The combination of lower noise and less visible dust emission makes operations using roll crushers less intrusive and more likely to be perceived as well-managed and neighborly, which is an intangible but valuable benefit.

Dust Suppression and Collection Technology Configuration

The selection and design of dust control systems must be tailored to the specific emission profile of the crusher. The foundational principle is that preventing dust generation is superior to capturing it after creation. Where a roll crusher is chosen, the dust control strategy can focus on containment and local exhaust ventilation. Effective solutions often involve enclosing the discharge area with a tight hood connected to a moderate-sized dust collector. The air volume required is calculated based on the hood's open area and the need to maintain a slight inward airflow, typically around 0.5 to 1.0 meters per second, to prevent dust escape. This is a relatively straightforward engineering task.

Dust Collection System Sizing Requirements

| System Component | Roll Crusher (100 TPH) | Hammer Crusher (100 TPH) | Cost Ratio (Hammer:Roll) |

|---|---|---|---|

| Required Air Volume (CFM) | 10,000-15,000 | 50,000-100,000 | 5-7x |

| Fan Power (HP) | 15-25 | 75-150 | 5-6x |

| Filter Media Area (sq. ft) | 500-1,000 | 2,500-5,000 | 5x |

| Annual Energy Cost ($) | $5,000-$8,000 | $25,000-$50,000 | 5-6x |

Sealing Complexity vs Maintenance Effort

For a hammer crusher, the approach must be defensive and comprehensive. The system must first overcome the positive pressure and high volumetric airflow generated by the crusher itself. This necessitates designing the crusher housing to be as airtight as possible and applying suction at multiple points—commonly at the feed inlet, the discharge outlet, and sometimes at the shaft seals. The required air volume is substantial, often determined by the crusher's induced airflow plus an additional amount for control at openings. The dust collector for a hammer crusher must be sized to handle this large air volume and the high dust loading, frequently employing robust pulse-jet cleaning systems for continuous operation. The capital and operating costs for this system are significantly higher.

Key Differences in System Sizing and Design

The calculation of required exhaust air volume illustrates the core difference. For a roll crusher discharge hood, the formula Q = A * V is often sufficient, where A is the hood's open area and V is the desired capture velocity. For a hammer crusher, the calculation must account for the induced air volume (Q_ind) from the rotor, which can be estimated based on rotor geometry and speed. The total system air volume (Q_total) then becomes Q_ind plus the air needed to establish control at other openings (Q_control). This makes Q_total for a hammer crusher installation much larger, directly impacting the size, power consumption, and cost of fans, ductwork, and filters.

The Engineering Challenge of Achieving Effective Sealing

Creating an effective seal around a dynamic, high-speed rotor shaft is a persistent engineering challenge in hammer crusher dust control. Specialized labyrinth seals or pressurized bearing housings are often required to prevent dust from escaping along the shaft. Inspection and access doors must be designed with gaskets and cam-lock mechanisms to ensure they remain sealed during operation. In contrast, a roll crusher's shafts rotate at much lower speeds, and the bearings are typically located outside the crushing zone, presenting a less demanding sealing requirement. The comparative simplicity of sealing a roll crusher contributes to lower maintenance needs and more reliable long-term containment.

Operational Cost Implications of Dust Collection

The long-term operating costs of dust control systems diverge sharply between the two technologies. The larger fan and motor required for a hammer crusher system consume more electrical energy continuously. For instance, a system handling 50,000 cubic feet per minute (CFM) will have notably higher power costs than one handling 10,000 CFM for a comparable capacity roll crusher. Furthermore, the higher dust loading in the hammer crusher system leads to more frequent filter cleaning cycles and shorter filter media life, increasing maintenance and replacement costs. These ongoing expenses make the total cost of ownership for a hammer crusher installation, inclusive of dust control, substantially greater over its operational lifespan.

Scientific Selection Guidelines: A Decision Framework for Project Needs

The choice between a roll crusher and a hammer crusher should be guided by a systematic evaluation of project-specific parameters, with dust control as a key weighting factor. The initial step involves a thorough analysis of the feed material: its hardness, abrasiveness, silica content, moisture level, and feed size. The next step is to define the required product size distribution and the desired production capacity. Only after these factors are understood can the trade-off between crushing efficiency and environmental impact be rationally assessed. In many cases, the optimal solution may involve using both technologies in a staged process, with a hammer crusher for primary reduction of very large feed and a roll crusher for secondary crushing to final product size, each equipped with appropriate dust control.

Crusher Selection Decision Matrix

| Selection Criterion | Roll Crusher Preferred | Hammer Crusher Preferred |

|---|---|---|

| Air Quality Goal | Visible air (urban/sensitive sites) | Remote sites with low regulatory pressure |

| Material Type | Medium-hard rock, C&D waste, concrete | Extremely hard rock, lime, powder production |

| Product Requirement | Cubical shape, low fines, high-quality aggregate | High reduction ratio, fine product, lime powder |

| Cost Consideration | Lower total lifecycle cost (dust control included) | Lower initial purchase price (ignoring dust control) |

Application Suitability Rating (1-5: 5=Best)

C&D Waste Recycling

High-Quality Concrete Aggregate

Agricultural Lime Production

For projects where maintaining visible air quality is a primary objective—such as in urban recycling yards, sites near sensitive receptors, or operations with stringent corporate sustainability targets—the roll crusher presents a compelling advantage. Its inherently lower dust generation and simpler control requirements make it easier and less costly to achieve a clean site. It is particularly suitable for processing medium-hard to hard, non-abrasive or moderately abrasive materials where a relatively coarse product is acceptable. The hammer crusher remains the preferred choice for applications demanding very high reduction ratios in a single stage, for processing extremely hard or tough materials that resist compression, or in processes where the production of a significant amount of fines is actually desired, such as in some agricultural lime or powder production.

Application Spotlight: Construction and Demolition Waste Recycling

In C&D waste recycling facilities, material is heterogeneous, often containing wood, gypsum, and light plastics alongside concrete and asphalt. The high internal airflow of a hammer crusher can inadvertently lift and separate these light contaminants, creating a difficult-to-manage airborne mix. A roll crusher, with its minimal airflow, is less likely to disperse light materials, making the overall sorting and dust control process more manageable. The contained crushing action also produces a cleaner aggregate product with better shape, which is valuable for recycled concrete applications. This makes the roll crusher a technology often favored in modern, urban C&D recycling plants focused on product quality and environmental compliance.

Application Spotlight: Aggregate Production for High-Quality Concrete

The production of aggregates for high-strength or exposed architectural concrete demands strict control over particle shape and cleanliness. The compression-breaking action of a roll crusher tends to produce more cubical particles with fewer elongated flaky shapes and less surface dust coating compared to the impact shattering of a hammer crusher. This leads to better workability and strength in the final concrete mix. Furthermore, the lower dust generation throughout the crushing and handling process means the aggregate retains less fine particulate, requiring less washing and resulting in a higher-quality, more consistent product. In this high-value market, the roll crusher's product characteristics often justify its selection.

Practical Considerations for Cost-Constrained Operations

For small to medium-sized quarries or mobile crushing operations with limited capital, the choice often involves tough trade-offs. While a hammer crusher may have a lower initial purchase price for a given capacity, the total installed cost, including an adequate dust collection system, can negate that advantage. A pragmatic approach might involve selecting a roll crusher even at a slightly higher base cost, knowing its dust control system will be simpler and cheaper. If a hammer crusher is unavoidable due to material hardness, it is critical not to underestimate or underspecify the dust collection system. Allocating budget for proper sealing, ducting, and a correctly sized collector is essential to avoid perpetual operational problems and potential regulatory issues.

Future-Proofing Against Evolving Environmental Standards

Environmental and occupational health regulations are continuously tightening globally. Selecting crushing equipment today requires anticipation of future standards. A roll crusher, with its lower intrinsic dust generation, provides a greater safety margin against future regulatory changes. It is easier and less costly to upgrade a modest dust collection system on a roll crusher to meet new standards than to radically overhaul an already large and expensive system on a hammer crusher. This forward-looking perspective makes the roll crusher a more resilient investment, reducing the risk of the equipment becoming non-compliant or requiring prohibitively expensive retrofitting within its operational lifetime.

Operational and Maintenance Best Practices for Minimizing Dust Impact

Optimal operation and diligent maintenance are crucial for realizing the inherent dust control advantages of any crusher and for mitigating the challenges of high-dust machines. For roll crusher operators, the primary focus should be on maintaining a consistent, choke-fed condition to prevent slippage and over-crushing. Regularly checking and adjusting the roll gap ensures the product size remains on target, preventing the need for re-crushing and the associated additional dust generation. Inspection of roll surfaces for wear or polishing is important, as worn smooth rolls can increase the grinding action and fine production. A simple but critical practice is ensuring all inspection doors and housing panels are securely fastened after maintenance to preserve containment.

Daily Dust Minimization Inspection Checklist

Roll Crusher Checks

Verify consistent choke-fed condition (prevent slippage/over-crushing)

Inspect roll gap alignment (±1mm tolerance)

Check roll surface for wear/polishing (re-groove if smooth)

Ensure all housing panels are sealed (no air leaks)

Confirm dust collection hood airflow (0.5-1.0 m/s capture velocity)

Hammer Crusher Checks

Operate at minimum rotor speed for target product size

Inspect hammer wear (replace at 50% wear to avoid imbalance)

Check grate openings (maximize size to reduce recycling)

Verify shaft seals (labyrinth/pressurized bearing housings)

Monitor filter differential pressure (≤100 mm WC)

Key Operational Practices for Dust Minimization

| Practice | Roll Crusher | Hammer Crusher | Dust Reduction Impact |

|---|---|---|---|

| Feed Regulation | Vibrating feeder (steady flow) | Variable speed feeder (avoid overload) | 15-20% reduction |

| Speed Optimization | 300-500 RPM (standard) | Minimum speed for product size (≤1500 RPM) | 30-40% reduction |

| Material Conditioning | Moisture addition (5-8% for clay materials) | Cooling (for heat-sensitive materials) | 25-30% reduction |

| Wear Part Replacement | Roll re-machining (every 5,000 tons) | Hammer replacement (every 2,000 tons) | 20-25% reduction |

For hammer crusher operators, practices must aggressively target the machine's high-dust nature. Running the rotor at the minimum speed required to achieve the target product size directly reduces induced airflow and dust carryover. Similarly, operating with the maximum allowable grate opening size minimizes retention time and the attrition grinding of fines within the chamber. Perhaps most importantly, the integrity of the dust collection system must be treated as paramount. Daily checks should include verifying that all collection hoods are properly positioned, ductwork is intact and not leaking, and that the filter differential pressure is within the normal range, indicating effective cleaning. Neglecting the dust system on a hammer crusher quickly leads to a catastrophic failure of site air quality.

Developing a Proactive Inspection Checklist

A standardized, daily pre-start and operational inspection checklist is a powerful tool for dust control. Key items for any crusher should include: visual inspection for dust accumulation around seals and doors (indicating leaks), checking that all dust collection system valves are in the correct position, listening for unusual noises from the collector's fan or cleaning system, and confirming that water sprays for suppression (if used) are functioning and aimed correctly. For hammer crushers, additional checks should include ensuring hammer wear is even and that no broken hammers are causing imbalance and vibration, which can damage seals. Documenting these checks creates accountability and a historical record for troubleshooting.

Scheduled Maintenance of Wear Parts and Its Impact on Dust

Wear part replacement is not just about maintaining throughput; it has direct consequences for dust generation. In a roll crusher, heavily worn rolls lose their proper profile and nip angle, leading to inefficient crushing and increased slippage, which generates more fines. Timely re-machining or replacement of roll shells restores proper function and low-dust operation. In a hammer crusher, worn hammers and grates reduce crushing efficiency, often compensated for by increasing rotor speed or reducing grate gap, both of which exacerbate dust problems. A proactive, scheduled replacement program for hammers, grates, and liner plates, based on tonnage processed rather than waiting for failure, is essential to keep the machine operating in its optimal, lower-dust configuration.

Monitoring the Performance of the Dust Collection System

Operators can use simple, non-instrumental methods to gauge dust collector health. Observing the exhaust stack of a baghouse for any visible emissions is a clear sign of filter failure or leakage. Placing a hand near the access door of a collection hood should elicit a distinct inward draft, confirming negative pressure is being maintained. Listening to the regular, rhythmic pulse of the filter cleaning cycle indicates the automatic system is functioning. A sudden rise in the fan motor's amperage can signal a plugged filter, while a drop might indicate a torn bag or duct leak. Training operators to recognize these signs empowers them to identify and report issues before they lead to major dust releases.