Roll Crusher Safety Features: A Guide to Essential Protective Devices

Operator safety is the highest priority in any mining or aggregate processing operation. Roll crushers, like all heavy machinery, present significant hazards that must be effectively managed. This guide provides a comprehensive comparison of safety features available on modern roll crushers, from basic mechanical guards to advanced electronic systems. Understanding these features empowers buyers to prioritize investments that create a safe working environment and protect both personnel and equipment.

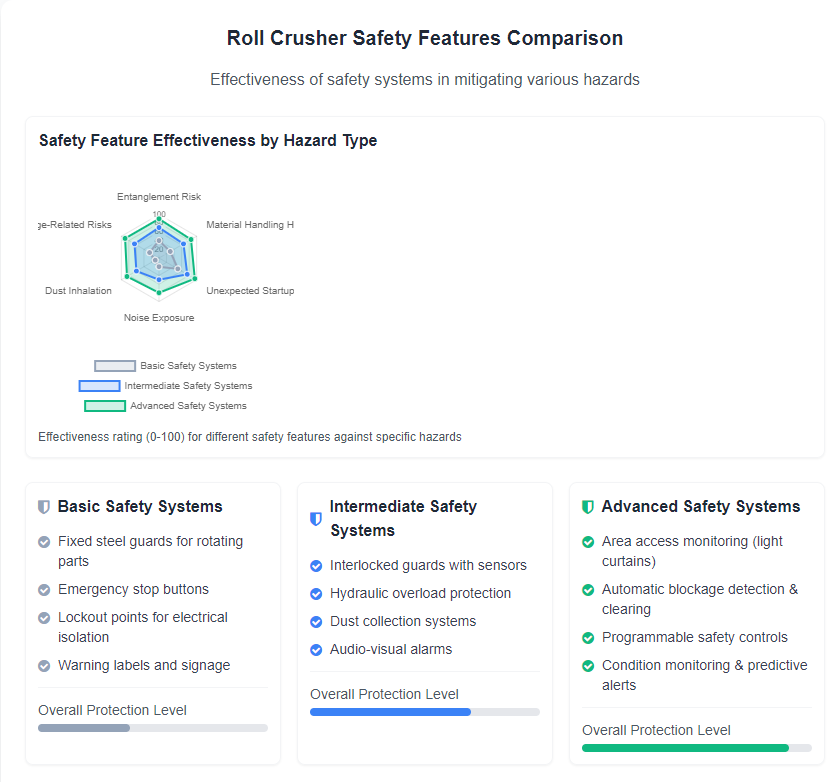

Identifying Hazards Associated with Roll Crushers

A thorough risk assessment is the foundation of any effective safety strategy. Recognizing the specific dangers posed by a roll crusher is the first step in selecting appropriate safeguards.

The Risk of Entanglement in Rotating Parts

The primary hazard of a roll crusher is the in-running nip point between the two counter-rotating rolls. Clothing, tools, or limbs can be drawn into this point with severe consequences. Additionally, drive mechanisms such as V-belts, couplings, and gears present entanglement risks if left exposed.

Effective guarding is the first and most critical line of defense against these mechanical hazards, ensuring personnel cannot accidentally contact moving parts during normal operation.

Hazards from Material Handling

The process of feeding material into the crusher and dealing with blockages presents several risks. Large rocks can fall during feeding, and attempting to clear a jam manually can expose workers to sudden material movement or the release of stored energy.

Strict procedures and engineered controls, such as remote clearing systems, are necessary to protect workers from these material-related dangers during operation and maintenance.

Dangers During Maintenance: Unexpected Startup

The most serious accidents often occur during maintenance, cleaning, or inspection when guards are removed. The unexpected startup of the machine, either manually or automatically, can have catastrophic results.

Robust energy isolation procedures, commonly known as Lockout/Tagout (LOTO), are essential to ensure the crusher is completely de-energized and cannot be operated while work is being performed.

Long-Term Health Hazards

Beyond immediate physical dangers, operators are exposed to long-term health hazards. High noise levels can lead to hearing loss, and airborne dust, particularly silica dust, can cause serious respiratory diseases over time.

Secondary safety systems, such as dust suppression and hearing protection zones, are vital for protecting the long-term health of the workforce.

Primary Safeguards: Physical Guards and Barriers

Physical guards are passive safety devices that provide a constant, physical barrier between personnel and hazards. Their design and construction are critical for effectiveness.

Design and Standards for Fixed Guards

Fixed guards must be robust, often constructed from steel mesh or solid plate, and securely attached to the machine. Their design must comply with international safety standards, which specify maximum allowable opening sizes to prevent access to danger zones while allowing for ventilation and observation.

These guards should only be removable with the use of tools, discouraging casual removal and ensuring that their replacement is a conscious act.

Interlocking Guard Systems

For guards that need to be opened regularly for inspection or maintenance, interlocking devices are essential. An interlock is a switch that automatically cuts power to the drive motor when the guard is opened. The system must be designed so that the machine cannot be restarted until the guard is securely closed again.

This functionality is crucial for areas like the feed chute, where blockages might need to be cleared periodically. The reliability of the interlock mechanism is paramount for safety.

Active Safety Systems for Operational Protection

Active safety systems monitor machine conditions and can automatically initiate a protective action to prevent an unsafe situation from escalating into an accident.

Overload Protection Mechanisms

If an un-crushable object like a metal tramp piece enters the crushing chamber, immense pressure can build up, potentially damaging the crusher or causing material to be ejected. Overload protection systems are designed to release this pressure.

This can be achieved with a mechanical shear pin that breaks under excessive force or, more commonly in modern crushers, a hydraulic system that allows the rolls to momentarily separate and then return to their set position.

Emergency Stop Systems

Clearly identified and easily accessible emergency stop buttons are a fundamental requirement. These devices must be hard-wired to immediately cut power to the crusher drive. Pull-wire emergency stop switches can be installed along the length of the crusher, allowing an operator to activate the stop from any point along the machine.

Regular testing of emergency stop functionality is a critical part of any preventative maintenance schedule to ensure they will work when needed.

Blockage Detection and Automatic Response

Modern crushers often include sensors that detect a buildup of material indicating a blockage. Upon detection, the control system can automatically reverse the rotation of the rolls for a short period to clear the jam, or it can shut down the machine and alert the operator.

This automated response prevents the crusher from becoming severely jammed, reducing the need for hazardous manual clearing and protecting the equipment from damage.

Energy Isolation for Safe Maintenance

Ensuring zero energy state during maintenance is non-negotiable. The crusher design must support and simplify proper Lockout/Tagout procedures.

Designated Lockout Points

The main electrical disconnect for the crusher should have built-in provisions for attaching multiple locks. This allows each member of a maintenance team to apply their own personal lock, ensuring the machine cannot be energized until all work is complete and all personnel are clear.

Isolation of Hydraulic and Pneumatic Systems

Beyond electrical power, potential energy stored in hydraulic and pneumatic systems must be safely released. The crusher design should include clearly marked isolation valves and bleed points to dissipate this energy before work begins.

Proper training on isolating all energy sources is essential for everyone who performs maintenance on the equipment.

Advanced Intelligent Safety Technology

Technology offers new ways to enhance safety through monitoring and control systems that reduce human exposure to hazards.

Programmable Safety Controls

Modern crushers use Programmable Logic Controllers that can manage complex safety functions. This includes ensuring the crusher can only be started in a specific sequence or only when all guards are in place and all conditions are safe.

Area Access Monitoring

Safety light curtains or laser scanners can create an invisible perimeter around the crusher. If this beam is broken by a person entering a restricted area, the system can send a warning or stop the machine entirely. This is particularly useful for large, automated crushing plants.

Condition Monitoring for Predictive Safety

Continuous monitoring of bearing temperature and vibration can serve a dual purpose. While primarily used for predictive maintenance, these systems can also alert operators to abnormal conditions that could lead to a mechanical failure, potentially creating a hazardous situation. Early detection allows for intervention before a safety incident occurs.

Integrating a cone crusher or other secondary crusher into a circuit also requires careful consideration of the entire system's safety, from the primary jaw crusher feed to the final product stockpile.

Building a Comprehensive Safety Management System

Technical safety features are most effective when integrated into a broader safety culture and management system.

Integrating Safety into Procedures and Training

Every safety feature must be explained in the equipment's Standard Operating Procedures. Operators and maintenance staff must be thoroughly trained on the purpose and function of each guard and system. Training should emphasize that safety devices are never to be bypassed or disabled.

Regular Inspection and Testing Regime

Safety systems must be regularly inspected and tested to ensure they are functional. This includes checking the integrity of guards, testing emergency stop buttons, and verifying the operation of interlock switches. A formal log of these checks should be maintained.

Investing in a roll crusher with a comprehensive suite of safety features is an investment in human well-being and operational reliability. A safe operation is a more productive and sustainable one, where personnel can perform their duties with confidence and protection.