A Guide to Inspecting and Maintaining Roll Crusher Foundations and Anchor Bolts

The foundation and anchor bolt system is the critical interface between a roll crusher and the ground, absorbing immense dynamic forces and ensuring operational stability. Often overlooked in daily operations, the integrity of this system is paramount for preventing misalignment, excessive vibration, and premature component failure. This guide provides a systematic approach to the periodic inspection, diagnosis, and maintenance of roll crusher foundations and anchor bolts. By implementing these practices, operators can proactively address issues, extend equipment service life, and ensure the long-term reliable performance of their crushing circuit.

The Critical Role of the Foundation and Anchor Bolts

Understanding the function of the foundation is key to appreciating its importance in the overall system. It acts as the stable base that manages the powerful forces generated during crushing.

Absorbing and Distributing Dynamic Loads

During operation, a roll crusher generates significant cyclic forces from the compression and breaking of rock. The massive concrete foundation's primary role is to absorb these dynamic loads and distribute them safely into the underlying soil or bedrock. A properly designed foundation has sufficient mass and area to prevent excessive movement or settlement.

If the foundation is inadequate or compromised, it cannot effectively dampen these forces, leading to increased vibration transmission that can damage the crusher itself and surrounding structures.

Maintaining Precise Equipment Alignment

The crusher's main frame is bolted to a sole plate, which is itself anchored to the foundation. The anchor bolts hold everything in precise alignment. If the foundation settles unevenly or the bolts loosen, the frame can shift. This misalignment puts undue stress on the crusher's bearings, gears, and the drive motor, leading to rapid wear and potential catastrophic failure.

Maintaining the foundation's integrity is therefore directly linked to protecting the crusher's most expensive and critical internal components.

Establishing a Periodic Inspection Regime

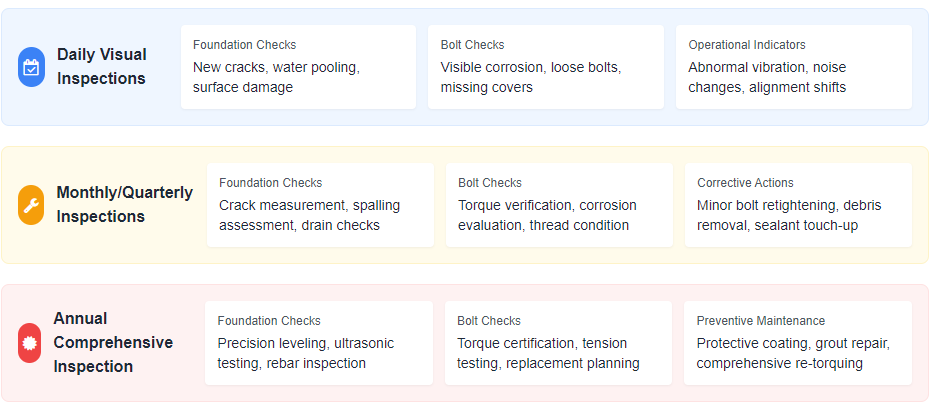

A proactive inspection schedule is essential for identifying problems early, before they escalate into major failures. This regime should include daily, monthly, and annual checks.

Key Points for Daily Visual Inspections

Operators should incorporate a brief foundation check into their daily rounds. This involves looking for obvious signs of new cracks in the concrete, checking for water pooling around the base, and listening for changes in the crusher's sound that might indicate increased vibration. A simple tactile check by placing a hand on the foundation can sometimes reveal abnormal vibrations.

These daily observations serve as an early warning system, prompting a more detailed investigation if any changes are noted.

Monthly and Quarterly Detailed Checklists

On a monthly or quarterly basis, a more formal inspection should be conducted. This involves a thorough visual examination of the entire foundation surface for cracks, spalling, or signs of chemical attack. The visible portions of the anchor bolts should be checked for severe corrosion or obvious deformation.

Using a basic wrench, technicians can perform a check for obvious bolt looseness. Any gaps between the crusher's base frame and the sole plate or between the sole plate and the concrete should be measured and recorded.

Comprehensive Annual Inspection During Major Shutdowns

The most thorough inspection occurs during an annual planned shutdown. This requires cleaning the foundation thoroughly to remove dirt and grease, allowing for a clear view of all surfaces. Detailed measurements of the foundation's level should be taken using a precision optical level or laser to detect any settlement that may have occurred over the year.

This is also the time for a detailed inspection of the anchor bolts, which may involve more advanced techniques like ultrasonic testing to check for internal defects.

Diagnosing and Remedying Common Foundation Defects

Concrete foundations can develop various issues over time. Correctly diagnosing the type and severity of the problem is essential for selecting the proper repair method.

Identifying Different Types of Cracks

Not all cracks are structurally significant. Hairline plastic shrinkage cracks that occur during the concrete's curing are typically superficial. However, cracks that are wide, deep, or actively propagating indicate more serious problems, often related to structural overloading or settlement.

Monitoring crack width over time with a crack gauge is a standard practice. Any crack that continues to widen requires immediate engineering assessment.

Repairing Spalling and Exposed Rebar

Spalling, where pieces of concrete break away from the surface, often occurs due to corrosion of the internal reinforcing steel (rebar). When rebar is exposed to air and moisture, it rusts and expands, cracking the concrete from within. Repair involves removing all unsound concrete, cleaning and treating the exposed rebar with an anti-corrosion coating, and patching the area with a high-strength, non-shrink epoxy mortar or grout.

This repair restores the structural integrity and protects the rebar from further corrosion.

Specialized Inspection and Maintenance of the Anchor Bolt System

The anchor bolts are the critical link that transfers force from the machine to the foundation. Their condition directly affects the crusher's stability.

Checking for Bolt Looseness and Preload Loss

Anchor bolts must maintain a specific preload tension to keep the crusher securely fastened. This preload can diminish over time due to vibration, a phenomenon known as relaxation. The most accurate way to check preload is by using a calibrated torque wrench or, for critical applications, a hydraulic bolt tensioner.

If bolts are found to be loose, they must be retightened to the manufacturer's specified torque value in the correct sequence to avoid distorting the crusher's base frame.

Assessing Corrosion and Physical Damage

Anchor bolts are susceptible to corrosion, especially at the thread area and at the interface where the bolt enters the concrete. Severe corrosion reduces the bolt's cross-sectional area and its load-bearing capacity. Bolts should be inspected for pitting, thinning, and thread damage.

If corrosion exceeds certain limits, the bolts must be replaced. This is a complex task that often involves drilling out the old bolts and installing new chemical or mechanical anchor systems.

Implementing a Preventive Maintenance Plan

Moving from reactive repairs to a scheduled preventive maintenance plan is the most effective way to manage foundation health.

Establishing a Re-tightening Schedule for Anchor Bolts

Based on historical data and manufacturer recommendations, a schedule for checking and re-torquing anchor bolts should be established. For new installations, bolts should be re-checked after the first 24 hours of operation, then again after 100 hours, and at regular intervals thereafter (e.g., annually).

Keeping a log of torque values for each bolt helps track their behavior over time and identify potential issues.

Protective Measures for the Foundation Surface

Applying a protective sealant or coating to the sound concrete surface can help prevent water and chemical ingress, reducing the risk of freeze-thaw damage and corrosion of the embedded steel. The area around the foundation should be graded to ensure water drains away from the structure.

These simple measures significantly extend the life of the foundation system. A well-maintained foundation is the bedrock of reliability for any roll crusher installation, ensuring it operates smoothly and efficiently for years to come.