Using Roll Crushers for Ceramic Raw Materials: Achieving Precise Fineness and Low Contamination

The quality of ceramic products, including their strength, whiteness, and sintering behavior, is profoundly influenced by the particle size distribution and purity of the raw materials. Roll crushers, with their controlled compression-breaking mechanism, are ideally suited for processing hard ceramic raw materials like quartz, feldspar, and clay. They produce uniform, cubical particles with minimal generation of undesirable fine powder and a low risk of iron contamination. This article explores how roll crushers can be optimized through precise gap control, specific roll surface designs, and process parameter adjustment to meet the exacting requirements of the ceramic industry, thereby enhancing final product quality and operational efficiency.

Ceramic Industry Specifications for Raw Material Fineness

Successful processing begins with a clear understanding of the final product's requirements. The ceramic manufacturing process imposes strict demands on the physical properties of its raw materials.

The Impact of Particle Size Distribution on Body Formation

The way ceramic particles pack together during forming processes like dry pressing or slip casting is crucial. A well-graded particle size distribution ensures dense, uniform packing, which leads to higher green strength and reduced shrinkage during firing. An excess of very fine particles can increase water demand in slurries and lead to excessive shrinkage and cracking, while too many coarse particles can result in a porous, weak fired body with a rough surface texture.

Therefore, achieving a controlled and consistent PSD from the crushing stage is fundamental to downstream manufacturing consistency.

The Need to Control Excessive Fines Generation

While some fines are necessary, an over-abundance is detrimental. Ultra-fine particles have a very high surface area, which increases their chemical reactivity during firing. This can lead to uncontrolled sintering, bloating, and warping of the ceramic piece. Furthermore, in the unfired state, high fines content can make the body overly plastic and difficult to handle.

Roll crushers are advantageous because their compression action typically produces a narrower size distribution with fewer ultra-fines compared to impact crushing methods.

The Importance of Controlling the Top Size

Controlling the maximum particle size is equally important. Large, hard particles of quartz or feldspar may not fully vitrify during the firing cycle. These particles can then pop out of the surface during polishing or, worse, create weak spots that lead to failure under thermal or mechanical stress. The top size must be carefully managed to ensure complete dissolution and reaction within the ceramic matrix.

The roll gap on a crusher is the primary control parameter for defining this top size.

The Imperative for Low Iron Contamination

Iron is a particularly harmful contaminant in whiteware and technical ceramics. Even trace amounts can impart a reddish or yellowish tint, degrading the product's aesthetic appeal and, in some cases, affecting its electrical properties. The crushing process must be designed to minimize the introduction of iron from worn crusher parts or from the ore itself.

This makes the choice of wear material for the crusher rolls a critical consideration for ceramic applications.

The Core Mechanism of Precision Crushing in Roll Crushers

The effectiveness of roll crushers for ceramic materials stems from their fundamental breaking action, which is more controlled and selective than other methods.

Controlled Compression Breaking for Uniform Particles

Roll crushers break material by applying high compressive pressure between two counter-rotating rolls. This "nipping" action causes particles to fracture along their natural cleavage planes. The result is a more controlled breakage that produces a uniform, cubical product with a lower percentage of irregular, flaky shapes and fines. This is in contrast to impact crushers, which shatter particles indiscriminately, generating a wider size distribution and more fines.

For ceramic applications, this controlled breakage is ideal for achieving the desired packing density and reactivity.

Quasi-Static Pressure and Mineral Liberation

The compression force applied by roll crushers is often described as "quasi-static," meaning it is applied more slowly than a dynamic impact. This type of force is particularly effective at liberating minerals along their grain boundaries without over-grinding the individual mineral grains. This results in particles with cleaner surfaces, which is beneficial for subsequent processes like magnetic separation to remove impurities.

This selective breaking action helps preserve the integrity of the valuable ceramic minerals.

The Roll Gap as the Primary Control Parameter

The distance between the two rolls, known as the roll gap, is the most direct factor determining the product's top size. A smaller gap produces a finer product, while a larger gap yields a coarser one. The relationship between feed size, roll gap, and product size is relatively predictable, allowing for precise control over the final output.

Modern roll crushers with hydraulic gap adjustment allow operators to easily fine-tune the product size to meet specific ceramic recipe requirements.

Key Selection and Configuration Criteria for Ceramic Applications

Choosing the right roll crusher and configuring it correctly is essential for meeting the stringent demands of ceramic production.

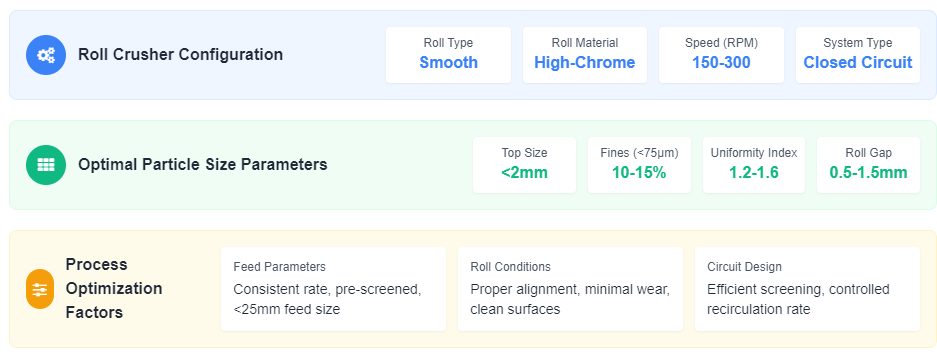

Smooth Rolls vs. Toothed Rolls for Different Materials

The choice of roll surface is important. Smooth rolls are typically preferred for ceramic raw materials as they provide a clean compression break, minimizing fines and producing a well-shaped particle. They are ideal for hard, abrasive materials like quartz. Toothed or corrugated rolls introduce a shredding action that can be beneficial for breaking up clay agglomerates or sticky materials, but they may produce a slightly higher fines content and incur greater wear.

The selection should be based on the characteristics of the predominant material in the feed.

Selecting Roll Materials to Minimize Iron Contamination

To achieve the low iron contamination required for high-quality ceramics, the roll shells should be made from materials that are highly wear-resistant and non-contaminating. High-chromium cast iron is a common choice due to its excellent abrasion resistance. For the most sensitive applications, rolls with ceramic liners or a tungsten carbide overlay can be used, virtually eliminating iron contamination from wear.

This choice directly impacts the purity of the final product and its suitability for premium ceramic applications.

The Role of Pre-screening and Closed-Circuit Systems

To achieve a tight particle size distribution, a closed-circuit crushing system can be highly effective. In this setup, the material from the roll crusher is fed onto a screen. The oversize material is recirculated back to the crusher feed, while the correctly sized product is sent to storage. This ensures that no oversized particles leave the circuit and allows for precise control over the final product's top size.

This method is more capital-intensive but is often justified by the superior product quality and consistency it delivers.

Optimizing Process Parameters for Target Particle Size

Fine-tuning the operational parameters of the roll crusher is necessary to consistently hit the target particle size distribution.

Establishing the Optimal Roll Gap Through Testing

The optimal roll gap setting is determined empirically for each specific material. Laboratory tests or small-scale production trials are conducted where the crusher is run at different gap settings. The output is then analyzed using sieve analysis to determine the resulting PSD. This data is used to create a model that correlates gap setting with product fineness for the given feed material.

This scientific approach replaces guesswork and ensures consistent product quality.

Optimizing Feed Rate for Efficient Breaking

The rate at which material is fed into the crusher affects the efficiency of the breaking process. A feed rate that is too high can overwhelm the rolls, leading to poor size reduction and potential choking. A feed rate that is too low reduces throughput and can cause unnecessary wear as the rolls may slip against the material. An optimized, steady feed rate ensures each particle has a high probability of being nipped and broken efficiently.

Vibratory feeders are commonly used to achieve this consistent and controlled feed.

Quality Control and the Application of Online Monitoring

Maintaining consistent quality requires robust monitoring and control systems to detect deviations from the target specifications.

Regular PSD Analysis Using Laser Diffraction

The industry standard for measuring particle size distribution is laser diffraction analysis. Regular samples of the crushed material should be taken and analyzed in a laboratory using such an instrument. This provides accurate data on the entire size distribution, allowing operators to confirm that the product meets specification and to make adjustments to the crusher parameters if necessary.

This objective data is essential for quality assurance and customer satisfaction.

Configuration and Efficiency of Magnetic Separation

Even with careful roll material selection, some iron contamination is possible. Powerful permanent magnets or electromagnetic separators should be installed on the conveyor leaving the crusher. The efficiency of these separators must be regularly checked by taking samples before and after the magnet and testing their iron content.

This ensures that the final product achieves the required low levels of ferrous contamination.

Utilizing a roll crusher specifically configured for ceramic raw materials is a highly effective strategy for achieving the precise discharge size and exceptional purity required by modern ceramic manufacturers, directly contributing to the production of high-value end products.