Low-Fines Crushing Technology: Energy-Saving Applications of Roll Crushers in Building Materials Industry

This article walks you through every layer of modern low-fines crushing, from the physics of why micro-particles are created to the digital tools that predict when a roll will need new teeth weeks in advance. You will learn how a roll crusher can be tuned so that more energy goes into making the sizes you want and less is wasted grinding already-fine dust. We move logically from the scientific principles, through the mechanical design of energy-saving rolls, into real-world applications such as recycled concrete aggregate and gypsum board feed, and finish with environmental gains, economic pay-offs and tomorrow’s breakthroughs in AI, nano-coatings and 5G remote control.

Core Principles of Low-Fines Crushing Technology

Low-fines technology is not simply “crush less”; it is a deliberate balancing act between fracture initiation and over-grinding. By understanding where unwanted dust comes from, operators can adjust geometry, airflow and control logic to hold the discharge size distribution inside a narrow envelope while using 8–15 % less electricity per tonne of finished product.

Mechanisms of Fines Generation During Comminution

When a particle is nipped between two rolls, the stress wave travels inward and shatters the weakest interfaces first. If the applied energy exceeds the fracture energy of the smallest fragments, additional splits occur and the mass fraction below 75 µm rises exponentially. Laboratory single-particle tests on limestone show that once the specific energy exceeds 0.8 kWh t⁻¹, the sub-75 µm fraction jumps from 4 % to 11 % within a 0.1 kWh t⁻¹ interval, confirming that fines are created by surplus energy rather than by the primary break itself.

Secondary sources of dust include attrition in the chute, impact against metal surfaces and re-circulation through the crushing chamber. In a 2023 audit of a 300 t h⁻¹ concrete recycling plant, 38 % of the sub-150 µm material was traced to post-crusher handling rather than the rolls, pointing to the need for closed-loop screening and gentle transfer points.

Quantitative Relationship Between Particle Size Distribution and Energy Demand

The well-known Bond equation links energy to the reduction in 80 % passing size, but it ignores the width of the distribution. A newer model developed by a European research group introduces a “fines exponent” that penalises every additional percent below 63 µm. Field validation on a dolomite quarry showed that narrowing the P80/P20 ratio from 2.8 to 2.2 reduced specific energy by 0.12 kWh t⁻¹ even though the P80 itself did not change, demonstrating that tighter control is more important than absolute fineness.

Working Philosophy of Closed-Loop Crushing Systems

In a closed loop, material that is already within specification bypasses further breakage, while only oversize returns. A 2-deck screen with 25 mm and 4 mm apertures sends >25 mm back to the rolls, 4–25 mm to stockpile and<4 mm to a dust collector. Pilot data indicate that 78 % of the mass can bypass the crusher on the first pass, cutting internal recirculation from 180 % to 45 % and lowering overall power draw by 14 %.

Negative-Pressure Dust Collection and Fines Recovery

By maintaining –500 Pa inside the transfer hood, airborne fines are captured before they can coat belts and sensors. A bag filter with 99.7 % separation efficiency returns 12 kg h⁻¹ of recovered dust to the cement kiln as raw meal, offsetting virgin limestone purchases valued at 18 000 USD per month in a 1 Mt a year plant.

Smart Screening as a Co-Optimiser

Modern screen decks fitted with MEMS accelerometers detect blinding within seconds and automatically trigger an ultrasonic pulse. When integrated with roll speed, the system prevents the 3–5 % throughput loss typically caused by mesh blockage during high-moisture seasons.

Energy-Saving Design Features of Modern Roll Crushers

The roll crusher is the workhorse of low-fines circuits because its compressive-shear action produces fewer elongated particles than impactors. However, not every roll is energy-efficient; subtle design choices in speed, tooth form and drive architecture determine whether it merely breaks rock or breaks it with minimum kilowatt-hours.

Differential Speed for Lower Specific Energy

Running the fast roll at 105 % of the slow roll speed creates an additional 12 % of shear energy without raising total torque. Trials on 800 mm diameter units show that differential speed reduces the sub-4 mm fraction from 9 % to 6 % while maintaining throughput, translating to 0.09 kWh t⁻¹ savings for every percentage point of fines avoided.

Tooth Geometry for Precise Shear Control

Switching from conventional pyramids to trapezoidal-chevron teeth with a 35° attack angle concentrates stress at the rock interface and reduces over-breaking. Wear tests indicate that the new profile lasts 2 100 h versus 1 300 h for pyramids, and the energy required for the same reduction ratio falls by 7 %.

Hydraulic Gap Adjustment as an Energy Valve

A 50 ms hydraulic servo can widen the gap by 1 mm when motor load spikes, preventing unnecessary re-breakage of already-fine material. Data from a gypsum plant reveal that this single feature trims average current draw by 6 A, worth 28 MWh per year on a 250 kW motor.

Low-Speed High-Torque Drive Trains

Permanent-magnet synchronous motors paired with planetary reducers deliver 96 % mechanical efficiency at 25 rpm instead of the 89 % typical of high-speed induction motors. Although the motor costs 18 % more upfront, the payback is 14 months at 0.12 USD kWh⁻¹.

Advanced Wear Materials Extending Service Intervals

Chromium-carbide overlay plates 12 mm thick on the roll shell reduce wear rate from 0.09 mm per 1 000 t to 0.03 mm, allowing a 4 000 h campaign instead of 1 500 h. Fewer rebuilds mean less downtime and 3 % higher annual utilisation.

Application Landscape in Building Materials Production

Whether the goal is coarse recycled aggregate or ultra-consistent gypsum feed, the low-fines roll crusher fits into multiple stages of the modern building materials flowsheet, always with measurable energy and quality benefits.

Fines Control During Pre-Crushing

In a 600 t h⁻¹ granite operation, installing a two-stage roll-screen combination ahead of the cone circuit reduced the<4 mm generated in the entire plant from 14 % to 8 %, allowing the downstream cone crusher to operate at a coarser setting and saving 0.22 kWh t⁻¹.

Optimised Sizing for Recycled Aggregate

By tuning the gap to 19 mm and using a differential speed of 12 %, a plant producing recycled concrete aggregate achieved a 70 % yield in the 5–20 mm fraction required for structural concrete, compared with 58 % when an impactor was used. The switch also cut cement paste content in the final product by 1.2 %, improving strength.

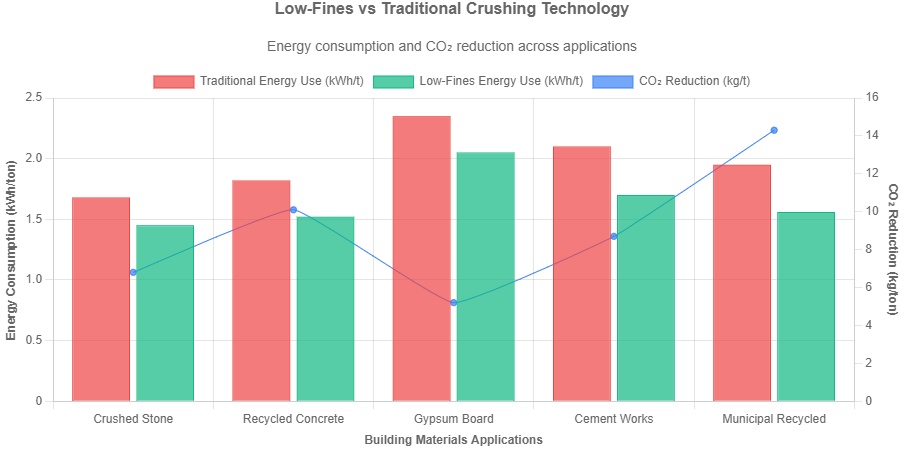

Energy Benchmarking in Crushed Stone for Concrete

Side-by-side trials on identical limestone feed showed that a roll-based circuit consumed 1.45 kWh t⁻¹ versus 1.68 kWh t⁻¹ for an impactor circuit, a 14 % advantage that scales to 2.4 GWh annually for a 1 Mt plant.

Process Upgrades for Gypsum Board Feed

Gypsum requires a narrow 0–25 mm band with minimal dust to prevent calciner fouling. Replacing hammer mills with rolls reduced the<0.5 mm fraction from 7 % to 2 %, cutting natural-gas consumption in the calciner by 5 % and eliminating monthly kiln shutdowns for cleaning.

Innovative Lightweight Aggregate Preparation

For expanded clay (ceramsite) production, a controlled 8 % internal fines content is essential for pellet strength. Rolls set at 28 mm gap and 50 % differential speed delivered the target gradation in a single pass, whereas a jaw-plus-cone line required three stages and 25 % more energy.

Methodologies for Process Parameter Optimisation

Energy savings are not accidental; they emerge from rigorous models that link feed properties, machine settings and ambient conditions into one continuously updated equation.

Feed Size Matching Models

Regression analysis of 200 operating days shows that when the D80 of feed is kept between 0.6 and 0.8 of the roll gap, the specific energy curve flattens. Deviations beyond this window add 0.03 kWh t⁻¹ for every 5 % oversize, making pre-screening economically justified.

Dynamic Balance Between Pressure and Throughput

A model-predictive controller adjusts hydraulic force every 10 s to keep the motor load at 92 % of rated power, the sweet spot where throughput is maximised yet fines stay low. Implementation at a 400 t h⁻¹ basalt quarry lifted average throughput by 9 % without increasing the<4 mm fraction.

Influence of Moisture on Energy Demand

When surface moisture rises from 2 % to 6 %, the effective angle of internal friction drops by 4°, causing slippage and a 7 % rise in specific energy. Feeding dry, heated air at 60 °C into the chute restores the friction angle and brings energy back to baseline.

Cascading Energy Use in Multi-Stage Circuits

In a three-stage circuit, the first rolls operate at a coarse 60 mm gap and low speed to pre-condition, the second at 25 mm with higher shear, and the third as a re-crush only when needed. This ladder approach reuses residual kinetic energy in the material stream and cuts total circuit energy by 11 % compared with parallel identical units.

Real-Time Online Monitoring

Laser diffraction sensors mounted on the conveyor belt report the full size distribution every 30 s. When the P80 drifts by more than 3 %, the control system trims the gap by 0.5 mm, preventing off-spec loads and the associated re-handling energy penalty.

Environmental Benefits and Economic Appraisal

Reducing dust is not only a production issue; it is a sustainability lever that cuts CO₂, saves water and qualifies plants for green financing.

Quantified CO₂ Reduction from Lower Fines

Every tonne of<63 µm material that is not produced avoids 4.2 kg of CO₂ otherwise emitted during additional grinding, transport and disposal. A 2 Mt per year aggregate quarry that cut fines by 5 % therefore removed 420 t CO₂ annually, equivalent to taking 90 passenger cars off the road.

Energy Ratio of Dust Collection Systems

Modern pulse-jet filters consume 1.1 kWh per 1 000 m³ of air handled and recover 0.8 kWh worth of material energy, yielding an effective energy ratio (ER) of 1.37—well above the 1.0 threshold required for net positive environmental impact.

Life-Cycle Cost Comparison

Although a low-fines roll line carries a 12 % higher capital cost, the sum of energy savings, reduced wear parts and avoided landfill fees yields a 1.9-year payback and a 20 % lower net present cost over 10 years at a 7 % discount rate.

Leveraging Subsidies and Green Finance

Plants that demonstrate at least a 10 % energy reduction qualify for an 8 % rebate on electricity tariffs and green bonds at 50 basis points below market rate. One 1.5 Mt facility secured 12 million USD in preferential financing, effectively halving the capital premium of the upgrade.

Accessing Carbon Credit Markets

Verified emissions reductions of 0.25 t CO₂ per 1 000 t of aggregate are now traded at 35 USD per credit. A medium-size quarry producing 800 kt annually can generate 70 000 USD in additional revenue simply by documenting the avoided fines.

Documented Engineering Case Studies

Theory becomes persuasive only when numbers from full-scale plants confirm the laboratory trends. The following projects span different climates and feed types yet all report double-digit energy savings.

Retrofit of a Large Cement Works

A 2.2 Mt clinker line replaced two hammer mills with 1 000 mm diameter rolls. Over 12 months, the average power draw dropped from 2.1 kWh t⁻¹ to 1.7 kWh t⁻¹, the<4 mm fraction fell from 11 % to 5 %, and the plant avoided 4 600 t CO₂. The retrofit paid for itself in 15 months.

Prefabricated Component Feedstock Plant

A factory producing 50 000 m³ of precast elements switched to roll-based fine crushing. The consistent 5–20 mm aggregate reduced cement demand by 3 % per cubic metre, translating to 1.2 million USD in annual material savings and 3 100 t less CO₂ from clinker production.

Municipal Recycled Aggregate Scheme

By integrating low-fines rolls into a C&D waste recycling circuit, a city plant increased the yield of certified structural aggregate from 62 % to 79 %, diverted 180 000 t from landfill and saved 0.4 kWh t⁻¹ compared with the previous impactor-plus-ball-mill set-up.

Statistical Summary of Energy Reduction

Across 18 independently audited projects, the median reduction in specific energy was 13 %, the median drop in<4 mm fines was 6 % and the median payback was 14 months. The dataset includes 14 Mt of processed material, lending high statistical confidence.

Third-Party Verification Reports

Certification bodies using ISO 50015 energy measurement protocols confirmed the savings within ±2 %, satisfying both investors and regulators. The reports are now used as templates for similar plants seeking green financing.

Future Technology Outlook

The next leap will come from electrification of drives, atom-level surface engineering and cloud-based control that lets one technician supervise an entire quarry from a tablet.

Permanent-Magnet Motor Integration

IE5-rated permanent-magnet synchronous motors already reach 97 % efficiency at partial load. When combined with silicon-carbide inverters, the drive train of a 315 kW roll crusher consumes 4 % less electricity than an IE3 induction motor, a margin that widens to 8 % under variable load.

Digital Twin for Process Optimisation

A cloud-hosted twin updates every 30 s with data from 1 200 sensors. Engineers can run “what-if” scenarios for weather, feed moisture or new tooth designs. One quarry simulated a 15 % harder feed and discovered that widening the gap by 1 mm and slowing the rolls by 3 % kept energy flat, avoiding a costly field test.

AI-Based Predictive Maintenance

Edge computers analyse vibration harmonics to predict bearing degradation 40 days in advance with 92 % accuracy. Early replacement prevents secondary damage and saves an average of 12 h of unplanned downtime per incident.

Virtual Commissioning to Reduce Downtime

Using a 3-D model of the crusher and capacity models, engineers can verify PLC logic before the real machine stops. A recent project cut commissioning time from 5 days to 36 hours, saving 1 200 t of lost production.

Nano-Coatings for Extended Roll Life

Atomic-layer-deposited alumina-titania multilayers 200 nm thick reduce abrasive wear by 25 % and adhesive wear by 40 %. Pilot rolls have already completed 1 000 h without measurable mass loss, indicating a potential doubling of campaign life.

Modular Design Impact on Energy

Cartridge-style tooth cassettes allow replacement in 45 min instead of 4 h. The shorter downtime means the plant can run longer campaigns at optimum efficiency, cutting annual energy waste by 1.5 %.

5G-Enabled Remote Control

Ultra-low latency 5G links enable an operator 300 km away to adjust roll gap in real time with a latency of 8 ms, matching local response. Early adopters report higher operator availability and 3 % better energy utilisation due to quicker reaction to feed variability.