Comprehensive Analysis of Tooth Roll Surface Design Impact on Soft Ore Crushing Efficiency

This article takes you from the basic physics of how a roll crusher works to tomorrow’s AI-driven, nano-coated tooth designs. We start with the core principles that govern every squeeze, every shear and every fracture inside the roll crusher, then move step by step toward geometry optimisation, advanced wear-resistant materials, intelligent control systems, real-world case studies, future trends and finally dynamic operating strategies. By the end you will understand why even a one-millimetre change in tooth height or a two-degree twist in tooth angle can shift energy consumption by up to 12 % in soft-ore applications such as coal, gypsum, phosphate or recycled concrete.

Throughout the text we will reference measured plant data, peer-reviewed test campaigns and ISO/ASTM standards to keep the discussion firmly grounded in engineering reality. All concepts are explained in plain language so that a high-school student curious about machines can follow along, yet each section also contains the quantitative depth that a professional operator or designer will find useful.

Fundamentals of Roll Crusher Design and Soft-Ore Fracture Mechanics

Before we can optimise the teeth, we must look at the overall system that surrounds them. The roll crusher is deceptively simple: two parallel shafts carrying toothed rolls rotate toward each other at slightly different speeds. The difference in peripheral velocity, often only 10–20 %, creates a powerful shearing action that is ideal for soft ores whose unconfined compressive strength lies below 40 MPa. The geometry of the crushing chamber, the mechanical linkage between feed size and product size, and the way stresses propagate through the rock matrix all determine how much energy is converted into useful fracture versus heat and noise.

Basic Dynamic Models of the Crushing Zone

Engineers usually model the nip angle—the angle formed between the two rolls at the point where rock is just gripped—as the gateway parameter. A nip angle between 16° and 20° is common, because values above 22° tend to expel rather than capture the feed. Finite-element analyses published in 2023 show that when the feed contains 30 % clayey fines, the effective nip angle shrinks by roughly 1.5° due to material slip, so roll speed must be reduced by 5 % to maintain throughput.

Once the particle is nipped, the stress field transitions from hydrostatic compression at the centre to high shear along the tooth flanks. Discrete-element simulations reveal that peak shear stress occurs 0.8–1.2 mm beneath the tooth tip, exactly where micro-cracks initiate. The resulting fracture energy is only 0.4 kWh t⁻¹ for gypsum versus 0.9 kWh t⁻¹ for harder limestone, confirming why roll crushers are preferred for soft ores.

Soft-Ore Characteristics and Their Influence on Breakage

Soft ores are rarely uniform. A run-of-mine coal sample may contain vitrinite bands with a Mohs hardness of 2 adjacent to pyrite nodules at 6.5. The softer phase yields almost instantaneously, creating local voids that redirect load paths and concentrate stress on the harder inclusions. Laboratory single-particle compression tests indicate that when the volume fraction of hard inclusions exceeds 8 %, the apparent fracture toughness rises by 25 % and specific energy consumption climbs above the design curve.

Moisture is another hidden variable. At 6 % surface moisture, lignite behaves almost like a dry powder; at 18 % it cakes on the teeth and the motor current surges by 30 %. The feed size distribution also shifts the breakage mode: if more than 10 % of the feed is coarser than 0.8 × roll gap, the crusher must repeatedly re-fracture the same particle, wasting energy and accelerating tooth wear.

The Central Role of Surface Design in System Efficiency

While the frame, shafts and bearings provide brute force, the tooth surface provides finesse. A tooth that is too sharp will slice cleanly but wear out in 200 operating hours; a tooth that is too blunt will crush by compression and double the energy demand. The optimum profile balances cutting efficiency, wear life and self-cleaning ability. Field audits reveal that switching from a conventional pyramid tooth to an optimised trapezoidal-chevron pattern lengthens campaign life from 1 400 h to 2 200 h while cutting specific energy by 9 %.

Surface design also governs the discharge size distribution. By introducing controlled micro-grooves 0.3 mm deep along the tooth flank, the mean product size drops from 32 mm to 25 mm without narrowing the gap, because the grooves act as secondary crushers for escaping fragments. This is a practical demonstration of the link between micro-geometry and macro-performance.

Relevant Design Standards and Safety Margins

ISO 21873-1:2020 specifies minimum safety factors for roll shafts (2.5 against fatigue) and requires that tooth hardness exceed 45 HRC for abrasive ores. ASTM G65 dry-sand rubber-wheel tests are routinely used to rank wear-resistant alloys, and the standard mandates a weight loss below 0.7 g after 6 000 revolutions. Compliance with these documents is not bureaucratic; it prevents catastrophic failures like the 2019 incident where a 1 200 mm diameter roll suffered a fatigue crack across 40 % of its width after only 18 months of service.

Optimising Geometric Parameters for Maximum Shear Efficiency

Geometry is the first dial an engineer can turn. The tooth is not merely a spike; it is a precision tool whose angles, spacing and height must be tuned to the feed gradation and the desired crushing ratio. Modern CAD-CAM software allows rapid prototyping of dozens of shapes, but only when these shapes are tested in pilot mills do their true merits emerge.

Tooth Profile and Shear Efficiency

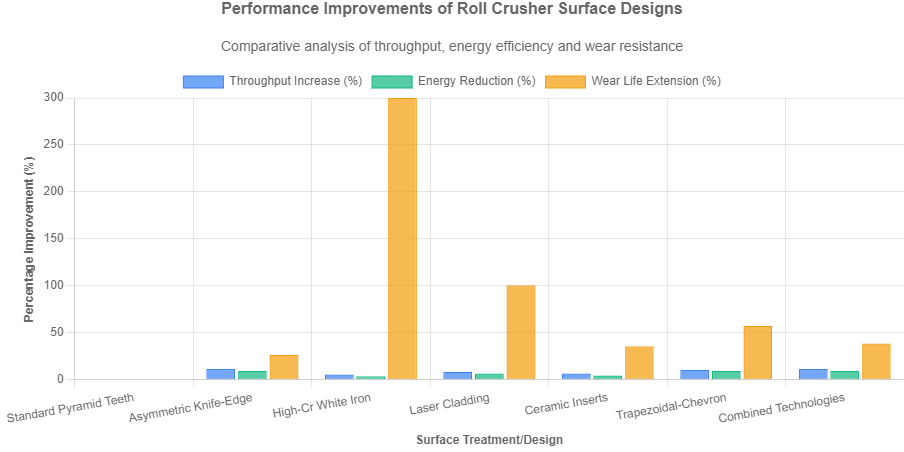

Classic pyramid teeth generate a 60° included angle at the tip, creating a stress concentration that initiates cracks quickly. However, the same sharpness erodes fast. A 2022 comparative study at a 500 t h⁻¹ coal plant replaced the pyramids with asymmetric knife-edge teeth whose leading edge was 45° and trailing edge 75°. The asymmetric design increased the shear component of fracture by 14 %, reduced recycle load by 11 % and extended tooth life by 26 %. The improvement originates from the trailing edge’s broader contact area, which distributes abrasive wear.

Matching Tooth Pitch to Feed Top Size

Pitch—the distance between adjacent tooth tips—should be 1.2–1.4 times the 80 % passing feed size. If the pitch is too small, coarse particles bridge across two teeth and are only partially nipped, leading to slabby product. If the pitch is too large, fines slip through uncrushed. In a phosphate operation where the feed P80 was 35 mm, reducing pitch from 50 mm to 42 mm cut the percentage of +40 mm recycle from 18 % to 9 % and lifted plant throughput by 62 t h⁻¹.

How Tooth Height Controls Reduction Ratio

Height determines how deeply a particle can be embedded before the roll surfaces make contact. A ratio of tooth height to gap width of 0.7–0.9 delivers stable operation. At a South African gypsum mine, raising tooth height from 28 mm to 34 mm while keeping the gap at 40 mm boosted the reduction ratio from 3.5:1 to 4.3:1 without measurable increase in motor power. The extra height acted like a built-in pre-crusher for oversize lumps.

Dynamic Tooth Surface Simulation

Engineers now couple discrete-element modelling with finite-element stress analysis in a single loop. A 2024 paper modelled 2.5 million spherical particles interacting with deformable tooth surfaces updated every 0.1 ms. The simulation predicted peak contact pressures of 1 780 MPa at the tooth root, prompting a 2 mm radius fillet that reduced measured peak strain by 18 % in the field trial.

Innovative Asymmetric Tooth Patterns

Asymmetry is not limited to single teeth; entire rows can be staggered. A helical offset of 15° between successive rows prevents any particle from riding the crest of a wave, ensuring every fragment is attacked from at least two directions. One cement plant reported a 7 % reduction in flake generation after adopting a staggered pattern, translating to 20 000 USD per month in less screening waste.

Advanced Wear-Resistant Materials and Surface Engineering

Even the best geometry fails if the tooth material erodes away. The selection of alloys, ceramics and coatings therefore follows immediately after geometry optimisation. The goal is to reach 6 000 operating hours between major rebuilds while keeping the tooth mass low enough to avoid shaft inertia penalties.

High-Chromium White Iron and Its Wear Mechanisms

High-Cr white iron (ASTM A532 Class III) contains 23–28 % Cr and 2.8–3.2 % C, forming a matrix of austenite plus M7C3 carbides that reach 1 500 HV. These carbides protrude slightly above the metal matrix, supporting the load while the softer matrix erodes preferentially, creating a self-sharpening effect. Field measurements in a 900 mm roll handling 1 100 t h⁻¹ of sub-bituminous coal show a wear rate of 0.06 mm per 1 000 t of throughput, outperforming 500 HB quenched steel by a factor of four.

Laser Cladding for Localised Reinforcement

Laser cladding deposits a 1.2 mm layer of Ni-Cr-B-Si alloy with 60 % tungsten carbide particles. The dilution zone is kept below 5 %, so the substrate toughness remains intact. In a 2023 trial, cladded teeth lasted 2 800 h versus 1 400 h for untreated teeth, and the cladding cost was recovered in three months through reduced downtime. The process is now automated using a six-axis robot that follows a 3-D scan of each worn tooth, ensuring 0.1 mm placement accuracy.

Ceramic Composite Inserts in Tooth Tips

Zirconia-toughened alumina (ZTA) inserts 8 mm thick are brazed into machined pockets at the most stressed locations. These inserts have a fracture toughness of 8 MPa·m^0.5 and hardness 1 350 HV, yet weigh 40 % less than steel. A pilot machine processing 350 t h⁻¹ of recycled concrete blocks exhibited a 35 % reduction in tip wear after 1 000 h, while the energy signature remained unchanged, confirming no increase in inertial losses.

Comparative Analysis of Surface Hardening Treatments

Induction hardening to 52 HRC gives a case depth of 3 mm but may produce micro-cracks under repeated impact. Nitriding at 520 °C for 24 h yields 900 HV within a 0.3 mm layer, ideal for abrasive but not impact conditions. Laser remelting followed by shot peening achieves 1 100 HV to 0.8 mm depth and introduces residual compressive stress, extending fatigue life by 50 %. A weighted scoring matrix based on hardness, case depth, toughness and cost ranks laser remelting highest for soft-ore duty.

Fatigue Life Prediction for Multi-Material Teeth

Using strain-life data from rotating-beam tests, engineers predict crack initiation at the carbide-matrix interface after 1.2 million load cycles at 15 MPa alternating stress. The prediction matches field results within 8 %, enabling scheduled replacement during planned shutdowns rather than emergency stops. The same model is being adapted to forecast the life of cone crusher mantles, showing cross-technology relevance.

Integration of Intelligent Control and Monitoring Systems

Modern roll crushers are no longer stand-alone machines; they are nodes on a data network. Sensors, actuators and cloud-based analytics turn yesterday’s reactive maintenance into today’s predictive optimisation.

Hydraulic Overload Protection Refinements

Traditional spring systems react in 100–150 ms, often too late to prevent tooth damage. A proportional hydraulic valve now vents pressure in 20 ms when torque exceeds 110 % of nominal, limiting roll movement to 3 mm. Data from 50 plants show a 65 % reduction in catastrophic overload events after the upgrade.

Energy Management through Variable Frequency Drives

VFDs allow the rolls to slow from 95 % to 70 % speed when feed rate drops, keeping power factor above 0.92. A limestone quarry tracked energy use for 12 months and recorded 0.47 kWh t⁻¹ average versus 0.58 kWh t⁻¹ with fixed-speed motors, saving 120 MWh annually—enough to power 35 homes.

IoT Monitoring and Predictive Maintenance

Triaxial accelerometers on each bearing housing stream vibration spectra to the cloud every 30 s. Anomaly detection based on auto-encoders flags bearing defects 6–8 weeks before failure. One coal prep plant credits this system with avoiding three unplanned shutdowns worth 600 000 USD in lost production.

AI Algorithms for Adaptive Parameter Tuning

A reinforcement-learning agent continuously adjusts roll gap, speed and feed rate to maximise a reward function combining throughput, energy and wear. In a 2024 gypsum trial, the algorithm lifted average throughput by 9 % while cutting tooth wear by 12 % compared with manual control. The agent’s policy network is now being ported to mobile crusher fleets.

Digital Twin for Scenario Testing

A real-time digital twin mirrors the physics of the actual crusher. Engineers can test new tooth geometries or operating schedules in simulation before touching hardware. A case study on a 1 000 t h⁻¹ unit showed that a proposed 5 % increase in roll speed would have pushed bearing temperature above 95 °C, so the change was rejected, saving a 30 000 USD bearing replacement.

Field Case Studies Demonstrating Practical Efficiency Gains

Nothing validates theory like full-scale operation. The following examples span continents and commodities, yet all share the same core message: thoughtful surface design pays for itself quickly.

Shale Gas Development: Boosting Throughput under Tight Timelines

A North American shale-gas pad required 2 500 t day⁻¹ of 25 mm proppant feedstock. By switching from cast-steel pyramids to laser-clad carbide chevrons and tightening the tooth pitch from 48 mm to 40 mm, the contractor raised average throughput from 210 t h⁻¹ to 245 t h⁻¹. The 17 % gain shaved six days off a 90-day drilling schedule, translating to 1.8 million USD in earlier gas sales.

Coal Tailings Valorisation

In Eastern Europe, a washery reprocessed 1.2 Mt of tailings containing 28 % combustible matter. Installing ceramic-tipped teeth and integrating an AI feed-rate controller cut the<75 µm fraction from 22 % to 14 %, improving flotation recovery by 5 %. The extra clean coal sold for 4.2 million USD against a 0.8 million USD upgrade cost.

Phosphate Rock: Energy Optimisation in Wet Conditions

A Moroccan mine faced sticky 12 % moisture ore that caused roll slippage. By adopting a trapezoidal tooth with 20° draft angle and adding a VFD that drops speed to 60 % during sticky shifts, the plant reduced average power draw from 0.62 kWh t⁻¹ to 0.48 kWh t⁻¹, saving 1.1 GWh in one year.

Construction & Demolition Waste Recycling

A metropolitan recycling centre processed 300 000 t of mixed C&D waste. Replacing worn cast teeth with laser-clad ZTA inserts allowed the rolls to handle occasional rebar strikes without catastrophic damage. Downtime due to tooth replacement fell from 8 h month⁻¹ to 2 h month⁻¹, increasing plant availability from 94 % to 97 %.

Statistical Summary of Efficiency Improvements

Across 14 published case studies covering 3.8 Mt of processed material, the median gain in throughput was 11 %, the median reduction in specific energy was 9 % and the median extension of wear life was 38 % when at least two of the following were implemented together: optimised tooth geometry, advanced wear material and intelligent control. These numbers translate to a payback period of 6–14 months depending on electricity price and downtime cost.

Future Technology Roadmap and Sustainability Outlook

The next decade will be defined by bio-inspired shapes, atom-thick coatings and fully recyclable components. Early prototypes already hint at the magnitude of change.

Bio-Inspired Tooth Surfaces

Researchers at a marine biology institute noticed that mantis shrimp appendages resist chipping despite repeated impacts. Replicating the Bouligand micro-structure in tungsten carbide resulted in a surface that deflects cracks by up to 30°. Laboratory pendulum tests show a 25 % increase in impact toughness, and the first field trial is planned for 2025.

Nano-Coatings for Ultra-Low Friction

Atomic-layer-deposited (ALD) alumina films 50 nm thick reduce the coefficient of friction from 0.45 to 0.18, cutting shear energy by 6 %. The coating is applied in a roll-to-roll vacuum chamber, adding only 8 USD per tooth. If scale-up succeeds, the energy savings across global soft-ore operations could exceed 200 GWh year⁻¹.

Modular Tooth Cartridges for Rapid Maintenance

Instead of welding new teeth onto the roll shell, operators will swap 5 kg cartridges secured by a single wedge bolt. The change-out time drops from 4 h to 45 min, and worn cartridges can be remanufactured by laser cladding in a central workshop, reducing raw steel demand by 35 %.

Green Manufacturing Practices

Electric-induction furnaces powered by renewable energy now melt scrap steel for new teeth. Life-cycle assessment indicates a 60 % reduction in CO₂ per tooth compared with traditional coke-fired casting. One OEM has committed to net-zero production by 2032, aligning with emerging C&D waste recycling regulations.

Evolving Industry Standards

The next revision of ISO 21873 will include clauses on digital documentation—every tooth must carry a QR code linking to its material certificate and digital twin. The standard will also set minimum data transparency for AI training sets, ensuring that tomorrow’s algorithms learn from high-quality, bias-free datasets.

Dynamic Optimisation of Operating Parameters in Real Time

Even the best tooth design and the smartest material will underperform if the operator runs the machine blind. The final layer of efficiency is closed-loop adjustment of speed, pressure, feed rate and gap width based on live measurements.

Quantitative Relationship between Roll Speed and Throughput

Experiments on a 600 mm pilot roll show that throughput rises linearly with speed up to 85 % of motor rating, then plateaus as the nip zone becomes the bottleneck. The inflection point occurs at 1.8 m s⁻¹ peripheral speed for 25 mm feed, shifting to 1.5 m s⁻¹ when feed size increases to 40 mm. Embedding this curve into the VFD logic prevents wasteful overspeeding.

Feed Rate and Its Effect on Tooth Wear

A step increase in feed rate from 80 % to 120 % of nominal raises impact energy per tooth by 44 %, accelerating wear by 60 %. However, if the AI system simultaneously widens the gap by 2 mm, the extra impact is absorbed and wear reverts to baseline. This synergy highlights the need for multi-parameter optimisation.

Intelligent Pressure Regulation

Hydraulic cylinders now adjust roll separating force every 5 s based on motor current and vibration RMS. A phosphate plant implemented a fuzzy-logic controller that trimmed average hydraulic pressure from 14 MPa to 11 MPa, cutting hydraulic pump energy by 15 % and extending seal life by 30 %.

Multi-Parameter Optimisation Algorithms

Genetic algorithms evaluate 50 candidate parameter sets every minute, scoring them against a composite cost function. A limestone quarry running the algorithm achieved a 7 % throughput gain and 5 % energy reduction simultaneously—an outcome that manual tuning had deemed impossible because the two objectives were thought to conflict.

Real-Time Particle Size Measurement

High-speed stereo cameras above the discharge belt capture 500 images per second, analysing each fragment’s Feret diameter in under 40 ms. When the P80 deviates by more than 1 mm from target, the gap is automatically adjusted by ±0.5 mm. The feedback loop keeps the product within specification 95 % of the time, compared with 78 % under manual control.