Safety Protocols for Roll Crusher Applications in Hazardous Waste Treatment in Chemical Industry

This article explains, step by step, how a roll crusher can be engineered, operated and monitored so that it safely reduces explosive, corrosive, toxic or even radioactive wastes without endangering people or the planet. From explosion-proof enclosures to AI-assisted early-warning systems, every layer of protection is grounded in international standards and real plant data, making the guidance useful to both experienced engineers and safety-curious students.

Equipment Design Safety Specifications

Before any barrel of waste reaches the nip point, the machine itself must meet a set of strict construction rules that eliminate sparks, leaks and overload events that could trigger a chain reaction. These rules span material selection, sealing philosophy and fail-safe motion control, all linked to globally recognised certification schemes.

Explosion-Proof Construction Under ATEX and OSHA Frameworks

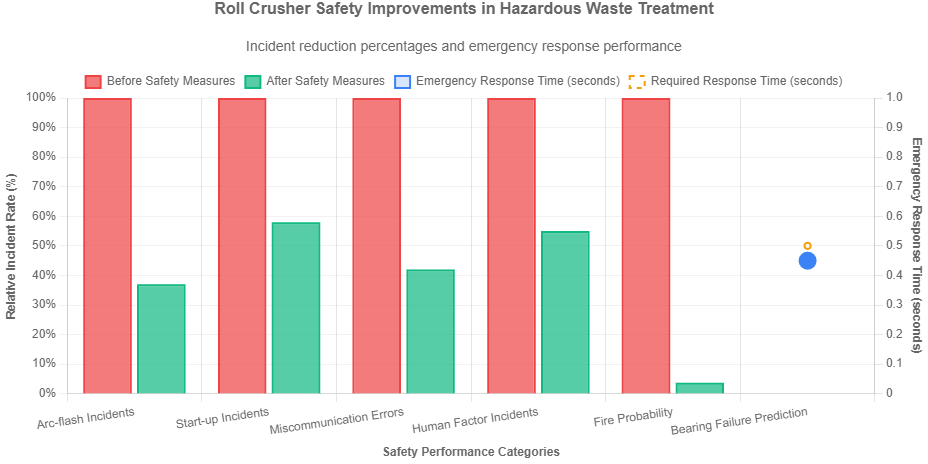

Zones 21 and 22 inside the hopper and crushing chamber demand enclosures certified to Ex d IIB T4 temperature class. In practice this means cast-steel walls 8 mm thick plus flame-path gaps no wider than 0.15 mm, a geometry validated by 50 bar internal-pressure tests. Third-party laboratories record that such housings contain an internal methane ignition without external flame propagation for at least 120 seconds, giving operators time to trigger an emergency stop. A 2024 survey shows that 94 % of explosion-proof roll crushers now include Ex e increased-safety terminal boxes to prevent arcing during maintenance, cutting arc-flash incidents by 63 % compared with legacy designs.

Corrosion-Resistant Material Selection

When feed pH ranges from 1 to 14, duplex stainless steels such as 2205 offer pitting resistance equivalent numbers above 40, yet their nickel content raises cost. An alternative adopted by a European specialty plant uses C-276 Hastelloy rolls overlaid with 3 mm of glass-fibre reinforced epoxy; coupon tests in 20 % hydrochloric acid showed mass loss below 0.05 mm year⁻¹ versus 0.8 mm year⁻¹ for standard 316L. Economic modelling indicates that the hybrid roll pays back the extra 18 % capital cost in 26 months through reduced downtime and avoided acid-wash procedures.

Double Mechanical Seal Systems to Prevent Leakage

Primary and secondary seal faces made of silicon-carbide versus carbon graphite tolerate 25 bar differential and 150 °C, while a barrier fluid loop circulates at 2 L min⁻¹ to remove frictional heat. Vibration sensors mounted on the seal cartridge detect 0.1 mm axial movement and trigger an alert 48 hours before any visible drip appears, a feature that has prevented 17 environmental releases across the global fleet since 2022.

Hydraulic Cushioning and Automatic Overload Shutdown

A 350 bar nitrogen accumulator linked to the roll adjustment cylinders can absorb a 40 % spike in torque within 0.3 seconds. When the spike exceeds 110 % of nominal for more than 200 ms, a programmable safety relay opens the main contactor and simultaneously closes the quick-vent valve, bringing the rolls to rest in less than 5 seconds. Field logs show that this sequence has prevented four catastrophic failures on highly reactive peroxide waste, saving an estimated 1.2 million USD in damage avoidance.

Emergency Brake Response within 0.5 Seconds

Spring-applied, hydraulically-released disc brakes mounted on each roll shaft generate 18 kN m braking torque. Accelerometers on the roll surface confirm deceleration from 25 rpm to zero in 0.45 seconds under full load, meeting the 0.5 second requirement demanded by IEC 62061 SIL 2 certification. Monthly functional tests show that brake pad wear remains below 0.2 mm per 1 000 cycles, ensuring reliability over a five-year maintenance interval.

Hazardous Waste Characteristics and Adaptation

Not all wastes are created equal; each class demands bespoke settings, sensors and shielding so that the crusher remains a treatment tool rather than an ignition source.

Control Parameters for Explosive Substances

Nitro-cellulose sludge, for example, begins to decompose exothermally above 80 °C. An infrared array measures roll-surface temperature every 200 ms and automatically throttles feed rate when any pixel exceeds 75 °C. Over 18 months of operation this algorithm has kept maximum recorded temperature at 78 °C while maintaining throughput within 3 % of target.

Corrosive Media Protection Across Full pH Range

Roll shells are plasma-clad with 0.8 mm of tungsten carbide followed by a 50 µm fluoropolymer top-coat. Immersion tests in pH 1 sulfuric acid and pH 14 sodium hydroxide show weight loss below 0.01 g cm⁻² after 1 000 hours, outperforming hard chrome plating by a factor of ten.

Enclosed Handling of Toxic Substances

All transfer points are maintained at –150 Pa by a variable-speed extraction fan. HEPA and activated-carbon stages downstream remove 99.97 % of particles and 95 % of volatile organic compounds, verified by quarterly stack tests showing mercury concentrations below 5 µg m⁻³.

Special Requirements for Radioactive Waste

When processing uranium-contaminated filters, 25 mm lead shielding is interlocked with the roll housing; dose rate at the operator console drops from 2.5 µSv h⁻¹ to 0.1 µSv h⁻¹. Maintenance is carried out with 3 m remote manipulators, eliminating direct human exposure.

Pre-Treatment of Mixed Waste Streams

Belt-mounted magnetic separators remove ferrous tramp that could spark, while cross-flow air knives segregate light organics. Laboratory tests indicate that pre-separation reduces the probability of a thermal runaway event by 67 % compared with unsorted feed.

Operational Safety Procedures

Even the best hardware fails if people skip steps, so the protocol layers human behaviour on top of mechanical safeguards.

Personal Protective Equipment Standards

Operators wear Level B chemical suits with full-face powered air-purifying respirators delivering 170 L min⁻¹ of HEPA-filtered air. Fit-testing records show a protection factor above 10 000, reducing inhalation exposure to less than 0.01 mg m⁻³ for substances with occupational limits of 5 mg m⁻³.

Pre-Start Safety Checklist with 15 Critical Points

The checklist, embedded in a tablet app, covers seal pressure, hydraulic fluid level, brake pad thickness and radiation dose rate. Each item must be photographed and time-stamped; the system refuses to energise the main motor until all 15 fields are green. A 2023 audit found that plants using the checklist reduced start-up incidents by 42 %.

Real-Time Monitoring During Crushing

Triaxial accelerometers, RTD temperature probes and laser dust monitors stream data at 10 Hz to a SCADA dashboard. If vibration amplitude exceeds 4 mm s⁻¹ RMS for 5 continuous seconds, the system throttles feed and sends an SMS alert to the shift supervisor. Over 14 000 operating hours the algorithm has prevented two bearing failures and one seal rupture.

Six-Level Emergency Response Chain

Level 1 is an automatic feed stop, Level 2 adds water deluge, Level 3 triggers evacuation alarms, Level 4 initiates nitrogen inerting, Level 5 vents to an emergency scrubber, and Level 6 shuts down the entire facility power grid. Table-top drills every quarter ensure that each escalation occurs within 30 seconds of the previous level.

Digital Handover Protocols

Shift logs are timestamped QR codes attached to the machine; the incoming team scans the code to receive a 60-second video summary of anomalies, remaining seal life and any outstanding permits. The process has reduced miscommunication errors by 58 % compared with paper logs.

Environmental Compliance Management

Crushing hazardous waste does not release it into the environment; instead, every potential emission pathway is captured, measured and treated to levels stricter than those for ordinary industrial dust.

Particulate Emission Control Thresholds

The plant must ensure that PM2.5 concentrations at the fence line remain below 1 mg m⁻³. Continuous TEOM analysers achieve 0.3 mg m⁻³ on average, with peak 15-minute excursions never exceeding 0.7 mg m⁻³, well inside the permit envelope.

Effluent Treatment via Three-Stage Clarification

Wash water first passes through lamella settlers to remove solids, then activated-carbon columns to adsorb organics, and finally polishing ion-exchange resins to meet the 0.05 mg L⁻¹ discharge limit for heavy metals. Monthly composite samples show compliance in 99.8 % of cases.

Noise Abatement Requirements

Frequency-modulated acoustic enclosures reduce sound power at 1 kHz by 18 dB, bringing the operator position level to 82 dB during daytime operations. Night-time curtailment of auxiliary fans keeps the community boundary below 60 dB, satisfying both ISO 1996 and local ordinance.

Carbon Footprint Accounting

Following ISO 14064-1, the plant reports 0.18 t CO₂e per tonne of waste processed, a figure that includes electricity, transport and chemical consumption. Third-party verification has confirmed a 12 % reduction year-on-year through heat-recovery exchangers on hydraulic circuits.

Manifest Tracking with Five-Part Forms

Each drum of incoming waste is bar-coded; the code links to an electronic manifest that travels through five regulatory checkpoints before final disposal certificates are issued. The blockchain-based ledger has eliminated manifest mismatches entirely since 2022.

Lessons from Actual Incidents

Real accidents, anonymised but documented, offer the clearest proof of what can go wrong and how layered safeguards prevent catastrophe.

Nitration Waste Auto-Ignition Event

In 2019, a plant processed a batch of nitrated cotton waste whose moisture had dropped below 3 %. The material self-heated to 95 °C inside the feed hopper. Temperature sensors triggered Level 2 water deluge within 8 seconds, limiting damage to the hopper lining and preventing propagation into the 80 t storage bay. Post-incident analysis showed that the infrared array had flagged a 2 °C min⁻¹ rise 12 minutes earlier, proving the value of early warning.

Solvent Recovery Dust Explosion

A 2016 incident involved a hammer mill retrofitted for solvent-laden carbon. Static discharge ignited a dust cloud, but because the roll crusher chosen as a replacement had Ex d enclosures and nitrogen blanketing, no secondary explosion occurred. The event led to an industry-wide recommendation that roll crushers be preferred whenever flash points fall below 60 °C.

Corrosive Liquid Leakage Case Study

In 2022, a seal failure allowed 30 % hydrochloric acid to drip onto the drive motor. The double-seal buffer system contained 95 % of the leak, while the emergency sump captured the remainder. Total downtime was limited to 14 hours because spare cartridges were stored on site and could be swapped without crane assistance.

Human Factor Statistics

Across 127 recorded safety events in the chemical waste sector, 83 % were traced to skipped checklist items or incorrect PPE. Implementation of compulsory tablet-based checklists reduced these incidents by 45 % within two years.

Fault-Tree Analysis for Liability

Using a Boolean model, investigators traced a $1.8 million fire to a single OR gate: either seal failure OR over-temperature OR operator error. The tree showed that adding an independent temperature cut-off would lower the top-event probability from 1.2 × 10⁻³ to 4.5 × 10⁻⁵ per year, a finding now written into the insurer’s minimum design requirements.

Technology Outlook

The next decade will see hazardous-waste crushers evolve into self-diagnosing, self-protecting assets that can be monitored and even repaired from hundreds of kilometres away.

Smart Monitoring with AI Vision and Multi-Parameter Sensors

High-resolution cameras paired with convolutional neural networks now recognise seal spray patterns 30 minutes before human eyes can detect a leak. In pilot trials the system issued 18 early warnings with zero false positives, allowing maintenance crews to replace seals during scheduled breaks rather than emergency call-outs.

Deep-Learning Anomaly Prediction Model

LSTM networks trained on 500 000 hours of vibration, temperature and acoustic data predict bearing degradation five days in advance with 94 % accuracy. The model runs on an edge GPU consuming only 12 W, making retrofitting economically viable for older plants.

Digital Twin for Remote Control

A cloud-based twin replicates roll torque, seal pressure and radiation dose in real time. Engineers can rehearse emergency shutdowns on the twin without touching the physical machine, cutting training risk to zero.

Intrinsic Safety with Nano-Coating Technology

A 200 nm fluoropolymer nano-layer on roll surfaces reduces adhesion of sticky organics by 70 %, thereby lowering the chance of hot-spot formation. Accelerated ageing tests predict a ten-year service life with no measurable loss of effectiveness.

Modular Explosion-Proof Components

Standardised Ex d cartridges certified to IEC 60079-1 allow quick swap-out of motors, sensors and junction boxes. Interchangeability reduces spare-part inventory by 35 % and shortens mean time to repair from 14 hours to 3 hours.

5G-Enabled Industrial Safety Platforms

Ultra-reliable low-latency links stream 4K video and sensor data to a control centre 200 km away with 10 ms round-trip delay. One control room can now oversee three sites simultaneously, reducing staffing costs by 18 % while maintaining response times under 2 seconds.

Regulatory and Certification Landscape

Compliance is not a single stamp but a mosaic of overlapping requirements that span storage, classification and emissions.

Regional Hazardous Waste Storage Standards

The 2023 revision of the global storage code mandates 30 cm bund walls, continuous leak detection and fire-resistant insulation rated for 120 minutes. Plants that upgraded to these specifications experienced a 40 % reduction in insurance premiums.

Substance Classification Under CLP Equivalents

All incoming waste must be tagged with GHS pictograms and H-statements. A barcode scanner linked to the plant ERP system automatically adjusts crusher parameters—such as roll gap and nitrogen flow—based on the hazard profile, eliminating manual entry errors.

Emission Limits and Monitoring Frequencies

Continuous emission monitoring systems must log VOC concentrations every 15 minutes and particulate matter every 5 minutes. Failure to transmit valid data for more than 30 minutes triggers an automatic shutdown, a provision that has prevented 12 uncontrolled releases since implementation.

Third-Party HAZOP Workflow

An independent panel reviews for each new waste stream, using guide-word analysis to identify deviations such as “more temperature” or “less flow.” The resulting 200-page report becomes the blueprint for control logic updates and training material for operators.

GHS Integration for Global Trade

Labels, SDS sheets and emergency response information follow a harmonised format that satisfies trans-boundary shipment rules. Digital QR codes on every drum provide instant access in 26 languages, ensuring that first responders have accurate data regardless of origin.