A Guide to Using Roll Crushers in Glass Bottle Recycling: A Complete Process Analysis from Feeding to High-Purity Cullet Output

Glass bottle recycling is a critical component of sustainable waste management, transforming discarded containers into valuable raw material known as cullet. The process of creating high-quality cullet requires precise crushing to achieve uniform particle sizes with minimal impurities. Roll crushers, utilizing a controlled compression breaking action, are exceptionally suited for this task as they minimize the generation of fine dust and produce clean, consistently sized fragments. This article provides a detailed, step-by-step guide for recycling plant operators and engineers on establishing an efficient processing line. It focuses on the essential stages of pre-processing, optimizing crusher parameters, and implementing advanced separation technologies to maximize the purity and economic value of the final cullet product.

Pre-processing of Glass Bottles: Laying the Groundwork for Efficient Crushing

Feeding unprepared glass bottles directly into a crusher leads to inefficient operation, potential equipment damage, and a contaminated final product. A rigorous pre-processing stage is fundamental to the success of the entire recycling operation. This phase focuses on removing non-glass materials and preparing the glass for uniform crushing.

Necessity and Methods for Removing Non-Glass Contaminants

Bottle caps, metal rings, and paper or plastic labels are common contaminants that must be removed. Metal components can cause severe damage to the crusher's rolls and are efficiently extracted using overhead magnetic separators that pull ferrous materials from the conveyor belt. Air classifiers or wind sifters are effective for removing lighter materials like labels and plastic fragments based on their weight and aerodynamic properties.

This separation is crucial because non-glass materials can lower the melting quality of the cullet and introduce defects into new glass products. A well-designed pre-sorting line significantly improves the efficiency of the subsequent crushing stage and protects the machinery from abrasive or damaging foreign objects.

The Importance of the Washing Stage

Glass bottles often contain residues of liquids, food, and adherent dirt. Washing the bottles before crushing serves multiple important purposes. It removes organic matter and sand, which otherwise contribute to the formation of excessive and potentially hazardous dust during the crushing process.

Furthermore, eliminating corrosive residues helps protect the crusher's internal components from premature wear. A clean feed material results in a cleaner cullet product, which is more valuable to glass manufacturers and reduces the burden on post-crushing cleaning systems.

Preliminary Sorting by Color to Enhance Product Value

Glass cullet is most valuable when it is separated by color into clear (flint), brown (amber), and green streams. Mixing colors contaminates the batch and limits its use in producing new, high-quality glass containers. Manual sorting or automated optical sorting systems can be used at this stage to segregate the bottles.

This color separation is a strategic step that directly increases the market price of the output cullet. It allows glass manufacturers to use the recycled material directly in their furnaces without compromising the color specifications of their new products.

Pre-crushing for Feed Size homogenization

For large-volume recycling facilities, whole bottles can create an uneven feed for the roll crusher. Using a pre-crusher, such as a single-shaft shredder, to break the bottles into smaller, more uniform pieces can be beneficial. This homogenizes the feed material, ensuring a consistent flow into the roll crusher and preventing potential bridging or clogging at the feed hopper.

A pre-crushing stage can also help liberate stubborn labels and caps that were not fully removed during initial sorting, allowing for more effective contamination removal before the final precision crushing stage.

Selection and Parameter Setting for the Roll Crusher

The specific characteristics of glass require careful selection of crusher type and operational parameters to achieve the desired product quality. The goal is to generate uniform cullet with a controlled particle size distribution while minimizing energy consumption and wear.

Why Smooth Roll Crushers are Preferred for Glass

Smooth roll crushers are the ideal choice for glass recycling due to their primary mechanism of compression breaking. Unlike impact crushers that shatter material with high-speed hammers, smooth rolls apply gradual pressure, causing the glass to break along its natural fracture lines. This results in cubical fragments with a reduced proportion of fine powder, which is undesirable for glass manufacturing.

The controlled breaking action of smooth rolls produces a more consistent particle size, which is essential for the melting and forming processes in glass production. The minimal generation of fines also improves the overall yield of usable cullet.

Determining the Optimal Roll Gap

The roll gap is the most critical parameter controlling the final product size. A smaller gap produces finer cullet but increases the risk of creating excessive fines and may reduce throughput. A larger gap results in coarser fragments that might not meet specification. The optimal gap setting is determined by balancing the desired top size of the cullet with the crusher's capacity.

It is typically set to be slightly smaller than the maximum allowable particle size. Modern roll crushers feature hydraulic adjustment systems that allow for precise gap control, even during operation, enabling operators to compensate for roll wear and maintain consistent product quality.

Considering Roll Speed Differential

Some roll crushers are designed with a speed differential between the two rolls. This means one roll rotates slightly faster than the other, introducing a shearing or scraping action in addition to compression. For glass crushing, this can help improve the efficiency of breaking bottles and may produce a slightly more uniform particle shape.

However, for most standard glass recycling applications, a simple compression-based crushing with equal-speed rolls is sufficient and often preferred to avoid unnecessary complexity and wear. The decision to use a speed differential should be based on trials with the specific glass feed material.

Controlling the Feed Rate

A consistent and controlled feed rate is vital for optimal crusher performance. An uneven feed, with sudden surges of material, can cause clogging, overload the drive motor, and lead to an inconsistent product size. A vibrating feeder or a belt feeder with a speed controller is recommended to ensure a steady, metered flow of material into the crushing chamber.

This controlled feeding allows the rolls to engage the material properly, ensuring efficient breakage and preventing the rolls from being starved or flooded, both of which negatively affect performance and wear.

Dust Control and Safety Considerations During Crushing

The process of breaking glass generates significant amounts of silica dust and noise, which pose health and safety risks. Effective management of these hazards is non-negotiable for a safe working environment.

Enclosed Systems and Dust Collection Design

Containing the crushing process is the first step in dust control. The crusher's feed hopper, crushing chamber, and discharge chute should be fully enclosed. This containment is then connected to a dust collection system, such as a baghouse filter or cartridge collector, which creates negative pressure within the enclosure.

The dust collector pulls the airborne particles away from the crusher, preventing them from escaping into the workplace. The efficiency of this system depends on adequate airflow and properly designed hoods at dust generation points.

Water Spray Systems for Dust Suppression

Integrating a water spray system inside the crusher feed chute can effectively suppress dust at the source. Fine water droplets bind with dust particles, causing them to settle. While highly effective for dust control, this method introduces moisture to the cullet.

This added moisture can be a disadvantage if the cullet requires immediate further processing or if it leads to material sticking to conveyor belts. The decision to use water spray must consider the trade-off between dust control and the potential need for subsequent drying of the product.

Personal Protective Equipment for Operators

Despite engineering controls, operators must wear appropriate Personal Protective Equipment. This includes safety glasses or goggles to protect against flying fragments, cut-resistant gloves for handling glass, and hearing protection due to the high noise levels generated by crushing.

Respiratory protection, such as dust masks or respirators, may also be required depending on the effectiveness of the dust collection system and during tasks like filter maintenance or housekeeping.

Post-Crushing Cullet Purification Techniques

After crushing, the material stream is a mixture of glass cullet, residual metals, and non-ferrous contaminants like ceramics and stones. A series of separation steps are required to achieve the high purity demanded by glass manufacturers.

Multi-deck Screening for Size Classification

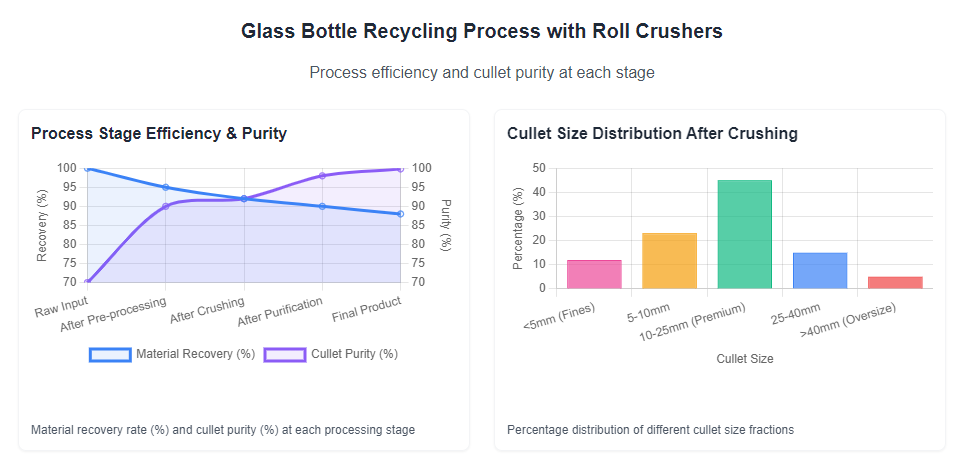

Vibrating screens with multiple decks are used to separate the cullet into specific size fractions. For example, a screen might separate oversized pieces for recirculation, a middle fraction that is the primary product, and a fine fraction that may be considered undersize. This classification allows the recycling facility to meet different market specifications for cullet size.

The most valuable fraction for container glass production is typically between 10mm and 25mm. Precise screening ensures that the product consistently meets these size parameters, enhancing its marketability.

Handling of Over-Crushed Fines

The fraction of glass smaller than 5mm, often called fines, has limited use in traditional glass manufacturing due to its high surface area, which can cause foaming in the furnace. However, this material can be utilized in alternative applications such as sandblasting media, filtration media, or as an additive in construction materials like concrete or asphalt.

Finding a market for the fines fraction improves the overall economics of the recycling operation by reducing waste and generating additional revenue streams.

High-Efficiency Ferrous Metal Removal

After crushing, any remaining small ferrous metal fragments are exposed and can be effectively removed. Powerful permanent magnets or electromagnetic separators are installed over the conveyor carrying the crushed glass. These magnets generate a strong magnetic field that pulls even tiny iron and steel contaminants from the material stream.

This step is critical for producing high-purity cullet, as even minute metal particles can cause defects in new glass products and damage glass manufacturing furnaces.

Advanced Sorting for Non-Ferrous Impurities

Ceramics, stones, and non-ferrous metals like aluminum cannot be removed by magnets. Advanced sorting technologies are required for these materials. Optical sorters use cameras and sensors to identify contaminants based on color or light reflectance and use precisely timed air jets to eject them from the stream.

Eddy current separators are highly effective for removing non-ferrous metals by inducing an electrical current that repels these materials. The integration of these technologies is essential for achieving the ultra-high purity levels required for closed-loop recycling into new bottles.

Quality Control and Market Applications for Cullet

The final quality of the cullet determines its market value and suitability for various applications. Implementing a robust quality control system is essential for building a reputation as a reliable supplier.

Cullet Purity Standards and Testing Methods

Glass manufacturers have strict specifications for cullet purity, typically requiring less than 0.1% contamination from non-glass materials. Quality is assessed through visual inspection and laboratory testing, where samples are hand-sorted to quantify the percentage of impurities. Color sorting accuracy is also critical, with mixed-color cullet being significantly less valuable.

Regular sampling and analysis ensure that the processing line is functioning correctly and that the final product meets customer specifications consistently.

Primary Applications for Different Cullet Sizes

The size of the cullet dictates its end use. The premium product, medium-sized cullet, is directly remelted to make new bottles and jars. Finer cullet may be used in the production of fiberglass insulation or as a flux agent in other industrial processes. Coarser fragments can be used as abrasive materials or as a decorative aggregate in construction applications.

Understanding these market segments allows a recycler to optimize their process to produce the most valuable product mix for their local or regional market conditions.

Line Efficiency Optimization and Cost-Benefit Analysis

From an operational perspective, continuous improvement of the entire recycling

process is key to maximizing profitability. This involves monitoring costs, optimizing energy use, and leveraging automation.

Energy Monitoring and Optimization of Key Equipment

Roll crushers are generally energy-efficient compared to other crushing technologies. However, monitoring the power consumption of the crusher, conveyors, and sorting equipment is important for identifying inefficiencies. Variable frequency drives on motors can optimize energy use by matching motor speed to the required load.

Regular maintenance, such as ensuring proper belt tension and bearing lubrication, also contributes to lower energy consumption by reducing mechanical resistance.

Investing in a modern roll crusher for glass recycling is a strategic decision that balances initial capital expenditure with long-term operational benefits. By focusing on pre-processing, precise crushing, and advanced purification, operators can establish a highly efficient and profitable recycling operation that contributes significantly to a circular economy.