Particle Size Control Strategies for Agricultural Waste Fuelization Using Roll Crushers

This article provides a detailed examination of the critical role particle size control plays in the efficient conversion of agricultural waste into biomass fuel, with a specific focus on roll crusher technology. We will explore the fundamental principles of biomass fuel preparation, the specialized design features of roll crushers for this application, and the optimization strategies for operational parameters. The discussion extends to the processing of various types of agricultural waste, an analysis of fuel quality and economic viability, environmental benefits, and relevant standardization. Furthermore, the article presents real-world case studies and looks ahead to emerging technological trends that are shaping the future of biomass fuel preparation.

Fundamentals of Biomass Fuel Preparation

The transformation of agricultural waste into a viable fuel source is a complex process governed by the inherent properties of the biomass. Understanding these properties is essential for designing an efficient size reduction process. The goal is not merely to crush the material, but to do so in a way that optimizes the fuel's energy content, handling characteristics, and combustion behavior. The physical and chemical composition of the waste directly dictates the approach required for effective comminution.

Key factors include the structural polymers that give plant material its strength, the relationship between particle size and energy yield, and the impact of moisture on processing. A successful fuel preparation strategy must account for all these variables simultaneously. The roll crusher, with its controllable compression and shear forces, is particularly well-suited to managing the fibrous and often heterogeneous nature of agricultural residues, allowing for the production of a consistent fuel product with desired specifications.

Analysis of Agricultural Waste Composition Characteristics (Cellulose/Hemicellulose/Lignin)

The mechanical behavior of agricultural waste during crushing is largely determined by its biochemical composition, primarily the ratios of cellulose, hemicellulose, and lignin. Cellulose provides tensile strength through its crystalline microfibril structure, making it resistant to straightforward breakage. Hemicellulose acts as a bonding agent between cellulose and lignin; it is more amorphous and easier to degrade. Lignin, a complex polymer, provides rigidity and compressive strength but is brittle.

For instance, rice straw has a high silica content deposited in its cellulose structure, increasing its abrasiveness. Nut shells are often rich in lignin, making them hard and brittle, requiring high compressive force but fracturing cleanly. Understanding this composition is crucial for selecting the right crushing mechanism. A roll crusher's combination of compression and shear is effective for tearing apart the fibrous cellulose and fracturing the brittle lignin, creating a particle size distribution conducive to efficient pelletization and combustion.

Quantitative Model of the Impact of Particle Size Distribution on Calorific Value

The particle size of biomass fuel directly influences its effective calorific value through two primary mechanisms: packing density and combustion efficiency. A well-graded particle size distribution allows for tighter packing in a fuel pellet or boiler feed system, increasing the mass of fuel per unit volume and thus the energy density. This is quantified as the bulk density, which has a linear relationship with the usable energy content per cubic meter.

More importantly, size affects combustion efficiency. Excessively large particles may not combust completely within the residence time of a boiler, leading to unburnt carbon and lower efficiency. Conversely, an overabundance of fine particles (fines) can be entrained in flue gases or cause slagging and fouling. Empirical models often show an optimal size range (e.g., P80 < 20mm) where combustion efficiency peaks. Operating a roll crusher to target this specific size distribution maximizes the net calorific value realized from the fuel, making the crushing process a key determinant of the final fuel's energy economics.

Fiber Structure Destruction Mechanism in the Crushing Process

The crushing of fibrous agricultural waste is not a simple fracturing process but involves the systematic destruction of the lignocellulosic structure. In a roll crusher, this occurs through a combination of compression, shear, and tearing. As the material is drawn into the nip point between the rolls, the initial compressive force causes brittle components (like nodes in straw) to fracture. The subsequent differential movement of the rolls (if equipped with differential speed) applies a shearing force that pulls and tears the long cellulose fibers apart.

This mechanical action breaks down the crystalline structure of cellulose, reducing its polymerization degree. This structural degradation is actually beneficial for subsequent processes like pelletization or anaerobic digestion, as it increases the specific surface area and makes the material more reactive. The goal of the crushing process is to achieve this fiber opening and size reduction without excessive energy consumption, which requires precise control of the roll gap, pressure, and rotational speed to match the material's mechanical properties.

Sensitivity Analysis of Moisture Content on Crushing Efficiency

Moisture content is arguably the most critical variable affecting the efficiency and outcome of crushing agricultural waste. The relationship is complex and non-linear. For most fibrous materials, there is an optimal moisture range (typically between 10-20%) for crushing. Below this range, the material becomes too brittle and dry, leading to the generation of excessive dust and fines. This is energy-inefficient and creates handling and combustion issues.

Above the optimal range, the material becomes too ductile and tough. The fibers do not break cleanly but instead get stretched and compressed, often wrapping around the crusher rolls and causing clogging. This dramatically increases the energy required for size reduction, as much of the energy is wasted on deforming the material rather than breaking it. The power draw of a crusher processing high-moisture straw can be 50-100% higher than when processing the same material at optimal moisture, highlighting the extreme sensitivity and the necessity of pre-drying in many applications to achieve energy-efficient operation.

Ash Control and Fuel Grade Standards

The ash content of biomass fuel and its melting behavior are key quality parameters that influence boiler operation and maintenance. While crushing itself does not alter the inherent ash content of the material, the process of size reduction and subsequent classification (screening) can be used to control the ash distribution in the final fuel product. In many agricultural wastes, ash is concentrated in specific parts of the plant (e.g., leaves and nodes in straw have higher ash than stems).

Efficient crushing can liberate these ash-rich components, allowing them to be removed by air classification or screening after the crushing stage. This improves the overall fuel grade. Furthermore, controlling the particle size helps manage ash-related problems like slagging and fouling in boilers. A consistent, optimal particle size promotes more complete and stable combustion, resulting in a finer, more manageable ash. Adherence to international standards like EN 15160 often specifies acceptable ash content and melting points, making ash control through selective crushing and sizing a critical step in meeting commercial fuel specifications.

Roll Crusher Adaptation Design

Standard roll crushers require specific adaptations to handle the unique challenges posed by agricultural biomass, which is often lightweight, fibrous, and variable. The design focus shifts from simply generating compressive force to managing material flow, controlling fiber length, and mitigating wear from abrasive impurities like soil and silica. An adapted roll crusher for biomass is engineered to be a precise tool for particle size control, not just a brute force machine.

Key design considerations include the mechanism for gripping and feeding low-density material, the type of forces applied to cut fibers rather than just crush them, and the ability to quickly adjust to different types of waste streams. The design must also incorporate features to maintain operational efficiency and longevity in an abrasive and potentially corrosive environment. These adaptations ensure that the crusher delivers the precise product size distribution required for high-quality biomass fuel production while operating reliably and economically.

Shearing Effect of Differential Rotation on Fiber Bundles

Differential rotation, where the two rolls of a crusher operate at different speeds, is a critical design feature for processing fibrous agricultural waste. This action introduces a powerful shearing force in addition to the compressive force. The faster-moving roll attempts to drag the material through at a higher velocity, while the slower roll provides resistance. This velocity difference effectively pulls and tears apart tangled bundles of fibers, such as those found in straw and stalks.

This shearing mechanism is far more effective and energy-efficient for cutting cellulose fibers than pure compression. It produces a product with a more defined cut length and reduces the amount of long, stringy material that can cause handling issues in downstream equipment like feeders and pellet mills. The differential speed ratio can often be adjusted, allowing operators to fine-tune the shearing action for different materials—a higher ratio for tough, fibrous straw and a lower ratio for more brittle materials like sunflower husks.

Matching Tooth Geometry Parameters with Material Flowability

The surface design of the crusher rolls is paramount for ensuring positive feed and controlled size reduction. For biomass, rolls are typically equipped with teeth or pockets designed to grip the material. The geometry of these teeth—including their height, spacing, angle, and profile—must be carefully matched to the flow characteristics of the feedstock. For low-density, slippery materials like rice husk, large, sharp, and widely spaced teeth are necessary to bite into the material and pull it into the crushing zone.

For more cohesive materials like moist straw, a finer tooth pattern might be preferable to prevent over-gripping and wrapping. The tooth design also influences the product size distribution. A chevron or diamond pattern can help center the material and provide a scissoring action. The optimal tooth geometry is a balance between achieving sufficient traction for feed, applying the desired crushing force, and minimizing wear. Wear-resistant nanocoatings are often applied to these teeth to maintain their profile and performance over extended periods.

Calibration Method for Hydraulic Roll Gap Adjustment System

Precise and reliable control of the roll gap is essential for maintaining a consistent product size distribution, especially given the fluctuating feed characteristics of agricultural waste. Modern roll crushers use hydraulic systems to adjust and maintain the roll gap. Calibrating this system involves establishing a accurate relationship between the hydraulic pressure (or piston position) and the actual physical gap between the rolls under load.

This calibration is typically performed during commissioning using calibrated shims or laser measurement tools. The system must account for the deflection of the rolls and frame under the high pressures of crushing. An accurately calibrated gap control system allows an operator to dial in a specific setting to achieve a target product size, and the system will automatically maintain that gap, compensating for wear and minor fluctuations in feed pressure. This ensures consistent product quality and prevents the energy waste associated with an incorrectly set gap that either fails to break the material or applies excessive force, generating fines.

Integration of Negative Pressure Dust Collection and Material Recovery

Crushing dry biomass inevitably generates dust, which poses health, safety, and environmental risks. An integrated negative pressure dust collection system is therefore essential. This system uses strategically placed extraction hoods at transfer points and above the crusher itself, connected to a powerful fan that creates a vacuum. This vacuum pulls dust-laden air into a network of ducts and delivers it to a central filter, such as a baghouse.

Beyond environmental compliance, this system serves a material recovery function. The collected dust, often a very fine biomass powder, can be highly combustible. Rather than being wasted, this material can be pneumatically conveyed and reintroduced into the main fuel stream or compacted into pellets. This integration improves overall material yield, reduces waste, and enhances the safety of the operation by preventing the accumulation of explosive dust clouds. The energy consumption of the dust collection system is a necessary part of the overall process energy balance.

Selection of Wear-Resistant Roll Surface Treatment Process

The rolls of a biomass crusher are subjected to severe wear from abrasive materials like silica in straw and sand picked up from the ground. Protecting the roll surface is therefore critical for maintaining crushing efficiency and operational economy. Several treatment processes are available. The most common is hardfacing, where a wear-resistant alloy is welded onto the roll surface in a specific pattern. This rebuilds the tooth profile and provides a hardened, abrasive-resistant layer.

More advanced treatments include thermal spray coatings (e.g., tungsten carbide) and laser cladding, which offer superior hardness and bond strength. The choice of process depends on the base material of the roll, the specific abrasiveness of the biomass feedstock, and the required interval between maintenance. A well-chosen and applied surface treatment can extend the service life of roll components by 300-500%, significantly reducing downtime for maintenance and the associated energy costs of disassembly and reassembly. It also maintains the designed tooth geometry for a longer period, ensuring consistent energy-efficient crushing.

Process Parameter Optimization Strategy

Optimizing the operation of a roll crusher for biomass involves a delicate balancing act between multiple interacting parameters. The goal is to achieve the target particle size distribution with the lowest possible specific energy consumption (kWh/ton) while maximizing throughput. This requires a systemic view of the entire crushing circuit, not just the crusher itself, and an understanding of how each adjustable parameter influences the final outcome.

Key levers for optimization include the properties of the incoming feed, the mechanical settings of the crusher, and the configuration of any auxiliary equipment like screens. Because agricultural waste is a highly variable feedstock, the optimal settings are not static. The most efficient operations employ strategies that allow for continuous or frequent adjustment of these parameters in response to changes in the feed material, moving towards an automated and adaptive control system.

Dynamic Balance Between Feed Size and Crushing Ratio (3:1 vs 8:1)

The crushing ratio, the ratio of the feed size to the product size, is a fundamental parameter. For biomass, attempting to achieve a very high single-stage crushing ratio (e.g., 8:1) is often inefficient. It forces the crusher to exert extreme force, which can lead to over-compression of the material, generating excessive fines and consuming more energy per ton. A more moderate ratio (e.g., 3:1 to 4:1) is typically more energy-efficient for fibrous materials.

Therefore, the strategy is to achieve a dynamic balance. The feed size should be controlled through pre-screening or a primary coarse crushing stage to ensure it is appropriate for the secondary roll crusher's designed ratio. This allows the roll crusher to operate in its most efficient range, applying the optimal amount of force to achieve the desired product size without waste. For a required final size, using two stages of crushing with lower individual ratios often results in a lower total energy consumption than using a single stage with a high ratio.

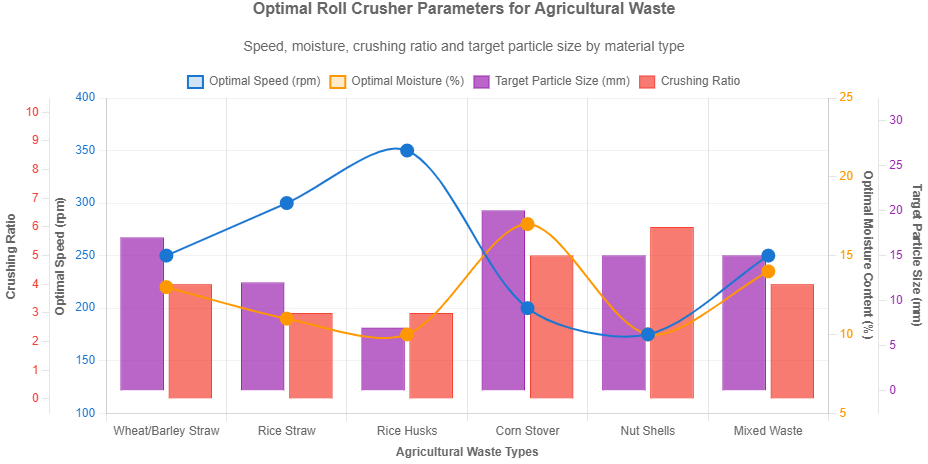

Influence of Speed Control on Particle Size Distribution (150-500 rpm)

The rotational speed of the rolls is a powerful tool for controlling the product characteristics. Higher speeds (e.g., 400-500 rpm) typically increase throughput but can lead to a wider and finer particle size distribution. This is because the material has less time to be nipped and properly broken between the rolls, leading to more attrition and splintering. It can also increase the amount of long, uncut fibers that get pulled through.

Lower speeds (e.g., 150-250 rpm) provide a more controlled break. The material is gripped more reliably and subjected to the compressive and shearing forces for a longer duration, resulting in a more uniform product with a higher proportion of the desired particle size. However, throughput is reduced. The optimal speed is a compromise that meets the production requirement while delivering the product quality needed for downstream processes. Variable Speed Drives (VSDs) on the crusher motors allow operators to fine-tune this parameter for different materials and production goals.

Collaborative Control Algorithm for Closed-Loop Screening System

The highest level of efficiency is achieved when the crusher is integrated into a closed-loop system with a screening device. In this setup, the crusher discharge is sent to a screen (e.g., a vibrating screen or a trommel). The screen separates the material into oversized (overs),合格 product, and fines. The oversized fraction is automatically returned (recirculated) to the crusher inlet for further reduction.

A collaborative control algorithm manages this entire process. It monitors the power draw of the crusher and the load on the screen. If the crusher power is low and the amount of recirculated oversize is high, the algorithm might automatically slightly close the roll gap to achieve a finer crush. Conversely, if the crusher power is trending towards its maximum and the recirculating load is low, it might open the gap slightly to protect the machine and save energy, accepting a slightly coarser product. This algorithm ensures the system is always balanced for optimal performance, maximizing the production of合格 product while minimizing energy waste on over-crushing.

Energy Cascade Utilization Scheme in Multi-Stage Crushing

For large-scale operations requiring a significant size reduction, a multi-stage crushing system designed with energy cascade utilization in mind is the most efficient approach. The principle is to use different types of crushers, each operating in their most efficient reduction ratio and speed range. A typical cascade might involve a coarse shredder or hammer mill for initial size reduction, followed by a roll crusher for precise sizing.

The primary crusher operates at high throughput, breaking down large bundles and lumps. Its product is then screened, and the intermediate-sized material is sent to the roll crusher. The roll crusher, now working with a more consistent and smaller feed, can operate at its optimal efficiency to make the final precision size reduction. This staged approach ensures that no single machine is forced to operate inefficiently across a very wide range of particle sizes. The total energy consumed across the two specialized stages is often lower than the energy a single machine would require to achieve the same overall reduction.

Real-Time Online Particle Size Monitoring Technology

Implementing real-time particle size analysis closes the loop on automated control. Modern online particle size monitors use technologies like laser diffraction or digital image analysis to measure the size distribution of the crushed product on a conveyor belt continuously. This provides instant feedback on the performance of the crusher.

This data is fed into the plant's process control system. If the product size begins to deviate from the target (e.g., becomes too coarse), the system can automatically adjust the crusher's roll gap or feed rate to correct it. This allows for immediate correction of drift caused by wear or changes in material properties, ensuring consistent product quality 24/7. This prevents the energy waste associated with producing off-spec material that may need to be re-crushed or that causes inefficiencies in downstream processes like pelletizing or combustion.

Typical Agricultural Waste Processing

The diversity of agricultural waste requires tailored approaches for each material type. While the core principles of size reduction remain constant, the specific strategies for optimizing a roll crusher's performance vary significantly depending on the physical and chemical properties of the feedstock. Understanding these material-specific nuances is key to designing an efficient and robust biomass fuel preparation system.

Processing systems must be flexible enough to handle seasonal variations and potentially mixed waste streams. The optimization goals may also differ: for some materials, the focus is on preventing over-crushing, while for others, it is on achieving a sufficient level of fiber destruction. The following sections explore the application of roll crusher technology to some of the most common categories of agricultural waste used for fuel production.

Over-Crushing Control in Rice Husk Processing

Rice husk is unique due to its high silica content and low density. It is inherently brittle and prone to generating a high percentage of fines if crushed aggressively. The goal in processing rice husk is often to break down any agglomerations and ensure a consistent, granular product without excessive pulverization. Over-crushing rice husk creates fine silica dust, which is abrasive, poses health risks, and can lead to slagging in boilers.

To control this, a roll crusher should be configured with a wide roll gap and low or no differential speed, applying just enough force to break the husks without grinding them. The use of smooth or lightly corrugated rolls is often preferable to toothed rolls to minimize the generation of fines. The focus is on gentle fragmentation rather than high-reduction crushing. Operating parameters must be carefully tuned to find the balance between achieving acceptable particle size and minimizing the creation of problematic fines.

Fiber Cut Length Optimization for Straw-Type Materials

Straw materials (wheat, rice, corn) present the challenge of long, tough fibers. The objective is not to pulverize the straw but to cut it into optimal lengths for pelletizing or combustion. An ideal pellet requires fibers of a certain length to interlock and form a durable pellet, while for direct combustion, a defined length ensures good flowability and complete burning.

A differential speed roll crusher is exceptionally well-suited for this task. The shearing action of the differentially rotating rolls acts like a pair of scissors, cleanly cutting the fibers to a length that is roughly proportional to the gap between the roll teeth. By controlling the gap and the differential speed ratio, operators can directly influence the average cut length of the straw. This allows for precise optimization of the product for its intended downstream use, maximizing the quality and efficiency of the final fuel product.

Hardness Adaptation Adjustment for Nut Shell Materials

Nut shells (e.g., almond, walnut, coconut) are characterized by high hardness and brittleness due to their high lignin content. They require high compressive force to fracture but break cleanly once their compressive strength is exceeded. The challenge is to apply this force efficiently without causing excessive wear on the crusher components.

For processing nut shells, a roll crusher should be configured with high pressure and a relatively small roll gap to ensure effective fracture. The rolls should have a robust tooth design to grip the hard, often round, shells and pull them into the crushing zone. Because the material is brittle, differential speed is less critical than pure compressive force. The focus is on applying high stress to cause catastrophic fracture of the particles, producing a granular product with a cubical shape. Wear protection on the rolls is paramount due to the high stresses and abrasive nature of these materials.

Separation and Crushing Process for Mixed Waste Streams

Many agricultural operations generate mixed waste streams (e.g., straw with adhered soil, or mixtures of different crop residues). Processing these mixtures effectively often requires a pre-separation step before crushing. For example, a pre-cleaning stage might be used to remove stones and soil that would cause excessive wear in the crusher.

For mixed biomass, the crushing strategy must be a compromise that works acceptably well for all components. A roll crusher with adjustable parameters (gap, pressure, speed) provides the flexibility needed. The system can be tuned to handle the toughest material in the mix, accepting that softer components might be slightly over-crushed. Alternatively, if the mix is consistent, a dedicated set of parameters can be found that delivers a suitable product from the blend. The ability to quickly adjust the crusher settings is key to handling variable and mixed feedstocks efficiently.

Energy Balance of Pre-Treatment Drying Steps

The decision to pre-dry biomass before crushing has significant energy implications that must be analyzed as a whole system. As established, crushing at optimal moisture (10-20%) is far more energy-efficient. However, the process of drying itself consumes a substantial amount of energy, typically from thermal sources.

Therefore, an energy balance must be calculated. The reduction in crushing energy achieved by drying must be weighed against the total energy consumed by the dryer. Often, it is beneficial to use waste heat from another part of the process (e.g., engine exhaust from a CHP plant, or low-grade heat from the pellet cooler) to perform the drying. This utilizes energy that would otherwise be wasted, making the overall process, from raw biomass to sized fuel, much more efficient. The optimal moisture content for crushing is thus determined by the point where the combined energy of drying and crushing is minimized.

Fuel Quality and Economic Analysis

The ultimate value of a biomass fuel is determined by its quality and the cost of producing it. The crushing process is a major contributor to both these aspects. The particle size distribution it produces directly influences the fuel's performance in combustion or pelletization, which in turn affects its market value. Simultaneously, the energy and maintenance costs of the crusher form a significant portion of the total production cost.

A comprehensive economic analysis must therefore link the technical performance of the crusher to the commercial viability of the fuel. This involves understanding the premium paid for high-quality, consistent fuel, the cost savings from efficient operation, and the potential to leverage government incentives designed to promote renewable energy. The goal is to optimize the crushing circuit not for the lowest standalone cost, but for the highest overall return on investment.

Correspondence Between Particle Size Standard and Combustion Efficiency (P80<20mm)

The P80 value (the sieve size through which 80% of the material passes) is a key metric for biomass fuel specification. A P80 of less than 20mm is a common industry standard for biomass fuels intended for fluidized bed boilers and many grate-fired systems. This size ensures adequate particle surface area for rapid devolatilization and combustion while being large enough to prevent excessive elutriation (being carried out of the boiler by combustion gases).

The relationship between P80 and combustion efficiency is well-established. Fuel that is too coarse (P80 > 30mm) may not burn out completely, leading to high carbon content in the ash and a loss of efficiency. Fuel that is too fine (P80 < 5mm) can cause operational problems like slagging, fouling on heat transfer surfaces, and high particulate emissions. By operating the roll crusher to consistently meet a P80 specification of, for example, 15mm, a fuel producer can guarantee a high-efficiency combustion product to their customers, which commands a better market price and ensures customer satisfaction.

Proportion of Crushing Cost in Total Fuel Cost (15-35%)

The comminution process is a significant energy consumer in the biomass fuel production chain. Its cost contribution typically ranges from 15% to 35% of the total production cost, depending on the initial size and moisture content of the feedstock, the target product size, and the efficiency of the equipment used. This cost includes electricity for the crusher and associated conveyors and screens, wear part replacement, and maintenance labor.

For a low-value material like agricultural waste, minimizing this cost is critical for economic viability. Investments in more efficient crushers (like modern roll crushers), pre-screening to remove already-sized material, and optimized control systems are all justified by their ability to reduce this 15-35% cost block. A small percentage improvement in crushing efficiency translates directly to a noticeable improvement in the profit margin of the final fuel product, making it a key area for operational focus and investment.

Life Cycle Energy Consumption Model of Equipment

When selecting crushing equipment, a Life Cycle Energy Consumption (LCEC) model provides a more complete picture than the initial purchase price alone. This model aggregates all energy-related costs over the expected operational life of the crusher (e.g., 10-15 years). It includes the embodied energy of manufacturing the machine, the energy consumed during its operation (the largest component), and the energy associated with maintenance (manufacturing and transporting wear parts).

Applying this model often reveals that a more energy-efficient crusher, which may have a higher initial purchase price, results in a much lower total life cycle energy cost. This total cost of ownership approach is essential for making a sound financial decision. It shifts the focus from short-term capital expenditure to long-term operational efficiency, aligning economic incentives with the goal of reducing the overall carbon footprint of the biomass fuel.

Utilization Strategy for Government Biomass Subsidy Policies

Many governments offer subsidies, tax credits, or grants to support the production of renewable energy from biomass. These policies are designed to improve the economics of bioenergy projects and accelerate the adoption of green technology. These incentives can often be applied to the capital cost of efficient preprocessing equipment, such as advanced roll crushers with energy-saving features.

A strategic approach involves identifying relevant subsidy programs during the project planning phase. The application process typically requires demonstrating that the technology improves efficiency, reduces emissions, or utilizes waste resources. The reduced energy consumption of an optimized crushing circuit is a strong qualifying argument. Successfully securing such subsidies can significantly improve the return on investment for the equipment, shortening the payback period and making the entire biomass fuel operation more financially robust.

Pathway for Participation in the Carbon Trading Market

By reducing the energy consumption of the biomass fuel preparation process, a producer directly lowers the carbon footprint of their final product. This reduction in greenhouse gas (GHG) emissions can be quantified and monetized through participation in carbon credit markets. The process involves having the emissions reduction verified by an accredited third party according to a recognized carbon standard.

Once verified, these carbon credits can be sold to companies or governments that need to offset their own emissions. This creates an additional revenue stream for the biomass fuel producer. The revenue from carbon credits improves the overall economics of the operation and provides a financial reward for investing in and operating energy-efficient technology like optimized roll crushers. It directly links operational efficiency to environmental benefit and financial gain.

Environmental Benefits and Standardization

The adoption of efficient biomass fuel production is driven not only by economics but also by its positive environmental impact. Precise particle size control through advanced crushing plays a significant role in realizing these benefits. It leads to cleaner combustion, reduced emissions, and more efficient use of a renewable resource. Standardization provides the framework for quantifying these benefits and ensuring the quality and sustainability of the fuel in the marketplace.

International standards define the acceptable parameters for biomass fuels, creating a common language for trade and ensuring that fuels perform as expected in end-use applications. Adherence to these standards, verified by independent bodies, builds trust and facilitates the growth of the bioenergy sector. The environmental credentials of a biomass fuel are thus underpinned by the technology and processes used to produce it.

Inhibitory Effect of Fines Reduction on Boiler Slagging

The generation of excessive fines during crushing is a major contributor to boiler slagging and fouling. Fine particles have a high surface area-to-volume ratio, which causes them to heat up very rapidly in a boiler. This can lead to the premature melting of ash components, which then stick to cooler heat exchanger surfaces or boiler walls, forming slag deposits.

By utilizing a roll crusher configured to minimize fines production (e.g., through controlled compression and shear rather than impact), the fuel producer directly reduces this risk. A fuel with a controlled, coarser size distribution heats more gradually, allowing ash minerals to react and transform in a way that results in a dry, powdery ash that is easily removed, rather than a sticky, molten slag. This improves boiler availability, reduces maintenance costs, and increases overall combustion efficiency, representing a significant environmental and economic advantage.

Calculation of Dust Collection System Energy Efficiency Ratio (ER)

The energy consumed by the dust collection system is a necessary part of the crushing process's overall energy budget. Its efficiency can be evaluated using an Energy Efficiency Ratio (ER) or similar metric. This ratio could be defined as the volume of air cleaned per unit of energy consumed (m³/kWh), or more meaningfully, the mass of dust captured per unit of energy.

An efficient system uses properly sized ducts, low-pressure-drop filters, and correctly specified fans to minimize energy consumption while still achieving the required capture efficiency. Investing in an energy-efficient baghouse with features like low-pressure compressed air pulsing for filter cleaning can reduce the parasitic load of the dust collection system. Calculating this ER helps operators understand the cost of compliance and safety and identify opportunities for optimization, ensuring that the energy spent on dust control is itself used efficiently.

EU EN 15160 Biomass Fuel Standard

The EN 15160 standard is part of a suite of European standards that specify the requirements for solid biofuels. While it may not be exclusively focused on particle size, it and related standards (like EN 14961) define critical fuel quality parameters that are directly influenced by the crushing process. These parameters typically include particle size distribution (P80 or fines content), moisture content, ash content, and calorific value.

Compliance with EN 15160 provides assurance to buyers, particularly in international markets, that the fuel meets minimum quality specifications. For a crusher operator, this means that the process must be controlled to consistently produce fuel within these defined limits. The standard provides the target for process optimization. Producing EN 15160-compliant fuel often allows producers to access premium markets and pricing, justifying the investment in precise crushing and screening technology.

Third-Party Testing Organization Verification Case

Independent verification of fuel quality claims by a accredited third-party testing organization is crucial for market credibility. For example, a producer might claim their fuel consistently meets a P80 of<15mm and a fines content of <5%. A third-party lab would sample the fuel over a period of time, conduct standardized sieve analysis, and issue a verification report.

This independent endorsement adds significant value to the fuel product, reducing the perceived risk for the buyer. It verifies that the crushing and screening process is under control and capable of delivering a consistent product. Case studies showing successful verification are powerful marketing tools and are often a requirement for participating in tenders or supplying large-scale energy producers. This verification process builds trust in the brand and the product.

Data Credibility Assurance Measures

Ensuring the credibility of operational and quality data is fundamental for process optimization, claims verification, and participation in incentive programs. This involves a system of measures including the use of calibrated instruments (for power measurement, weighing, and particle size analysis), secure data logging systems, and standardized operating procedures for sampling and testing.

For critical data, such as that used to calculate energy savings for a carbon credit application, the process may be audited by an external verifier. This ensures that the data is accurate, complete, and has not been tampered with. Implementing these measures creates a foundation of trust for all stakeholders—management, customers, regulators, and investors. It turns operational data into a valuable and reliable asset for decision-making and commercial advantage.

Typical Engineering Case Studies

Real-world examples provide the most compelling evidence for the effectiveness of optimized roll crusher strategies in agricultural waste fuel production. These case studies move beyond theoretical models to demonstrate the tangible benefits achieved in operating plants. They highlight the practical challenges encountered and the solutions implemented, offering valuable insights for other projects.

Long-term data from these cases is particularly valuable, as it shows the sustainability of the improvements and the impact of factors like maintenance and wear on overall performance. Analyzing these cases helps validate the economic and environmental arguments for investing in advanced crushing technology and provides a blueprint for successful implementation.

Transformation of Fuel Preparation System in a Biomass Power Plant

A 50 MW biomass power plant primarily using straw and wood chips was experiencing frequent boiler outages due to slagging and inconsistent fuel flow, caused by an uncontrolled particle size distribution from their old hammer mill crushers. The mill produced a wide range of sizes, with a high percentage of fines.

The plant underwent a transformation by installing a modern differential speed roll crusher in a closed circuit with a screen. The system was designed to achieve a specific P80 of 18mm. The results were dramatic. Boiler slagging incidents reduced by over 80%, and combustion stability improved significantly due to the consistent fuel size. The specific energy consumption of the crushing circuit itself was reduced by 30% compared to the old hammer mills. This case demonstrated how targeted particle size control directly translates to improved reliability and economics in power generation.

Optimization Example of a Straw Pellet Fuel Production Line

A pellet plant producing fuel pellets from wheat straw was facing high energy costs in their pellet mill and poor pellet durability. The root cause was identified as an inconsistent feedstock from the primary crusher, which contained everything from long, uncut fibers to fine powder. This mix did not compress evenly in the pellet mill die.

The optimization involved replacing the primary crusher with a roll crusher tuned for fiber length optimization. The gap and differential speed were set to produce a product where over 90% of the fibers were between 5mm and 15mm in length. This optimized "furnish" for pelletizing led to a 15% reduction in the energy required by the pellet mill due to smoother operation and a higher compression ratio. Furthermore, pellet durability increased significantly, reducing breakage and fines during handling and transportation. The overall quality and value of the final pellet product were enhanced.

Improvement of Particle Size Qualification Rate in Statistical Data (92% → 98%)

A large-scale biomass processing facility tracked its particle size qualification rate (the percentage of output meeting the P80<20mm specification) over several years. Before optimization, using an open-circuit crushing system, the qualification rate averaged 92%. This meant 8% of the product was off-spec, often requiring re-handling or being sold at a discount.

After implementing a closed-circuit crushing system with a roll crusher and an automated control system based on real-time power draw and feed rate, the qualification rate steadily increased to an average of 98%. This improvement was reflected in the statistical process control (SPC) charts. This 6% increase in yield directly improved revenue and customer satisfaction. The case highlights how process control and the right technology can significantly reduce variation and improve product consistency.

Correlation Analysis Between Equipment Failure Rate and Particle Size Control

An operation noted a correlation between crusher maintenance events and a drift in product size distribution. In the weeks leading up to a failure (e.g., of a bearing or drive component), the control system had to constantly adjust the roll gap to maintain the target product size, and the power draw became more erratic.

Analysis showed that impending mechanical problems manifested first as an inability to maintain consistent crushing performance. The worn components introduced vibration and slack, preventing the precise application of force. By monitoring trends in the standard deviation of the product size and the frequency of gap adjustments, the maintenance team could predict pending failures. This reinforced the idea that precise particle size control is not only a quality goal but also an indicator of the mechanical health of the crushing system. Maintaining the crusher in good health is prerequisite to maintaining product quality.

Long-Term Operational Data Comparison (3+ Years)

A three-year comparative study was conducted at a facility that processed multiple types of agricultural waste. The study compared the performance of a traditional hammer mill circuit against a new roll crusher circuit installed halfway through the period. The long-term data encompassed specific energy consumption (kWh/t), wear part costs ($/t), availability (%), and product quality consistency (standard deviation of P80).

The data unequivocally showed that the roll crusher circuit delivered a 25-40% reduction in energy consumption, depending on the material. Wear part costs were also 30% lower due to the lower rotational speed and different wear mechanism. Most importantly, the availability of the roll crusher circuit was 5% higher, resulting in greater overall production. The product quality was also significantly more consistent. This long-term data provided a solid business case for the superiority of the roll crusher technology for their specific application, justifying the capital investment.

Technology Development Trends

The field of biomass crushing is continuously evolving, driven by the demands for higher efficiency, greater flexibility, and lower operating costs. The integration of digital technologies and advanced materials is transforming the roll crusher from a simple mechanical device into an intelligent, connected component of a larger optimized system. These trends point towards a future where crushing operations are largely autonomous, self-optimizing, and seamlessly integrated into the industrial IoT landscape.

Emerging technologies focus on gaining deeper real-time insights into the process, using data to make predictive decisions, and designing equipment for maximum adaptability and longevity. These innovations promise to further reduce the energy and environmental footprint of producing biomass fuel, making it an even more competitive and sustainable alternative to fossil fuels.

Application of Online Near-Infrared Spectroscopy (NIRS) Detection Technology

Near-Infrared Spectroscopy (NIRS) is a powerful analytical technique that is being adapted for online use in biomass processing. An NIRS sensor mounted above a conveyor belt can analyze the flowing stream of crushed material in real-time. It provides instantaneous data on key quality parameters far beyond particle size, including moisture content, ash content, and even approximate calorific value based on organic composition.

This real-time chemical analysis provides a game-changing level of control. The crusher's operating parameters (e.g., gap, speed) can be automatically adjusted not just based on particle size, but also on the detected moisture or ash content of the feed. For example, if the NIRS detects a wet patch of feedstock, it can signal the crusher to temporarily open the gap to prevent plugging. This moves the control system from reactive to predictive, optimizing the process for multiple quality variables simultaneously and ensuring a more consistent final product.

Machine Learning for Optimizing Crushing Parameters

Machine learning (ML) algorithms are capable of finding complex, non-linear relationships in operational data that are impossible for human operators to discern. An ML system can be trained on historical data from the crusher, including feed rate, power draw, roll gap setting, motor speed, and the resulting product size (from an online particle size analyzer).

Once trained, the model can predict the optimal crusher settings for any given set of feed conditions to achieve the target product size with the lowest energy consumption. It can continuously learn and adapt as the crusher wears or as the characteristics of the agricultural waste change seasonally. This represents the pinnacle of process optimization, where the crusher is not just controlled but truly self-optimizing, constantly pushing towards the limits of its efficiency.

Adaptive Control Model Based on Material Characteristics

Building on machine learning, an adaptive control model can be developed. This model would use direct or inferred measurements of the feed material's characteristics (e.g., moisture from NIRS, hardness inferred from power draw) to automatically select a pre-defined set of optimal operating parameters from a library of recipes.

For instance, when switching from processing brittle sunflower husks to tough wheat straw, the system would automatically adjust the roll gap, pressure, differential speed ratio, and feed rate to the predetermined optimal values for each material. This drastically reduces the transition time and material waste associated with manual adjustments and ensures the crusher is always operating in the correct regime for the feedstock it is receiving, maximizing both quality and efficiency.

Predictive Maintenance System Development

Predictive maintenance (PdM) uses data from sensors (vibration, temperature, acoustic emissions, motor current analysis) to forecast when a component will fail, allowing maintenance to be planned just before it becomes necessary. For a roll crusher, PdM can predict the failure of bearings, gears, and hydraulic components.

By analyzing trends in vibration spectra, an algorithm can detect the early stages of bearing wear weeks before it leads to catastrophic failure. This prevents unplanned downtime, which is extremely costly in a continuous operation. It also ensures that the crusher is always maintained in peak condition, which is a prerequisite for operating at peak energy efficiency. A poorly maintained crusher with worn bearings or misaligned gears will consume more energy to achieve the same output.

Impact of Modular Design on Multi-Material Adaptability

The future of crusher design lies in modularity. Instead of a fixed machine, a crusher could be built from interchangeable modules. For example, a base frame could accept different roll modules: one set with large, aggressive teeth for coarse primary crushing of straw bales, and another set with fine, smooth corrugations for gentle size reduction of rice husk.

This allows a single processing facility to handle a wide variety of seasonal agricultural wastes with optimal efficiency for each. Changing from one material to another becomes a matter of swapping modules, which could be done in a matter of hours rather than requiring a complete and costly machine replacement. This modular approach maximizes the utilization of capital equipment and provides the flexibility needed to process the variable waste streams typical of agriculture.

Application of 5G Technology in Remote Parameter Adjustment

The high speed, low latency, and high device density supported by 5G networks are ideal for industrial IoT applications. In a biomass crushing context, 5G enables the reliable and secure wireless connection of all sensors and actuators on the crusher and throughout the plant.

More importantly, it enables true remote expert support. A specialist located anywhere in the world can use a secure connection to view real-time operational data and even make fine-tuning adjustments to the crusher's parameters to optimize performance. This is particularly valuable for plants located in remote agricultural areas where local expertise may be limited. The low latency ensures that adjustments are made in near real-time, making remote operation and optimization a practical reality. This technology supports the trend towards centralized, expert-led monitoring of distributed assets.