Cost-Effectiveness Comparison: Mobile Crushing Stations vs. Fixed Crushing Plants in Mining Operations

This article provides a systematic analysis of the economic differences between mobile crushing equipment and fixed crushing systems in mining scenarios, offering a data-driven foundation for equipment selection. By incorporating the latest industry case studies and data projections for 2025, it reveals the total lifecycle cost structures and operational efficiency variations of these two dominant crushing solutions. The comparison spans initial investment, operational throughput, maintenance management, and long-term financial viability, providing a holistic view for strategic decision-making in mineral processing operations.

The fundamental choice between mobile and fixed crushers significantly impacts a project's profitability and adaptability. Mobile crushers, with their integrated design and autonomous operation, offer unparalleled flexibility for specific applications. In contrast, fixed crushing plants, known for their massive scale and high-volume processing capabilities, represent traditional industrial strength. This analysis delves beyond superficial specifications to examine hard economic data, including capital expenditure, operational overheads, and residual values, providing a comprehensive financial perspective on this crucial operational decision.

Initial Investment Costs: Capital Expenditure Analysis

The initial investment phase presents fundamentally different financial structures for mobile and fixed crushing solutions. Mobile crushing stations typically command 30-50% higher equipment purchase prices compared to individual fixed plant components due to their integrated engineering and compact design. However, this premium is frequently offset by the elimination of extensive civil engineering works, which represent a substantial portion of fixed plant investments. The financial dynamics of this initial phase often determine project feasibility, particularly for medium-scale operations with limited capital resources.

Fixed crushing plants require significant groundwork before equipment installation can commence. This includes reinforced concrete foundations that alone account for approximately 40% of the total initial investment. Additionally, fixed plants demand substantial supporting infrastructure, including electrical substations, control rooms, and permanent environmental protection systems. These ancillary investments, while creating permanent assets, substantially increase the initial capital outlay before any material processing can begin.

Equipment Procurement Price Variations

The purchase price differential between mobile and stationary crushers reflects their distinct engineering philosophies. A complete mobile crushing station, incorporating primary and secondary crushing units, screening modules, and integrated conveyors, represents a concentrated capital investment ranging between $1.2-2.5 million depending on capacity and specifications. This integrated approach consolidates multiple processing functions into a single equipment purchase, simplifying procurement but requiring substantial upfront capital.

Fixed plant equipment purchases follow a different pattern, with individual components acquired separately—primary jaw crushers, secondary cone crushers, vibrating screens, and conveying systems—typically totaling 30-50% less than equivalent mobile systems. However, this apparent savings is misleading without considering the additional costs of plant construction, infrastructure development, and installation engineering that transform individual machines into an operational processing plant.

Site Preparation Expenses

Mobile crushing equipment demonstrates distinct advantages in site preparation requirements. These self-contained units can be deployed directly on prepared mining benches or processing areas without dedicated foundation works. The minimal site preparation typically involves leveling and compacting an area approximately 50% larger than the equipment footprint to ensure operational stability and safety, representing a negligible cost compared to fixed plant requirements.

Fixed crushing plants demand extensive site preparation spanning 3-6 months before equipment installation. This process includes geological surveying, bulk excavation, reinforced concrete foundation pouring, and the construction of permanent structures. The civil engineering component alone typically costs $500,000-1,000,000 for medium-capacity plants, representing a non-recoverable investment that significantly impacts project financials, particularly in temporary mining operations.

Installation and Commissioning Timeline

Mobile crushers offer remarkable deployment speed, achieving operational status within 72 hours of arrival on site. This rapid commissioning is possible due to factory-preassembled modules that require only connection between units and basic calibration. The "plug-and-play" nature of modern mobile crushing plants allows producers to begin processing material almost immediately, reducing project lead times and accelerating revenue generation.

Fixed crushing plants require extended installation periods of 2-4 weeks for equipment assembly and additional time for structural completion. This process involves crane-assisted placement of major components, precise alignment of crushers and screens, installation of extensive conveyor systems, and integration of electrical and control systems. The prolonged installation period represents significant opportunity costs through delayed production initiation.

Auxiliary Facility Investments

Mobile crushing stations incorporate numerous auxiliary functions within their design, eliminating separate infrastructure costs. Self-contained power generation systems, dust suppression units, and control cabins are integrated into the equipment design. This comprehensive engineering approach avoids the need for separate infrastructure investments, particularly beneficial in remote locations where grid connection proves impractical or prohibitively expensive.

Fixed plants require substantial auxiliary facilities including dedicated power distribution stations, permanent dust collection systems, water recycling facilities, and maintenance workshops. These supporting structures typically add 25-30% to the initial equipment investment cost. While creating permanent infrastructure, these investments represent sunk costs that cannot be recovered if the processing needs change or the resource is depleted.

Operational Efficiency: Throughput and Productivity Metrics

Operational efficiency represents the crucial economic differentiator between mobile and fixed crushing solutions throughout their service life. Mobile crushing stations achieve superior operational efficiency through their unique ability to implement continuous "drill-blast-crush-haul" cycles without intermediate material handling. This integrated approach eliminates double handling of material, reducing operational costs by 15-20% compared to traditional fixed plant operations that require front-end loader transport between face and plant.

Fixed crushing plants excel in raw processing power and consistency for high-volume operations. Their stationary nature permits optimized material flow patterns and larger equipment sizes that can sustain throughput rates exceeding 6000 tons per hour in major mining operations. The operational efficiency of fixed plants increases with scale, making them economically superior for large, long-life deposits where the high initial investment can be amortized over decades of operation.

Raw Material Processing Capacity

Mobile crushers demonstrate particular advantages in direct face crushing applications where they process material immediately after blasting. This approach eliminates the need for primary loading and haulage to a fixed plant, reducing both cycle times and equipment requirements. Modern mobile units can achieve processing rates of 400-600 tons per hour, sufficient for most medium-scale mining operations and particularly effective in selective mining applications where the processing equipment must follow the mineralization.

Fixed crushing plants offer substantially higher maximum capacities, with some installations processing over 10,000 tons per hour in massive mining operations. This volume advantage comes from the ability to install extremely large primary crushers and extensive pre-screening systems that optimize the crushing circuit. The consistent operating environment of fixed plants allows precise optimization of crushing parameters for specific rock types, maximizing throughput and product quality.

Energy Consumption Patterns

Mobile crushing equipment typically operates with diesel-powered generators, resulting in energy costs approximately 8% higher than grid-powered fixed plants. However, modern mobile units incorporate advanced dual-power systems that allow connection to grid power when available, significantly reducing operating costs during stationary operational phases. This flexibility provides operational cost advantages in scenarios where equipment must frequently relocate between powered and unpowered areas.

Fixed plants connected to grid electricity benefit from substantially lower energy costs and more stable power quality. The consistent power supply enables optimized motor performance and reduced maintenance costs associated with power fluctuations. Additionally, fixed plants can implement sophisticated energy management systems that shift non-critical operations to off-peak hours, further reducing electricity expenses through strategic power consumption scheduling.

Labor Cost Structure

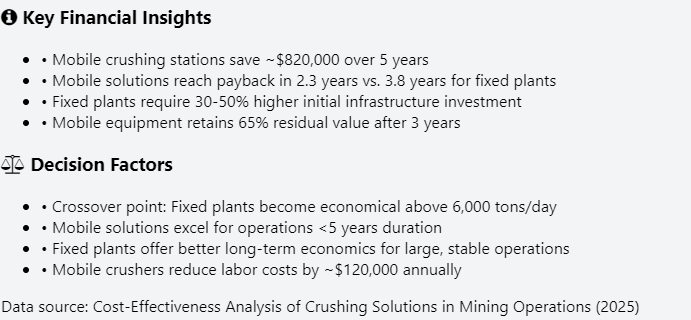

Mobile crushing operations require significantly reduced crew sizes compared to fixed plant operations. A typical mobile crushing spread can be operated by 2-3 personnel per shift, compared to 5-6 for equivalent fixed plant operations. This labor efficiency translates to annual savings of approximately $120,000 in direct operating costs, in addition to reduced overhead for facilities, supervision, and support services for the smaller workforce.

Fixed crushing plants require dedicated maintenance teams, control room operators, and material handling personnel, resulting in higher labor costs. However, this specialized workforce often achieves higher equipment availability through proactive maintenance and continuous operational optimization. The stationary nature of fixed plants also permits more comprehensive training and development of operation-specific expertise, potentially improving overall plant performance despite higher direct labor costs.

Production Flexibility and Adaptation

Mobile crushing equipment offers unparalleled operational flexibility, with the ability to relocate between different faces or sites within hours. This mobility permits optimal deployment of processing capacity to match mining sequences, minimizing haul distances as the operation progresses. The rapid reconfiguration capability allows operators to respond quickly to changing geological conditions or market demands by adjusting product specifications through mechanical adjustments or crusher parameter modifications.

Fixed plants require substantial modification periods of 6-8 weeks for significant capacity changes or process adjustments. This inflexibility represents a significant operational constraint when facing changing ore characteristics or market requirements. However, fixed plants can be designed with inherent flexibility through multiple crushing lines and bypass arrangements, though at increased capital cost compared to single-line configurations.

Maintenance and Component Management Strategies

Maintenance approaches differ fundamentally between mobile and stationary crushing systems, impacting both operating costs and equipment availability. Mobile crushers experience approximately 12% higher wear rates on crushing components due to more variable operating conditions and frequent relocations. However, they incorporate advanced quick-change systems for wear parts that reduce replacement downtime to hours rather than days, significantly improving operational availability despite more frequent maintenance requirements.

Fixed crushing plants benefit from stable operating conditions that reduce component wear and permit optimized maintenance scheduling. The permanent installation allows implementation of sophisticated maintenance platforms and permanent lifting equipment that reduces both the time and cost of major component replacements. The controlled environment of fixed plants also enables more accurate monitoring of component condition, permitting proactive replacement before catastrophic failure occurs.

Wear Part Replacement Frequency

The crushing chamber components in mobile crushers experience accelerated wear due to frequent changes in feed material characteristics when moving between locations. Modern mobile units address this challenge through advanced wear monitoring systems that track component life and schedule replacements during planned maintenance periods. Quick-change jaw plates and cone liners can be replaced in 4-8 hours, compared to 24-48 hours for equivalent fixed plant components.

Fixed plant crushers operate in more consistent conditions, permitting precise optimization of wear part design and materials for specific rock characteristics. This specialization extends component life by 20-30% compared to general-purpose mobile crusher components. The stationary installation also permits the use of larger, more durable components that would be impractical in mobile applications due to weight and size constraints.

Breakdown Response and Service Availability

Mobile crushing equipment manufacturers typically provide comprehensive service agreements including 48-hour on-site technical support. This rapid response capability minimizes production losses during unplanned downtime. Many mobile crushers also incorporate remote monitoring systems that automatically alert service centers to developing problems before they cause operational interruptions, enabling proactive maintenance scheduling.

Fixed plants often rely on local maintenance teams whose response times vary significantly by location. In remote mining areas, specialized technical support may require several days to reach site, potentially extending downtime periods. However, the scale of fixed operations typically justifies maintaining comprehensive on-site maintenance facilities and specialized personnel, reducing dependence on external support for all but the most major repairs.

Equipment Residual Values

Mobile crushing equipment maintains remarkably high residual values, typically retaining 65% of original value after three years of operation. This strong secondary market results from the equipment's flexibility and adaptability to various applications. Well-maintained mobile crushers often have service lives exceeding 10 years through component refurbishment and technological upgrades, providing excellent long-term value retention.

Fixed plant equipment demonstrates poor residual value characteristics, with most value residing in the structural components rather than the processing equipment itself. Upon mine depletion, fixed crushing plants typically yield only scrap value for the structural steel and recoverable components. The specialized nature of fixed plant installations makes relocation economically impractical in most cases, resulting in complete write-off of the facility upon resource exhaustion.

Environmental Compliance Costs

Modern mobile crushers incorporate comprehensive environmental protection systems meeting Tier 4 emission standards and stringent noise regulations. These integrated systems avoid the need for additional environmental infrastructure investments. Advanced dust suppression systems automatically activate during crushing operations, maintaining particulate emissions within regulatory limits without operator intervention through sophisticated moisture monitoring and spray control systems.

Fixed plants require substantial additional investments in environmental controls including enclosed transfer points, baghouse filtration systems, and wastewater treatment facilities. These environmental management systems typically add 15-20% to the initial plant capital cost and require ongoing operational expenditure for maintenance and monitoring. However, the permanent nature of these installations permits more comprehensive environmental management strategies than typically achievable with mobile equipment.

Total Lifecycle Cost Modeling: Comprehensive Financial Analysis

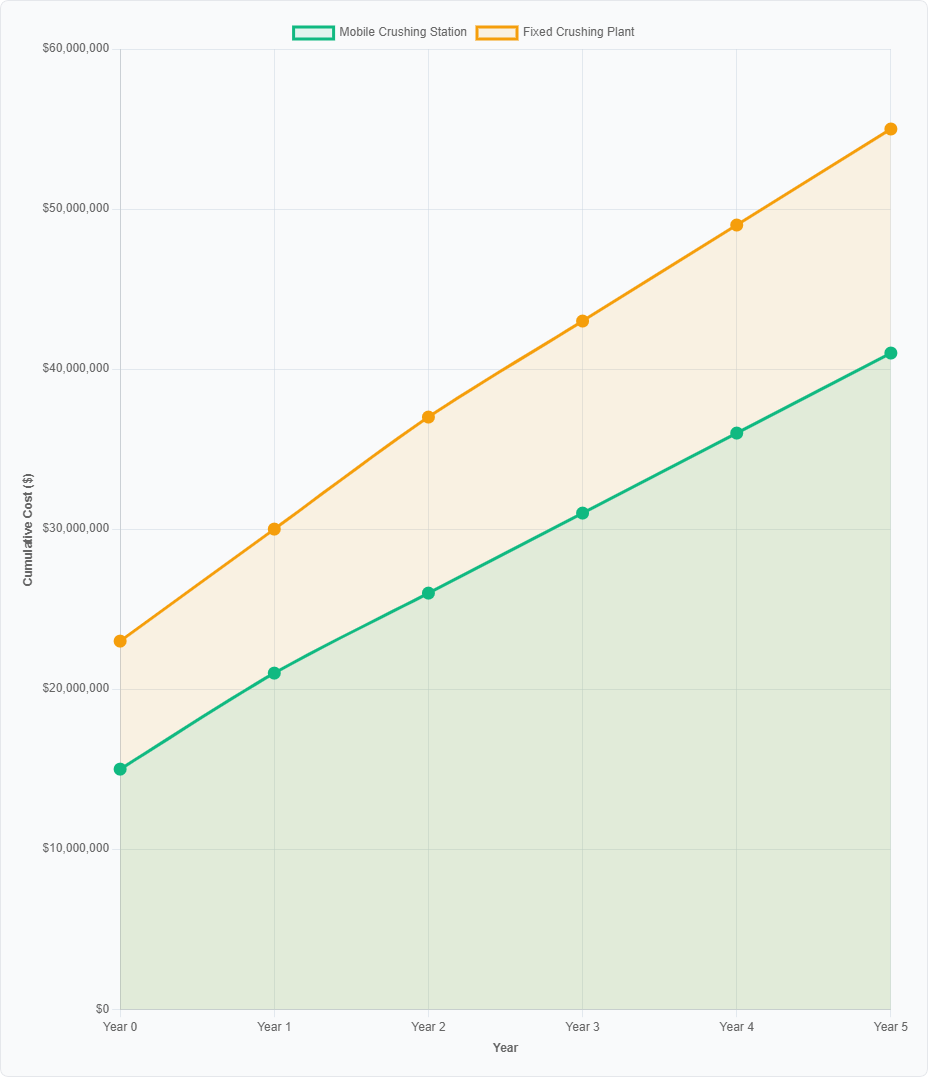

The total cost of ownership (TCO) over a typical 5-year period reveals significant advantages for mobile crushing solutions in many applications. Comprehensive modeling demonstrates that mobile crushing stations achieve 18-25% lower TCO compared to fixed plants across a range of operating scenarios. This advantage is particularly pronounced in operations requiring frequent relocation, where mobile equipment avoids the substantial costs associated with fixed plant modification or reconstruction.

For a medium-scale operation processing 4,000 tons per day, the mobile crushing solution demonstrates a cumulative savings of approximately $820,000 over the 5-year analysis period. This financial advantage derives from reduced initial infrastructure investment, lower operating costs through reduced material handling, and higher residual equipment values. The financial model incorporates all capital and operating cost elements, providing a comprehensive comparison of the economic performance of both solutions.

Five-Year Total Cost of Ownership Comparison

The TCO analysis incorporates all direct and indirect costs associated with crushing operations, including equipment depreciation, energy consumption, labor, maintenance, and overhead allocations. Mobile crushers demonstrate particular cost advantages in the first three years of operation, where their lower initial infrastructure requirements and higher operational flexibility provide superior financial performance. The cost differential narrows in later years as fixed plants fully depreciate their initial infrastructure investments.

Fixed plants achieve cost parity with mobile solutions only in very high-volume applications exceeding 6,000 tons per day where their superior energy efficiency and lower per-ton maintenance costs offset the higher capital investment. The crossover point between mobile and fixed plant economic advantage varies significantly with specific operational parameters including electricity costs, labor rates, and maintenance requirements.

Investment Payback Period Analysis

Mobile crushing equipment typically achieves capital recovery within 2.3 years of operation through reduced initial investment and lower operating costs. This rapid payback period provides significant financial flexibility, permitting operators to recoup their investment before major component replacements become necessary. The shorter investment horizon also reduces financial risk in uncertain market conditions or variable resource quality scenarios.

Fixed crushing plants require approximately 3.8 years to reach breakeven due to their substantial initial capital requirements. This extended payback period increases financial exposure to operational disruptions, market changes, or resource depletion. However, once the initial investment is recovered, fixed plants typically generate superior cash flows in the later years of operation due to their lower operating costs at high production volumes.

Economies of Scale Considerations

The economic advantage between mobile and fixed crushing solutions reverses at approximately 6,000 tons per day processing capacity. Below this threshold, mobile solutions demonstrate superior economics through flexibility and lower capital requirements. Above this capacity, fixed plants benefit from economies of scale that reduce per-ton processing costs despite higher initial investments. This crossover point varies based on specific operational factors including mine life, rock characteristics, and product specifications.

Massive mining operations processing over 10,000 tons per day achieve crushing costs 30-40% lower than theoretically possible with mobile equipment due to the extreme economies of scale available with fixed plant installations. These operations utilize equipment sizes and configurations that would be impossible to implement in mobile applications, achieving unprecedented efficiency through mechanical optimization and process integration.

Policy Risk Mitigation Strategies

Mobile crushing equipment provides inherent protection against regulatory changes and permitting challenges. Their temporary nature typically avoids the extensive environmental impact assessments and permitting processes required for fixed installations. This regulatory advantage can reduce project development time by 6-12 months in jurisdictions with complex approval processes, providing significant financial benefits through earlier production commencement.

Fixed crushing plants face substantial regulatory risks including changing environmental standards, zoning restrictions, and community relations challenges. These permanent installations require ongoing compliance investments as regulations evolve throughout the operational life. Additionally, fixed plants face potential asset stranding if resource depletion occurs before capital recovery, creating significant financial risk in uncertain resource environments.

Application-Specific Selection Guidelines

The optimal selection between mobile and fixed crushing solutions depends fundamentally on specific application requirements and operational parameters. Mobile crushers demonstrate particular advantages in short-duration projects under 5 years where their rapid deployment and flexibility provide superior economics. Their ability to follow the mining face reduces haulage requirements and permits continuous operation close to the extraction point, minimizing equipment requirements and operational costs.

Fixed crushing plants remain the preferred solution for large-scale, long-life operations exceeding 200 million tons annual production. Their superior energy efficiency and lower operating costs at scale provide compelling economics despite higher initial investments. Fixed installations also permit more sophisticated process control and product optimization through precise circuit configuration and consistent operating conditions.

Open-Pit Mining Applications

In open-pit mining, mobile crushers excel in operations with multiple discrete pits or frequently changing mining faces. Their ability to relocate between operating areas minimizes haul distances as the mine develops, reducing both cycle times and fuel consumption. Mobile units can be positioned directly at the mining face, processing material immediately after blasting and loading directly to long-distance conveyors or haul trucks for transport to processing facilities.

Fixed plants serve massive open-pit operations where consistent high-volume processing justifies the substantial infrastructure investment. These installations typically receive material from multiple mining faces via haul trucks or in-pit crushing and conveying systems. The fixed nature permits optimization of the entire material handling system from face to plant, maximizing overall operational efficiency through integrated system design.

Construction Waste Recycling Operations

Mobile crushing equipment dominates construction and demolition waste recycling through its ability to process material on-site, avoiding transportation costs and landfill fees. Modern mobile units can be operational within hours of arrival at a demolition site, processing concrete and asphalt into valuable aggregate products directly where needed. This on-site processing approach eliminates double handling and transportation of waste materials, significantly improving project economics while providing environmental benefits through reduced truck movements.

Fixed recycling plants serve urban areas generating consistent volumes of construction waste, where centralized processing justifies the infrastructure investment. These facilities typically incorporate sophisticated sorting and separation systems that maximize material recovery rates and product quality. The stationary nature permits implementation of extensive environmental controls that minimize impacts on surrounding communities through comprehensive dust and noise management systems.

Emergency and Disaster Response Scenarios

Mobile crushing stations provide critical capabilities in disaster response situations where rapid processing of debris is essential for recovery operations. These units can be deployed within 72 hours to disaster areas, processing collapsed structures and debris into usable material for reconstruction efforts. The self-contained nature of mobile crushers permits operation in areas without infrastructure, supporting recovery efforts when traditional facilities are unavailable or destroyed.

Fixed crushing plants cannot provide the rapid response capabilities required in emergency situations due to their permanent nature and extensive infrastructure requirements. However, they play crucial roles in later phase recovery operations, processing massive volumes of debris more efficiently than mobile equipment once temporary infrastructure is established and the scale of operations justifies centralized processing.

Cross-Border Mining Development Projects

Mobile crushing equipment offers significant advantages in international mining projects where equipment importation tariffs and regulations complicate fixed plant establishment. The classification of mobile crushers as temporary equipment often permits duty-free importation under specific customs regimes designed to facilitate temporary project operations. This regulatory advantage can reduce equipment costs by 15-25% compared to permanently imported fixed plant equipment subject to full import duties.

Fixed crushing plants face complex regulatory challenges in cross-border operations, often requiring local content commitments, permanent importation duties, and extensive environmental approvals. These requirements frequently delay project development by 12-24 months compared to mobile solutions that can begin operation under temporary permits while permanent approvals are processed.

Technological Development Trajectories

Crushing technology continues evolving along distinct paths for mobile and fixed applications, driven by different operational priorities and constraints. Mobile crushing systems increasingly incorporate artificial intelligence and machine learning technologies that optimize performance based on feed material characteristics and product requirements. These intelligent systems automatically adjust crusher parameters to maximize throughput and minimize wear, significantly improving operational economics without operator intervention.

Fixed crushing plants are evolving toward fully automated processing facilities with minimal human intervention. These advanced installations incorporate sophisticated process control systems that coordinate multiple crushing stages, screening operations, and material handling systems to optimize overall plant performance. The stationary nature permits implementation of technologies impractical in mobile applications, including extensive instrumentation and sophisticated optimization algorithms.

Intelligent Control System Implementation

Modern mobile crushers incorporate AI-powered performance optimization systems that automatically adjust crusher settings based on real-time processing conditions. These systems analyze feed material characteristics through vision systems and load sensors, modifying operation to maximize productivity while protecting the equipment from damage. The latest control systems can predict maintenance requirements based on operating patterns, scheduling interventions during natural breaks in operation to minimize production impact.

Fixed plants implement plant-wide optimization systems that coordinate multiple processing stages to maximize overall efficiency rather than individual equipment performance. These sophisticated control systems balance production rates, energy consumption, and product quality across the entire processing circuit, achieving efficiencies impossible through individual equipment optimization. The extensive instrumentation available in fixed installations provides the data richness required for these advanced control strategies.

Energy System Innovations

Mobile crushing equipment is rapidly adopting hybrid power systems that combine traditional diesel generators with battery storage and renewable energy sources. Solar-assisted systems can reduce diesel consumption by up to 35% through peak shaving and operational optimization. These hybrid systems permit operation in environmentally sensitive areas where emissions restrictions would otherwise prohibit equipment operation, expanding potential application areas for mobile crushing.

Fixed crushing plants increasingly integrate with microgrid systems that optimize energy costs through strategic power sourcing. These installations can shift non-critical operations to periods of renewable energy availability or lower electricity prices, significantly reducing operational costs. Some fixed plants incorporate energy recovery systems that capture kinetic energy from the crushing process and regenerative braking from conveyors, improving overall energy efficiency by 10-15%.

Advanced Material Applications

Wear component technology continues advancing with new materials extending service life and reducing maintenance requirements. High-manganese steel formulations now achieve service lives exceeding 12,000 operating hours in abrasive applications, reducing replacement frequency and associated downtime. Ceramic composite materials are increasingly employed in highly abrasive applications, providing superior wear resistance while reducing equipment weight compared to traditional metallurgical solutions.

Fixed plants benefit from massive wear components impractical in mobile applications due to weight and size constraints. These oversized components achieve extended service lives through increased material volume and sophisticated design optimization. The stationary nature also permits implementation of advanced wear monitoring systems that accurately predict remaining component life, enabling planned replacement during scheduled maintenance periods rather than emergency shutdowns.

Circular Economy Integration

Mobile crushing equipment enables distributed processing models that support circular economy principles by processing materials at their source. This approach minimizes transportation requirements and facilitates reuse of materials in local applications, reducing the environmental impact of construction and mining operations. Mobile units can create temporary processing hubs that serve multiple projects within a region, maximizing equipment utilization while minimizing material movement.

Fixed crushing plants are evolving into permanent recycling hubs that process material from extensive catchment areas. These facilities incorporate sophisticated sorting and separation technologies that maximize material recovery rates and product quality. The scale of fixed installations permits economic processing of contaminated or complex material streams that would be uneconomical in smaller mobile operations, supporting comprehensive material recovery from diverse waste streams.