Economic Viability Analysis of Mobile Jaw Crushers in Small-Scale Open-Pit Mines

This article provides a comprehensive analysis of the economic feasibility of mobile jaw crushers in small-scale open-pit mining operations. By utilizing quantified data models and scenario-based case studies, we will break down the Return on Investment (ROI) and total lifecycle economics of these mobile crushing solutions. The latest 2025 industry data is incorporated to highlight the specific cost advantages mobile systems offer in particular operational contexts. This analysis aims to serve as a crucial decision-making tool for small mining enterprises with limited resources, helping them choose the most efficient and economical equipment for their specific needs.

The core of this investigation lies in comparing mobile jaw crushers against their traditional fixed-plant counterparts across various financial and operational dimensions. We will explore initial capital expenditure, ongoing operational efficiency, maintenance management, and the total cost of ownership over the machine's lifespan. Understanding these factors is essential for any mining operation looking to optimize its crushing capacity while controlling expenses.

Initial Investment Cost Structure

The initial investment required for deploying crushing equipment is a primary concern for small mining companies operating with constrained capital. A mobile jaw crusher typically commands a higher single-unit purchase price, often ranging from 20% to 35% more than an equivalent fixed crusher. This upfront cost difference can be a significant initial hurdle for many operations. However, this price tag must be evaluated in the broader context of the complete setup, where the mobile solution offers substantial savings in other critical areas.

Beyond the machine itself, a fixed crushing plant requires extensive and costly preparatory work. This includes constructing a permanent concrete foundation, which can account for up to 40% of the total initial investment. Mobile crushers eliminate this need entirely, as they are mounted on a robust chassis designed for stability on prepared ground. Furthermore, the deployment time for a mobile unit is dramatically shorter, often requiring less than seven days to be fully operational, compared to the two to three months typically needed for the site preparation and foundation pouring of a fixed plant.

Equipment Procurement Price Comparison

The direct purchase price of a mobile jaw crusher is indeed higher than a fixed model. Market data indicates a premium of approximately 20-35% for the mobile unit. This is attributed to the integrated chassis, hydraulic systems for setup and leveling, and the engineering required to make the unit portable and durable. Despite this higher sticker price, the overall financial picture changes when considering the eliminated costs associated with a fixed installation.

The most significant saving comes from the complete avoidance of permanent infrastructure. A fixed crusher requires a heavy-duty concrete foundation, which involves material costs, labor, engineering surveys, and time. This infrastructure can represent nearly 40% of the total project's initial capital outlay. Therefore, while the mobile crusher's price is higher, the total initial investment can be lower for many small-scale sites when all factors are considered.

Site Adaptation Costs

The adaptability of mobile jaw crushers to various terrains provides a distinct economic advantage. These machines require minimal site preparation; often, a leveled patch of compacted earth is sufficient for stable operation. This eliminates the extensive earthmoving, grading, and compaction work necessary for a fixed plant, saving both time and money. The logistical flexibility allows a mine to begin production much closer to the initial blast site.

In contrast, installing a fixed crusher demands a long-term commitment to a single location. The process involves weeks of land clearing, soil stabilization, and constructing a complex concrete foundation designed to withstand years of vibration and heavy loads. This not only delays the start of revenue-generating crushing activities by 2-3 months but also incurs substantial costs for heavy machinery rental, construction materials, and skilled labor.

Installation and Commissioning Expenses

Commissioning a mobile jaw crusher is a remarkably streamlined process. These units are designed for "plug-and-play" operation, often arriving on site pre-assembled and tested. They can be set up and begin crushing within a single working day, with commissioning costs approximately 60% lower than those for a fixed plant. This rapid deployment translates into immediate productivity and a quicker return on investment.

Fixed crushers present a more complex and expensive commissioning phase. The process involves the careful alignment of multiple components—the crusher itself, feeders, conveyors, and screens—which must be integrated into a single, synchronized system. This multi-stage process requires specialized technicians and often involves lengthy safety inspections and regulatory approvals before operations can commence, adding to the project's upfront costs and timeline.

Auxiliary System Investments

Mobile jaw crushers are typically self-contained units. Many models come equipped with their own onboard power generation, often a diesel generator set, eliminating the immediate need to connect to the regional power grid. They also frequently integrate dust suppression systems, such as water sprayers, to comply with environmental regulations directly from the factory, reducing the need for additional peripheral investments.

A fixed crushing plant, however, requires significant investment in auxiliary infrastructure. This includes constructing a dedicated power substation and running high-voltage electrical lines to the site, which is particularly costly in remote mining areas. Additionally, separate environmental control systems, such as permanent dust collection baghouses or water recycling systems for spraying, must be designed, purchased, and installed, adding considerable expense and complexity to the project.

Operational Efficiency Analysis

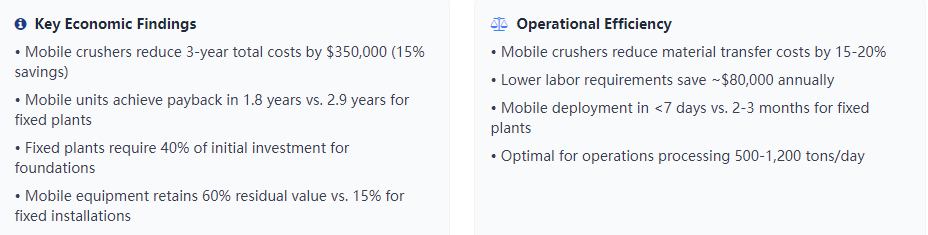

The true value of a mobile jaw crusher is most apparent during daily operations. Its inherent mobility allows for a fundamental optimization of the material handling process. By moving the crusher directly to the mining face, the operation achieves an integrated "blast-crush-transport" workflow. This strategy drastically reduces the number of times material needs to be handled, primarily by minimizing the use of wheel loaders for shuttle hauling between the face and a distant fixed plant.

Studies of small-scale mining operations have shown that this integrated approach can reduce material transfer costs by 15% to 20%. The reduction in loader hours leads to direct savings on fuel, maintenance, and operator wages. Furthermore, by shortening the haul distance for the loaders or trucks feeding the crusher, the cycle time per load is decreased, which can significantly increase the overall throughput of the operation without investing in additional loading equipment.

Raw Material Processing Optimization

The ability to position the crusher at the source of the raw material is a game-changer for operational logistics. This "pit-forward" philosophy means that the primary haulage vehicles, often large dump trucks, travel a much shorter distance to unload. This reduces diesel consumption, tire wear, and truck maintenance costs. The entire process becomes more continuous and less fragmented, leading to a smoother and more efficient production flow.

In a traditional setup with a fixed plant, material must be transported from the constantly moving mining face, which can become progressively farther away. This leads to escalating haulage costs over the life of the mine. The mobile solution inherently avoids this cost escalation by relocating the crusher to follow the resource, maintaining an optimal and consistent haulage distance throughout the project.

Energy Consumption Models

From an energy perspective, mobile jaw crushers powered by diesel engines can have a higher per-ton energy cost compared to fixed crushers connected to the electrical grid—sometimes around 10% higher. However, this simple comparison misses critical nuances. Many modern mobile crushers offer dual-power options, allowing them to connect to grid power when available, providing operational flexibility and potential cost savings.

The reliability of energy supply is another crucial factor. In remote mining locations, connection to a stable electrical grid can be unreliable or non-existent. Fixed plants in these areas face the risk of unexpected power outages, which halt all production. Mobile units with their independent diesel power are immune to grid failures, ensuring operational continuity and protecting against costly downtime, which can far outweigh the slightly higher cost of diesel energy.

Labor Cost Composition

Mobile crushing plants are designed for operational simplicity and often require a smaller crew to run effectively. It is common for a mobile jaw crusher operation to require two fewer operators per shift compared to a fixed plant that may need dedicated personnel for feeding, crusher management, and conveyor monitoring. For a operation running multiple shifts, this reduction in manpower can lead to substantial annual savings, potentially up to $80,000 in reduced wages and associated benefits.

Fixed crushing installations often necessitate a dedicated, on-site maintenance team of 3 to 5 technicians to manage the complex system of conveyors, feeders, and the crusher itself. The mobile setup, by contrast, is a single, integrated unit. While it still requires maintenance, the simplicity of having one primary machine to focus on can reduce the required maintenance labor hours and the need for a large, specialized team permanently on site.

Production Flexibility

One of the most significant advantages of a mobile jaw crusher is its ability to quickly adapt to changing production needs and locations. When the mining face advances, the crusher can be relocated in a very short time, often in less than four hours. This means crushing can resume almost immediately at the new location, minimizing any disruption to the production schedule and ensuring a continuous supply of crushed material.

A fixed crusher lacks this flexibility. If the deposit is scattered or the primary mining face moves beyond an economical haulage distance, the fixed plant becomes a liability. Adjusting the fixed system's capacity or relocating it is a major undertaking, involving disassembly, transportation, and reassembly, a process that can take one to two weeks or more, during which time the entire crushing operation is shut down, resulting in significant lost revenue.

Maintenance and Wear Management

Maintaining peak operational efficiency requires diligent management of wear parts and maintenance schedules. The wear characteristics of a mobile jaw crusher can differ from a fixed unit due to variations in feeding conditions and potential for more frequent setup and teardown. Specifically, the jaw plates in a mobile unit may experience a slightly higher wear rate, estimated around 8% more in some comparative studies. However, this is often mitigated by design features focused on rapid maintenance.

Modern mobile crushers are engineered for quick and easy access to key components. Many feature hydraulic adjustment systems and jacking legs that allow for fast replacement of wear parts like jaw plates, reducing downtime to a matter of hours instead of days. This design philosophy prioritizes minimizing lost production time, which is often the most significant cost associated with maintenance in a mining environment.

Wear Parts Replacement Cycle

While the wear rate on components like jaw plates and liners might be marginally higher in mobile applications, the ease and speed of replacement dramatically reduce the overall impact on productivity. Manufacturers have developed quick-release systems and tool-less adjustment mechanisms that allow a single technician to replace wear parts efficiently. This focus on serviceability is a core design principle for mobile equipment.

Repairing a fixed crusher, particularly major components within the crushing chamber, often requires a complete production shutdown for the entire plant. The downtime for such repairs can be extensive, sometimes lasting several days. With lost production potentially costing $5,000 or more per day, these extended outages represent a major financial risk that mobile crushers are specifically designed to avoid.

Fault Response Efficiency

Service support is a critical consideration. Leading manufacturers of mobile crushing equipment typically offer comprehensive service agreements that include rapid on-site response, often within 48 hours for up to 90% of their operational territories. This guaranteed support provides peace of mind and ensures that any major mechanical issues are resolved quickly by factory-trained technicians, minimizing operational risk.

Fixed plants often rely on the availability and expertise of local third-party service providers. In remote mining areas, the average response time for a qualified technician can be 72 hours or longer. This delay, combined with potential difficulties in sourcing specialized parts for fixed crushers, can prolong downtime and exacerbate production losses, making the supported mobile crusher model a more reliable choice.

Equipment Resale Value

The investment lifecycle of equipment is an important economic factor. Mobile jaw crushers retain a high residual value due to their versatility and demand in the used equipment market. It is not uncommon for a well-maintained mobile crusher to hold up to 60% of its original value after three years of service. This high resale value improves the overall return on investment and provides flexibility for equipment upgrades.

In contrast, a fixed crushing plant is a permanent installation. Its value is heavily tied to its specific location and infrastructure. If a mine is depleted or the plant needs to be relocated, the cost of dismantling is high, and the resale value of the used equipment is often low, sometimes recovering only about 15% of the initial investment, primarily from the scrap value of the steel structure and components.

Environmental Compliance Costs

Meeting environmental regulations is non-negotiable. Modern mobile jaw crushers are designed with integrated environmental controls. They commonly feature advanced dust suppression systems that use water sprays or sometimes even enclosed conveyor belts to control particulate matter, ensuring compliance with stringent standards like Tier 4 emission regulations directly from the factory.

A fixed plant must have these systems designed and built on-site. This often involves constructing large, enclosed buildings or shelters to contain dust, installing complex baghouse filtration systems, and building water recycling ponds for spray systems. These additional infrastructure requirements can add significant capital cost, often exceeding $120,000, to a fixed plant project that a mobile crusher owner avoids.

Total Lifecycle Cost Model

Evaluating the total cost of ownership (TCO) over a typical project lifespan provides the most accurate financial picture. When all factors are considered—initial investment, operational efficiency, maintenance, and resale value—mobile jaw crushers consistently demonstrate a lower TCO for small-scale applications. Analyses show that the TCO for a mobile system can be 12% to 18% lower than a fixed plant, with the exact figure highly dependent on the number of relocations required.

For a typical small-scale operation processing 1,000 tons per day, the cumulative savings over a three-year period can be substantial, often reaching $350,000 or more. These savings are derived from the aggregation of lower initial infrastructure costs, reduced haulage expenses, lower labor requirements, and minimized downtime. This holistic view is essential for making a sound financial decision on equipment selection.

3-Year Total Cost of Ownership (TCO)

The TCO model encapsulates all direct and indirect costs associated with the crushing equipment. The mobile crusher's advantage is

not in any single category but in the sum of its parts: avoided infrastructure, flexible operation, and lower indirect costs. The frequency of relocating the crusher is a key

variable; the more a mine face moves, the greater the economic advantage of the mobile solution becomes compared to the static, high-haulage-cost model of a fixed

plant.

In a scenario with high relocation frequency, the savings on trucking fuel and maintenance alone can justify the mobile crusher's premium. When these operational savings are combined with the avoided capital costs of fixed infrastructure, the financial argument for a mobile solution in small-scale or short-duration mines becomes overwhelmingly strong, clearly illustrating a TCO reduction of 12-18%.

Investment Payback Period

The speed at which an investment recoups its cost is a vital metric for any business. Due to lower initial capital outlay and faster time-to-production, mobile jaw crushers typically achieve a much quicker payback. Industry data suggests an average payback period of approximately 1.8 years for a mobile unit. This means the machine has paid for itself through generated profits and cost savings in under two years.

A fixed crushing plant, with its higher upfront capital requirements for civil works and installation and its slower commissioning time, takes significantly longer to reach its break-even point. The average payback period for a fixed plant in a similar small-scale application extends to nearly 2.9 years. This longer period represents increased financial risk and a longer wait for a return on the invested capital.

Economy of Scale Threshold

The economic viability of mobile versus fixed crushers is heavily influenced by the scale of operation. Mobile jaw crushers exhibit their strongest economic advantage in small to medium-sized mining operations, typically those with daily production rates between 500 and 1,200 tons. Within this range, their flexibility and lower overall TCO make them the superior choice.

The economic balance begins to shift for larger, high-volume operations. For mines consistently processing over 1,500 tons per day, the higher per-ton energy cost of diesel-powered mobile units and the potential need for multiple machines can erode their advantage. At this scale, the high throughput efficiency and lower per-ton energy cost of a large, grid-powered fixed crushing plant can make it the more economical long-term investment, achieving true economies of scale.

Policy Risk Mitigation

Mining operations are subject to various external risks, including regulatory and policy changes. The portable nature of mobile crushers provides a unique form of risk mitigation. Because they are not permanent structures, they often circumvent the need for lengthy and uncertain land acquisition permits and environmental approvals for fixed construction, potentially saving 6 to 8 months in project startup time.

A significant risk for a fixed plant is asset stranding. If a mineral resource is depleted sooner than expected or if mining permits are not renewed, the fixed plant becomes a largely immovable asset, facing a dramatic loss in value. Experts estimate that the residual value of a stranded fixed plant can be reduced by up to 40% due to the high cost of dismantling and relocation. Mobile crushers are inherently protected from this risk, as they can be easily transported to a new site and redeployed.

Typical Application Scenario Decision Tree

Selecting the right equipment depends on matching its strengths to the specific project parameters. Mobile jaw crushers are exceptionally well-suited for certain well-defined scenarios. Their flexibility and rapid deployment make them ideal for projects with a short operational timeline or those operating in challenging environments where traditional fixed plants are impractical or too expensive to install.

A decision tree for equipment selection would first consider the project's duration and scale. It would then factor in geographical constraints, logistical challenges, and specific operational requirements like the need for rapid mobility or dealing with complex terrain. By answering these key questions, a mine operator can clearly identify which type of crushing solution will deliver the best economic outcome.

Short-Cycle Mine Development

For mining projects with a contracted lifespan of less than three years, such as many quarrying contracts or small mineral deposits, mobile jaw crushers are the unequivocal choice. The ability to quickly commission, operate, and then demobilize the equipment aligns perfectly with the project's timeline. This avoids sinking large capital into permanent infrastructure that will have minimal useful life and low salvage value.

Fixed crushing plants are the domain of long-term, high-volume operations. They are economically justified in large quarries or mines with a confirmed resource life exceeding five years and annual production volumes greater than 500,000 tons. In these settings, the initial capital investment is amortized over a long period and a large tonnage, making the higher efficiency and lower per-ton operating cost of the fixed plant the deciding factor.

Topographically Complex Mining Areas

Mining in mountainous or otherwise difficult terrain is a prime application for mobile crushers. These units can operate on slopes exceeding 15 degrees with proper stabilization, allowing the crushing process to be brought directly to the resource without the need for massive and expensive earthmoving projects. This capability preserves the natural landscape and avoids triggering extensive environmental reviews often associated with major ground disturbance.

Installing a fixed plant in rugged topography is a major engineering challenge. It requires flattening a large area of land, constructing retaining walls, and ensuring foundational stability, which can add over $200,000 to the project's cost before any equipment is even purchased. The mobile crusher's ability to work on terraces or natural benches within the pit eliminates this prohibitive preparatory expense.

Emergency and Disaster Relief Scenarios

The rapid deployment capability of mobile jaw crushers makes them invaluable in emergency situations. Following natural disasters like earthquakes or hurricanes, there is an urgent need to clear and process vast amounts of concrete and masonry rubble. Mobile units can be transported to the disaster zone and be fully operational within 72 hours, facilitating rapid recycling of debris into usable aggregate for reconstruction efforts.

Fixed crushing plants are completely incapable of meeting this rapid-response need. Their permanent nature and long construction timeline render them irrelevant in disaster scenarios where speed is of the essence. The agility of mobile crushing systems provides a critical function in community recovery and rebuilding efforts, turning a problem of waste disposal into a source of valuable construction material.

Cross-Border Mining Development

International mining projects present unique logistical and financial challenges, particularly regarding the importation of equipment. Mobile crushers can often be classified as temporary equipment, which may help in avoiding or reducing hefty import tariffs and taxes in some countries, potentially saving up to 18% on associated costs. This classification simplifies the logistics of moving equipment across borders for specific contracts.

Fixed plants face significant hurdles in international projects. Many countries have strict localization policies that require a certain percentage of equipment to be manufactured or assembled locally. Complying with these policies for a fixed plant can be incredibly complex and expensive, potentially increasing project costs by 25% or more through the need for local sourcing, additional engineering, and meeting specific national standards.

Technology Development Trends

The future of crushing technology is focused on enhancing efficiency, reducing environmental impact, and lowering operating costs through innovation. Mobile jaw crushers are at the forefront of this evolution, integrating sophisticated technology that makes them smarter, cleaner, and more productive. These advancements are continuously improving their economic viability and expanding their range of applications.

Key areas of development include the integration of artificial intelligence for operational optimization, the adoption of alternative energy sources to reduce carbon footprint, the invention of new materials to extend component life, and the creation of new business models centered on the principles of a circular economy. These trends are shaping the next generation of crushing equipment, making it more sustainable and cost-effective.

Intelligence Upgrade Systems

Automation and data analytics are revolutionizing crushing operations. Modern mobile crushers can be equipped with AI-powered systems that continuously monitor and optimize performance. These systems can automatically adjust the crusher's settings, such as the discharge size and feed rate, in real-time based on the hardness of the rock and the desired product specification, maximizing throughput and efficiency while minimizing wear.

Fixed plant technology is also advancing, moving towards the concept of the modular plant. These designs pre-assemble major sections of the plant in a factory environment, leading to a significant reduction—potentially up to 50%—in on-site installation and commissioning time. This hybrid approach combines the high capacity of a fixed plant with some of the deployment speed traditionally associated with mobile solutions.

Energy Structure Transformation

The industry is actively seeking ways to decarbonize operations. For mobile crushers, a prominent innovation is the integration of hybrid power systems. Some models now incorporate solar panel arrays that assist in powering the machine's hydraulic and control systems, potentially reducing diesel consumption by 30% during daylight operation. This not only cuts fuel costs but also significantly reduces greenhouse gas emissions and noise levels on site.

Fixed plants are leveraging their connection to the electrical grid to optimize energy costs. Sophisticated energy management systems can now schedule high-energy-consuming processes, like crushing, to occur during off-peak hours when electricity tariffs are lowest. This strategy, known as peak shaving, can lead to substantial savings, reducing a plant's overall electricity bill by an average of 15% without any reduction in production output.

Material Innovation Advances

The longevity of wear parts is critical to operating costs. Material science has made great strides, with new alloys and composites dramatically extending service life. The development of high-chromium iron for jaw plates and liners has been a breakthrough, allowing these components to last for 8,000 hours or more of operation in abrasive conditions, directly reducing downtime and the cost of replacement parts.

Beyond metals, ceramic and polymer composites are being used in non-load-bearing areas to address other operational challenges. For instance, composite liners are being used to dampen noise and vibration, reducing the sound pressure level generated by the crusher by up to 12 decibels. This contributes to a safer and more compliant working environment, reducing the need for additional sound-dampening enclosures.

Circular Economy Models

Mobile crushers are the enabling technology for new, sustainable business models in material processing. Their mobility allows for the creation of temporary processing hubs directly at the source of raw materials, be it a mining pit, a construction demolition site, or a stockpile of industrial by-products. This "process-on-site" philosophy can slash transportation requirements and associated costs by up to 40%, making the recycling of materials much more economical.

Fixed crushing plants are also finding a new role in the circular economy as permanent urban mining centers. Located near large population centers, these facilities are dedicated to processing construction and demolition waste, converting it into high-quality recycled aggregates. This model promotes a high resource recovery rate, with modern plants able to divert over 25% of incoming waste from landfills and back into the construction material supply chain, supporting sustainable urban development.