Mobile Jaw Crusher vs. Mobile Impact Crusher: Selecting the Right Tool for Material and Product Needs

This article provides a detailed comparison between two dominant forces in mobile crushing: the jaw crusher and the impact crusher. The core of the selection process hinges on two critical factors: the hardness of the material to be processed and the desired shape of the final product. Understanding the fundamental operating principles of each machine is essential for making an informed decision that optimizes efficiency, product quality, and operational costs for a specific application.

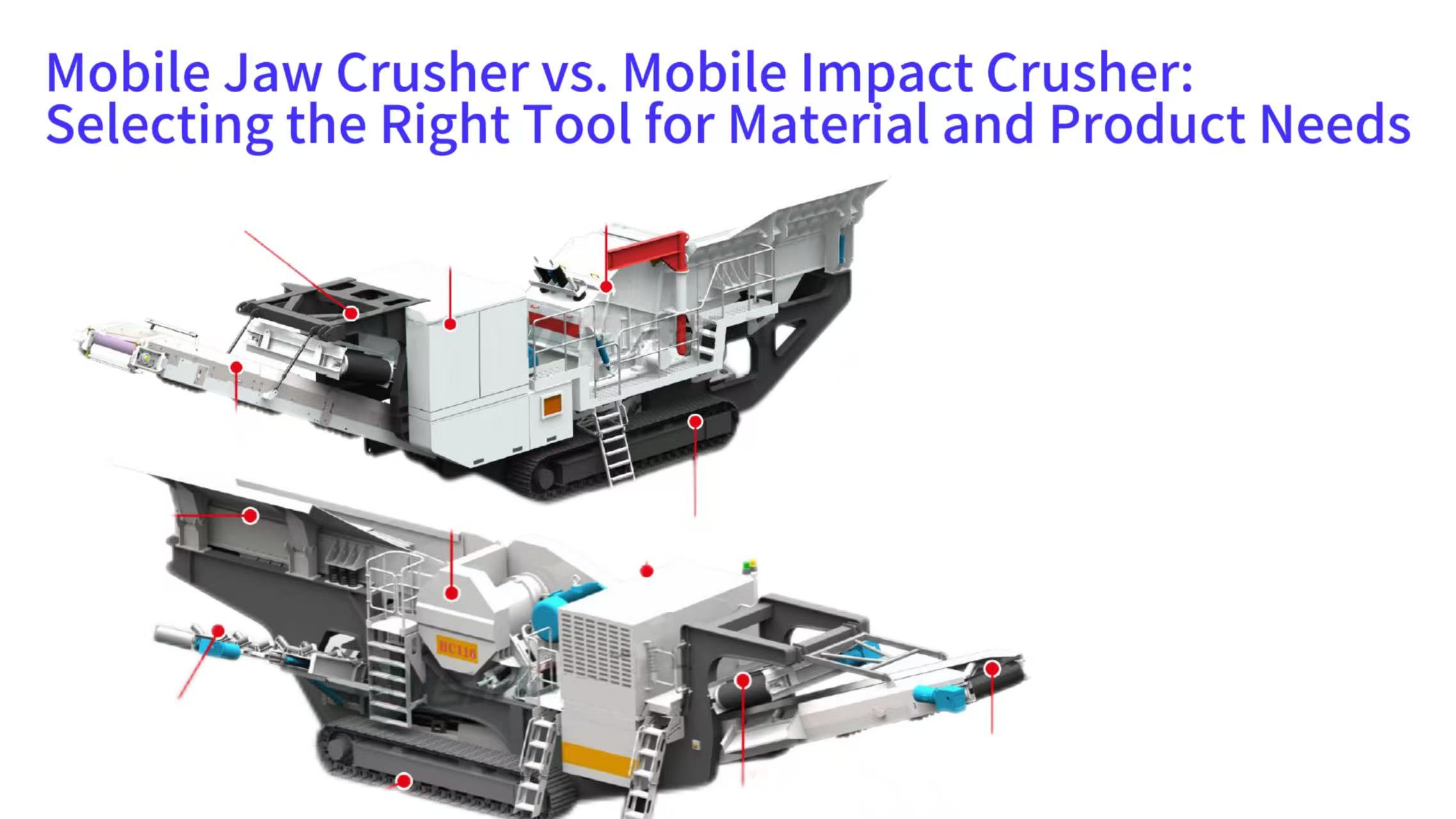

Fundamental Principles and Design Differences

The primary distinction between a mobile jaw crusher and a mobile impact crusher lies in their method of applying force to break down rock. A jaw crusher utilizes a compressive force, much like a giant nutcracker, where a fixed jaw and a moving jaw squeeze material until it fractures. An impact crusher, in contrast, employs dynamic impact energy, hurling material against hard surfaces or allowing rocks to collide with each other at high speed. This fundamental difference in crushing action dictates their respective strengths and ideal applications.

The design of each crusher follows its principle. A jaw crusher is characterized by its robust, heavy-duty frame and large feed opening, built to withstand immense pressure. An impact crusher features a high-speed rotor equipped with hammers or blow bars and impact aprons or plates, designed to absorb and transfer kinetic energy efficiently. These design philosophies result in distinctly different performance profiles.

The Working Principle of a Jaw Crusher

A mobile jaw crusher operates on a straightforward compression mechanism. The material is fed into a V-shaped chamber where a movable jaw plate moves rhythmically against a fixed jaw plate. This action repeatedly compresses the trapped rock until it breaks into smaller pieces. The size of the crushed material is determined by the gap between the jaws at their furthest point of separation.

This compression-based method is exceptionally effective for breaking hard, abrasive materials. The direct application of force with minimal movement of internal parts contributes to the jaw crusher's reputation for simplicity and reliability in demanding primary crushing roles.

The Crushing Mechanism of an Impact Crusher

An impact crusher reduces material size through rapid impact rather than slow compression. The central component is a high-speed rotor that spins within a crushing chamber. As material enters, it is struck by the rotor's blow bars and flung against the impact aprons lining the chamber. Further reduction occurs as particles ricochet and collide with each other.

This process of accelerated impact and inter-particle crushing is highly effective at producing a well-shaped, cubical product. It is particularly suited for medium-hard to hard materials where a specific particle shape is a critical requirement for the end use.

Key Component Comparison: Jaw Plates vs. Impact Elements

The wear parts in a jaw crusher are the jaw plates, which are subjected to extreme compressive and abrasive forces. These plates are typically made from high manganese or other advanced alloys to resist wear and are designed to be reversible to maximize service life. The integrity of the jaw plates is vital for maintaining the crusher's performance and product gradation.

In an impact crusher, the primary wear parts are the blow bars on the rotor and the impact aprons. These components endure significant shock loads and abrasion. Blow bars are often designed with multiple edges so they can be rotated to present a fresh crushing surface, and aprons can be adjusted to control the product size and compensate for wear.

Feed and Discharge Characteristics

A distinct advantage of a mobile jaw crusher is its ability to accept very large feed material. The geometry of the crushing chamber allows it to process sizable rocks, often directly from a quarry face, making it an ideal primary crusher. The discharge size is controlled by adjusting the gap between the jaw plates, but the product tends to be more angular.

An impact crusher generally requires a more controlled feed size to operate efficiently and protect the rotor. However, it offers superior control over the final product's shape, producing more cubical particles that are highly valued in applications like concrete and asphalt production.

Analysis of Material Hardness on Machine Selection

Material hardness, often measured on scales like Mohs, is arguably the most critical factor in choosing between a jaw and an impact crusher. Selecting the wrong crusher type for a given material hardness can lead to excessive wear, high operating costs, and inadequate product yield. The compressive strength and abrasiveness of the rock dictate which crushing mechanism will be most effective and economical.

Jaw crushers excel with hard, abrasive materials because their compression-breaking action is less susceptible to wear from abrasion than the high-velocity impact method. Impact crushers perform best on less abrasive, medium-hard materials where their ability to shape the product can be fully utilized without incurring prohibitive maintenance costs.

Processing High Hardness Materials

For very hard and abrasive rocks like granite, basalt, or quartzite, a mobile jaw crusher is typically the superior choice. The slow, deliberate compression force is highly effective at fracturing these tough materials. The wear on the jaw plates is progressive and predictable, leading to lower cost per ton in these demanding applications.

Using an impact crusher on high-hardness materials accelerates wear on the blow bars and aprons exponentially. The high-speed collisions cause rapid deterioration of these components, increasing downtime for replacements and driving up operational expenses, making it an economically unfavorable option for sustained hard rock crushing.

Adaptability to Medium and Low Hardness Materials

When processing medium-hard materials such as limestone, dolomite, or recycled concrete, a mobile impact crusher often demonstrates significant advantages. The impact crushing action efficiently breaks these materials while simultaneously shaping the particles into a cubical form. This dual benefit of size reduction and product shaping can eliminate the need for additional processing stages.

While a jaw crusher can also process these materials, the end product will be more flaky and elongated. For applications where particle shape is important, such as in high-quality aggregate for asphalt or concrete, the impact crusher's product commands a higher market value and performance characteristic.

Considerations for Abrasive Materials

Abrasion is a separate challenge from hardness, though often correlated. Materials with high silica content are highly abrasive. Jaw crushers, with their straightforward compression and fewer moving parts interacting directly with the material stream, generally handle abrasion more effectively. The wear is concentrated on the jaw plates, which are designed for easy replacement.

In an impact crusher, the entire rotor assembly and the aprons are exposed to the abrasive material stream. This results in a larger surface area subject to wear and can lead to more frequent maintenance intervals and higher consumable costs when processing highly abrasive feed stock.

Comparison of Product Shape Requirements

The shape of the crushed material is a crucial quality parameter for many end-use applications. The different crushing mechanisms of jaw and impact crushers naturally produce distinct particle shapes. The choice between them often comes down to whether the priority is maximum yield of sized material or a specific, high-quality particle geometry that enhances the performance of the final product.

Angular, flaky particles can lead to issues in applications like asphalt paving or concrete mixing, where interlocking and workability are important. Cubical particles provide better compaction, higher strength, and require less cement or asphalt binder. Therefore, the crusher selection directly influences the value and usability of the output.

Jaw Crusher Product Characteristics

The product from a jaw crusher is typically angular and flaky. The compression-breaking action tends to cleave the rock along its natural fissures, resulting in a higher proportion of elongated and slab-like particles. This product is perfectly adequate for use as a base material in road construction or as fill material where particle shape is less critical.

To improve the shape of jaw crusher product for more demanding applications, it is often necessary to add a secondary crushing stage, frequently with an impact crusher or a cone crusher. This two-stage process increases the overall cost and complexity of the crushing circuit but may be necessary to meet specifications.

Impact Crusher Product Advantages

The primary advantage of an impact crusher is its ability to produce a well-shaped, cubical product. The combination of direct impact and inter-particle crushing rounds off the sharp edges of the rocks, resulting in a more uniform and desirable end product. This is why impact crushers are often referred to as "shape crushers".

This cubical product is essential for high-value applications such as the surface course of asphalt roads, high-strength concrete, and railway ballast. The improved particle shape leads to better compaction, higher density, and improved mechanical properties in the final application, justifying a premium price for the aggregate.

Particle Shape Metrics and Industry Standards

Industry standards often quantify particle shape using metrics like the Flakiness Index or the Cubicity Index. A low Flakiness Index indicates a low percentage of flat or elongated particles, which is a desirable trait. Impact crushers consistently produce material with a superior Flakiness Index compared to jaw crushers operating under similar conditions.

Specifications for major infrastructure projects increasingly mandate a maximum flakiness index to ensure the long-term performance and durability of the construction. This trend makes the impact crusher the preferred choice for contractors supplying materials to these high-specification projects.

Performance Parameters and Operational Economy Comparison

Beyond the primary considerations of material hardness and product shape, the overall economic viability of a crusher is determined by its performance parameters. These include throughput capacity, energy consumption, wear part costs, and maintenance requirements. A comprehensive analysis of the total cost of ownership is necessary to make a truly cost-effective decision.

While initial purchase price is a factor, the ongoing operational expenses often have a greater impact on long-term profitability. A machine with a lower purchase price but high wear costs or energy consumption may ultimately be more expensive to operate than a more robust, efficient alternative.

Throughput Capacity Considerations

For a given machine size and power rating, a jaw crusher will often achieve a higher throughput when processing hard, abrasive materials. Its efficient compression action can process more tonnage per hour under these conditions. The crushing capacity of a jaw crusher is well-suited for high-volume primary crushing applications.

An impact crusher can achieve impressive throughput on medium-hard materials, and its ability to produce a finished, well-shaped product in a single pass can make the overall plant throughput more efficient by reducing the need for secondary crushing stages.

Comparison of Energy Consumption

Jaw crushers are generally considered to be energy-efficient machines for their primary crushing role. The slow, high-torque crushing stroke consumes power effectively. Impact crushers require significant energy to accelerate the rotor to high speeds and to impart sufficient kinetic energy to the material for effective breakage.

However, this energy comparison must be viewed in the context of the entire process. If an impact crusher eliminates a secondary crushing stage, the total energy consumption of the crushing circuit may be lower despite the impact crusher's higher individual energy use.

Differences in Wear Part Costs

The cost of wear parts is a major component of operating expenses. Jaw crusher wear parts, primarily the jaw plates, are large and heavy, making them expensive to replace. However, their wear life is generally long when processing appropriate materials, leading to a predictable and often lower cost per ton over time.

Impact crusher wear parts, such as blow bars, are typically smaller and less expensive individually. However, they may need to be replaced more frequently, especially when processing abrasive materials. The total wear cost per ton must be calculated based on the specific material being processed to determine the most economical option.

Application Scenarios and Selection Guidelines

The ideal application for a mobile jaw crusher or a mobile impact crusher depends on a combination of factors, including the project's primary objective, the characteristics of the feed material, and the specifications for the final product. There is no universal "best" choice; the best crusher is the one that most effectively meets the specific requirements of the job at hand.

For primary crushing of hard, abrasive rock in a quarry or mine, the robustness and simplicity of a jaw crusher make it the default choice. For recycling applications or producing high-quality aggregate from less abrasive rock, the shaping capabilities of an impact crusher are often indispensable.

Mining and Hard Rock Crushing Scenarios

In hard rock mining and quarrying operations, the primary crushing stage is almost always handled by a jaw crusher or a gyratory crusher. The ability to accept large feed size and withstand the immense forces required to break tough ores makes the jaw crusher the workhorse of the industry. Reliability and uptime are paramount in these high-value operations.

Impact crushers may be used in these settings as secondary or tertiary crushers to refine the product shape after the initial size reduction has been performed by a jaw crusher. This combination leverages the strengths of both technologies.

Construction Aggregate and Recycling Applications

In the construction aggregate industry, particularly for limestone and similar materials, mobile impact crushers are extremely popular. Their ability to produce a spec-compliant, cubical product in a single machine makes them highly efficient. They are also the preferred choice for C&D waste recycling because they can effectively process concrete with rebar and can liberate reinforcing bar from the concrete matrix.

Mobile jaw crushers are also used in aggregate production, often as the primary crusher in a multi-stage setup. They provide the initial reduction before the material is sent to an impact crusher for final shaping.

Mobility Requirements and Site Constraints

Both crushers are available in highly mobile configurations, either on tracks or wheels. Track-mounted mobile crushers offer excellent mobility within a site and can be repositioned quickly as the face advances. The choice between a mobile jaw and a mobile impact crusher in a constrained site will depend more on the material and product requirements than on mobility itself, as both offer similar setup times.

However, the layout of a mobile impact crusher can sometimes be more compact, which might be an advantage in very tight spaces. The need for a pre-screen or a post-screen will also influence the overall footprint of the crushing setup.

Technological Advances and Future Trends

The technology behind mobile crushing is continuously evolving, blurring the lines between traditional crusher types and enhancing their capabilities. Innovations in automation, materials science, and power systems are making crushers more efficient, durable, and easier to operate. The future points towards smarter, more connected, and more sustainable crushing solutions.

Hybrid designs that combine crushing principles are emerging, offering new possibilities for processing a wider range of materials efficiently. The integration of digital technology is also transforming how crushers are monitored, controlled, and maintained.

Development of Hybrid Designs

Some manufacturers are developing crushers that incorporate elements of both jaw and impact crushing. These hybrid machines aim to offer the high reduction ratio and hard-rock capability of a jaw crusher with the superior product shape of an impact crusher. While still a developing area, these innovations promise greater flexibility for operators who face variable feed materials.

These designs might use an initial compression zone to break the largest rocks, followed by an impact chamber to refine the shape of the product, all within a single machine.

Intelligent Control for Performance Optimization

Modern mobile crushers are increasingly equipped with sophisticated automation systems. These systems can automatically adjust crusher settings, such as the rotor speed in an impact crusher or the closed-side setting in a jaw crusher, based on real-time feedback from the machine. This ensures optimal performance and product quality even as feed material characteristics change.

These smart controls can also protect the crusher from damage by detecting overload conditions and adjusting accordingly, thereby reducing downtime and repair costs. The data collected can be used for predictive maintenance, scheduling part replacements before they fail.

Material Science Enhancing Wear Resistance

Advancements in metallurgy and composite materials are continuously improving the lifespan of wear parts. New grades of steel and ceramic composites are being developed that offer greater resistance to abrasion and impact. This is particularly beneficial for impact crushers, allowing them to process harder and more abrasive materials than was previously economical.

Longer-lasting wear parts translate directly into lower operating costs, less frequent downtime for changes, and increased overall machine availability, making both jaw and impact crushers more productive and profitable.