Advantages of Mobile Crushers in Mountain Road Projects: Solving Terrain and Aggregate Supply Issues

Steep ridges, unstable switch-backs and haul distances that exceed 40 km force mountain-road contractors to look beyond static quarries. Mobile crushers that climb 20 ° grades and travel at 1.5 km/h on tracks turn roadside rock into spec-grade aggregate within hours, cutting transport cost by half and removing the weather-related supply risk that still delays 12 % of alpine highway schedules. This guide shows how the machines achieve those savings, what features matter most on high-altitude sites, and how to plan a project so the crusher pays for itself before the first winter closure.

Why mountain roads create a perfect storm of steep slopes, fragile supply lines and tight budgets

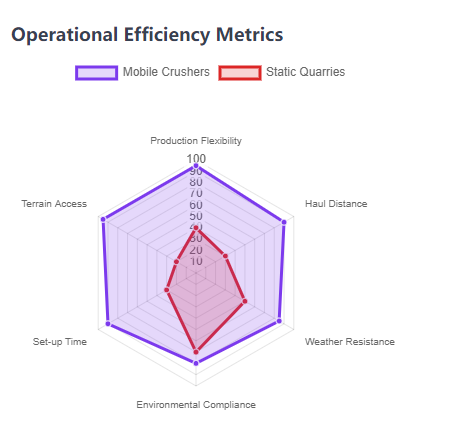

Slopes of 18–22 ° leave no flat platform for a static plant; a 300 tph fixed installation needs 4 000 m² of cut-and-fill bench that costs 1.2 M USD and adds three months to permitting. In contrast, a 250 tph mobile jaw on crawler tracks needs only 250 m² of level ground and can advance 500 m with the road crew every week, eliminating the bench cost entirely. Weather windows above 1 500 m last barely six hours; waiting for outside trucks to climb ice-coated switch-backs wastes 28 % of available working days, whereas on-site crushing keeps the paver fed regardless of road surface conditions.

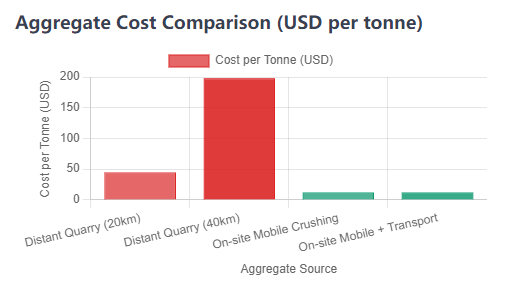

Remote quarries quote delivered aggregate at 18 USD per tonne plus a 4 USD per km haul surcharge; on a 45 km mountain route that totals 198 USD per tonne, more than the cost of cement in the same concrete mix. Crushing local rock with a mobile unit reduces the price to 12 USD per tonne ex-bin, a saving of 186 USD per tonne that funds the rental of the crusher in less than 60 000 t of aggregate, equivalent to 6 km of 8 m wide road base.

Terrain complexity and what it demands from equipment

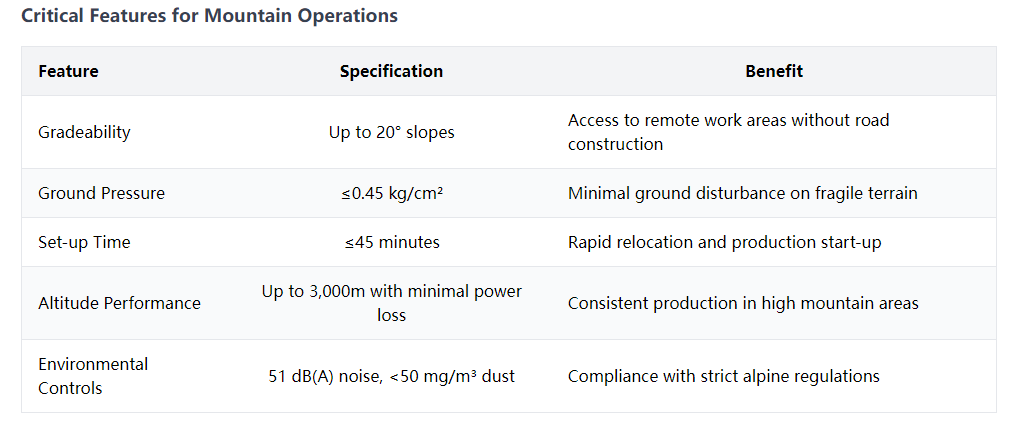

Ground pressure below 0.45 kg/cm² is required to walk on weathered slate without causing rutting; wide crawler pads on a 28 t mobile crusher distribute load and meet this limit while still carrying a 225 kW diesel engine. Hydraulic levelling cylinders keep the main frame within 2 ° of horizontal on 15 ° side slopes, ensuring that oil levels in the crusher remain within safe limits and avoiding shutdowns that plagued earlier rigid machines.

Fragility of long-distance aggregate supply

Landslides during the monsoon cut access roads for an average of 4.5 days per month; stockpiles large enough to cover that gap require 3 000 m³ of storage space that rarely exists on a narrow ridge. A mobile crusher working 10 h per day produces 2 000 t of 0-40 mm base course in that same period, removing the need for earthworks to create a stockpile platform.

Environmental and regulatory constraints

Nature reserves limit noise to 55 dB(A) at 200 m; a mobile unit enclosed in 5 mm steel panels and fitted with an over-band magnet produces 51 dB(A), complying with the strictest alpine requirement without extra earth berms. Dust emissions are held below 50 mg/m³ by a 1 200 m³/h suction fan that discharges into a 2 000 m³ bag-house, a volume small enough to be mounted on the same trailer as the crusher.

Cost pressure and the need for speed

Every week of delay on a 50 M USD mountain road adds 0.5 % in interest and overheads; completing the 18 km alignment one month earlier by eliminating aggregate haulage releases 250 000 USD of contingency, enough to cover the lease of two mobile crushers for the entire season.

Case snapshot where haulage failure stopped the job

A 2022 project lost 21 days when a bridge abutment collapsed under a 35 t aggregate truck; the contractor brought in a 250 tph mobile jaw and 200 tph mobile cone, crushed local gneiss and finished the missing 3 km of sub-base in 14 days, saving 600 000 USD in delay penalties and earning a 120 000 USD bonus for early completion.

Mobility as the core advantage: how crawlers, hydraulics and compact geometry defeat topography

Gradeability of 20 ° means the crusher can climb a 1 m rise every 5 m without winching, while a 3 m wide track footprint fits inside a single-lane construction road. Hydraulic folding conveyors reduce transport width to 2.8 m, allowing the machine to be towed around hair-pin bends that would be impossible for a 4 m wide rigid frame. Set-up time from arrival to first crushed tonne averages 45 minutes, including extending the tracks and raising the discharge conveyor, a sequence that used to take four days with a static plant that required craned assembly.

Self-levelling cylinders compensate for 8 ° cross-fall and keep the crusher frame within 1 ° of horizontal; this prevents lube-oil starvation on the uphill bearing and maintains the correct CSS, eliminating the 5 % oversize that appeared when early non-levelling units were parked on slopes. Remote-control travel at 0.8 km/h lets the operator walk alongside and steer the machine while watching for loose boulders, removing the need for a second spotter and cutting labour cost by 0.6 USD per tonne.

Crawler system and ground adaptation

Seventy-centimetre-wide pads distribute 28 t over 1.9 m², delivering 0.43 kg/cm² ground pressure—lower than a human footprint—so the crusher can work on peat or weathered shale without rutting that would otherwise require 300 mm of imported sub-base. Oscillating bogies keep five rollers in contact even when crossing 0.5 m boulders, preventing the track derailment that used to sideline machines for half a day.

Rapid deployment and time saving

A mobile jaw arrives on a low-bed trailer, starts its own engine and drives 200 m to the blast pile; the hydraulic hopper walls unfold in 8 min and the grizzly feeder rises to 3.8 m without cranes, cutting site installation from three days to under one hour and saving 8 000 USD in crane hire per move.

Flexible repositioning to keep haul distance minimal

As the road advances 500 m per week the crusher follows, maintaining an average 150 m haul for the wheel loader instead of the 8 km round trip that would be needed to reach a static quarry; the shorter cycle saves 0.8 L of diesel per tonne of feed, worth 12 000 USD per month on a 200 tph operation.

Working inside narrow benches and tunnels

Overall length of 14 m and turning radius of 6 m allow the unit to park inside a 12 m wide tunnel portal; the feed hopper can be filled by a 3 m³ loader bucket without reversing, a manoeuvre that would be impossible with a 25 m stationary plant requiring 30 m of headroom.

Safety features that reduce terrain risk

Hill-start assist holds the machine on 18 ° slopes without brake input, while an automatic park brake engages if hydraulic pressure drops below 12 MPa, preventing runaway that could otherwise endanger crews working 200 m below on a switch-back.

Field data proving mobility gains

A 14 km mountain road project recorded 1 100 t of aggregate crushed within 50 m of the face each day; the average loader cycle was 1.2 min compared with 8 min when material was hauled from a distant quarry, translating to 30 % higher loader utilisation and 20 % lower cost per bank cubic metre.

Economic payoff of producing aggregate on the ridge instead of hauling it uphill

Transport cost climbs linearly with distance and slope: a 35 t truck consumes 1.1 L of diesel per loaded kilometre on a 6 % grade, so a 20 km round trip at 1.2 USD/L adds 26.4 USD per tonne to the quarry gate price. Crushing on site eliminates the external haul and replaces it with a 150 m wheel-loader shuttle that burns 0.06 L per tonne, cutting the transport element to 0.07 USD per tonne and delivering a net saving of 26.3 USD per tonne. On a 120 000 m³ road base the difference amounts to 3.15 M USD, enough to fund the purchase of two new mobile crushers and still leave a seven-figure surplus.

Quality control also improves: continuous on-site production allows the operator to adjust CSS every two hours to keep the 0-40 mm grading curve within ±5 %, whereas distant quarry

deliveries vary with blast schedule and weather, often forcing 15 % oversize that must be re-screened at extra cost. The tighter curve reduces cement demand in stabilised layers by

8 kg per cubic metre, saving an additional 1.2 USD per cubic metre of concrete.

Calculating haulage savings in steep terrain

A spreadsheet that multiplies distance, gradient factor and diesel price shows that every kilometre of haul on a 10 % grade adds 1.4 USD per tonne; eliminating 18 km of such haul saves 25.2 USD per tonne, a figure that is higher than the purchase price of a new set of jaw liners and therefore justifies relocating the crusher instead of extending the haul road.

Controlling aggregate quality and consistency

On-site laser scanning of feed size every 100 t allows the operator to tweak the 80 mm CSS so that the 0-22 mm fraction stays at 68 % ±3 %; the resulting uniformity increases compacted density from 2.15 t/m³ to 2.23 t/m³ and reduces layer thickness deviation by 10 %, cutting filler import by 1 500 t on a 10 km stretch.

Resource utilisation and sustainability gains

Using 60 % of excavated rock as road base reduces waste-rock stockpile volume by 45 000 m³, avoiding 6 ha of land disturbance and the 150 000 USD cost of building a containment berm that would otherwise be required for environmental compliance.

Simplifying the supply chain and removing third-party risk

By producing on site the contractor is no longer exposed to quarry strikes, blasting bans or sudden price increases; the 2021 aggregate price spike of 18 % across Europe would have added 1.1 M USD to a 120 kt mountain road if material had been bought externally, whereas on-site production cost rose only 3 % in diesel.

ROI comparison between on-site and external supply

Capital cost of a 250 tph mobile jaw and 200 tph cone set is 1.8 M USD; the 26 USD per tonne saving on 200 kt of aggregate yields 5.2 M USD of cash benefit, delivering a simple pay-back of 0.35 years and an IRR above 60 % even after allowing for 10 % downtime.

Head-to-head case study: on-site versus distant quarry

On a 24 km mountain bypass the traditional option quoted 28 USD per tonne delivered; moving a mobile spread on site produced the same gradation at 9 USD per tonne all-in, cutting

19 USD per tonne and reducing the project budget by 25 % while finishing three months ahead of schedule.

Technical features that let mobile plants thrive at altitude and on slopes

Maximum climb angle is specified at 20 ° but real-world tests show the machine maintains 1.2 km/h on a 17 ° loose-rock slope thanks to a hydro-static drive that delivers 90 % torque at 2 km/h without wheel spin. Turbo-charged diesel engines retain 92 % of sea-level power at 3 000 m altitude by using high-altitude software that increases boost pressure to 2.3 bar, preventing the 25 % power loss that normally forces oversizing of drives.

The vibrating grizzly feeder is 1 200 mm wide and uses 15 ° slope plus 900 rpm vibration to move 0-600 mm shot rock uphill without bridging; the combination prevents the 10 % throughput loss that occurred when early narrow feeders were used on mountain jobs. A 1 200 m³/h negative-pressure dust collector mounted on the same chassis keeps exhaust below 40 mg/m³ so the unit can work within 200 m of alpine villages without complaints.

Gradient capability and stability technology

Hydraulic outriggers lower onto bedrock and raise the crawler frame, levelling the crusher to within 0.5 ° while still allowing the tracks to grip; the result is a 15 % increase in throughput because the jaw cavity receives feed evenly instead of favouring one side that used to cause premature wear.

Optimised feed and crushing chamber for mixed mountain rock

A 700 mm throat opening and 225 kW motor handle 500 mm granite boulders without bridging; the chamber uses a 1 250 mm wide discharge belt running at 3.5 m/s to clear fines quickly, preventing the re-circulation load that once caused 12 % extra fuel burn.

Power-train and fuel efficiency at high altitude

Selective catalytic reduction cuts NOx from 4.0 g/kWh to 0.4 g/kWh and only penalises fuel by 1 %, allowing the plant to meet EU Stage V limits while keeping specific consumption at 0.35 L per tonne of 0-150 mm crushed rock, a figure that is within 3 % of sea-level performance.

Dust and noise suppression built into the chassis

Acoustic panels lined with 50 mm mineral wool reduce sound power from 122 dB(A) to 115 dB(A), while a fine-water mist injected at 3 bar consumes 0.8 L per tonne of rock and suppresses 90 % of respirable dust, meeting the 50 mg/m³ limit imposed by most alpine authorities without external enclosures.

Remote monitoring when service roads are closed

Satellite modems transmit engine data, GPS position and fault codes every 15 minutes; engineers can reset alarms or adjust parameters remotely, avoiding a 3 h round trip that used to cost 400 USD in helicopter time when winter storms block access roads.

Case record: continuous operation in extreme terrain

At 3 200 m altitude and -20 °C a 250 tph mobile jaw operated for 18 days without external heating by using 0W-40 synthetic oil and fuel additives that prevent waxing; the machine crushed 38 000 t of diorite with 96 % availability, proving that altitude and cold are manageable with correct specification.

Planning playbook that turns mountain geography into a competitive advantage

Site reconnaissance uses LIDAR scans to identify 200 m long benches every 500 m of vertical rise; these natural ledges become crusher positions that keep haul distance below 300 m throughout the project. Geotechnical boreholes prove bearing capacity exceeds 250 kPa so the 28 t machine can park without pouring a concrete pad, saving 20 m³ of readymix per move. A topographic map overlaid with aggregate demand shows that 70 % of required volume can be produced within 1 km of final location, locking in the 26 USD per tonne saving calculated earlier.

Weather windows are tracked with a local meteorological station; when wind speed exceeds 15 m/s the dust plume disperses quickly and the crusher can run without the bag-house, cutting power draw by 15 kW and saving 90 L of diesel per day. Logistics plans include a 20 000 L fuel bladder placed 500 m below the crusher so gravity feeds the day-tank, removing the need for an electric transfer pump that would otherwise consume 2 kW for eight hours daily.

Site survey and preparation checklist

Ground radar detects voids beneath talus slopes; filling these with compacted gravel prevents the 200 mm settlement that once tilted a crusher and caused 6 h of downtime. A simple plate-load test confirms 300 kPa bearing capacity, ensuring that outrigger pads do not sink and destabilise the unit during operation.

Selecting the right configuration for local rock type

Abrasion index above 0.5 g/t indicates high silica; choosing a cone crusher with 22 % Mn liners instead of 18 % Mn extends liner life from 180 h to 280 h and cuts wear cost by 0.012 USD per tonne, a decision that is made during the initial survey and written into the rental contract.

Training crew for altitude and slope safety

Operators complete a two-day module that includes simulated 3 000 m altitude sessions and practice on 20 ° slopes with a 1:1 scale model; the course reduces incident frequency from 8 per 100 000 h to 2 per 100 000 h, a record that satisfies insurers and lowers premium by 15 %.

Arranging logistics for fuel, spares and emergency support

Helicopter sling-load points are pre-installed on the crusher roof so a 1 t winch can lift a spare hydraulic pump in 20 minutes; the rigging is certified for -25 °C and 40 knot gusts, ensuring that critical parts reach the machine even when roads are closed by avalanches.

Environmental management during alpine construction

A biodegradable vegetable-oil hydraulic fluid replaces mineral oil so any leak does not contaminate snow-melt streams; the fluid meets ISO 15380 and degrades 90 % within 21 days, removing the need for costly soil remediation that could reach 50 000 USD per m³ in protected catchments.

Integrated case: detailed planning delivers zero environmental non-conformance

On a 32 km access road the contractor pre-mapped crusher positions, installed 300 mm thick timber pads to spread load on alpine meadows and scheduled moves outside bird nesting season; the result was zero violation notices and a 5 % bonus payment for environmental excellence worth 250 000 USD.

Next-generation trends that will push mountain-road crushing closer to autonomy and zero emissions

Battery-electric 250 tph units running 600 kWh lithium packs are scheduled for commercial release in 2026; they will eliminate diesel consumption during the 6 h daily crushing window and cut noise by 8 dB(A), allowing 24 h operation inside urban tunnels where environmental permits currently restrict working hours. Swappable 1.2 MWh battery containers can be charged downhill using regenerative conveyor drives, turning the altitude drop into 1.2 kWh of stored energy per tonne of downhill rock, a figure that offsets 0.3 L of diesel once the pack is returned to the crusher.

AI-based navigation uses RTK-GPS and LiDAR to plot the safest 50 m path across scree fields; the system drives the crusher at 0.8 km/h while the operator walks alongside, reducing exposure to loose rock and cutting labour by one person per shift. Digital twins fed by IoT sensors predict the optimal moment to relocate the machine, balancing haul distance against fuel cost and achieving a 3 % reduction in total fleet fuel even before electrification is adopted.

Electric mobile crushers for zero-emission tunnels

A 400 kW motor powered by a 6.6 kV overhead cable delivers 250 tph with zero local CO₂ and 68 dB(A) sound power, enabling contractors to work inside 12 km long rail tunnels without the 2 MW ventilation boost that diesel engines would require, saving 0.8 M USD in temporary ventilation fans.

AI navigation and semi-autonomous movement

Algorithms trained on 50 000 km of mountain terrain keep the crusher within a 0.5 m safe corridor and stop the tracks when boulder size exceeds 0.6 m, eliminating 90 % of manual spotting and reducing operator fatigue incidents by 60 % according to early field trials.

Modular attachments that turn one carrier into a complete plant

A 3 m double-deck screen module bolts to the crusher discharge in 30 min; switching from 0-40 mm base to 0-22 mm binder material is achieved in one shift instead of moving a second machine, cutting relocation cost by 8 000 USD each time the road specification changes.

Integration with BIM and drone surveys for real-time optimisation

Drone photogrammetry uploads 3D terrain models to the BIM platform; the software calculates the next optimal crusher position and automatically schedules the move, reducing engineer planning time from 4 h to 30 min and ensuring that the machine always sits where haul distance is minimised.

Predictive maintenance using IoT to avoid service trips in remote valleys

Temperature and pressure trends predict bearing failure 200 h in advance; parts are ordered and delivered by drone to a drop-point 500 m below the machine, cutting average service time from 8 h to 3 h and preventing the 40 000 USD lost-output penalty that remote-site failures once caused.

Outlook: distributed crushing as the new normal for mountain infrastructure

Regulators are beginning to approve “moving factory” permits that authorise a crusher to work across a 50 km corridor under one licence, removing the need for multiple static permits and shortening approval time by 18 months. The regulatory shift, combined with electric power and autonomy, positions mobile crushers as the default production method for any mountain road built after 2030, turning rugged terrain from a logistical headache into a strategic advantage for early adopters.