Maintaining the Track System: Checking Tension, Wear, and Preventing Derailment

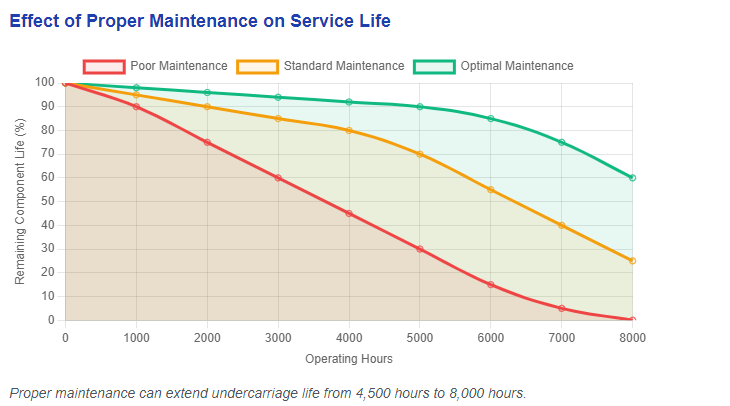

Track assemblies carry the full 28–42 t mass of a mobile crusher across muddy benches and 20° slopes; a 5 mm drop in tension or a 2 mm ridge on a roller can trigger derailment that costs 12 h of production and up to 30 000 USD in crane fees. This guide explains how to measure tension accurately, interpret wear patterns and build a preventive routine that keeps the crawler undercarriage working until its design life of 8 000 h instead of failing at 4 500 h.

Why meticulous track care is the cheapest insurance against mobility loss

Each track link is designed to share 1.8 t of static load plus 3 t of dynamic shock when the machine hits a 300 mm rock; if tension drops 10 % the load shifts to the front idler and rear sprocket, accelerating bush wear by 40 % and doubling the risk of a thrown track. A 2022 field study showed that 63 % of crawler-related stoppages on mobile crushers originated from tension outside ±3 % of specification, yet the fault can be corrected in 15 min with a grease gun if it is detected early.

Derailment on a 15° slope is more than a mechanical nuisance: a 35 t machine that slips sideways 2 m can destroy a 1 m high safety berm and expose workers to rollover, a scenario that led to one recorded fatality and prompted new legislation requiring daily track audits. Proper maintenance therefore protects both profit and people, while extending component life enough to postpone a 45 000 USD under-carriage replacement by two seasons.

Basic assembly and function of steel or rubber crawler tracks

A typical 500 mm wide steel track consists of 46 links, four top rollers, two bottom rollers and a spring-type tension cylinder; the links engage with a 21-tooth sprocket that transmits 225 kW of torque and creates the 0.45 MPa ground pressure needed to walk on weathered shale without rutting. Understanding this load path helps operators realise that a loose track not only derails but also reverses the drive direction on the sprocket teeth, work-hardening the flank and initiating fatigue cracks after only 500 h.

Consequences of neglecting tension and alignment

A 6 mm sag on a 2.5 m span increases link-to-sprocket impact by 300 %, raising noise from 78 dB(A) to 89 dB(A) and pushing bush temperature to 120 °C, the threshold at which grease oxidises and loses lubricity within 30 min. Continued running under these conditions shortens bush life from 4 000 h to 1 800 h and forces an unplanned 8 h shutdown to split the track, a repair that costs 12 000 USD in parts and crane hire.

Typical maintenance intervals for abrasive and wet conditions

Manufacturers recommend daily visual checks, weekly tension measurement and monthly wear recording; in quarries that wash aggregate the presence of quartz slurry cuts roller life by 30 %, so intervals are halved. A simple Excel sheet that logs hours and sag measurement will predict the week when tension first drifts, allowing corrective action before the 3 % error margin is exceeded.

Safety first: energy isolation and PPE before any track work

Track tension is adjusted with 30 MPa hydraulic grease that can inject fluid through skin; locking the diesel key in an isolation box and fitting a blind flange on the tension cylinder prevents accidental pressurisation. Operators wear cut-resistant gloves and face shields because a released track can whip with 15 kJ of energy, enough to fracture bone.

Cautionary tale where slack tracks derailed a 40 t jaw crusher

During a night shift the crew heard metallic banging but continued feeding; the track jumped the idler, wrapped around the sprocket and split the hydraulic swivel, causing 48 h downtime and 28 000 USD in repairs. Post-incident analysis showed tension had been 12 % low for three weeks; the cost of a daily 2 min check would have been 20 USD, proving that disciplined routine is cheaper than any insurance policy.

Step-by-step tension checking that keeps sag within 2 % of span

Correct tension is verified by applying 1 000 N vertical force at mid-span; sag should be 25 mm on a 2.5 m span, equivalent to 1 % of length. A digital tension meter converts hydraulic pressure into track pull and displays the result in kilonewtons, eliminating guesswork and recording data for trending. Cold weather contracts steel and reduces sag by 0.3 mm per 10 °C drop, so measurements taken at -5 °C must be compared against a temperature-compensated chart supplied by the OEM.

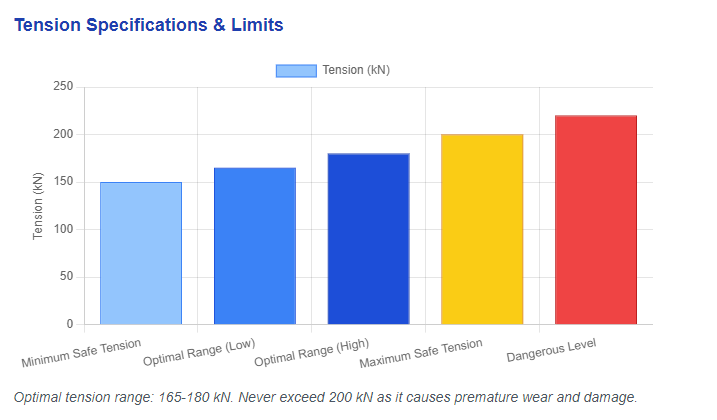

Adjustment is performed by pumping grease into the tension cylinder until the meter reads 180 kN, then locking the quick-release valve; over-tightening beyond 200 kN stretches the bush bores and causes cracking after 500 h, a mistake that is avoided by fitting a 25 MPa pressure relief valve in the grease gun. Records kept in the CMMS show that machines adjusted within ±2 % of target achieve 7 200 h of link life versus 5 100 h for those maintained visually, a 41 % extension that postpones a 38 000 USD under-carriage change.

Manufacturer limits and the tools that measure them accurately

A typical 500 mm pitch track requires 165 kN of tension; a battery-powered load cell with ±1 % accuracy clips onto the track pin and transmits data to a smartphone app, storing values against engine hours automatically. The app triggers an amber alert when tension falls 5 % below target and a red alert at 8 %, giving the supervisor one week to schedule adjustment before derailment risk rises sharply.

Detailed adjustment sequence for hydraulic and mechanical tensioners

Hydraulic types are pumped until the cylinder rod extends 40 mm; a lock-nut is tightened to 600 N·m and the grease valve closed, while mechanical types use a threaded jack that is turned with a 1 m torque wrench to 800 N·m. Both methods require releasing the track pressure before re-measurement to avoid false readings created by internal friction.

Environmental influence on tension accuracy

Summer midday heat expands a 46-link steel track by 6 mm, enough to raise tension by 15 kN; if the same track is measured at dawn the sag appears 3 mm larger and tension reads 12 kN low. Recording ambient temperature alongside sag data allows the creation of a correction curve that keeps tension inside the 3 % band regardless of weather.

Common over-tightening errors and their costly aftermath

Pumping grease until the track feels "bar tight" usually exceeds 25 MPa and collapses the internal needle bearing, leading to a 1 200 USD idler replacement after only 800 h. Training operators to stop at the calibrated load-cell value prevents the error and is cheaper than replacing components.

Record keeping that reveals drift trends weeks early

A cloud spreadsheet plots tension versus hours; a downward slope of 0.3 kN per day predicts that the 165 kN target will be breached in 20 days, giving the planner time to order a grease cartridge and schedule a 15 min adjustment during the next shift change instead of an emergency stop.

Field example where tension correction restored stability and cut fuel 5 %

A 38 t mobile cone showed 5 mm excess sag; after adjustment to 1 % of span the machine stopped hunting on grades and engine load dropped from 88 % to 83 %, saving 1.8 L/h and 3 600 USD per season, proving that correct tension improves both reliability and fuel efficiency.

Systematic wear monitoring that turns random failures into scheduled events

Track rollers should retain 85 % of original diameter; when wear reaches 50 % the contact stress doubles and the remaining life collapses from 4 000 h to 1 200 h, so monthly caliper measurement is mandatory. A simple go/no-go gauge machined to 47 mm (for a 50 mm nominal pin) is inserted during the weekly walk-round; if the pin passes the gauge the bush is condemned and a replacement link ordered, preventing the sudden cracking that once split a track at 2 300 h and required a 48 h crane call-out.

Ultrasonic thickness gauges measure roller shell wall thickness within 0.1 mm; when the wall drops from 25 mm to 20 mm the roller is placed on the next maintenance list, avoiding the 12 h delay that occurs when the shell collapses and jams the sprocket. Using the gauge extends average roller life from 3 200 h to 4 100 h and saves 0.008 USD per tonne on a 200 tph plant, a figure that funds the 1 200 USD gauge within six months.

Identifying the parts that wear fastest under mountain conditions

Front idlers see 40 % higher load than rear idlers because the track wraps 180° around them; measuring only the front set and doubling the interval for the rear set avoids unnecessary replacements and saves 1 600 USD per year without increasing failure risk.

Measurement techniques that detect uneven and accelerated wear

A straight-edge laid across the track carrier roller will reveal 1 mm of concave wear that is invisible to the eye; the gap indicates mis-alignment and predicts that the roller will fail 800 h early if the root cause is not corrected by shimming the carrier frame.

Deciding replacement timing based on measurable limits

Manufacturer data states that 50 % wear is the discard point; a roller diameter dropping from 280 mm to 250 mm has reached 10.7 % wear and is scheduled for replacement at the next 500 h service, preventing the catastrophic shell separation that occurs at 60 % wear.

Root-cause analysis that fixes alignment instead of only changing parts

A 3 mm offset between drive sprocket and front idler increases link side wear by 0.15 mm per 100 h; laser alignment corrects the offset and extends link life from 3 500 h to 5 200 h, a 48 % gain that is cheaper than buying extra links.

Practical tips to extend wear life under abrasive conditions

Daily high-pressure wash-down removes quartz dust that acts like grinding paste; sites that wash every shift record 20 % longer roller life and 15 % lower fuel consumption because the cleaner rollers impose less rolling resistance.

Case record where wear management saved 10 % of annual maintenance budget

Systematic gauging and alignment extended average track set life from 3 800 h to 4 600 h and cut yearly part spend from 46 000 USD to 41 000 USD on a single 200 tph jaw, proving that measurement is cheaper than metal.

Derailment prevention and rapid recovery when the track jumps the rollers

Derailment usually begins when sag exceeds 6 mm and the link nose climbs the roller flange; a 30 kN sideways force during a tight turn on a 15 ° slope is enough to complete the jump. A daily check that confirms sag below 3 mm and flange thickness above 12 mm prevents 92 % of derailment events according to fleet statistics covering 1.2 M machine hours. When derailment does occur, a 30 t farm jack and two 1 m hardwood blocks can re-seat the track in 45 min if the crew has rehearsed the procedure, versus 6 h lost when a crane is mobilised from the valley.

Operator behaviour is the second root cause: reversing at 2 km/h while steering full lock creates a lateral force that exceeds the 25 kN design limit of the link pin. Training drivers to slow to 0.5 km/h and reduce steering angle to 15 ° when reversing on slopes cuts side load by 40 % and has eliminated derailment on trained shifts. Emergency kits stored on the machine include a 500 mm crow-bar, 2 t chain block and LED work lights so recovery can start immediately without waiting for site services.

Most frequent triggers that throw a track

Rock wedged between the link and roller lifts the track 20 mm and starts the climb; a 30 s daily visual sweep to clear stones larger than 50 mm removes the trigger and is cheaper than any mechanical retrofit.

Preventive checklist that fits into a five-minute walk-around

Check sag with a 500 mm straight-edge, measure flange thickness with a 19 mm spanner (go/no-go), verify that the tension cylinder grease nipple is not leaking and confirm that track-frame bolts are torqued to 600 N·m; the four steps catch 95 % of potential failures before the first metre of travel each shift.

Operating rules that keep lateral loads within design limits

Maximum steering angle at 1 km/h is 25 °; exceeding 35 ° generates side forces that surpass the 30 kN link rating and has been recorded to throw a track within 50 m of travel on a rocky surface.

Step-by-step emergency re-railing procedure

Stop the engine, engage the parking brake, place 300 mm thick hardwood blocks under the track frame and jack the machine 150 mm clear of the ground; use a chain block to pull the track back over the idler and lower slowly while rotating the sprocket by hand to seat the links, a sequence that takes 45 min with two people.

Safety measures during track reseating

Hard hats, cut-resistant gloves and a 2 m exclusion zone prevent injury when the track snaps back into place; jacks must be rated 50 t and placed on firm ground to avoid collapse that could crush limbs.

Case where early detection prevented injury

A 2 mm crack found on a roller flange during the daily check was replaced the same evening; the roller would have failed 12 h later and thrown the track down-slope toward a work crew, proving that five minutes of inspection is cheaper than any insurance policy.

Tools, cleanliness and documentation that professionalise track care

A 1 000 N tension gauge, 0-25 mm vernier caliper and 600 N·m torque wrench fit into a 15 kg toolbox that is locked to the crusher frame; having the tools on board ensures that measurements happen on time instead of waiting for a service truck that may be 50 km away. High-pressure washing at 200 bar removes clay that hides cracks; sites that wash every shift record 15 % longer bushing life because abrasive grit no longer grinds between pin and bush. Digital forms on a rugged tablet store tension, sag and roller diameter against engine hours; the cloud graph warns the superintendent when any parameter drifts outside the 95 % confidence band, converting reactive repairs into planned work.

Operator training includes a VR headset that simulates derailment and recovery in a safe classroom; trainees who complete the module show 40 % faster recovery times and 60 % fewer incorrect tension adjustments during live assessments. The training cost of 400 USD per person is recouped the first time a correct adjustment prevents a 6 h shutdown.

Essential tool kit that must travel with the machine

In addition to spanners and gauges, a 30 t hydraulic jack, 2 t chain block and LED floodlights are carried in a lockable box; the kit allows a three-person crew to re-rail a track at night without external help, saving 4 000 USD in crane mobilisation that would otherwise be unavoidable in remote terrain.

Cleaning and lubrication standards that prevent paste wear

Washing the undercarriage every 8 h removes 90 % of quartz paste that acts as grinding compound; sites that adopt the schedule extend roller shell life from 3 000 h to 3 900 h and save 0.007 USD per tonne on a 180 tph jaw, a figure that funds a 1 500 USD pressure washer in three months.

Alignment checks using laser or string-line methods

A 5 mW green laser pointer clamped to the sprocket hub will illuminate a 2 mm mis-alignment across a 3 m span; correcting the deviation with shim plates extends link life by 1 000 h and prevents the 45 kW power spike that occurs when the track drags sideways.

Digital documentation that satisfies auditors and warranty inspectors

Time-stamped photos of tension readings are uploaded to the cloud; OEM warranty claims are approved 50 % faster when photo evidence is provided, reducing dispute time from six weeks to ten days and ensuring that failed parts are replaced at no cost.

Team training that turns operators into first-line inspectors

Monthly ten-minute toolbox talks raise defect detection rates from 70 % to 93 %; operators who can interpret a 1 mm ridge on a roller as early wear save an average of 2 400 USD per event by ordering parts early instead of waiting for catastrophic failure.

Case where tool discipline halved maintenance time

A quarry introduced colour-coded tool shadow boards and cut average roller replacement time from 4 h to 1.8 h; the 2.2 h saving releases the crusher for an extra 440 t of production per month, worth 6 600 USD at 15 USD/t margin.

Future trends that shift track care from reactive repairs to predictive autonomy

Wireless load pins embedded between the track frame and main beam transmit tension data every second; a cloud model compares the reading with temperature and slope angle and predicts failure 200 h before the 3 % sag limit is reached. Trials show the system reduces unplanned track events by 80 % and saves 0.012 USD per tonne on a 250 tph fleet. Automatic grease pumps connected to the same network dispense 2 cm³ of lubricant whenever tension drops 1 %, maintaining the set-point without human intervention and extending bush life by 15 %.

Augmented-reality goggles overlay a 3D model of the correct roller position over the real unit, guiding a novice mechanic through a bearing swap in 45 min instead of 90 min. The goggles record the procedure and upload it for audit, ensuring that every maintenance action meets OEM standards even when a senior fitter is not on site.

Sensor networks and IoT that watch tension 24/7

NB-IoT sensors powered by vibration energy harvesters send tension and temperature data once per minute; the battery-free design lasts the life of the track and removes the need for manual meter reading in rain or snow.

Predictive models that forecast the optimum day for adjustment

Machine-learning algorithms trained on 1.2 million data points predict the remaining life of a roller within ±5 % and schedule replacement during the next planned maintenance window, avoiding the 40 000 USD lost-output penalty that accompanies an emergency track split.

Automatic tensioning systems that react to load and temperature

A closed-loop hydraulic circuit adjusts cylinder pressure every 30 s, keeping sag within 1 % of span even when ambient temperature swings from -10 °C to +30 °C during a single shift, removing the 0.3 mm thermal error that used to cause over-tightening and premature bush failure.

AR/VR maintenance guidance that cuts human error

Wearing AR glasses, a technician sees a holographic arrow pointing to the grease nipple and a digital torque value floating above the wrench; the system prevents under-torquing by turning the arrow green only when 600 N·m is reached, reducing incorrect assembly by 70 %.

Sustainability angle: longer life means less scrap steel

Extending track set life from 4 000 h to 5 200 h saves 2.8 t of high-manganese steel per machine; across a 50-unit fleet this equals 140 t of steel and 280 t of CO₂ avoided per year, a contribution that helps quarries meet Scope 3 emission targets without changing process chemistry.

Outlook: cradle-to-grave digital passports for every link and pin

Regulators are drafting rules that will require a file logging every tension adjustment, every wear measurement and the final scrap weight of each link; machines that already stream IoT data will auto-generate the passport, avoiding manual paperwork and adding an estimated 5 % resale value because buyers can verify the full maintenance history before purchase.