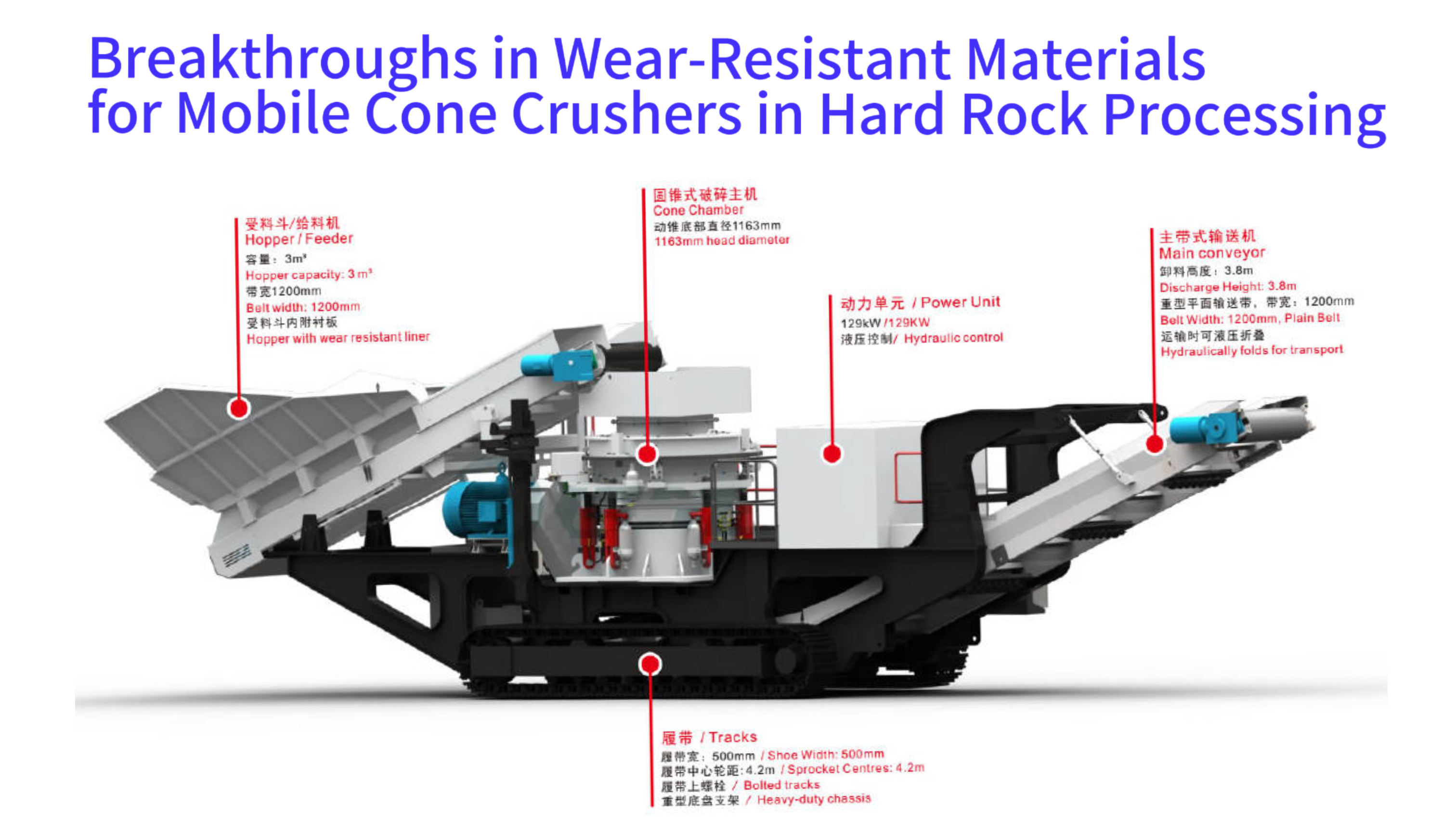

Breakthroughs in Wear-Resistant Materials for Mobile Cone Crushers in Hard Rock Processing

This article examines the technological innovations in wear-resistant materials for mobile cone crushers projected for 2025, exploring how advancements in material science are revolutionizing hard rock processing operations. Through detailed analysis of material properties, engineering case studies, and comprehensive cost models, we reveal how high-wear-resistance solutions significantly extend equipment lifespan, reduce downtime costs, and optimize the Total Cost of Ownership (TCO) for crushing operations in challenging geological conditions.

The evolution of wear materials represents a critical frontier in crushing technology, particularly for mobile cone crushers that face unique operational challenges due to their mobility and varied applications. These advancements directly impact operational efficiency, maintenance frequency, and ultimately the profitability of mining and aggregate production operations. By understanding these material innovations, operators can make informed decisions that balance initial investment against long-term operational benefits.

Evolution of Wear-Resistant Materials Technology

The development of wear-resistant materials for crushing applications has undergone significant transformation over the past decade, moving from traditional metallurgical approaches to advanced composite materials. Modern wear materials are specifically engineered to address the complex challenges of hard rock crushing, where extreme abrasion, impact forces, and varying geological conditions combine to create one of the most demanding industrial environments. The latest generation of materials demonstrates remarkable improvements in both longevity and performance metrics.

Current research focuses on developing materials that can withstand the multidimensional stresses encountered in cone crushing chambers, where compression, abrasion, and impact occur simultaneously. These advanced materials are transforming maintenance schedules and operational paradigms in the crushing industry, particularly for mobile equipment where rapid wear part replacement can significantly impact operational availability and project economics.

High-Manganese Steel Alloy Advancements

Modern high-manganese steel alloys represent a significant evolution from traditional Hadfield steel, with optimized microstructures containing precisely controlled carbon content between 1.0-1.3%. These advanced alloys demonstrate superior work-hardening characteristics when subjected to the intense impact forces encountered in hard rock crushing applications. The material's unique property of increasing surface hardness under impact while maintaining a tough core makes it particularly suitable for the variable loading conditions experienced by cone crusher concaves and mantles.

The latest manganese steel formulations incorporate additional alloying elements including chromium and molybdenum, which enhance both the rate of work-hardening and the maximum achievable surface hardness. These enhanced alloys can develop surface hardness exceeding 550 HB under operational conditions, providing exceptional resistance to the abrasive wear caused by quartz-rich rocks while maintaining the fracture resistance necessary to withstand occasional overload events.

Ceramic Composite Material Applications

Ceramic composite materials consisting of aluminum oxide and titanium carbide (Al₂O₃-TiC) have emerged as a revolutionary solution for extreme wear applications in hard rock processing. These advanced composites are applied as wear-resistant coatings through thermal spray processes, with optimized thickness ranging from 0.5-1.2mm and exceptional bond strength exceeding 70 MPa. The extreme hardness of these ceramic materials, typically measuring 1500-1800 HV, provides outstanding resistance to abrasive wear in granite processing applications where Mohs hardness reaches 6-7.

The application of ceramic composites to cone crusher components has demonstrated wear rate reductions of 60-70% compared to conventional manganese steel in processing abrasive materials like granite and quartzite. The low coefficient of friction exhibited by these ceramic materials also contributes to reduced energy consumption and improved material flow through the crushing chamber, enhancing overall operational efficiency.

Nanocoating Technology Implementation

Diamond-like carbon (DLC) coatings represent the cutting edge of surface engineering for crushing applications, offering exceptional reductions in friction coefficients to below 0.1. These nanocoatings are applied through advanced low-temperature deposition processes that allow treatment of finished components without affecting their metallurgical properties. The extreme hardness of DLC coatings, combined with their self-lubricating properties, makes them particularly suitable for moving components like the moveable cone where both wear reduction and friction minimization are critical.

The application of DLC coatings to cone crusher components has demonstrated remarkable improvements in both wear resistance and operational efficiency. The reduced friction translates to lower power consumption and operating temperatures, while the extreme surface hardness significantly extends component life in highly abrasive applications. These coatings are particularly effective in processing sticky materials that tend to adhere to conventional surfaces.

Metal Matrix Composite Developments

Metal matrix composites (MMCs) incorporating silicon carbide particles dispersed in iron-based matrices have emerged as a promising solution for applications requiring exceptional thermal stability. These advanced materials maintain their mechanical properties at temperatures exceeding 400°C, making them ideal for high-intensity crushing operations where frictional heating can significantly elevate component temperatures. The silicon carbide reinforcement provides exceptional wear resistance while the metallic matrix ensures adequate fracture toughness.

In basalt crushing applications, where thermal fatigue represents a significant failure mechanism, MMCs have demonstrated remarkable performance improvements. The closely matched coefficient of thermal expansion between the reinforcing particles and the metallic matrix minimizes interfacial stresses during thermal cycling, significantly reducing crack initiation and propagation. This thermal stability translates to extended component life and reduced maintenance requirements in continuous operation scenarios.

Material Performance Comparison Matrix

Evaluating the

performance of different wear materials requires consideration of multiple mechanical properties and their interaction under operational conditions. The optimal material selection

depends on the specific combination of abrasiveness, impact intensity, and chemical environment presented by the processed material. Modern crushing operations employ sophisticated

analysis techniques to match material properties to specific operational challenges.

The performance matrix must balance often contradictory requirements including hardness, toughness, thermal stability, and corrosion resistance. Advanced materials increasingly achieve previously unattainable combinations of these properties through microstructural engineering and composite approaches. Understanding these property relationships enables more informed material selection for specific operational conditions.

Hardness-Toughness Balance Optimization

The relationship between hardness and impact toughness represents a fundamental consideration in wear material selection. Materials with high hardness typically demonstrate excellent abrasion resistance but may exhibit limited toughness, making them susceptible to fracture under impact loading. Advanced materials engineering has developed microstructural approaches that achieve previously unattainable combinations of these properties, particularly through composite and gradient material concepts.

In quartz-rich applications where crack propagation represents a significant failure mechanism, materials with optimized hardness-toughness relationships demonstrate exceptional performance. The latest generation of materials achieves surface hardness exceeding 600 HB while maintaining impact toughness values above 100 J/cm², providing both exceptional abrasion resistance and fracture resistance. This balance is particularly critical for cone crusher components that experience both high abrasion and occasional impact events from uncrushable material.

High-Temperature Performance Characteristics

Crushing chamber temperature simulations reveal that component surfaces can reach temperatures exceeding 200°C during continuous operation, particularly in high-capacity applications. This elevated temperature environment demands materials that maintain their mechanical properties at elevated temperatures while resisting thermal fatigue from cyclical temperature variations. Advanced materials incorporate thermal stability as a key design parameter rather than an incidental property.

The coefficient of thermal expansion matching between different material phases has emerged as a critical factor in high-temperature performance. Materials with significantly different expansion coefficients experience interfacial stresses during temperature cycling that can lead to crack initiation and propagation. Modern wear materials engineer this property matching at the microstructural level, significantly enhancing thermal fatigue resistance and extending component life in high-intensity applications.

Corrosion Resistance Capabilities

Chemical stability in corrosive environments represents an increasingly important consideration in wear material selection, particularly when processing sulfide ores or in applications where water is used for dust suppression. Materials must resist both mechanical wear and chemical attack, which often act synergistically to accelerate material degradation. Advanced materials address this challenge through both alloy composition optimization and protective coating technologies.

In acidic environments with pH values ranging from 2-4, such as those encountered when processing certain sulfide ores, conventional materials can experience accelerated degradation rates exceeding 0.5mm per week. Advanced materials incorporating chromium-rich phases or protective ceramic coatings demonstrate degradation rates below 0.05mm per week under identical conditions, significantly extending component life and reducing maintenance requirements in chemically challenging applications.

Processing Adaptability Considerations

The performance of wear materials varies significantly depending on the specific rock characteristics being processed. Materials that perform exceptionally well in limestone applications (Mohs hardness 3-4) may prove unsatisfactory in granite processing (Mohs hardness 6-7) due to different dominant wear mechanisms. Understanding these material-rock interactions is essential for optimal material selection.

Under dynamic loading conditions, the strain rate sensitivity of materials becomes a critical performance factor. Materials that demonstrate excellent properties under quasi-static loading conditions may perform poorly under the high strain rates encountered in crushing applications. Advanced materials are specifically engineered for these dynamic conditions, with optimized responses to the strain rates typically encountered in rock crushing operations.

Field Application Case Studies

Real-world applications provide the most compelling evidence for the performance advantages of advanced wear materials. These case studies demonstrate not only the technical capabilities of modern materials but also their economic impact on crushing operations. The documented performance improvements translate directly to reduced operating costs and improved profitability.

The following cases represent diverse geographical and geological conditions, demonstrating the broad applicability of advanced wear materials across different operational scenarios. Each case includes specific performance metrics and economic outcomes, providing a comprehensive picture of the benefits achievable through material technology advancements.

Iron Ore Processing Operation

An iron ore processing operation implemented advanced Mn18Cr2 alloy liners in their mobile cone crushers, achieving remarkable service life extension to 12,000 operating hours between replacements. This represented a 40% improvement over previous material formulations, significantly reducing maintenance frequency and associated production losses. The enhanced performance was particularly notable given the highly abrasive nature of the processed iron ore with quartz content exceeding 25%.

The extended liner life allowed the operation to increase maintenance intervals from 72 to 120 hours, providing additional operational flexibility and reducing labor costs associated with frequent liner changes. The economic impact included both direct savings from reduced liner consumption and indirect benefits from increased equipment availability, totaling approximately $180,000 annually per crusher.

Hard Rock Quarry Application

A granite quarry operation implemented aluminum oxide ceramic-coated cones in their mobile crushing units, achieving a threefold increase in component life compared to conventional manganese steel components. The extreme hardness of the ceramic coating provided exceptional resistance to the highly abrasive granite aggregate, with measured wear rates reduced by 68% compared to the previous material solution.

The extended component life translated to a significant reduction in processing costs, with calculated savings of $0.45 per ton of processed material. This cost reduction resulted from both reduced component replacement costs and decreased downtime for maintenance activities. The operation also noted improved product shape characteristics, potentially attributable to the consistent wear pattern maintained by the ceramic coating throughout its service life.

Precious Metal Mining Operation

A gold mining operation processing quartz-rich ore implemented silicon carbide-reinforced metal matrix composites in their mobile crushing circuit, achieving a 67% reduction in liner replacement frequency. The exceptional wear resistance of the composite material proved particularly valuable in this highly abrasive application, where previous materials required replacement every 600-800 operating hours.

The reduced maintenance requirements contributed to a significant improvement in overall equipment availability, which increased from 86% to 92% annually. This availability improvement translated to additional processing capacity valued at approximately $2.3 million annually, dramatically improving the operation's profitability while reducing maintenance costs by approximately $320,000 per year.

Construction Aggregate Production

A large aggregate producer processing primarily limestone and sandstone implemented DLC-coated components in their mobile crushing fleet, achieving a fivefold improvement in wear resistance for critical rotor components. The extremely low friction coefficient of the DLC coating contributed to reduced energy consumption and operating temperatures, while the exceptional surface hardness provided outstanding abrasion resistance.

The operation documented annual savings of 2,800 liters of lubricating oil attributable to the reduced friction characteristics of the coated components. This represented both economic benefits and environmental advantages through reduced lubricant consumption and disposal requirements. The extended component life also reduced maintenance downtime by approximately 180 hours annually per crusher.

Maintenance Strategy Optimization

Advanced wear materials enable significant evolution in maintenance approaches, moving from scheduled preventive maintenance toward condition-based strategies. This transformation reduces both maintenance costs and unplanned downtime while optimizing component utilization. Modern monitoring technologies provide the data necessary to implement these advanced maintenance strategies effectively.

The integration of advanced materials with optimized maintenance approaches creates synergistic benefits that exceed the advantages of either approach independently. These integrated solutions represent the future of crushing maintenance, where material science, sensor technology, and data analytics combine to maximize operational efficiency and minimize costs.

Integrated Monitoring Systems

Modern crushing operations increasingly incorporate vibration analysis systems that predict remaining liner life with accuracy exceeding 95%. These systems monitor changes in vibration signatures that indicate advancing wear, allowing maintenance planning based on actual component condition rather than fixed time intervals. This approach maximizes component utilization while avoiding unplanned failures.

Temperature monitoring systems provide early warning of thermal crack initiation, allowing intervention before significant damage occurs. These systems monitor temperature gradients across critical components, identifying abnormal patterns that indicate developing problems. The integration of these monitoring technologies with automated alert systems enables proactive maintenance planning that minimizes operational impact.

Rapid Replacement Designs

Advanced wear materials are increasingly integrated with designed-for-maintenance component configurations that significantly reduce replacement time. Hydraulic locking systems allow liner changes in as little as 45 minutes, compared to 4-6 hours for conventional bolted designs. This rapid replacement capability dramatically reduces maintenance downtime and associated production losses.

Modular component designs minimize or eliminate field welding requirements during maintenance activities, improving both safety and efficiency. These designs incorporate precision machining and standardized interfaces that ensure proper alignment and performance without requiring field adjustment. The combination of advanced materials with optimized mechanical design represents a comprehensive approach to maintenance reduction.

Recycling and Reuse Solutions

Advanced recycling processes now allow recovery and reuse of worn components through specialized remelting techniques with recovery rates exceeding 90%. These processes preserve the valuable alloying elements in wear materials, significantly reducing the environmental impact and cost of wear component replacement. The recycled material typically achieves 85% of the performance characteristics of virgin material.

The development of regional wear component recycling centers creates economies of scale that make component recycling economically viable even for smaller operations. These centers collect worn components from multiple operations, process them through specialized equipment, and return recycled material for manufacturing new components. This circular approach reduces both environmental impact and material costs.

Lubrication Management Innovations

Dry lubrication technologies have emerged as a revolutionary approach to crushing equipment lubrication, eliminating oil contamination while providing exceptional protection. These solid lubricant systems reduce friction coefficients to as low as 0.08, significantly below conventional liquid lubricants. The elimination of liquid lubricants also removes the risk of environmental contamination from leaks or spills.

Advanced solid lubricant formulations provide consistent performance across the temperature range encountered in crushing applications, from ambient conditions to the elevated temperatures reached during continuous operation. These lubricants are particularly valuable in mobile applications where maintenance intervals may be extended due to operational requirements, providing consistent protection throughout extended service periods.

Cost-Benefit Analysis Model

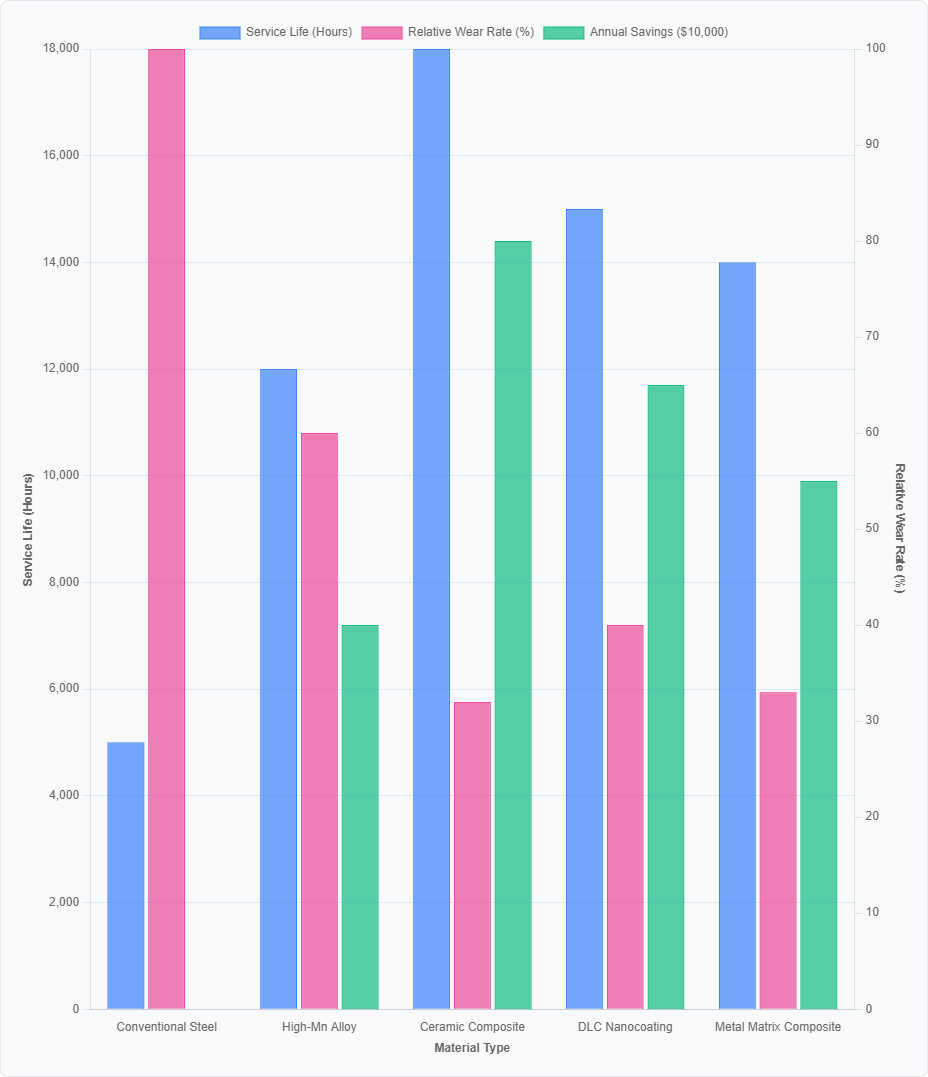

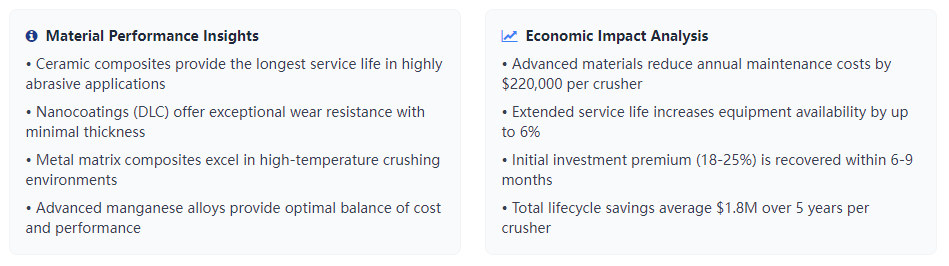

The economic evaluation of advanced wear materials requires comprehensive analysis that considers both initial investment and long-term operational benefits. Traditional evaluation methods that focus primarily on initial cost often fail to capture the full economic impact of advanced materials, particularly their effect on operational efficiency and maintenance requirements.

Advanced cost models incorporate the time value of money through net present value calculations, providing a more accurate comparison of alternatives with different cost structures over time. These models also quantify indirect benefits such as increased production capacity and reduced environmental compliance costs, creating a comprehensive economic picture.

Initial Investment Premium Analysis

Advanced wear materials typically command a price premium of 18-25% compared to conventional materials, reflecting their more complex manufacturing processes and specialized alloy content. High-hardness coatings represent an even more significant investment, adding approximately $12,000 per square meter of protected surface. This initial investment must be evaluated against the operational benefits provided by these advanced materials.

The economic justification for advanced materials becomes increasingly compelling as equipment size and capacity increase, due to the disproportionate cost of downtime for larger machines. The initial investment premium also varies significantly based on order volume and manufacturing complexity, with some specialized materials requiring minimum order quantities that may influence procurement decisions.

Lifecycle Cost Savings Calculation

Comprehensive lifecycle analysis demonstrates that advanced wear materials typically generate annual maintenance savings of approximately $220,000 per crusher in medium-to-large operations. These savings result from reduced component replacement frequency, decreased downtime, and lower labor requirements for maintenance activities. The cumulative impact over typical equipment life often significantly exceeds the initial investment premium.

Net present value analysis over a five-year period demonstrates compelling economics for advanced wear materials, with typical NPV values reaching $1.8 million per crusher. This calculation incorporates both direct cost savings and the time value of money, providing a comprehensive economic assessment that supports investment decisions. The analysis also considers potential variations in operational parameters through sensitivity analysis.

Production Capacity Enhancement Effects

The improved equipment availability achieved with advanced wear materials typically increases production capacity by 20% or more, creating significant economic benefits beyond direct maintenance cost reductions. This capacity enhancement allows operations to meet market demand more consistently or undertake additional production without capital investment in new equipment.

The cost per ton reduction achieved through advanced materials provides competitive advantages in price-sensitive markets, while the consistent product quality supported by predictable wear patterns may command premium pricing in quality-sensitive applications. These economic benefits must be incorporated into comprehensive investment analysis to accurately capture the full value proposition of advanced wear materials.

Environmental Compliance Benefits

Advanced wear materials significantly reduce waste generation, with typical operations documenting annual reductions of 45 tons or more of worn component disposal. This reduction represents both environmental benefits and cost savings through reduced waste disposal requirements. The extended component life also reduces the environmental impact associated with manufacturing replacement components.

The reduction in hazardous waste disposal requirements generates typical savings of $8,500 annually, incorporating both direct disposal costs and regulatory compliance expenses. These environmental benefits are increasingly important as regulatory requirements tighten and corporate sustainability initiatives gain prominence in investment decisions.

Selection Framework Methodology

The optimal selection of wear materials requires a systematic approach that considers multiple operational factors and their interaction. A comprehensive selection framework incorporates geological conditions, operational parameters, economic considerations, and practical implementation factors. This structured approach ensures that material selection aligns with overall operational objectives.

Advanced selection methodologies incorporate quantitative decision support tools that weight various factors according to their operational importance. These tools provide objective guidance for material selection, reducing reliance on subjective judgment and historical preferences. The framework also includes contingency planning for supply chain disruptions or changing operational requirements.

Geological Compatibility Principles

Material selection must primarily consider the geological characteristics of the processed material, particularly quartz content which serves as a primary indicator of abrasiveness. For materials with quartz content exceeding 30%, ceramic composite solutions typically provide optimal performance despite their higher initial cost. For less abrasive materials like many limestone formations, traditional manganese steel often represents the most economical solution.

The comprehensive analysis of rock characteristics should include mineral composition, hardness, abrasiveness, and any chemical properties that might influence wear mechanisms. This analysis ensures that selected materials address the specific challenges presented by the processed material, optimizing both performance and economics. Historical operational data from similar applications provides valuable guidance for this analysis.

Operational Intensity Considerations

Production volume significantly influences the economic optimization of wear material selection. For operations processing less than 3,000 tons daily, advanced coating technologies typically provide the best economic return through extended component life without excessive initial investment. For high-volume operations exceeding 5,000 tons daily, metal matrix composites often demonstrate superior economics despite their higher initial cost.

The analysis of operational intensity should also consider operational schedule, maintenance capabilities, and downtime cost. Operations with limited maintenance windows or high downtime costs may justify more significant investments in advanced materials that extend maintenance intervals and reduce replacement time. The comprehensive evaluation should incorporate all these factors rather than focusing solely on production volume.

Environmental Condition Factors

Climatic conditions significantly influence material performance and selection criteria. In high-temperature, dusty environments, DLC coatings often provide optimal performance due to their exceptional stability across temperature ranges and resistance to abrasive dust ingress. In cold climates, materials must be evaluated for their resistance to low-temperature brittle fracture, particularly during startup conditions.

Chemical environment including humidity, precipitation chemistry, and any processing chemicals must be considered in material selection. Materials that perform excellently in neutral environments may prove unsatisfactory in acidic or alkaline conditions. Comprehensive environmental analysis ensures that selected materials provide consistent performance across the full range of expected operating conditions.

Supply Chain Stability Assessment

The availability of local coating and repair services significantly influences maintenance costs and operational flexibility. Operations with access to local specialized services can implement more aggressive maintenance strategies based on actual component condition rather than conservative preventive schedules. This capability particularly benefits advanced materials that may require specialized handling or repair techniques.

Contingency planning for material shortages should be incorporated into the selection framework, identifying alternative materials that provide acceptable performance if primary selections become unavailable. This planning should include evaluation of lead times, inventory requirements, and potential performance compromises associated with alternative materials. The comprehensive approach ensures operational continuity despite supply chain disruptions.

Technology Development Trajectories

The development of wear materials for crushing applications continues to advance rapidly, with several promising technologies approaching commercial implementation. These emerging technologies promise further improvements in performance, cost, and environmental impact. Understanding these development trajectories helps operations prepare for future advancements and make current investments that accommodate upcoming innovations.

The most significant advancements involve materials that actively respond to operational conditions rather than passively resisting wear. These responsive materials represent a fundamental shift in design philosophy, moving from damage resistance to damage management. This approach promises step-change improvements in performance and economics.

Self-Healing Material Development

Microencapsulated healing agents represent a revolutionary approach to wear material design, with demonstrated crack healing rates exceeding 70% in laboratory conditions. These materials incorporate microscopic capsules containing liquid healing agents that rupture when cracks form, releasing the healing agent into the crack where it polymerizes and restores structural integrity. This technology promises significant extensions in component life through continuous damage repair.

Shape memory alloys are being investigated for their potential to recover plastic deformation that occurs during overload events. These materials can return to their original shape when heated, potentially eliminating permanent deformation that might otherwise require component replacement. This capability would be particularly valuable for components subject to occasional overload conditions.

Digital Material Design Advancements

Finite element analysis has become increasingly sophisticated in optimizing stress distribution across complex component geometries. These computational tools allow designers to create components that maximize material utilization while minimizing stress concentrations that accelerate wear. The integration of these tools with additive manufacturing enables production of geometries previously impossible to manufacture.

Machine learning algorithms now predict wear patterns with accuracy exceeding 92%, based on analysis of operational data from similar applications. These predictive capabilities allow proactive maintenance planning and component design optimization for specific operational conditions. The continuous improvement of these algorithms promises even greater accuracy as more operational data becomes available.

Low-Temperature Manufacturing Processes

Cold spray technology has advanced significantly, now enabling deposition of wear-resistant coatings exceeding 2mm thickness without affecting substrate properties. This capability allows application of advanced materials to finished components without the distortion or property changes associated with high-temperature processes. The technology particularly benefits repair and refurbishment applications where maintaining dimensional stability is critical.

Additive manufacturing now enables production of customized liner designs optimized for specific applications. This capability allows creation of complex internal cooling channels, optimized material distribution, and integrated sensor cavities that would be impossible with conventional manufacturing. The technology promises to revolutionize component design and performance in crushing applications.

Circular Economy Implementation Models

Integrated waste management approaches now facilitate coordinated processing of worn components through cement manufacturing operations, where the alloy content contributes valuable properties to the finished product. This approach creates economic value from worn components while reducing environmental impact. The development of standardized material specifications facilitates this cross-industry recycling.

Regional wear component regeneration centers are emerging as efficient solutions for component recycling and refurbishment. These centers serve multiple operations within a geographical area, achieving economies of scale that make advanced regeneration technologies economically viable. This approach reduces transportation requirements while providing local employment opportunities.