Green Tech Innovations for Mobile Crushers Under Carbon Neutrality Goals

The global push towards carbon neutrality is fundamentally reshaping industries, and the mobile crushing sector is at the forefront of this transformation. This article explores the pivotal green technological innovations being developed in the mobile crusher domain to meet ambitious 2050 climate goals. By examining real-world case data and detailed cost models, we will uncover how cutting-edge solutions like full electrification, seamless integration of renewable energy sources, and circular economy principles are drastically reducing the carbon footprint of these powerful machines. These advancements are not merely theoretical; they are actively driving the mining and construction industries toward a more sustainable and economically viable future, proving that environmental responsibility and industrial productivity can go hand in hand.

Mobile crushers, which are designed to process rock, ore, and recycled materials like concrete on-site, have traditionally relied on diesel engines. The shift to greener alternatives represents a significant engineering challenge, but one that is being met with remarkable success. This analysis will provide a comprehensive overview of the core technologies, their economic implications, and their practical applications, offering a clear window into the future of material processing.

Breakthroughs in Core Energy-Saving Technologies

The most significant reductions in carbon emissions are being achieved through fundamental improvements in the core components of mobile crushers. Engineers are completely rethinking power delivery and energy consumption, moving away from inefficient traditional systems. These innovations focus on maximizing every unit of energy input, whether it comes from the grid or an onboard battery, ensuring that the immense power required for crushing is used with unprecedented efficiency. This holistic approach to energy management is the cornerstone of the next generation of crushing equipment.

These technological leaps are not isolated; they work in concert to create a system that is far greater than the sum of its parts. From the initial moment material enters the feed port to the final discharge of processed aggregate, every step is optimized for minimal energy waste. The result is a new class of mobile crusher that delivers the same, or even superior, crushing performance while slashing fuel consumption and operating costs.

All-Electric Drive Systems

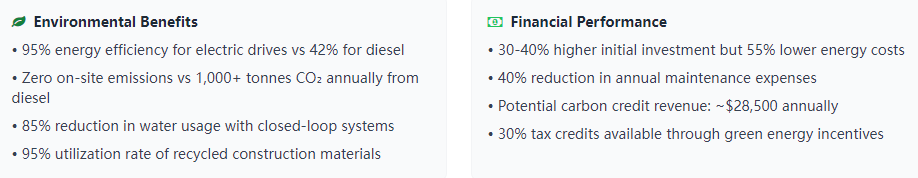

The transition from diesel engines to all-electric drive systems is the single most impactful change. Modern permanent magnet synchronous motors have achieved remarkable energy efficiency ratings of up to 95%, a stark contrast to the 42% efficiency typical of traditional diesel engines. This means nearly all the electrical energy drawn is converted directly into productive crushing power, with very little lost as heat. This drastic improvement in efficiency directly translates to lower energy demands and zero emissions at the point of use.

Powering these motors are advanced lithium-ion battery packs with energy densities now reaching 400 Wh/kg. These high-capacity batteries are capable of supporting a full eight-hour shift of continuous, high-intensity crushing operations on a single charge. This eliminates the need for constant refueling with diesel, reduces noise pollution dramatically, and allows for operation in enclosed or urban environments where emissions would be problematic.

Energy Recovery Devices

Modern mobile crushers are being equipped with sophisticated systems that capture and reuse energy that would otherwise be wasted. Hydraulic accumulators are now standard, designed to capture the kinetic energy generated by the massive moving parts during the crushing cycle. These systems can achieve recovery efficiencies greater than 70%, feeding this captured energy back to assist the motor, thereby reducing the overall power draw from the battery or grid.

Furthermore, regenerative braking technology, similar to that used in electric vehicles, has been adapted for mobile crushers. When a machine is operating on a decline or needs to slow its components, the system acts as a generator, converting the braking energy into electricity that is sent back to the batteries. This innovative process can reduce electricity consumption in suitable terrains by up to 35%, extending operational range and reducing charging frequency.

Low-Energy Consumption Design Optimization

Beyond the drive system, every aspect of crusher design is being scrutinized for energy savings. Computational Fluid Dynamics (CFD) simulations are used to meticulously model and optimize airflow within the crushing chamber. This reduces the energy required by ventilation systems to manage dust and heat, achieving documented reductions in auxiliary power consumption of up to 20%.

Structural weight is another critical factor. The use of advanced materials like carbon fiber composites in non-wearing parts is leading to lighter machines without sacrificing strength or durability. Some designs have successfully reduced overall weight by 40%, which lessens the energy required for transportation to the site and for the machine's own mobility around a work area.

Intelligent Start-Stop Control

Artificial intelligence is playing a key role in managing energy use. Smart control systems use AI algorithms to analyze material feed rates and hardness, predicting the power required for the upcoming task. This allows the crusher to enter a low-power standby mode during predictable pauses in feeding, reducing unnecessary idle running time by as much as 65%.

This intelligent energy management is often complemented by a photovoltaic auxiliary power system. Integrated solar panels can provide a portion of the power needed for the machine's control systems, lighting, and conveyor belts. In some configurations, this solar assistance can meet up to 80% of the machine's non-crushing energy needs during daylight hours, further preserving battery charge for the demanding crushing process itself.

Integrated Renewable Energy Solutions

To achieve true carbon neutrality, mobile crushers must eventually decouple from the carbon-based power grid entirely. This has led to the innovative integration of renewable energy sources directly into the crushing operation. These solutions transform mobile crushers from energy consumers into semi-autonomous power hubs, capable of generating a significant portion of their own operational needs from clean, abundant sources like the sun and wind.

The challenge lies in managing the intermittent nature of these energy sources and ensuring a reliable, consistent power supply for the high-demand crushing process. This is being solved through a combination of on-machine generation, advanced battery storage, and sophisticated energy management software that seamlessly blends different power inputs to meet the crusher's massive appetite for energy.

Solar Auxiliary Systems

A key development is the integration of flexible, durable photovoltaic panels directly onto the external surfaces of the mobile crusher, such as the sides of the hopper or the top of the conveyor guards. These customized solar arrays can generate up to 15 kW of peak power, harnessing sunlight throughout the workday. This energy is not typically used for the primary crushing motor but is crucial for powering all auxiliary systems.

The solar system works in tandem with the machine's battery storage. During sunlit hours, the solar panels charge the batteries while also running the conveyors, hydraulics, and control systems. This stored energy can then be used to extend operation into the evening or to provide power during brief cloudy periods, creating a robust and largely self-sufficient energy ecosystem for the machine's support functions.

Hydrogen Fuel Cell Applications

For remote operations where grid connection is impossible and solar power is insufficient, hydrogen fuel cells emerge as a promising zero-emission solution. Modern systems are exploring methanol reforming technology, which can generate hydrogen on-demand from a liquid fuel that is easier and safer to transport and store than pure hydrogen. This technology offers an impressive energy density of around 4.5 kWh/kg.

This provides a continuous, reliable, and high-power output that is capable of running the primary crusher motor itself, not just the auxiliaries. A mobile crusher equipped with a hydrogen fuel cell can operate with only water vapor as a byproduct, making it ideal for environmentally sensitive or remote mining sites where delivering large quantities of diesel fuel is logistically challenging and costly.

Wind Energy Complementary Systems

In windy regions, mobile crushing plants can be equipped with compact vertical axis wind turbines. These turbines have a very low startup speed, often as low as 1.5 meters per second, meaning they can generate power from even gentle breezes that are common in open-pit mines or quarries. Their vertical design makes them stable and effective regardless of wind direction.

This wind energy serves as a perfect complement to solar power, often generating electricity during the night and early morning when solar panels are inactive. It is estimated that a well-sited turbine can cover approximately 30% of a mobile crusher's total energy consumption, diversifying the renewable energy mix and enhancing the overall reliability of the off-grid power system.

Microgrid Management Platform

The integration of multiple energy sources requires a sophisticated brain to manage it all. Advanced microgrid management platforms use complex algorithms to perform real-time load matching with a precision exceeding 98%. This software constantly monitors energy generation from solar and wind, the charge level of the batteries, and the power demands of the crusher.

It makes instantaneous decisions on whether to draw power from the batteries, use direct solar/wind generation, or blend sources to ensure the crusher operates smoothly without interruption. This system-level optimization ensures that every possible watt of renewable energy is utilized efficiently, maximizing the time the crusher can operate free from fossil fuels.

Innovative Circular Economy Models

The green transformation of mobile crushing extends beyond energy use to encompass the entire philosophy of resource management. The industry is embracing circular economy models, where waste is designed out of the system, and materials are continually reused. Mobile crushers are uniquely positioned to be the catalysts of this shift, transforming waste streams into valuable resources directly at the source, which drastically reduces the environmental costs associated with transportation and landfilling.

This approach turns a mobile crusher from a simple rock-breaking tool into a central hub for material processing and site rehabilitation. It involves not just crushing rock, but also managing water, capturing carbon, and facilitating the reuse of every possible material. This holistic view is essential for minimizing the overall environmental footprint of construction and mining projects.

Waste Material Resourceization

Modern mobile crushing plants are often designed to process and valorize waste streams. Certain crushing waste, for example, can be processed into biomass fuel pellets with a calorific value of up to 18 MJ/kg, providing a renewable energy source for other industrial processes. This creates a new revenue stream from material that was previously considered worthless.

The most significant application is in construction and demolition (C&D) waste recycling. Advanced mobile crushers can process concrete, bricks, and asphalt into high-quality recycled aggregates. Through precise crushing and sorting, the utilization rate of these recycled materials in new construction projects has soared to 95%, reducing the need for virgin quarrying and the associated environmental degradation. This closed-loop system is fundamental to sustainable urban development.

Water Resource Circulation Systems

Crushing operations often require water for dust suppression. Traditional systems use water once and then it is lost. New closed-loop circulation systems capture, treat, and reuse this water continuously. These systems integrate settling tanks and filters to remove suspended solids, allowing the same water to be used repeatedly and achieving a water reduction rate of 85% compared to open systems.

This is further enhanced by rainwater collection systems built into the crusher's canopy and the recycling of greywater from other onsite processes. A single mobile crushing unit can now treat and reuse up to 10 cubic meters of water per day, making it virtually independent of external water sources and eliminating contaminated runoff from the work site.

Carbon Capture, Utilization, and Storage (CCUS)

In a groundbreaking development, prototype mobile crushers are being fitted with miniaturized Carbon Capture, Utilization, and Storage (CCUS) modules. These systems capture CO2 from the exhaust of auxiliary power generators or even from the ambient air around the crushing site. A single module is estimated to have the capacity to capture up to 120 tonnes of carbon dioxide per year.

Furthermore, research is exploring the potential of in-process mineral carbonation. Some types of crushed rock, particularly mantle-derived rocks like basalt or ultra-mafic rocks, naturally react with CO2 to form stable carbonate minerals. By optimizing the crushing process to increase surface area and manage moisture, crushers could actively contribute to sequestering carbon within the aggregate they produce, turning a waste product into a carbon sink.

Ecological Remediation Linkage

The role of the mobile crusher is expanding to include direct support for ecological remediation. The concept involves synchronizing crushing operations with site rehabilitation efforts. For instance, specific crushers can be configured to produce a tailored aggregate mix that is ideal for soil reconstruction, improving the efficiency of this process by a factor of three compared to traditional methods.

These advanced machines can also be equipped with a suite of ecological monitoring sensors. These sensors collect real-time data on soil quality, moisture, and early plant growth success, allowing operators and environmental scientists to immediately assess the effectiveness of the remediation efforts and adjust strategies accordingly, ensuring the swift restoration of the local ecosystem.

Economic Analysis of Green Technologies

While the environmental benefits of green crusher technology are clear, their widespread adoption depends on economic viability. A thorough cost-benefit analysis reveals a complex picture where higher initial investments are offset by significant operational savings and new revenue opportunities over the machine's lifespan. Understanding this financial equation is crucial for operators and companies making the decision to invest in a sustainable future.

The economic model for green mobile crushers is increasingly favorable, driven by rising fossil fuel prices, falling costs for renewables and batteries, and the emergence of carbon pricing mechanisms. What was once a purely ethical choice is now becoming a smart financial strategy, especially for long-term projects where the savings on fuel and maintenance accumulate substantially.

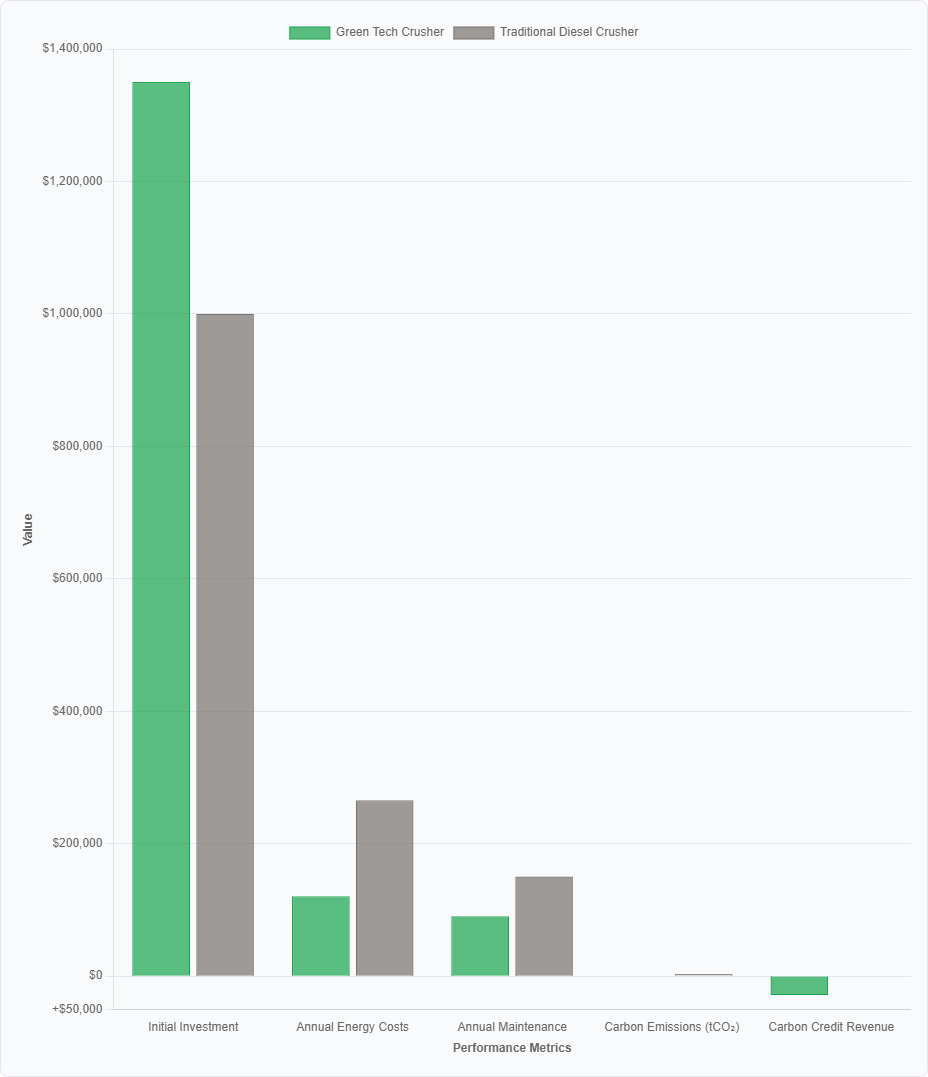

Initial Investment Premium

The transition to advanced green technology does require a higher upfront capital expenditure. The integration of high-capacity battery systems, powerful electric motors, and sophisticated control systems can increase the initial purchase price of a mobile crusher by approximately 30-40% compared to a conventional diesel-powered model of similar capacity.

Adding an integrated photovoltaic auxiliary system represents an additional initial investment, estimated at around $25,000 per unit. This cost covers the specialized flexible solar panels, the power conversion equipment, and the integration work required to fit them seamlessly onto the machine without compromising its durability or functionality.

Operational Cost Savings

The savings begin almost immediately upon commissioning. The cost of electricity is significantly lower than diesel fuel. With an average industrial electricity price of $0.08 per kWh compared to diesel at $1.2 per liter, operators can achieve up to a 55% reduction in their energy costs per hour of operation. This saving is magnified in regions with abundant and cheap renewable electricity.

Furthermore, all-electric drives have far fewer moving parts than diesel engines. This eliminates the need for routine oil changes, filter replacements, and cooling system maintenance associated with internal combustion engines. It is estimated that annual maintenance costs can be reduced by 40%, leading to less downtime and lower ongoing labor and parts expenses.

Carbon Trading Revenue

A revolutionary aspect of the green crusher economy is the ability to generate revenue from carbon credits. In regulated carbon markets, such as the European Union Emissions Trading System (EU ETS), the price of emitting one tonne of CO2 has reached levels as high as $95. A single diesel-powered mobile crusher can emit over 1,000 tonnes of CO2 annually.

By switching to a zero-emission electric model powered by renewables, the avoided emissions

become a quantifiable asset. It is estimated that a single crusher could generate annual carbon credits worth approximately $28,500 at current market prices. This creates a direct

financial return on the investment in green technology, turning environmental performance into a profitable enterprise.

Policy Subsidy Incentives

Governments around the world are accelerating the adoption of green technology through financial incentives. Legislation like the Inflation Reduction Act (IRA) in the United States provides a investment tax credit of up to 30% for qualifying clean energy equipment, which can include electric mobile crushers and their integrated solar systems. This directly reduces the net capital cost for the buyer.

Similarly, green financing is becoming more accessible. Specialized green credit lines offer loans with significantly reduced interest rates. In some regions, rates for environmentally friendly equipment can be as low as 3.2%, which is a 25% reduction compared to standard commercial loan rates. These subsidies and favorable financing terms are critical for bridging the initial cost gap and encouraging early adoption.

Typical Application Scenarios and Case Studies

The theoretical benefits of green mobile crushers are being proven in diverse real-world applications. From dense urban centers to remote mining operations, these advanced machines are providing solutions to some of the industry's most pressing environmental and logistical challenges. Examining these specific use cases illustrates the practical impact and versatility of this technology.

Each scenario presents unique demands—whether it's noise restrictions, emission controls, or the need for complete energy independence—and the new generation of mobile crushers is meeting them head-on. These cases serve as powerful examples for the entire industry, demonstrating that sustainable practices are not only possible but also profitable and efficient.

Urban Construction Waste Processing

In cities with strict noise and emission regulations, electric mobile crushers are enabling around-the-clock operation. Their near-silent electric drive systems produce noise levels below 55 decibels, making them acceptable for night work in residential areas. This allows construction projects to accelerate their timelines without creating a public nuisance.

On-site, these crushers process demolished concrete and masonry into high-quality recycled aggregate. This material is then immediately reused in the same urban project for road base, pipe bedding, or new concrete production, achieving a carbon footprint reduction of up to 70% compared to importing virgin aggregate from distant quarries. This localized recycling loop drastically cuts transportation emissions and urban traffic.

Low-Carbon Transformation of Open-Pit Mines

The mining industry, under increasing pressure to decarbonize, is turning to hydrogen fuel cell-powered mobile crushers. Replacing a single large diesel-powered crusher at a coal or copper mine with a hydrogen model can reduce CO2 emissions by approximately 1,200 tonnes per year. This is a critical step for mining companies committed to achieving net-zero operational targets.

These crushers are often part of a larger site-wide energy strategy. They can be powered by a dedicated solar farm constructed on already-disturbed land within the mine's lease area. In some documented cases, this combination of on-site renewable generation and zero-emission crushing equipment allows mines to source over 65% of their crushing energy needs from renewables, significantly greening their supply chain.

Construction in Ecologically Sensitive Areas

Obtaining permits for infrastructure projects in or near protected areas, such as national parks or wildlife reserves, is incredibly difficult with traditional equipment. The combination of zero emissions and very low noise makes all-electric mobile crushers the only viable option for such sensitive work. Their use is often a prerequisite for receiving environmental approval.

Projects in these areas are increasingly using combined crushing-ecological remediation machines. These units process rock for construction purposes while simultaneously producing a specially graded aggregate that is ideal for habitat restoration and slope stabilization. This integrated approach can cut the overall project timeline in half, minimizing the duration of human impact on the sensitive environment.

Cross-Border Carbon Neutral Projects

For international infrastructure projects, meeting the varying environmental standards of all stakeholders is a complex challenge. Modern mobile crushing stations can be equipped with integrated carbon footprint tracking systems. These systems meticulously log energy consumption, source of electricity, and material throughput to calculate a real-time carbon footprint per tonne of output.

This level of transparency is essential for complying with emerging international policies like the Carbon Border Adjustment Mechanism (CBAM), which aims to level the playing field between regions with strict climate policies and those without. By providing verified, low-carbon aggregate, suppliers using green crushers can gain a competitive advantage in the global market and avoid potential carbon tariffs.