Quantifying the Role of Toggle Plate Thickness in Crusher Safety

This examination details the critical function of the toggle plate in jaw crushers, specifically analyzing how its dimensional characteristics directly influence the machine's overload protection mechanisms. Through mechanical analysis and performance data, we explore the balance between structural integrity and safety responsiveness.

Fundamental Principles of Overload Protection

Jaw crushers are subjected to immense mechanical stresses during operation, particularly when unbreakable materials enter the crushing chamber. The toggle plate serves as a deliberately designed weak link in the assembly, a sacrificial component that fails predictably under excessive force. This mechanical fuse is engineered to fracture before more expensive and critical components like the eccentric shaft or the main frame sustain irreversible damage.

The fundamental operation relies on the principle of controlled mechanical failure. When the load exerted on the movable jaw exceeds a predetermined threshold, the stress concentrated within the toggle plate surpasses its ultimate tensile strength. This intentional fracture immediately disrupts the kinematic chain of the crusher, halting the transfer of crushing force and bringing the machine to a stop, thereby preventing a catastrophic failure.

Mechanical Stress and Material Behavior

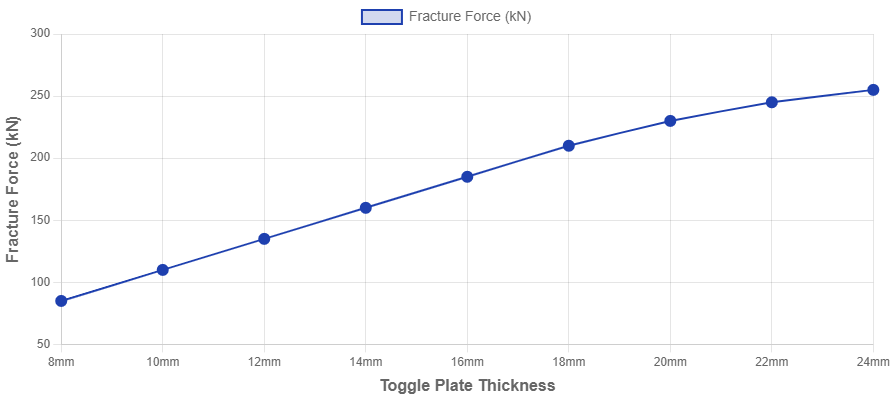

The relationship between toggle plate thickness and its failure point is not linear but follows principles of solid mechanics. Increasing the thickness of a plate made from a specific material raises its cross-sectional area, which in turn increases the absolute force required to cause tensile failure. However, thickness also influences the distribution of stress throughout the component under load.

Finite Element Analysis simulations reveal that a thicker toggle plate exhibits a different stress profile than a thinner one. While a thicker plate can withstand a higher overall force, it may also redistribute stress away from the intended failure zone, potentially leading to unpredictable fracture patterns or a failure to activate when needed. The material's grade and its ductile-to-brittle transition temperature further modulate this relationship, ensuring the plate fails in a brittle, predictable manner rather than deforming plastically.

Evaluating Protection System Sensitivity

Sensitivity in this context refers to the precision with which the overload protection system activates at its designated load threshold. A highly sensitive system will fracture consistently within a narrow range of forces just above the safe operating limit. Sensitivity is quantified by measuring the variance in the actual fracture force across multiple tests compared to the designed fracture force.

Factors affecting sensitivity include dimensional tolerances, material homogeneity, and the alignment of the toggle plate within its seats. A plate that is too thick may exhibit a high standard deviation in its fracture force, sometimes failing to break significantly above the desired limit, which exposes the crusher to risk. Conversely, a plate that is too thin may fracture below the operational limit, causing unnecessary downtime and reducing operational efficiency.

Experimental Analysis of Thickness Variation

Controlled laboratory testing provides empirical data on how thickness alters performance. In such tests, toggle plates are manufactured to precise thickness gradients, for example, 10mm, 15mm, and 20mm, from the same batch of cast iron or alloy steel. These plates are then subjected to controlled hydraulic loading that simulates the crushing force, while sensors record the exact force at the moment of fracture.

The data from repeated tests allows for the construction of a performance curve. Results typically indicate an optimal thickness range where fracture force is both consistent and aligned with engineering specifications. Plates outside this range, whether too thin or too thick, show greater performance variance and are therefore less reliable as safety components. This testing is crucial for validating computer models and informing design choices.

Implications for Crusher Design and Operation

The findings from stress analysis and physical testing directly influence crusher manufacturing and maintenance protocols. Engineers must select a toggle plate thickness that offers an ideal compromise between strength and predictable failure. This choice is not universal; it must be tailored to the crusher's model, its intended application like granite crushing, and the expected maximum operating load.

For crusher operators, understanding this relationship is key to effective maintenance. Using a non-standard or incorrectly specified toggle plate can disable the primary safety system, turning a minor incident into a major repair. Therefore, replacement components must always match the original equipment manufacturer's specifications for dimensions and material properties to ensure the overload protection functions as designed.

Beyond the Toggle Plate System Integration

While the toggle plate is a fundamental mechanical fuse, modern crushers often integrate it with other systems for enhanced protection. Hydraulic overload protection systems can work in tandem with a traditional toggle plate, using hydraulic cylinders to adjust the crusher setting and relieve pressure automatically when an overload is detected.

This integrated approach creates a more robust safety net. The immediate response of a hydraulic system can sometimes prevent an overload from reaching a severity that would fracture the toggle plate, thereby reducing downtime. However, the mechanical toggle plate remains an essential fail-safe, a final layer of protection that is entirely passive and reliable regardless of the status of hydraulic or electrical systems, ensuring ultimate machine safety.