Complete Guide to Selecting Jaw Crushers Based on Material Characteristics

Selecting the right jaw crusher requires careful consideration of material properties and operational requirements. This comprehensive guide examines how material hardness, moisture content, particle size, and other factors influence crusher selection and performance. Understanding these relationships ensures optimal crushing efficiency, equipment longevity, and cost-effective operation in various industrial applications.

Material Hardness and Jaw Crusher Selection Criteria

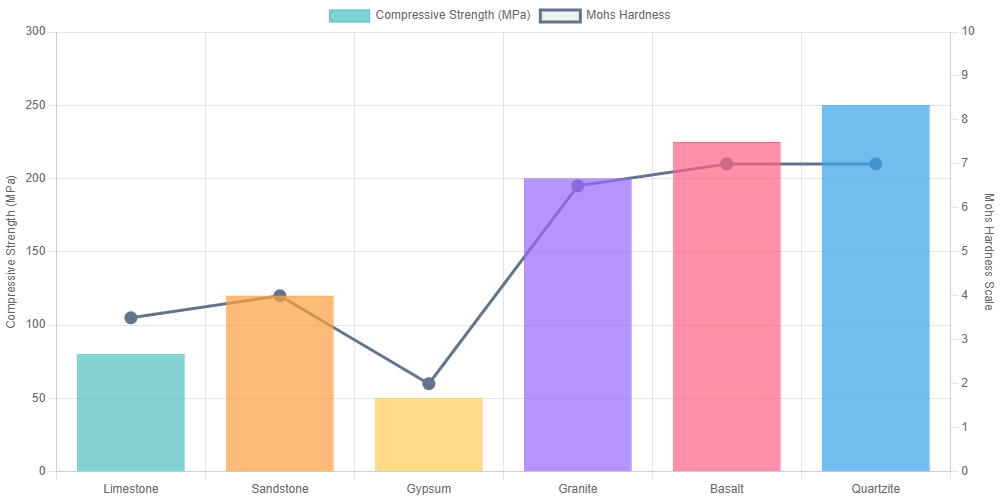

Material hardness significantly impacts jaw crusher selection and configuration. The Mohs scale and compressive strength measurements provide crucial data for determining appropriate crusher specifications. Materials with high compressive strength, such as granite (100-300 MPa) and basalt (150-300 MPa), require robust crushers with enhanced crushing capabilities and wear-resistant components.

Different rock types exhibit varying hardness characteristics that directly affect crusher performance. Quartzite, scoring 7 on the Mohs scale, demands different crushing approaches compared to limestone, which typically measures 3-4. The selection of jaw plates with appropriate hardness and composition becomes critical for maintaining crushing efficiency while minimizing wear costs in different applications.

Hard Material Processing: Manganese Steel Jaw Plate Selection

High-manganese steel jaw plates, typically containing 11-14% manganese, provide exceptional durability for processing abrasive materials. These plates work harden under impact, developing surface hardness up to 550 BHN while maintaining tough inner cores that resist cracking. The selection of appropriate manganese content depends on the specific abrasiveness and impact characteristics of the processed materials.

For extremely abrasive applications, composite jaw plates with tungsten carbide inserts offer extended service life. These specialized components can last 3-5 times longer than standard manganese steel plates in high-wear applications. The initial higher investment is justified through reduced downtime and lower replacement costs in continuous operations processing hard, abrasive materials.

Soft Material Processing: Standard Steel Jaw Plate Applications

Softer materials including limestone, gypsum, and certain sandstones allow the use of standard carbon steel jaw plates. These materials, typically with compressive strengths below 150 MPa, generate less wear and require less aggressive hardening treatments. Standard plates provide cost-effective solutions while delivering satisfactory service life in appropriate applications.

The reduced abrasiveness of soft materials enables longer operational periods between maintenance interventions. However, proper plate selection remains important as some soft materials can be abrasive due to quartz content or other hard mineral inclusions. Regular inspection schedules help maximize plate life and maintain crushing efficiency throughout the operational cycle.

Hardness Testing Methods for Accurate Selection

Standardized hardness testing methods including Brinell, Rockwell, and Vickers tests provide quantitative data for material classification. Field testing methods such as the Schmidt hammer test offer practical solutions for on-site hardness assessment. These measurements help correlate material properties with crusher performance requirements and appropriate wear protection levels.

Advanced mineralogical analysis using X-ray diffraction and petrographic examination provides detailed information about mineral composition and abrasive potential. This comprehensive analysis enables precise crusher configuration and wear protection selection, optimizing both performance and operational costs based on specific material characteristics.

Relationship Between Hardness and Crushing Efficiency

Material hardness directly influences energy consumption and crushing efficiency. Harder materials require more energy for size reduction, typically increasing power consumption by 20-40% compared to medium-hard materials. The crushing chamber design and kinematics must accommodate these energy requirements while maintaining efficient material flow and reduction.

Optimized jaw crusher designs incorporate variable speed drives and advanced chamber profiles that maintain efficiency across different material hardness levels. Modern control systems automatically adjust operational parameters based on material characteristics, ensuring optimal performance while protecting equipment from excessive wear or damage.

Moisture Content Impact and Processing Strategies

Material moisture content significantly affects jaw crusher performance and operation. High moisture levels, typically above 5-8%, can cause material buildup, reduced throughput, and potential blockages. Different materials exhibit varying sensitivity to moisture, with clay-containing materials being particularly challenging due to their cohesive properties when wet.

Modern jaw crushers incorporate design features that address moisture-related challenges. Specialized hopper designs and feed systems prevent material bridging and ensure consistent feed rates. Anti-clogging mechanisms and automated clearing systems maintain operation continuity even with challenging material conditions.

Challenges in High-Moisture Material Processing

High moisture content causes materials to adhere to crushing surfaces and chamber walls, reducing effective volume and throughput capacity. Materials with moisture content exceeding 10% can reduce processing capacity by 20-30% compared to dry conditions. This adhesion also accelerates wear on certain components while potentially protecting others from direct impact.

Seasonal variations and weather conditions significantly affect material moisture levels in outdoor operations. Crushers must accommodate these fluctuations without compromising performance or requiring extensive operational adjustments. Proper planning and equipment selection ensure consistent operation despite changing material conditions.

Anti-Adhesion Jaw Plate Designs

Specialized jaw plate designs incorporate surface treatments and geometric features that reduce material adhesion. Polished surfaces, non-stick coatings, and strategic rib patterns help materials flow freely through the crushing chamber. These designs typically improve material discharge and reduce buildup by 40-60% compared to standard plates in high-moisture applications.

The selection of appropriate plate materials also influences adhesion characteristics. Certain alloy compositions and surface treatments demonstrate superior performance in wet conditions, maintaining cleaner surfaces and more consistent operation. Regular maintenance and cleaning protocols further enhance performance in challenging moisture conditions.

Integrated Heating Systems for Moisture Reduction

For operations processing consistently high-moisture materials, integrated heating systems provide effective solutions. These systems typically reduce moisture content by 3-5 percentage points, significantly improving material flow and crushing efficiency. Electric or fuel-based heating elements maintain optimal material temperature while ensuring safe operation.

The energy requirements for moisture reduction must be balanced against operational benefits. Modern systems incorporate heat recovery and insulation features that maximize efficiency while minimizing additional energy consumption. Properly implemented heating systems can increase throughput by 15-25% in high-moisture applications.

Moisture Monitoring and Parameter Adjustment

Advanced moisture monitoring systems using microwave or infrared sensors provide real-time moisture content data. These systems automatically adjust crusher parameters including feed rate, closed-side setting, and crushing speed to optimize performance under varying moisture conditions. This automation maintains consistent product quality while protecting equipment from moisture-related issues.

The integration of moisture data with process control systems enables predictive adjustments before material enters the crushing chamber. This proactive approach prevents blockages and maintains optimal operation, significantly reducing downtime and maintenance requirements in variable moisture conditions.

Feed Size and Jaw Crusher Inlet Compatibility

Proper matching of feed size to crusher inlet dimensions is crucial for efficient operation and equipment protection. The maximum feed size should typically not exceed 80-85% of the crusher's gape dimension to ensure proper grip and efficient crushing. Oversized material can cause blockages, reduced throughput, and increased wear on crusher components.

Modern jaw crushers incorporate advanced feed opening designs that accommodate varying material sizes while maintaining efficient operation. The relationship between feed size, crusher capacity, and product quality requires careful consideration during equipment selection and operation planning.

Large Feed Size Processing: Wide Inlet Designs

Jaw crushers designed for large feed sizes feature extended inlet dimensions and reinforced structures to handle massive rock pieces. These crushers typically process feed material up to 1500mm in size, reducing it to manageable fragments in primary crushing applications. The robust construction ensures durability while handling high impact loads from large, irregularly shaped rocks.

The crushing chamber geometry in large-feed crushers optimizes material grip and crushing action. Steeper nip angles and longer crushing surfaces ensure efficient reduction of large particles while minimizing vibration and shock loads. Proper feed distribution systems prevent segregation and ensure uniform loading across the crushing surface.

Small Feed Size Processing: Precision Feed Control

Smaller feed sizes require precise control systems to maintain optimal crusher operation. Vibrating feeders with variable speed control ensure consistent feed rates that match crusher capacity. This precision feeding maximizes efficiency while preventing overload conditions that can damage crusher components.

Advanced control systems monitor crusher power consumption and adjust feed rates accordingly. This automation maintains optimal operational parameters, ensuring consistent product quality while protecting the crusher from damaging conditions. The integration of pre-screening systems further optimizes operation by removing undersize material before crushing.

Balancing Inlet Size and Crushing Efficiency

The relationship between inlet size and crushing efficiency involves careful optimization. Larger inlet dimensions increase capacity but may reduce reduction ratios if not properly configured. Modern crusher designs optimize this balance through advanced chamber profiles and kinematics that maintain high reduction ratios while accommodating larger feed sizes.

Operational parameters including crusher speed, stroke length, and closed-side setting significantly influence the efficiency of different feed sizes. Proper adjustment of these parameters ensures optimal performance across varying feed conditions, maintaining high throughput and consistent product quality.

Particle Size Distribution Impact on Crushing Results

The size distribution of feed material significantly affects crusher performance and product characteristics. Well-graded feed materials typically process more efficiently than uniformly sized materials due to better packing and inter-particle crushing effects. Understanding these relationships helps optimize feed preparation and crusher operation.

Advanced monitoring systems track particle size distribution in both feed and product streams. This data enables real-time adjustments to crusher parameters, maintaining optimal performance despite variations in feed characteristics. The continuous optimization ensures consistent product quality while maximizing throughput and efficiency.

Crushing Ratio and Performance Optimization

The crushing ratio, defined as the ratio of feed size to product size, significantly influences jaw crusher selection and operation. Different applications require specific crushing ratios, typically ranging from 4:1 to 8:1 for primary crushing applications. Higher crushing ratios generally require more power and generate greater wear but produce finer product sizes.

Modern jaw crushers incorporate features that optimize crushing ratios while maintaining efficiency and wear resistance. The selection of appropriate crushing ratio parameters depends on material characteristics, production requirements, and downstream processing needs.

Deep Crushing Chamber Designs for High Reduction Ratios

Deep crushing chambers enable higher reduction ratios by providing extended crushing zones and multiple crushing points. These designs typically achieve reduction ratios of 6:1 to 8:1 while maintaining efficient operation. The extended residence time in deep chambers ensures thorough size reduction and improved product shape characteristics.

The chamber geometry in high-reduction crushers optimizes material flow and crushing action. Strategic wear protection and optimized kinematics ensure efficient operation while minimizing wear costs. These designs particularly benefit applications requiring significant size reduction in single crushing stages.

Symmetric Structure Advantages for Uniform Crushing

Symmetric crusher designs ensure uniform loading and wear distribution across crushing surfaces. This symmetry maintains consistent product quality throughout the wear life of jaw plates and reduces maintenance requirements. The balanced design also minimizes vibration and extends structural component life.

Advanced manufacturing techniques ensure precise symmetry in critical components including pitmans, frames, and crushing chambers. This precision manufacturing maintains optimal alignment and operation throughout the equipment's service life, ensuring consistent performance and reduced operating costs.

Relationship Between Crushing Ratio and Product Size

The crushing ratio directly determines the maximum product size for given feed conditions. Higher crushing ratios produce finer products but require more power and generate increased wear. Understanding this relationship helps select appropriate crusher configurations for specific product requirements.

Modern control systems allow adjustment of crushing ratios through hydraulic setting adjustment while operating. This capability enables operators to optimize product size distribution based on real-time requirements while maintaining efficient operation. The flexibility supports varying production needs without requiring mechanical modifications.

Optimizing Crushing Ratio Through Jaw Gap Adjustment

Hydraulic jaw gap adjustment systems enable precise control of product size and crushing ratio. These systems typically allow adjustment ranges of 6:1 or greater, providing flexibility for varying material conditions and product requirements. The adjustment capability maintains optimal operation throughout wear cycles.

Advanced control systems automate jaw gap adjustments based on operational parameters and product quality feedback. This automation maintains consistent product quality while optimizing efficiency and wear characteristics. The integration with overall process control ensures comprehensive optimization of crushing operations.

Power System Selection and Energy Efficiency

Proper power system selection ensures jaw crushers operate efficiently while meeting performance requirements. Motor power requirements typically range from 75 kW to 400 kW depending on crusher size and application. The selection considers material characteristics, production capacity, and operational conditions to ensure optimal performance.

Modern jaw crushers incorporate energy-efficient designs that minimize power consumption while maintaining high performance. Advanced motor selection and control strategies significantly reduce energy costs while ensuring reliable operation under varying conditions.

Motor Power Selection for Crushing Requirements

Motor power selection must consider both normal operating conditions and peak load requirements. Typical jaw crushers operate with power utilization between 70-85% of motor capacity during normal operation, with temporary overload capacity for challenging material conditions. Proper power matching ensures efficient operation while protecting equipment from damage.

Variable frequency drives optimize motor performance by matching speed to operational requirements. These systems typically reduce energy consumption by 15-25% compared to fixed-speed operation while providing soft-start capabilities that reduce mechanical stress during startup.

Energy Consumption Monitoring and Optimization

Advanced energy monitoring systems track power consumption in real-time, identifying optimization opportunities. These systems typically identify energy savings of 10-20% through operational adjustments and maintenance improvements. The continuous monitoring ensures optimal energy utilization throughout equipment life.

Power quality monitoring protects equipment from electrical issues that can reduce efficiency and cause damage. Voltage stability, power factor, and harmonic distortion monitoring ensure optimal electrical system performance and equipment protection.

Variable Frequency Drive Technology for Improved Efficiency

Variable frequency drives provide precise control of crusher speed and operation. This control optimizes energy consumption based on material characteristics and production requirements. Modern drives typically achieve energy savings of 20-30% while improving product quality and reducing wear.

The integration of drive systems with process control enables comprehensive optimization of crushing operations. Automated adjustments based on material conditions and production requirements maintain optimal efficiency while ensuring consistent product quality.

Power System Maintenance for Extended Service Life

Regular maintenance ensures power systems operate efficiently throughout their service life. Predictive maintenance techniques including vibration analysis, thermal imaging, and oil analysis identify potential issues before they cause failures. This proactive approach typically extends equipment life by 25-40% while reducing maintenance costs.

Comprehensive maintenance programs include electrical system inspections, bearing maintenance, and alignment checks. These programs ensure optimal performance while preventing unexpected downtime and repair costs. The systematic approach maintains efficiency and reliability throughout equipment life.

User Feedback and Market Reputation Analysis

User feedback provides valuable insights into jaw crusher performance and reliability in real-world applications. Comprehensive analysis of user experiences helps identify strengths and weaknesses across different brands and models. This information guides selection decisions and helps anticipate potential operational challenges.

Market reputation analysis considers long-term performance, reliability, and support services. Established manufacturers typically demonstrate better performance consistency and support capabilities. The evaluation of user feedback helps identify manufacturers that consistently meet performance expectations and provide reliable support services.

User Feedback Collection Channels and Methods

Multiple channels provide user feedback including direct customer surveys, equipment performance databases, and industry publications. Systematic collection and analysis of this information identifies performance trends and common issues. The comprehensive approach ensures balanced assessment based on actual operational experience.

Long-term performance tracking provides the most valuable feedback for equipment evaluation. Data spanning 5-10 years of operation reveals durability characteristics and long-term maintenance requirements. This extended perspective helps make informed decisions about equipment selection and operational planning.

Reputation Analysis: Identifying Quality Brands and Models

Reputation analysis considers multiple factors including product reliability, technical support, parts availability, and manufacturer stability. Established manufacturers with long market presence typically demonstrate better overall performance and support capabilities. Independent verification through user references and industry reports provides objective assessment.

Performance metrics including availability, maintenance costs, and production consistency provide quantitative measures for comparison. These objective criteria help evaluate manufacturers based on actual operational performance rather than marketing claims. The comprehensive analysis ensures selection of equipment that meets specific operational requirements.

Case Studies: Successful Application Examples

Detailed case studies demonstrate jaw crusher performance in specific applications and conditions. These studies typically document operational parameters, production results, and maintenance requirements over extended periods. The analysis of successful applications provides practical insights for equipment selection and operation.

Performance benchmarks from similar applications help set realistic expectations for new installations. Comparison of actual results with manufacturer specifications reveals typical performance variations and helps establish achievable operational targets. This information guides both equipment selection and operational planning.

After-Sales Service Evaluation for Long-Term Support

Comprehensive after-sales service evaluation considers technical support capabilities, parts availability, and service response times. Manufacturers with global support networks typically provide better service continuity and parts availability. The assessment of service capabilities ensures adequate support throughout equipment life.

Service quality metrics including mean time to repair, first-time fix rates, and preventive maintenance effectiveness provide objective measures of support capabilities. These metrics help evaluate manufacturers based on actual service performance rather than promised capabilities. The thorough evaluation ensures selection of partners that can support long-term operational requirements.