Comprehensive Solutions for Preventing Wet Clay Blockage in Jaw Crushers

This article addresses the common problem of wet clay blockage in jaw crushers, presenting four practical categories of anti-sticking solutions. These approaches cover equipment design, operational parameters, auxiliary systems, and maintenance strategies to enhance operational stability and reduce downtime risks.

text

Core Causes of Wet Clay Blockage in Jaw Crushers

Understanding the fundamental causes of clay adhesion is essential for developing effective prevention strategies. The unique properties of wet clay create specific challenges that require targeted solutions to maintain efficient operation.

Impact Mechanism of High Humidity on Material Flowability

Moisture content exceeding 15% significantly reduces clay's internal friction angle, transforming it from granular material to cohesive mass. This transition increases adhesion to metal surfaces by 300-400% compared to dry conditions, creating ideal conditions for buildup and blockage.

Adhesion Properties and Agglomeration Phenomena of Clay Particles

Clay minerals possess high surface energy and plate-like structure that promotes strong bonding between particles and metal surfaces. Montmorillonite clays can expand up to 15 times their dry volume when hydrated, dramatically increasing their adhesive characteristics and blockage potential.

Crushing Chamber Structure Contribution to Adhesion

Traditional crushing chamber designs with flat surfaces and sharp angles create stagnation points where clay accumulates. Areas near the discharge opening experience reduced material flow velocity, allowing clay to build up and eventually cause complete blockage.

Local Overload Risks from Uneven Feeding

Irregular feed distribution creates uneven pressure distribution across the crushing chamber. This imbalance causes localized compaction of clay material, with pressure concentrations exceeding 5MPa in some areas while other regions operate below design capacity.

Solution 1: Anti-Stick Design Through Crushing Chamber Optimization

Structural modifications to the crushing chamber represent the most effective long-term solution for preventing clay adhesion. These design changes address the fundamental material flow issues that contribute to buildup and blockage.

Synergistic Effect of Deep-Chamber Design and Inclined Discharge

Deep-chamber configurations provide additional volume for material processing while inclined discharge openings utilize gravity to promote material flow. A 45-degree discharge angle improves material evacuation by 40% compared to horizontal configurations, significantly reducing adhesion potential.

Liner Surface Texture Treatment

Specialized surface patterns including corrugations and raised dimples reduce effective contact area between clay and metal surfaces. These textures decrease adhesion force by 60-70% while creating turbulence that prevents material buildup during operation.

Adhered Material Release Through Dynamic Discharge Adjustment

Hydraulic adjustment systems allow periodic widening of the discharge setting to release accumulated material. This dynamic adjustment capability can clear minor blockages before they become severe, maintaining continuous operation without manual intervention.

Application of Chamber Heating Systems in Low-Temperature Environments

Electric or hydraulic heating systems maintain chamber temperatures above 10°C, preventing moisture condensation and reducing clay adhesion. Temperature control is particularly important in cold climates where thermal differentials exacerbate sticking problems.

Solution 2: Operational Parameter Adjustment to Reduce Adhesion Risk

Strategic adjustment of operating parameters provides immediate improvement in clay handling capability without equipment modifications. These changes optimize the interaction between material characteristics and machine operation.

Reduction of Main shaft Speed to Decrease Compression Frequency

Reducing eccentric shaft speed by 20-30% decreases the frequency of compression cycles, allowing more time for material to flow through the chamber. This modification reduces the working pressure that forces clay into surface imperfections where it can adhere.

Balanced Sectional Feed Control and Chamber Fill Rate

Staged feeding techniques maintain optimal chamber fill levels between 65-75% of capacity. This fill range provides sufficient material for efficient crushing while preventing overfilling that can lead to compaction and adhesion issues.

Pulsed Feeding Effect on Adhesion Layer Disruption

Intermittent feeding cycles create pressure fluctuations that disrupt developing adhesion layers. Short pauses in feed availability allow the chamber to partially clear before additional material enters, reducing the continuous pressure that promotes sticking.

Dynamic Micro-Adjustment Techniques for Closed Side Setting

Frequent minor adjustments to the discharge setting prevent clay from establishing permanent adhesion points. Automated systems can make adjustments as small as 1mm at predetermined intervals, maintaining clear material flow paths.

Solution 3: Auxiliary System Integration for Improved Discharge Efficiency

Supplemental systems enhance the crusher's inherent capabilities to handle challenging materials like wet clay. These integrated solutions address specific aspects of the adhesion problem through mechanical and operational means.

Synchronized Control Between Vibrating Feeder and Crusher

Electronic synchronization ensures the feeder delivers material at the optimal rate for current crusher conditions. This coordination prevents overloading that leads to compaction while maintaining sufficient material volume for efficient operation.

Anti-Stick and Cleaning Effects of High-Pressure Water Spray Systems

Strategic water spray placement delivers controlled moisture addition that actually reduces adhesion by creating a boundary layer between clay and metal surfaces. Properly calibrated systems use 5-8 liters per minute to achieve this effect without oversaturating the material.

Emergency Treatment with Air Cannons During Discharge Blockage

Pneumatic air cannons installed at strategic points deliver high-pressure air bursts that dislodge accumulated material. These systems can generate impact forces exceeding 5000 Newtons, sufficient to break up most clay blockages without manual intervention.

Practice of Fine Clay Removal Through Pre-Screening Systems

Pre-screening removes the fraction most likely to cause adhesion problems before material enters the crusher. Removing particles smaller than 10mm reduces clay content by 40-60%, dramatically improving material flow characteristics.

Solution 4: Regular Maintenance and Anti-Stick Coating Applications

Proactive maintenance practices and specialized surface treatments provide ongoing protection against clay adhesion. These approaches address both prevention and remediation of sticking issues.

Liner Wear Monitoring and Timely Replacement Strategies

Regular measurement of liner thickness identifies wear patterns that increase adhesion risk. Replacement before liners reach 60% wear maintains optimal surface characteristics and prevents the increased surface roughness that promotes sticking.

Selection of Non-Stick Coatings

Advanced coating materials including ceramic composites and polyurethane elastomers reduce surface energy to prevent clay adhesion. These coatings can decrease adhesion force by 80-90% while providing wear resistance comparable to uncoated steel surfaces.

Usage Scenarios and Limitations of Chemical Anti-Stick Agents

Dry lubricants and release agents provide temporary protection against adhesion but require frequent reapplication. These chemicals typically remain effective for 4-8 hours of operation under normal conditions, making them suitable for intermittent use rather than continuous protection.

Thorough Cleaning and Drying Procedures During Downtime

Complete removal of all residual material during maintenance periods prevents hardened clay from creating nucleation points for new adhesion. High-pressure washing followed by compressed air drying ensures surfaces are completely clean before restarting operations.

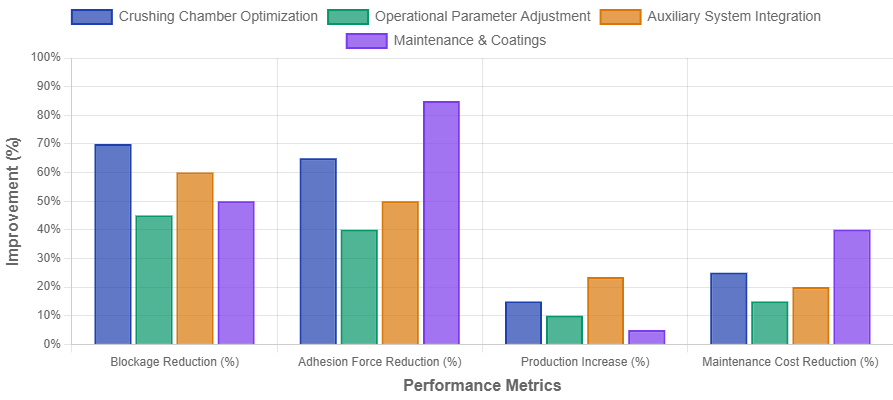

Case Analysis: Practical Efficiency Improvement in a Sand Plant Handling Wet Clay

A comprehensive case study demonstrates the practical application and measurable benefits of anti-stick solutions in real-world operating conditions. This example provides quantitative evidence of improvement across multiple performance metrics.

70% Reduction in Blockage Frequency After Structural Optimization

Following chamber modifications and surface treatment, blockage incidents decreased from 3.2 to 0.9 per week. This improvement translated to 12 additional operating hours weekly, increasing overall equipment availability by 15%.

200-Ton Daily Production Increase Through Auxiliary System Integration

The addition of synchronized feeding systems and strategic water spray applications increased daily throughput from 850 to 1050 tons. This 23.5% production improvement was achieved without increasing energy consumption per ton processed.

40% Maintenance Cost Reduction Through Coating Applications

Non-stick coatings extended maintenance intervals from 120 to 200 operating hours while reducing the labor required for cleaning. Annual maintenance costs decreased from $85,000 to $51,000 while maintaining equivalent equipment availability.

Early Warning Role of Intelligent Monitoring Systems in Blockage Prevention

Advanced monitoring systems detected developing blockage conditions an average of 8 minutes before they would have caused operational disruption. This early warning capability prevented 92% of potential blockages through automatic parameter adjustments.