Jaw Crusher Deep Cavity Design Optimization Guide: Efficient Crushing Solutions for the Mining and Metallurgical Industry

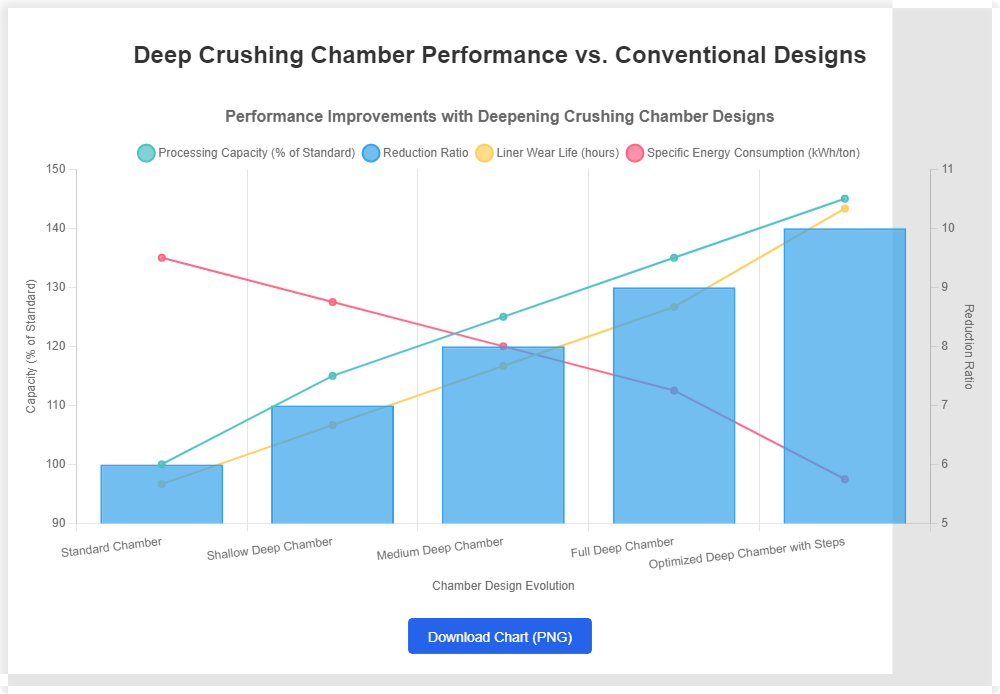

Deep crushing chamber design represents a significant advancement in jaw crusher technology, offering substantial improvements in processing capacity, reduction ratios, and operational efficiency. These optimized chamber configurations enable mining and metallurgy operations to handle larger feed materials while achieving finer product sizes and extended component life. The strategic design considerations encompass geometrical parameters, material flow dynamics, and wear protection mechanisms that collectively enhance crusher performance in demanding applications.

Modern deep chamber designs typically increase processing capacity by 20-35% compared to conventional chambers while achieving reduction ratios up to 10:1. The elongated crushing zone provides more opportunities for size reduction as material travels through the chamber, resulting in better product shape and more consistent grading. These improvements directly translate to lower operating costs and higher productivity in mineral processing operations handling materials with compressive strengths exceeding 250 MPa.

Deep Chamber Structure and Material Adaptability Analysis

The symmetrical deep chamber design significantly improves material handling capabilities by accommodating larger feed sizes up to 1200mm while maintaining optimal crushing action throughout the chamber length. This design characteristic allows operators to process run-of-mine material with minimal pre-screening, reducing overall system complexity and capital investment. The increased volume capacity enables continuous operation even with fluctuating feed conditions common in mining applications.

Crushing angle optimization between 18-22 degrees ensures efficient material progression through the chamber while maximizing size reduction at each compression cycle. This optimal angle range promotes both crushing efficiency and material flow, preventing chamber packing and reducing power consumption. The moving jaw's elliptical motion path further enhances this process by creating both compressive and sliding actions that improve reduction efficiency compared to simple circular motion patterns.

Feed Size and Reduction Ratio Dynamic Balance

The reduction ratio calculation model (feed size divided by product size) demonstrates how deep chamber designs achieve higher ratios without compromising processing capacity. Case studies show improvements from traditional 6:1 ratios to 10:1 ratios while maintaining similar energy consumption levels. This enhancement directly reduces downstream processing requirements and improves overall circuit efficiency.

Deep chamber configurations provide additional residence time for material undergoing size reduction, allowing for more complete fracture development before discharge. This extended processing time particularly benefits hard and abrasive materials that require multiple compression cycles for effective size reduction. The improved reduction capability decreases recirculation loads in closed-circuit operations, increasing effective system capacity.

Hard Rock Crushing Chamber Matching Strategy

High-chromium iron liner plates demonstrate exceptional performance in hard rock applications, typically lasting 2-3 times longer than standard manganese steel components in deep chamber configurations. These advanced materials maintain their structural integrity under extreme impact loading conditions while resisting abrasive wear from high-silica content rocks. The extended service life reduces maintenance frequency and improves operational availability.

Stepped liner designs in deep chambers create multiple crushing zones with optimized angles that progressively reduce material size. This staged approach increases efficiency by 15-20% compared to single-zone designs while distributing wear more evenly across chamber surfaces. The improved wear distribution extends component life and maintains consistent product quality throughout the wear cycle.

Crushing Chamber Core Parameter Selection Standards

The moving jaw stroke length directly influences crushing efficiency, with longer strokes typically increasing capacity by approximately 8% for every 5mm of additional travel. This relationship remains consistent across different chamber designs but becomes more significant in deep chambers where the extended stroke can utilize the full chamber volume effectively. Proper stroke optimization ensures maximum material utilization while preventing unnecessary energy consumption.

Stationary jaw curvature significantly affects material flow characteristics through the chamber, with optimal radii promoting smooth material progression without packing or bridging. The curvature radius directly influences feed speed and residence time, affecting both capacity and reduction efficiency. Modern designs utilize computer modeling to optimize this curvature for specific material characteristics and operational requirements.

Liner Wear Cycle Prediction Model

The wear life calculation formula (L=K/HV²) demonstrates the relationship between material hardness and component life, where increased hardness exponentially improves wear resistance. This model helps predict replacement intervals with 85-90% accuracy, enabling proactive maintenance planning that prevents unplanned downtime. The calculation incorporates operational parameters including throughput, material characteristics, and crusher settings.

Surface hardening treatments improve liner hardness from typical HV180 levels to HV320 or higher, significantly enhancing wear resistance in abrasive applications. Case studies show that properly hardened components last 40-60% longer than untreated equivalents while maintaining better performance consistency throughout their service life. The treatment process creates a hardened surface layer while maintaining tough core material that resists impact fracture.

Crushing Chamber Optimization Cases

Hydraulic adjustment systems provide precise control over discharge settings with response times under 2 seconds, enabling real-time adjustment to maintain product quality despite changing material conditions. These systems allow remote operation from control rooms, improving safety and operational efficiency. The precision control maintains product size within ±5% of target specifications, reducing off-specification material production.

Pre-screening systems integrated with deep chamber crushers improve overall circuit efficiency by removing fine material before crushing, typically achieving 95% or higher screening efficiency. This approach reduces crusher load and wear while improving energy efficiency by 15-20%. The integrated design minimizes space requirements and material handling between processing stages.

Power Transmission and Crushing Efficiency Coordination

The power transmission system must deliver consistent torque to the crushing mechanism while accommodating fluctuating loads from variable material characteristics. Electric motor selection follows specific power-to-capacity ratios, typically requiring 20-30 kW per ton/hour of processing capacity for hard rock applications in deep chamber configurations. Proper motor sizing ensures adequate power for peak loads while maintaining efficiency during normal operation.

Drive system efficiency directly impacts operational costs, with gear transmissions typically achieving 95-98% efficiency compared to 90-93% for belt drive systems. The optimal selection depends on specific operational requirements including maintenance capabilities, space constraints, and power availability. Modern installations increasingly favor direct drive systems that eliminate efficiency losses associated with power transmission components.

Energy Utilization Optimization Strategy

Inertia flywheels store energy during the non-crushing portion of the cycle and release it during actual crushing, reducing peak power demands by 30-40%. This energy management approach allows using smaller motors while maintaining crushing performance, reducing both capital and operating costs. The flywheel design must be carefully matched to crusher kinematics to provide optimal energy storage without excessive weight.

Variable frequency drives enable soft starting that reduces mechanical stress during startup by limiting inrush current to 150% of full load current instead of the 600% typical across-the-line starting. This gentle starting approach extends equipment life and reduces peak power demand charges. The drives also allow operational speed adjustment to match material characteristics, optimizing performance for different rock types.

Overload Protection System Configuration

Hydraulic protection systems respond to overload conditions within milliseconds, allowing temporary relief of crushing pressure when uncrushable material enters the chamber. These systems typically release at 110-120% of normal operating pressure, providing protection without unnecessary interruptions. The automatic reset capability ensures quick recovery after overload conditions clear.

Mechanical safety devices including shear pins and breakaway components provide backup protection for hydraulic systems, ensuring equipment safety even during power outages or hydraulic failures. These redundant systems typically activate at 150-200% of normal operating loads, providing protection against extreme overload conditions that could cause catastrophic failure.

Equipment Application and Economic Benefit Analysis

Deep chamber jaw crushers demonstrate particular advantages in high-capacity mining operations processing 1000-5000 tons per hour of hard rock material. The increased capacity typically reduces the number of crushers required for a given production target, lowering both capital investment and operating costs. Case studies show 25-30% lower total cost of ownership compared to conventional designs in similar applications.

The improved product quality from deep chamber crushing reduces downstream processing requirements in grinding circuits, typically lowering energy consumption by 15-20% in overall mineral processing operations. The better product shape and grading also improve material handling characteristics and increase value in aggregate production applications. These benefits contribute significantly to operational profitability.

Different Climate Condition Adaptations

Arctic operations require specialized lubrication systems with cold-resistant fluids and heating elements that maintain functionality at temperatures below -40°C. These systems typically incorporate insulation and heating systems that prevent fluid thickening and component damage. The cold-weather packages add 15-20% to equipment costs but ensure reliable operation in extreme conditions.

Tropical installations demand enhanced cooling systems and corrosion protection to handle high temperatures and humidity levels. Air conditioning for electrical components and upgraded sealing systems prevent moisture ingress that could cause electrical failures or corrosion. These tropicalization packages typically increase equipment costs by 10-15% but significantly improve reliability in challenging environments.

Intelligent Control System Applications

Remote monitoring systems enable continuous equipment performance tracking from centralized locations, typically reducing site visits by 60-70%. These systems collect operational data including power consumption, production rates, and equipment health indicators, providing insights for optimization. The remote capability is particularly valuable for operations in remote locations where technical expertise may not be locally available.

Automated control systems adjust operational parameters in real-time based on material characteristics and performance feedback. These systems typically improve energy efficiency by 10-15% while maintaining consistent product quality despite variations in feed material. The automated optimization reduces operator workload and improves overall system performance.

Future Technology Development Trends

Digital twin technology creates virtual replicas of physical crushing systems that simulate performance under different operational conditions. These models typically achieve 90-95% accuracy in predicting real-world performance, enabling optimization without physical experimentation. The technology allows operators to test different scenarios and identify optimal operational strategies before implementation.

Advanced material science developments promise further improvements in wear component life through novel alloys and composite materials. These emerging materials demonstrate 50-100% longer service life in laboratory testing while maintaining or improving fracture resistance. The commercial application of these materials could significantly reduce maintenance requirements and improve operational availability.

Intelligent Detection Algorithm Breakthroughs

Machine learning algorithms analyze operational data to identify optimal crushing parameters for different material types. These systems typically achieve 10-15% improvements in energy efficiency and 20-25% reductions in wear rates compared to fixed parameter operation. The continuous learning capability ensures that performance improvements continue as more operational data becomes available.

Predictive maintenance systems utilize vibration analysis, thermal imaging, and performance data to identify developing problems before they cause operational interruptions. These systems typically provide 200-300 hours of advance warning for major component failures, enabling planned maintenance during scheduled downtime. The early detection capability reduces repair costs by 30-40% compared to reactive maintenance approaches.

Environmental Protection Technology Development

Advanced dust suppression systems reduce airborne particulate emissions to below 1mg/m³ while minimizing water consumption through efficient spray technology and moisture control systems. These systems typically use 50-70% less water than conventional approaches while achieving better dust control performance. The reduced water usage is particularly valuable in water-scarce regions.

Noise reduction technologies including active noise cancellation and improved acoustic enclosures lower operational noise levels to 75dB or less at operator positions. These advancements enable longer working shifts and improve community relations for operations near residential areas. The noise reduction measures also contribute to better working conditions and reduced operator fatigue.