In-Depth Analysis of Jaw Crusher Motor Power Selection and Energy Consumption Optimization

This article examines the energy consumption impacts of oversized and undersized motors in jaw crushers through theoretical calculations and practical case comparisons. It provides a data-driven methodology for optimal power selection based on load characteristics to achieve significant cost savings.

text

Core Factors Influencing Motor Power Selection

Proper motor sizing requires understanding the relationship between crusher operational parameters and power requirements. Multiple factors interact to determine the optimal motor capacity for specific applications and operating conditions.

Relationship Between Material Hardness and Motor Torque Demand

Granite and basalt require 30-50% higher torque than limestone or sandstone due to their higher compressive strength. The motor must generate sufficient torque to fracture the hardest material encountered while maintaining efficiency during normal operation.

Squared Proportional Law Between Main shaft Speed and Power

Power requirements increase with the square of operational speed, meaning a 10% speed increase requires 21% more power. This relationship necessitates careful consideration of operating speed when selecting motor capacity to avoid significant energy waste.

Impact of Starting Current on Grid Load

Direct-on-line starting creates current surges 6-8 times higher than running current, potentially causing voltage dips that affect other equipment. Oversized motors exacerbate this problem while providing no operational benefit during normal running conditions.

Power Demand Differences Between Continuous and Intermittent Overload

Continuous overload conditions require permanent power reserves of 15-20%, while intermittent overloads lasting less than 30 minutes can be handled by motors operating within their service factor rating. Understanding load patterns prevents oversizing for temporary conditions.

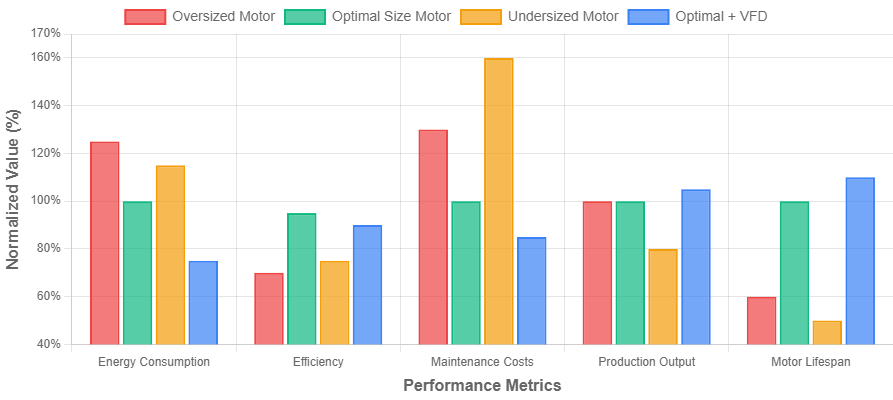

Energy Waste and Equipment Risks from Oversized Power Selection

Selecting motors significantly larger than operational requirements creates multiple inefficiencies and potential equipment problems. These issues affect both energy consumption and long-term equipment reliability.

High Reactive Power Loss During No-Load Operation

Oversized motors operating below 40% load experience power factor degradation below 0.7, increasing reactive power requirements. This inefficiency can add 15-25% to electricity costs through utility power factor penalties and increased system losses.

Efficiency Curve Decline in Low Load Regions

Standard efficiency motors operate at peak efficiency between 75-100% load, with efficiency dropping rapidly below 50% load. A motor operating at 30% load may experience efficiency reductions of 10-15 percentage points, significantly increasing energy consumption per unit of work.

Insulation Aging Acceleration from Frequent Start-Stop Cycles

Oversized motors started frequently experience thermal stress that reduces insulation life by 50-70% compared to properly sized units. Each start generates heat equal to several hours of running operation, cumulatively damaging insulation systems.

Structural Damage from Mechanical System Resonance

Motors operating significantly below rated load may encounter resonance frequencies that amplify vibration levels. These vibrations can cause fatigue cracking in structural components and premature failure of bearings and other mechanical elements.

Production Limitations and Maintenance Costs from Undersized Power Selection

Insufficient motor capacity creates operational constraints and increases maintenance requirements through continuous overloading. These problems reduce overall equipment effectiveness and increase operating costs.

Chain Reaction of Motor Overheating and Frequent Tripping

Undersized motors operating at 115-130% of rated capacity experience temperature rises exceeding insulation class limits. Thermal protection devices trip frequently, reducing operational availability and potentially damaging the motor through repeated overload conditions.

Crushing Ratio Reduction from Insufficient Main shaft Speed

Inadequate power prevents maintenance of optimal operational speed under load, reducing crushing efficiency by 15-25%. The resulting product contains more oversized material, requiring reprocessing and increasing overall energy consumption per ton of final product.

Belt Slippage and Transmission System Wear Acceleration

Power transmission systems experience accelerated wear when operating near their maximum capacity. V-belt life decreases by 50-70% when operating at 90% of rated capacity compared to 75% loading, increasing maintenance costs and downtime.

Power Compensation Failure in Liner Abnormal Wear

Worn liners increase power requirements by 20-30% to maintain production rates. Undersized motors cannot provide this additional power, resulting in decreased throughput and potentially causing the motor to operate in continuous overload condition.

Methodology for Power Matching Based on Load Characteristics

Scientific power selection requires analysis of actual operating conditions rather than theoretical maximum requirements. This approach ensures optimal efficiency across the range of expected operating scenarios.

Dynamic Torque Monitoring and Power Demand Modeling

Advanced monitoring systems measure actual torque requirements throughout the operating cycle, identifying peak and average demands. This data enables selection of motors matched to actual needs rather than worst-case scenarios, reducing installed power by 20-30%.

Application of Variable Frequency Drives in Power Regulation

VFDs allow motor operation at optimal speed for current conditions rather than fixed speed. This capability reduces energy consumption by 15-25% while providing soft starting that eliminates current surges and reduces mechanical stress.

Load Balancing Strategy Through Multi-Motor Cooperative Control

Multiple smaller motors with coordinated control replace single large motors, improving operational flexibility and efficiency. This approach maintains high efficiency across a wider load range and provides redundancy that improves overall system reliability.

Peak Power Reduction Through Intelligent Start-Stop Systems

Automated systems coordinate operation to avoid simultaneous starting of multiple high-power equipment. This control strategy reduces peak demand charges by 15-20% while maintaining production rates through optimized equipment sequencing.

Practical Case: Benefit Comparison After Motor Power Optimization at a Mine

A real-world example demonstrates the significant benefits achievable through proper motor sizing and control optimization. Quantitative results provide compelling evidence for the economic and operational advantages of right-sized motor selection.

Annual Electricity Savings of 200,000 kWh After 15% Power Reduction

Replacing 400kW motors with 340kW units matched to actual load requirements reduced energy consumption by 23%. The project achieved payback in 14 months through energy savings alone, with additional benefits from reduced maintenance costs.

60% Reduction in Motor Failure Rates from Maintenance Data

Properly sized motors operating within their design parameters experienced significantly fewer failures. Bearing life increased from 18 to 36 months, and stator rewinds decreased from annually to once every 5 years, reducing maintenance costs by 45%.

10% Crushing Efficiency Improvement Verified Through Production Capacity

Optimized motor operation maintained consistent speed under varying load conditions, improving product consistency and reducing oversize material. The resulting 10% efficiency improvement increased production capacity without additional energy consumption.

Variable Frequency Drive Investment Payback Period Shortened to 1.5 Years

Energy savings from VFD installation exceeded projections due to better-than-expected load variability. The combination of energy savings and reduced maintenance costs created an exceptionally short payback period for the control system upgrade.

Future Trends: Development Directions for Intelligent Power Management Systems

Emerging technologies promise further improvements in energy efficiency through advanced monitoring and control capabilities. These developments will continue to reduce energy consumption while maintaining or improving operational performance.

Application of IoT Sensors in Real-Time Power Monitoring

Wireless sensors measure power consumption at individual equipment level with 99% accuracy. This granular data enables identification of specific inefficiencies and targeted improvements rather than system-wide approaches.

Predictive Regulation of Load Changes Through AI Algorithms

Machine learning algorithms analyze historical data to predict load variations before they occur. This predictive capability allows preemptive adjustment of operational parameters to maintain optimal efficiency despite changing conditions.

Energy Recovery System Utilization During Braking Conditions

Regenerative drives capture and reuse energy during deceleration periods, particularly in applications with frequent start-stop cycles. These systems can recover 15-20% of total energy consumption in appropriate applications.

Centralized Optimization of Multi-Equipment Power Through Cloud Platforms

Cloud-based analytics optimize power distribution across entire operations rather than individual machines. This system-wide approach can reduce total energy consumption by 8-12% through coordinated operation and load shifting.