Hydraulic System Maintenance Guide for Extending Jaw Crusher Service Life

This article provides a systematic exploration of the maintenance strategies for jaw crusher hydraulic systems. It covers core aspects such as fluid management, fault diagnosis, and seal replacement, offering a complete solution for enterprises aiming to achieve long-term, reliable operation of their heavy-duty crushing equipment. The principles discussed are fundamental to the industrial machinery used to reduce large rocks and ores into smaller, more manageable aggregate.

Understanding the Core Components and Functions of a Hydraulic System

The hydraulic system is the powerhouse behind a jaw crusher's immense crushing force, often operating under extreme pressures. It functions by transmitting power through an incompressible fluid, allowing for the precise control of the crushing jaws. This system is comprised of several critical components that work in unison to apply and regulate the tremendous forces needed to fracture hard materials like granite and basalt.

Key elements include the hydraulic pump, which generates the flow of fluid, and the hydraulic cylinder, which converts fluid power into linear mechanical force to move the crushing jaw. Connecting these components are high-strength hydraulic lines designed to contain the intense pressure. Finally, a suite of hydraulic valves acts as the control center, meticulously managing the direction, pressure, and flow of the hydraulic fluid to ensure efficient and safe operation.

The Role of the Hydraulic Pump

Acting as the heart of the system, the hydraulic pump is responsible for converting mechanical energy from the engine or motor into hydraulic energy. It creates a flow of oil, which is then pressurized within the system. Common types used in crushers include robust gear pumps, suitable for many applications, and more efficient piston pumps, which are often preferred for their higher pressure capabilities and durability in continuous operation.

The selection of a pump is critical and is based on its pressure rating and flow capacity. For jaw crushers, pumps are typically selected to operate reliably within a pressure range of 20 to 35 Megapascals (MPa). This ensures they can generate enough force to crush the toughest materials without succumbing to premature failure, making their maintenance a top priority.

Function of the Hydraulic Cylinder

The hydraulic cylinder serves as the muscle of the operation. In a jaw crusher, a powerful double-acting cylinder is commonly used, meaning it can exert force in both extension and retraction. This allows for precise adjustment of the crusher's discharge opening, which directly controls the final product size, and provides a critical function known as tramp release.

When an uncrushable object, like a piece of steel, enters the crushing chamber, the hydraulic system must protect itself. The cylinder is part of an overload protection system that instantly releases the pressure, allowing the jaw to open and the foreign object to pass through, thereby preventing catastrophic damage to the crusher's internal components.

Importance of Hydraulic Lines and Connections

Hydraulic lines are the arteries that carry life-giving fluid throughout the system. These are not ordinary hoses; they are engineered to withstand immense pressure and constant vibration. Systems often use a combination of rigid steel pipes for fixed runs and flexible, reinforced rubber hoses for connections to moving parts like the cylinder.

These lines are rated for pressures significantly higher than the system's operating pressure, often at 40 MPa or more, to provide a safety margin. A primary maintenance focus is preventing leaks, which can lead to system inefficiency, environmental contamination, and potential fire hazards. Regular inspection for wear, abrasion, and loose fittings is essential for preventative maintenance.

Controlling the System with Hydraulic Valves

Hydraulic valves are the sophisticated nervous system that directs the operation. A relief valve is arguably the most important safety component, as it is set to open and divert fluid flow back to the tank if the system pressure exceeds a predetermined safe limit, typically calibrated with a precision of around ±2%. This protects every component downstream from pressure spikes.

Directional control valves, often solenoid-operated, manage the path of the hydraulic fluid. They determine whether the cylinder extends, retracts, or holds its position. The precise and reliable operation of these valves is paramount for the automated and safe functioning of the modern jaw crusher, ensuring optimal performance during aggregate processing.

Optimizing Performance Through Hydraulic Pump Selection

Choosing the right hydraulic pump is a strategic decision that impacts not only the crusher's performance but also its operating costs and energy consumption. The two main contenders are gear pumps and piston pumps, each with distinct advantages. The choice between them involves a trade-off between initial cost, efficiency, and longevity.

Beyond the basic type, the advent of variable displacement pumps has revolutionized energy efficiency in hydraulic systems. Unlike fixed pumps that run at a constant output, variable pumps adjust their flow rate to meet the immediate demand of the system, significantly reducing energy waste, especially during periods of lower crushing force requirement.

Comparing Gear Pump and Piston Pump Efficiency

Gear pumps are known for their simplicity, ruggedness, and lower initial cost. They are highly effective for many industrial applications. However, their volumetric efficiency—the measure of how much fluid they actually deliver versus what they theoretically could—is generally lower, often around 85%. This means more energy is lost to internal leakage, especially as the pump wears or operates at high pressures.

In contrast, axial piston pumps are more complex and expensive but offer superior performance. They can achieve volumetric efficiencies of 92% or higher. This higher efficiency translates directly into lower energy consumption for the same amount of work output and often results in less heat generation within the hydraulic oil, which contributes to longer oil and component life.

The Advantage of Variable Displacement Pumps

The implementation of variable displacement piston pumps represents a significant leap in hydraulic technology for crushing equipment. Traditional fixed pumps provide a constant flow of hydraulic fluid, which must then be diverted over a relief valve when not needed, wasting a substantial amount of energy and generating excess heat.

A variable pump, however, senses the system's pressure demand and automatically reduces its output flow to exactly what is required. This "load-sensing" capability can lead to dramatic energy savings, often quantified as a reduction in power consumption of 20% or more. This not only lowers electricity costs but also reduces the thermal load on the system, diminishing the need for extensive cooling. For a detailed look at other efficient crusher types, you can explore cone crusher technology.

Selecting the Right Seals for Hydraulic Cylinders

Hydraulic cylinder seals are deceptively simple components that play a monumental role in system integrity. Their primary function is to contain the high-pressure fluid within the cylinder and prevent external contaminants from entering. A failed seal can lead to hydraulic fluid leaks, loss of pressure, contamination of the system, and ultimately, cylinder failure and downtime.

Seals are not one-size-fits-all. They are designed for specific roles, operating conditions, and fluid types. The correct selection of seal material and design is critical for ensuring a long service life and reliable operation. Factors such as operating pressure, temperature, fluid compatibility, and the type of motion (static, dynamic, rotating) must all be carefully considered.

O-Rings vs. V-Seals for Different Applications

O-rings are one of the most common sealing solutions, prized for their simplicity and effectiveness. They are typically used in static sealing applications, where there is no relative motion between the seal and the components it is sealing. They work by being compressed in a groove, creating a tight barrier against fluid passage. Their effectiveness depends on precise gland design and the right amount of compression.

For dynamic applications involving linear motion, such as a piston moving inside a cylinder bore, more specialized seals are required. V-type seals or polyurethane U-cups are often employed. These seals are designed to maintain contact and sealing effectiveness even as the metal surfaces move against them. They are more complex and can handle higher pressures and tolerate a degree of wear better than simple O-rings.

Choosing High-Temperature Seal Materials

The operating environment of a jaw crusher can be harsh, with ambient heat from the motor, friction from crushing, and the inherent heat generated by the hydraulic system itself. Standard nitrile rubber seals have a limited temperature range and can quickly degrade, harden, and fail when consistently exposed to temperatures exceeding 80°C.

For high-temperature applications where fluid temperatures can reach 120°C, more resilient materials are essential. Fluorocarbon rubber (FKM/Viton) is a common choice for its excellent resistance to high temperatures, chemicals, and oils. Using these advanced materials in critical sealing locations prevents premature seal failure, reduces unplanned maintenance, and ensures system reliability in demanding conditions like those found in mining and quarrying.

Mastering Hydraulic Fluid Management

Hydraulic fluid is the essential lifeblood of the system, serving three critical functions: transmitting power, lubricating moving parts, and aiding in heat transfer. Consequently, the condition of this fluid is the single greatest factor determining the health and longevity of the entire hydraulic system. Contaminated or degraded oil is a leading cause of component failure.

Effective fluid management is a proactive strategy, not a reactive one. It involves selecting the correct oil type from the start, rigorously preventing contamination, and regularly monitoring its condition to determine the optimal time for change-out. A disciplined approach to fluid management can double or even triple the life of expensive components like pumps and valves.

The Critical Impact of Fluid Cleanliness

Cleanliness is non-negotiable for hydraulic oil. Microscopic abrasive particles, even those invisible to the naked eye, act like lapping compound when they circulate through pumps, valves, and cylinders. They cause gradual wear that erodes tolerances, leading to internal leakage, loss of efficiency, and eventual catastrophic failure.

The industry standard for measuring fluid cleanliness is the ISO 4406 code, which counts the number of particles of specific sizes per milliliter of fluid. For a crusher hydraulic system, a target cleanliness level of ISO 18/16/13 or better (equivalent to NAS 1638 Class 6) is typically recommended. Maintaining this level requires high-quality filtration and vigilant practices to prevent contaminants from entering during maintenance. This is as crucial as managing the feed size of material into the crusher.

Selecting the Correct Hydraulic Oil Grade

Hydraulic oils are not all the same. They are formulated with specific base oils and additive packages to perform under different conditions. A common classification is the ISO viscosity grade (e.g., ISO VG 46 or ISO VG 68). The number indicates the oil's kinematic viscosity at 40°C. Using the wrong viscosity oil is a common mistake; oil that is too thick can cause cavitation and high energy consumption, while oil that is too thin leads to increased wear and leakage.

Furthermore, premium anti-wear hydraulic oils, classified as HM or HV, contain additives that protect metal surfaces under high pressure. An HV (high viscosity index) oil is particularly beneficial for crushers operating in environments with large temperature swings, as its viscosity changes less with temperature, ensuring consistent lubrication and protection from startup to operating temperature.

Establishing Effective Filter Change Intervals

Filters are the kidneys of the hydraulic system, continuously removing contaminants from the oil. However, filters have a finite capacity and will eventually become clogged. If a filter is not changed, it will either bypass dirty oil (if equipped with a bypass valve) or collapse under the pressure differential, both of which lead to unfiltered, contaminated oil circulating through the system.

The service life of a filter depends on the system's contamination level, but a common preventative maintenance interval is every 500 operating hours. Using filters with a beta rating of 10 microns at a minimum efficiency of 200 (meaning they capture 99.5% of particles 10 microns and larger) is standard practice. For maximum protection, some systems employ a dual-filter setup, allowing one filter to be changed without shutting down the crusher.

Implementing Proactive Oil Analysis and Contamination Control

Waiting for a component to fail is the most expensive maintenance strategy. Proactive oil analysis is a powerful predictive tool that allows maintenance teams to see inside the hydraulic system without disassembly. By regularly taking oil samples and analyzing them, it is possible to detect problems like excessive wear, contamination, and oil degradation long before they cause a breakdown.

This practice, often called condition monitoring, transforms maintenance from a calendar-based activity to a need-based one. It provides a data-driven basis for deciding when to change the oil, when to service filters, and when to investigate a potential component issue, ultimately maximizing equipment availability and reducing repair costs.

Utilizing Particle Counters for Precision Monitoring

A particle counter is an essential instrument for any serious fluid analysis program. It automatically counts and sizes the particles in a hydraulic oil sample, providing an accurate ISO cleanliness code. This objective data is far more reliable than a visual inspection, which can only detect relatively large contamination.

By trending the particle count data over time, maintenance personnel can identify a sudden increase in contamination, which might indicate a filter failure or an ingress point for dirt. They can also detect a steady rise in fine metallic particles, a telltale sign of abnormal wear occurring within a pump, motor, or cylinder, allowing for intervention before a failure occurs. This is similar to monitoring the discharge size to understand crusher performance.

Employing Centrifuges for Advanced Oil Purification

While inline filters are excellent at removing solid particles, they are less effective at removing water and sludge. For systems that have suffered significant contamination or water ingress, a centrifuge offers a powerful cleaning solution. A centrifugal oil cleaner spins the oil at extremely high speeds, using centrifugal force to separate out contaminants that have a different density than the oil, including water and fine particulate matter.

Centrifuges can achieve purification efficiencies of 90% or higher, effectively restoring contaminated oil to a like-new condition. This can be a highly cost-effective alternative to dumping and replacing large volumes of expensive hydraulic oil, while also being an environmentally friendly practice. They are particularly useful in mobile crushers that operate in challenging conditions.

Managing Hydraulic System Temperature for Longevity

Temperature is a critical parameter in any hydraulic system. The ideal operating temperature for most hydraulic fluids is between 45°C and 55°C. If the oil temperature gets too low, viscosity increases, making it harder to pump and leading to cavitation. If it gets too high, typically above 60°C, the oil begins to oxidize rapidly, breaking down and forming sludge and varnish that clog valves and small orifices.

Heat is generated whenever there is a power loss in the system, primarily through pressure drops across valves and internal leakage in pumps and motors. A well-designed system includes means to reject this heat to keep the oil within its optimal temperature window, ensuring consistent viscosity, good lubrication, and a long fluid life.

Selecting an Appropriate Cooling System

Many smaller crushers rely on the hydraulic reservoir itself to dissipate heat. However, for larger, high-power systems or those operating in hot climates, this is insufficient, and an auxiliary cooler is required. The two main types are air-cooled (radiator) and water-cooled (heat exchanger) coolers.

Air-cooled radiators are simpler to install, as they require no water connection, and are well-suited for mobile equipment or plants where water is scarce. Water-cooled heat exchangers are generally more compact and efficient, capable of handling higher heat loads, making them ideal for large, stationary crusher plants where a reliable cool water source is available. The choice often depends on the maximum ambient temperature, which can frequently reach 40°C in many quarries.

Integrating Temperature Sensors for System Protection

Modern crushers are equipped with sophisticated sensors that continuously monitor system health. Temperature sensors immersed in the hydraulic reservoir are a vital part of this network. They are connected to the crusher's control logic system, which can be programmed to take automatic action if unsafe conditions are detected.

For instance, if the oil temperature sensor reads a value exceeding a preset threshold of 60°C, the control system can first trigger a warning alarm to alert the operator. If the temperature continues to climb, the system can be programmed to automatically reduce the crusher's workload or even initiate an orderly shutdown to prevent the oil from overheating and undergoing thermal degradation, protecting a significant capital investment. This is a key aspect of modern mobile crusher automation.

Developing a Comprehensive Preventive Maintenance Schedule

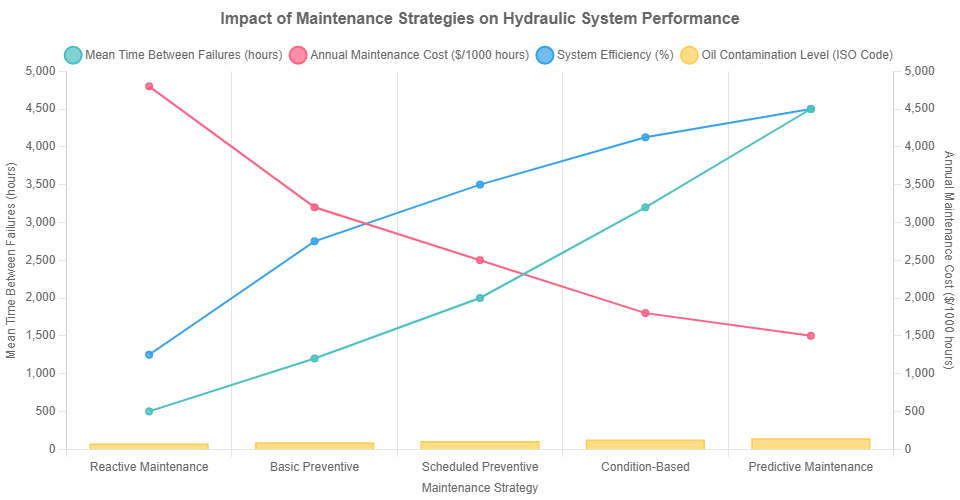

A proactive, scheduled maintenance regimen is the ultimate strategy for maximizing the life and reliability of a jaw crusher's hydraulic system. This approach involves performing inspections, services, and replacements at regular intervals based on time or operating hours, rather than waiting for something to break. It is a planned and coordinated effort designed to find and fix small problems before they evolve into large, expensive ones.

A well-documented maintenance schedule ensures that critical tasks are never overlooked. It allocates resources, minimizes unplanned downtime, and provides a historical record of the equipment's care. This systematic approach to maintenance is what separates high-performing, efficient crushing operations from those plagued with reliability issues and high operating costs.

Daily and Weekly Inspection Checklists

The foundation of any maintenance program is consistent visual and operational checks. Operators should be trained to perform a daily walk-around inspection before startup. This includes checking for any visible hydraulic oil leaks around cylinders, hose connections, and the pump. They should also verify the oil level in the reservoir and check the sight glass for signs of excessive cloudiness (water) or foam (air ingress).

On a weekly basis, more thorough inspections should be conducted. This includes feeling hoses for signs of softening, cracking, or abrasion; checking that all fittings are tight; and ensuring the hydraulic oil cooler fins are clean and free of debris. Listening for unusual noises from the pump and noting any changes in crusher performance, such as slower cycle times, can provide early warnings of developing issues. This routine is vital for all equipment, from a hammer crusher to a primary jaw unit.

Scheduled Fluid and Filter Changes

Even with excellent filtration, hydraulic oil will eventually lose its protective properties due to thermal degradation and additive depletion. Following the manufacturer's recommended interval for a complete oil and filter change is crucial. This interval, often between 2,000 to 5,000 operating hours, should be treated as a maximum; oil analysis can often justify extending it, but never should it be ignored.

When changing the oil, it is not enough to simply drain and refill. The reservoir should be cleaned to remove any settled sludge. The system should be flushed with a low-viscosity flushing fluid if possible, to remove old oil and contaminants from the lines and components. All filters, including suction, pressure, and return line filters, must be replaced with new, high-quality elements to ensure the new oil starts its life in a clean environment.

Periodic Component Testing and Calibration

Over time, critical components can drift from their original settings. An annual or bi-annual maintenance shutdown should include testing and calibration of all system parameters. The most important is checking and adjusting the system's relief valve pressure setting using a calibrated pressure gauge to ensure it opens at the correct pressure, providing reliable overload protection.

Other tasks include checking the condition and operation of solenoid valves, testing the accuracy of temperature and pressure sensors, and possibly testing the pump's output flow and pressure to assess its internal condition. This systematic verification ensures the hydraulic system operates as designed, with the precision needed for effective and safe crushing operations, much like the precise adjustments needed in a impact crusher.