Understanding How Jaw Crushers Safely Process Limestone

This article explores the operational principles of jaw crushers, focusing specifically on their application in limestone crushing. It details the inherent risks associated with dust generation and the comprehensive engineering and procedural controls implemented to mitigate the danger of dust explosions, ensuring a safe and efficient industrial process.

The Nature of Limestone Dust in Crushing Operations

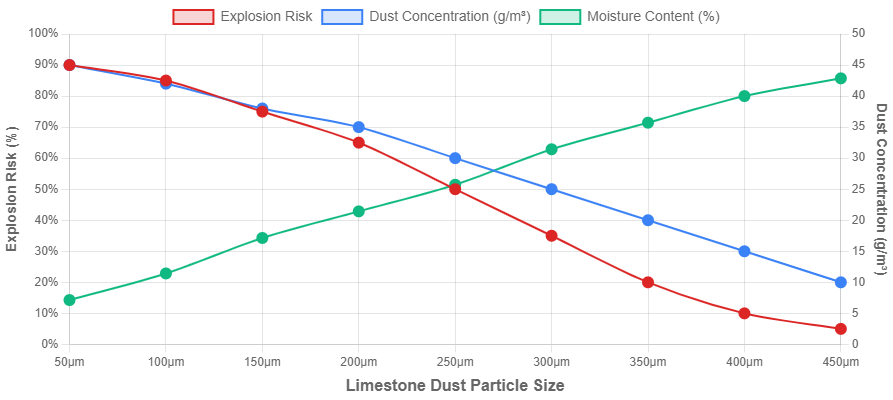

Limestone, a prevalent sedimentary rock, is reduced in size through mechanical compression within a jaw crusher. This process inevitably generates fine particulate matter. The properties of this dust are critical in assessing potential hazards. Dust particles smaller than 420 microns can become suspended in air, forming a combustible mixture under specific conditions.

The explosibility of this dust cloud is influenced by its concentration, dispersion, and the particle size distribution. A concentration exceeding 30 grams per cubic meter of air can create a significant explosion risk if an ignition source is present. The moisture content of the limestone feed material also plays a crucial role, as higher humidity can suppress dust dispersal and lower its combustion potential.

Engineering Controls for Dust Suppression

Modern jaw crushers incorporate advanced design features to control dust at its source. A primary method involves the integration of effective local exhaust ventilation systems. These systems create a negative pressure environment within the crushing chamber, actively drawing dust particles away from the operational zone before they can disperse into the surrounding atmosphere.

The captured dust is typically transported through ductwork to a collection unit, such as a baghouse or a wet scrubber. The design of the crusher itself contributes to dust minimization. Effective sealing around the movable jaw and other access points prevents the uncontrolled escape of fine particles during the compression cycle.

Preventing Ignition Sources

Eliminating potential ignition sources is a fundamental aspect of dust explosion prevention. Within a crusher setup, mechanical sparks from metal-on-metal contact, overheating bearings, or static electricity discharge can provide the necessary energy to ignite a dust cloud. Equipment is therefore designed and selected to minimize these risks.

This includes the use of anti-friction bearings with temperature sensors, specially designed liners to reduce metal contact, and comprehensive grounding systems to dissipate static charges. Electrical components, including motors and switchgear, are often rated for use in explosive atmospheres to prevent electrical arcing from becoming an ignition source.

Operational Practices for Risk Reduction

Beyond engineering controls, strict operational protocols are essential for safety. A key practice is the controlled reduction of the feed size of limestone entering the crusher. Pre-sizing material to a more consistent dimension can reduce the amount of fine dust generated during the primary crushing stage.

Regular and systematic housekeeping is another critical practice. This involves the removal of dust accumulations on ledges, floors, and equipment surfaces. Allowing dust to build up provides fuel for a secondary explosion, which can be more destructive than the initial event. Therefore, cleaning schedules are rigorously maintained using approved methods that do not generate dust clouds.

Monitoring and Emergency Preparedness

Continuous monitoring provides a final layer of defense. Laser-based dust monitoring systems can be installed in critical areas to provide real-time data on airborne dust concentrations. These systems are programmed to trigger alarms if dust levels approach dangerous thresholds, allowing operators to intervene before a hazardous condition develops.

Despite all precautions, emergency response plans must be in place. This includes the strategic placement of appropriate fire suppression equipment, such as Class D fire extinguishers, and clearly marked evacuation routes. Regular training ensures all personnel understand the specific risks and the correct actions to take in the unlikely event of an emergency, aligning with best practices for limestone crushing safety.

The Role of Particle Size Management

The final product size, controlled by the crusher's discharge size setting, indirectly influences dust-related risks. While a jaw crusher is a primary crusher, optimizing its output can reduce the burden on downstream processes that might be more prolific dust generators. A well-configured crusher produces a product with a controlled range of particle sizes, minimizing the generation of superfluous fines.

This approach to particle size control is part of a holistic safety strategy. By managing the entire crushing process from feed to product, operators can effectively control the volume of respirable and combustible dust created, thereby systematically reducing the overall risk profile of the operation.