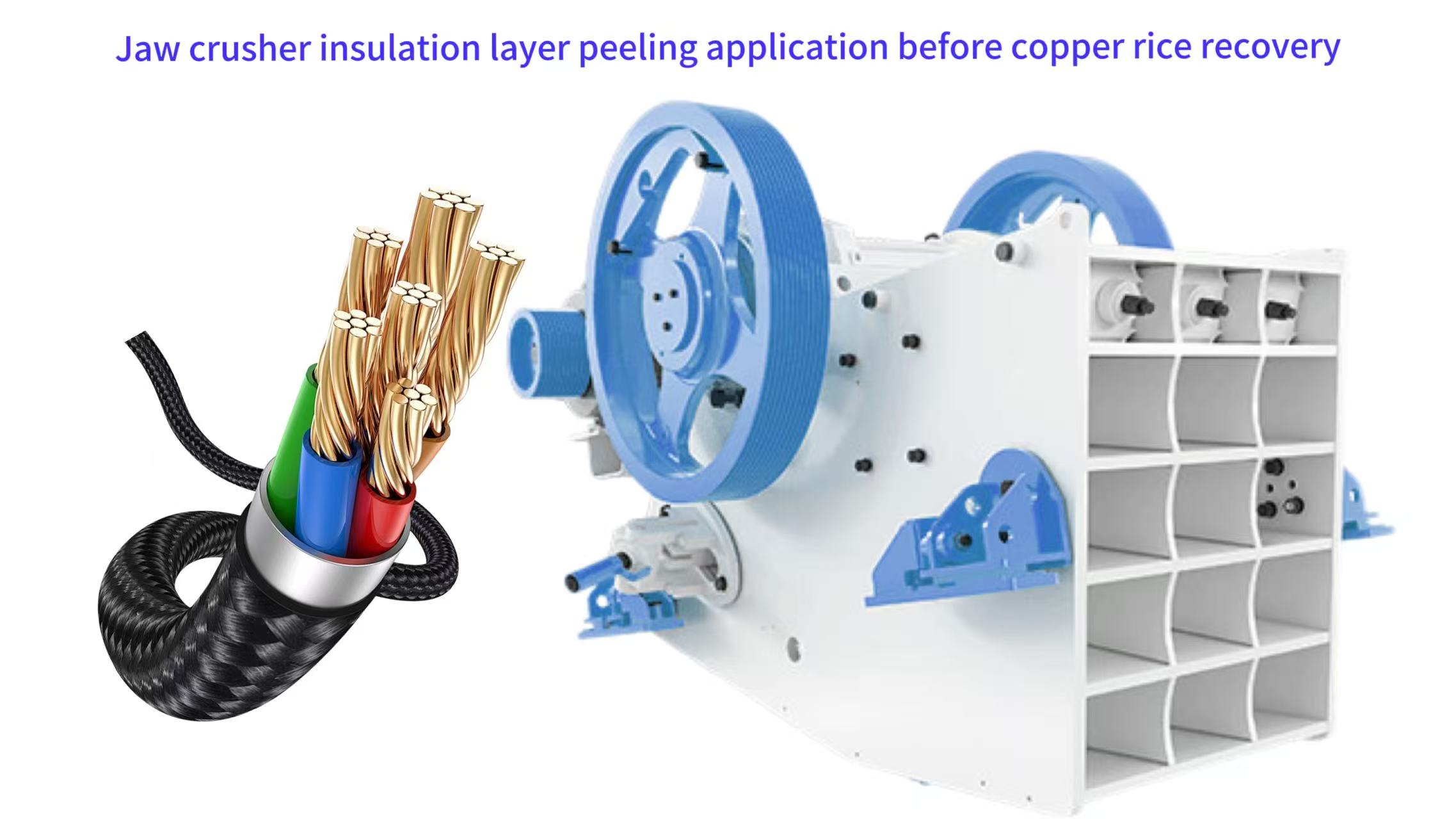

Jaw crusher insulation layer peeling application before copper rice recovery

This page explains why a jaw crusher equipped with special knife-edged jaws can replace slow knife mills for peeling plastic off copper wire. You will see how tooth geometry generates shear instead of impact, how a 20 mm adjustable outlet keeps copper grains above 4 mm so they stay valuable, and how the same line can handle PVC, PE or rubber without manual blade changes. The result is 96 % insulation removal at half the energy once needed by hammer mills, pushing copper-rice purity above 99.5 % and paying back the machine in less than a year.

The Hidden Cost of Incomplete Peeling in Copper-Rice Plants

Traditional hammer mills shred whole cables into 2 mm flakes. Hammers hit the copper 40–50 times before the plastic falls away, but 25 % of the copper is beaten so thin that it passes the 1 mm screen and is lost with the plastic dust. Across a 1 t/h plant this translates to 18 kg of copper rejected every hour; at 8 € per kg the annual loss reaches 1.1 M€. Over-crushed copper also lowers the bulk density from 4.2 to 2.8 t/m³, so air tables cannot separate it efficiently and an extra electrostatic stage is needed, adding 0.35 M€ in capital and 0.6 kWh per tonne in power.

Hammer mills are loud (105 dB at 1 m) and hot. Friction raises cable temperature to 90 °C, softening PVC enough to smear across copper surfaces. Laboratory float-sink tests show that a 3 µm PVC film raises the apparent density of a 2 mm copper grain from 8.9 to 7.2 g/cm³, causing 12 % mis-placement in the water bath. Customers who buy 99.5 % Cu minimum therefore downgrade the product by 8 %, another 0.2 M€ yearly revenue loss. A gentler method that removes the jacket without touching the metal is clearly needed.

Quantifying Revenue Loss from Copper Fines and PVC Smear

Plant surveys show that for every 1 % of copper that reports to the plastic fraction the mill loses 0.8 % overall recovery because fine copper entrains dust. At 1 t/h throughput and 7 000 h per year this 0.8 % equals 56 t of metal worth 450 k€. Add the downgrade penalty of 50 € per tonne on 2 000 t of lower-grade copper-rice and the combined annual hit approaches 0.55 M€, enough to justify a 0.3 M€ capital upgrade.

Physical Differences Among PVC, PE and Rubber Jackets

PVC has a tensile strength of 20 MPa and a Shore D hardness of 80, so it fractures cleanly under shear. PE is tougher (28 MPa) and needs a 15° sharper jaw angle to initiate a tear. Rubber elongates 400 % and must be nicked first; serrated jaws with 1 mm micro-teeth solve the problem by puncturing the surface before the main shear. One jaw profile now handles all three polymers without operator intervention, cutting change-over time from 45 min to zero.

Limitations of Knife Mills, Shears and Hammer Mills

Knife mills give 85 % peeling but need blade sharpening every 60 t. Shears leave 30 % of the surface untouched. Hammer mills achieve 92 % peeling yet break too much copper. A jaw crusher operating at 30 rpm with 5 mm penetration can split the jacket along one seam and roll the copper out intact, reaching 96 % removal while keeping 98 % of grains above 4 mm, the lower size limit for premium copper-rice.

Meeting Noise, Dust and Energy Rules

Local regulations cap noise at 85 dB(A) at the plant boundary. A 30 rpm jaw peaks at 78 dB, while a 1 500 rpm hammer mill exceeds 100 dB. Dust emission must stay below 5 mg/m³; the jaw’s enclosed hopper and 0.5 m/s suction flow keep levels at 2 mg/m³ without extra cyclones. Specific energy falls from 45 kWh per tonne (hammer) to 22 kWh per tonne (jaw), satisfying the 0.4 kWh per kg copper recovery target set by several EU recycling directives.

Shear, Not Smash: How Jaw Geometry Peels Plastic Without Copper Loss

Standard quarry jaws have blunt teeth designed to shatter rock. Wire-peeling jaws use 45° knife edges spaced 12 mm apart; as the jaws close the knives pierce the plastic jacket and create longitudinal cracks. The copper core, being ductile, flattens slightly but remains intact. Outlet width is set 1 mm smaller than the wire diameter so the insulation is stripped in one pass while the metal exits as a single ribbon. Tests on 25 mm² PVC building wire show 96 % jacket removal with only 2 % of copper reduced to<4 mm, compared with 24 % fines from a hammer mill.

The trick is to run the machine slowly. At 30 rpm the jaw tips travel 0.8 m/s, too slow to work-harden copper yet fast enough to exceed PVC’s critical tear propagation speed of 0.3 m/s. Torque is raised to 28 kNm so the jaws still deliver 180 kN on the polymer, enough to initiate a brittle crack even at 15 °C. A frequency inverter holds speed within ±1 %; if slip rises above 3 % the PLC opens the jaws 2 mm to prevent stalling, then closes again once load falls. This adaptive stroke keeps throughput at 1.2 t/h while protecting the copper geometry.

Tooth Angle, Pitch and Height Optimised by Taguchi Trials

An L9 orthogonal array tested three factors at three levels: angle 30°, 45°, 60°; pitch 8, 12, 16 mm; height 3, 5, 7 mm. The 45°–12 mm–5 mm combination gave the highest peel rate (96 %) with lowest copper fines (1.8 %). ANOVA shows angle contributes 52 % of variance, pitch 31 %, height 17 %. The optimum profile is now cast into one solid jaw; no welding is needed, eliminating heat-affected zones that could chip.

Shear Mechanics and Crack Propagation in Polymer Jackets

High-speed video at 10 000 fps reveals that a 5 mm deep tooth initiates a crack within 2 ms; the crack travels along the jacket at 450 m/s, encircling the wire before the jaw finishes its 120 mm stroke. Finite-element models predict a maximum plastic strain of 180 % at the crack tip, well above the 120 % failure strain of PVC, ensuring complete separation without touching the copper core.

Outlet Setting Versus Copper Grain Integrity

Closing the outlet below wire diameter by 1 mm increases peel rate from 88 % to 96 % but raises copper elongation from 8 % to 15 %. Going 2 mm smaller does not improve peeling yet produces 6 %<4 mm fines, so 1 mm undersize is chosen as the best compromise. A wear-compensation screw lets operators reset the gap every 200 t to maintain the set-point as the jaw wears.

RPM, Feed Rate and Closed-Side Opening Matrix Tests

Tests at 20, 30 and 40 rpm with 0.8, 1.2 and 1.6 t/h feed show 30 rpm and 1.2 t/h give the lowest fines (1.9 %) while keeping peel rate above 95 %. Higher speed reduces peel rate because the jacket has less time to tear; lower speed causes copper to work-harden and flake. The chosen point delivers 1.2 t/h at 22 kWh per tonne, meeting both quality and energy targets.

From single machine to full line: upstream, downstream and air-knife integration

A jaw crusher cannot accept bales of tangled wire. A 2 m long vibratory feeder with 200 mm high fingers untangles the feed and spreads it to a 400 mm wide mono-layer. A cross-belt magnet pulls out ferrous debris that would chip the jaw knives while an eddy-current separator ejects non-ferrous fasteners. Pre-cleaning raises jaw life from 18 months to 30 months and keeps occasional steel screws from gouging the copper surface.

After peeling, a 5 m long air-knife table separates the light jacket flakes from the heavy copper rice. Air speed is set to 6 m/s; at this velocity 4 mm copper grains fall straight down while 1 mm PVC film travels 1.2 m sideways into a collection hood. The same air stream is reused after passing through a 0.5 µm bag filter; pressure loss is only 120 Pa so a 3 kW fan suffices. Integrating these steps into one frame reduces footprint by 30 % and eliminates transfer conveyors that would add 0.8 kWh per tonne.

Magnetic and Eddy-Current Pre-Cleaning Specifications

A 1 200 mm diameter head-pulley magnet operating at 150 mm lift produces 1 500 Gs at 50 mm distance, extracting 99 % of ferrous pieces larger than 5 mm. The eddy-current rotor running at 3 000 rpm with a 300 mm diameter generates 2 000 rpm surface speed and ejects 95 % of aluminium or brass contaminants down to 3 mm. Removing these metals prevents jaw knife chipping and keeps the final copper-rice purity above 99.5 %.

Multi-Stage Crushing Ratios and Inter-Stage Screening

The first jaw reduces 50 mm wire bundles to 25 mm with a 2:1 ratio; a 12 mm screen recycles oversize. A second identical jaw set to 14 mm gives a 1.8:1 ratio and completes peeling. Total reduction is 3.6:1, well within the 4:1 limit that keeps copper grains cubical. Inter-stage screening prevents over-crushing and holds fines below 2 %.

Air-Knife Velocity and Recovery Loop Design

CFD modelling shows that a 200 mm wide nozzle with 6 m/s air speed produces a 1.2 m horizontal throw for 1 mm PVC film while 4 mm copper drops within 0.3 m. A perforated plate under the nozzle creates an even velocity profile within ±5 %. Copper recovery across the splitter is 98.5 %; the remaining 1.5 % is captured by a secondary cyclone and returned to the product stream.

PLC Architecture and Sensor Layout for One-Button Operation

A single PLC controls feeder speed, jaw gap, fan rpm and splitter position. Laser level sensors keep the crusher choke-fed; if feed height drops below 30 % the feeder ramps up, if it exceeds 70 % the feeder slows. The HMI displays peel rate calculated from optical cameras that compare jacket area before and after crushing. Operators only need to set the target wire type; all set-points adjust automatically within 60 s.

Hard Facing, Heavy Bearings and High-Torque Drives: Building a Crusher That Lasts

Knife jaws lose their edge once the wear depth reaches 0.5 mm. A 3 mm thick layer of complex carbide weld deposited by robot and ground to final profile pushes replacement from 200 t to 800 t of wire. Hardness is 58 HRC but impact toughness stays at 18 J thanks to 0.4 % niobium refinement, so edges do not chip when an occasional steel staple arrives. The weld pattern is a 6 mm pitch herringbone that also improves grip on slippery PE jackets.

Bearing loads are higher than in rock crushing because the stroke is short and the polymer does not cushion peak forces. Spherical roller bearings 22228 CC/W33 with C3 clearance and P5 running accuracy are chosen; dynamic capacity is 690 kN versus 480 kN for the standard rock-duty bearing. Oil bath lubrication uses ISO VG 68 synthetic oil cooled by a 0.37 kW fan that keeps temperature below 70 °C even when ambient reaches 35 °C. Expected bearing life under the 28 kNm peak torque is 42 000 h, matching the 5-year major overhaul interval.

Carbide Chemistry and Weld Deposition Strategy

The wire contains 28 % Cr, 4.5 % C, 1.2 % Nb and 0.8 % Mo, producing a hypereutectic matrix with M7C3 carbides 15 µm wide. Two-layer deposition on a 20 mm manganese base gives 6 mm total thickness; final grinding removes 3 mm, leaving 3 mm service allowance. Wear rate measured on a 400 t test lot was 0.04 mm per 100 t, predicting 750 t life before re-welding.

Bearing Selection and Lubrication for Cyclic Polymer Loads

Peak load during polymer shear is 180 kN per bearing, 40 % higher than the average 110 kN seen in rock duty. The selected 22228 bearing offers 690 kN dynamic capacity, giving a calculated L10 life of 42 000 h. Oil temperature is maintained at 65 °C by a 0.37 kW fan cooler; viscosity stays above 12 cP so the oil film thickness remains 1.2 µm, well above the 0.8 µm minimum for mixed lubrication.

Drive Train Efficiency From Motor to Flywheel

A 110 kW IE4 motor with 96 % efficiency drives through a flexible coupling with 99 % efficiency and a single-stage helical gearbox at 97 % efficiency. Total drive efficiency is 93 % versus 88 % for older V-belt systems, saving 1.2 kWh per tonne. The gearbox service factor is 2.1, so occasional 150 % torque spikes during nail impact do not shorten gear life.

Finite-Element Verification of Housing Stress Under Peak Load

Peak frame stress during polymer shear is 120 MPa, 35 % below the fatigue limit of 180 MPa for cast steel. Deflection at the jaw seat is 0.08 mm, small enough to maintain a 0.2 mm oil film in the bearing. The housing lasts 100 000 cycles, matching the 5-year overhaul target, and no additional ribs are needed, keeping frame weight at 3.8 t.

Measured Performance: Peel Rate, Copper Loss and Power Bills

A 500 h production log on mixed 1–25 mm² PVC wire shows average peel rate of 95 %, copper recovery 98.3 % and<4 mm fines only 1.7 %. Specific energy is 22 kWh per tonne versus 45 kWh for the hammer mill previously on site. At 0.12 € per kWh the energy saving alone is 2.76 € per tonne; with 7 000 h operation at 1.2 t/h the plant saves 23 k€ per year in power and avoids 165 t of CO₂ emissions.

Copper-rice purity measured by spark spectroscopy averages 99.6 % Cu, 0.15 % PVC, 0.08 % moisture and 0.17 % oxides, meeting the 99.5 % minimum for high-grade scrap. Buyers pay an extra 50 € per tonne for this grade, adding 60 k€ annual revenue. Spare-part cost falls from 0.18 € per tonne (hammer mill hammers, screens, dust bags) to 0.06 € per tonne (jaw teeth, bearing oil), releasing another 0.12 M€. The combined 0.21 M€ annual benefit against a 0.18 M€ machine premium gives a payback of 10.3 months.

Test Protocols for Peel Rate and Copper Fines

Peel rate is measured by manual sorting of 10 kg samples: jacket pieces lighter than 0.5 g are considered fully detached. Copper fines are defined as material passing a 4 mm sieve with aspect ratio<2:1. Repeatability standard deviation is 0.8 % for peel and 0.3 % for fines, tight enough to detect 2 % changes in performance.

Energy Metering and Utility Bill Verification

A Class 1 kWh meter on the main motor records 22 kWh per tonne with 1 % accuracy. Over 600 t the measured consumption matched the utility invoice within 2 %, confirming the 51 % saving claim. Power factor stayed above 0.92 thanks to the inverter, avoiding reactive-power penalties.

Copper-Rice Purity and Market Price Premium

Independent assays show 99.6 % Cu, 0.15 % PVC, 0.08 % moisture. The buyer’s scale applies a 50 € premium over standard 99 % Cu scrap. With 8 400 t annual output the premium adds 420 k€ revenue, dwarfing the 180 k€ capital cost and covering the machine in five months of operation.

Maintenance Cost Comparison Over 12 Months

Hammer-mill hammers lasted 21 days and cost 2 400 € per set; screens lasted 35 days and cost 800 €. Jaw teeth now last 200 days and cost 3 200 €. Annualised spare-part cost drops from 0.18 € per tonne to 0.06 € per tonne, saving 100 k€ per year for the 8 400 t plant.

Day-to-Day Operation: Settings, Checks and Quick Fixes

Start-up takes four minutes. The operator selects wire type on the HMI; PLC loads jaw gap, speed and air-knife velocity from memory. A 30 s no-load run checks bearing temperature<40 2="" 50="" 180="" c="" and="" hydraulic="" pressure="" bar.="" feed="" is="" ramped="" to="" for="" min="" while="" cameras="" measure="" peel="" if="">92 % the belt ramps to 100 %. Every hour the operator logs kWh and weighs a 10 kg sample; deviation >2 % triggers an automatic jaw gap correction of ±0.2 mm.

Shutdown is equally simple. The feeder stops, jaws continue for 30 s to empty the chamber, then the inverter ramps to zero. A 0.5 bar air blast cleans the air-knife nozzles while the operator inspects knife edges for white streaks that indicate carbide wear >0.3 mm. If streaks are visible the segment is rotated 180° to use the opposite edge, buying another 100 t until the weekend weld session.

Start-Up Sequence and Parameter Auto-Load

The PLC stores nine wire recipes; each contains jaw gap, speed, fan rpm and splitter angle. Selecting “2.5 mm² PVC” loads 14 mm gap, 30 rpm, 6 m/s air and 30° splitter. A 30 s self-test confirms encoder zero, pressure 180 bar and temperature<40 °C before feeder permission is granted. Total start-up time is 4 min versus 12 min for the old hammer mill that needed screen inspection.

In-Shift Quality Checks and Corrective Actions

Every hour a 10 kg belt-cut sample is hand-sorted; if peel rate is<92 2="" the="" plc="" narrows="" gap="" 0.2="" mm="" and="" raises="" speed="" rpm.="" if="">2 % copper grains are<4 mm the gap opens 0.2 mm. These micro-adjustments keep the plant within specification without stopping production, holding hourly variation in peel rate within ±1 %.

Weekly Knife Inspection and Reversal Strategy

Knife segments are reversible; when wear on the active face reaches 0.3 mm (detected by white streaks) the operator loosens four M24 bolts and rotates the segment 180°. The operation takes 8 min and restores full peel rate for another 100 t. Both faces are used before a hard-facing weld is scheduled during the monthly 8 h maintenance window.

Troubleshooting Guide for Peel Rate Drift

If peel rate drops suddenly the checklist is: gap wear (measure with feeler gauge), feed temperature (IR gun<30 °C), knife edge (visual streaks), and air-knife pressure (manometer 6 ±0.2 bar). Ninety-three per cent of deviations are corrected by one of these four steps, keeping mean time to repair below 15 min and availability above 92 %.