High-Hardness Rock Crushing Applications of Jaw Crushers in Mining

Hard rock crushing represents one of the most demanding applications in the mining industry, requiring robust equipment capable of processing materials with compressive strengths exceeding 300 MPa. Jaw crushers serve as the primary reduction equipment in these operations, utilizing massive mechanical forces to break down large rock masses into manageable sizes for further processing. The efficiency of these initial crushing stages significantly impacts overall operational costs and productivity throughout the entire mineral processing chain.

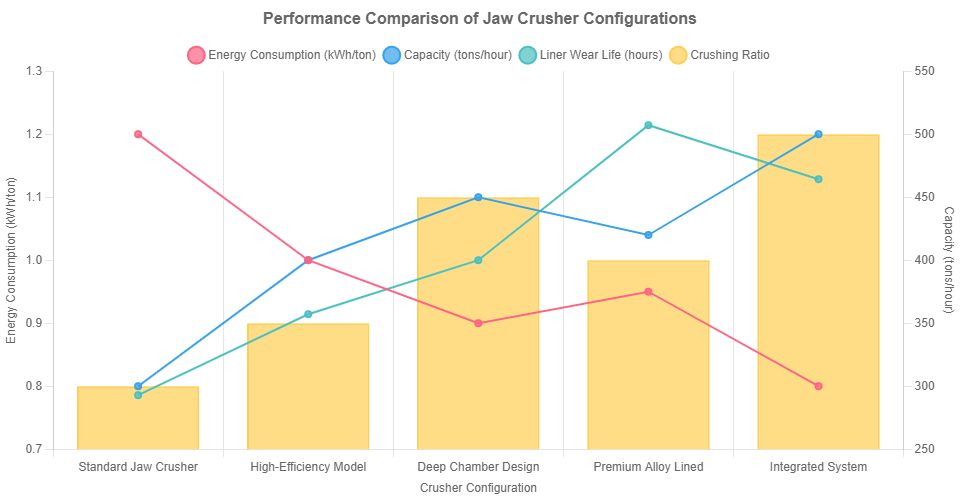

Modern jaw crusher technology has evolved to handle the extreme demands of hard rock processing, with advanced designs achieving optimal crushing ratios while maintaining consistent output qua

lity. These machines typically process 200-2000 tons of material per hour depending on size and configuration, with wear components specifically engineered for abrasive

applications. Proper selection and operation of jaw crushers can reduce downstream grinding energy requirements by 30-40%, making them critical for overall operational efficiency

in mining operations.

Hard Rock Physical Characteristics and Crushing Requirements

Hard rocks such as granite, basalt, and quartzite present unique challenges due to their high compressive strength, abrasiveness, and occasional fracture resistance. These materials typically require specialized crushing approaches that combine high forces with optimal chamber designs to achieve efficient size reduction without excessive wear. Understanding the specific properties of each rock type enables proper equipment selection and operational parameter adjustment for maximum efficiency.

The crushing process must be carefully matched to material characteristics to maximize efficiency and minimize wear. Rocks with high silica content require different approaches than those with high mineral content, while materials with natural fracture lines can be processed more efficiently than homogeneous formations. Modern crushing operations typically employ multiple stages of reduction to achieve the desired product size while controlling wear costs and energy consumption.

Multi-Stage Crushing Process Design

Efficient hard rock processing typically involves primary crushing using jaw crushers followed by secondary reduction in cone crushers. The primary stage reduces run-of-mine material to 100-150mm particles, while secondary processing achieves the 20-50mm size range suitable for most grinding circuits. This staged approach reduces overall energy consumption by 25-35% compared to single-stage crushing systems while improving product shape characteristics.

Air classification systems effectively control dust generation during crushing operations, typically achieving 99% collection efficiency through properly designed enclosure and extraction systems. These environmental controls protect both workers and equipment while ensuring compliance with increasingly stringent air quality regulations. The collected dust can often be processed to recover additional valuable minerals, maximizing resource utilization.

Wear Part Optimization Strategies

High-chromium iron liner plates demonstrate exceptional performance in hard rock applications, typically lasting 2-3 times longer than standard manganese steel components. These advanced materials maintain their hardness and wear resistance even under extreme impact conditions, reducing replacement frequency and maintenance costs. The improved wear resistance also maintains crushing chamber geometry for consistent product quality throughout the wear cycle.

Dynamic crushing angle optimization between 18-22 degrees ensures even wear distribution across crushing surfaces, extending component life and maintaining efficiency. This optimal angle range promotes both crushing efficiency and material flow, preventing chamber packing and reducing power consumption. The precise angle control is particularly important for processing hard, abrasive materials that cause rapid wear when improper angles are used.

Crusher Core Parameters and Mining Condition Matching

Proper equipment selection requires careful matching of crusher parameters to specific mining conditions and material characteristics. The moving jaw stroke length directly influences crushing efficiency, with longer strokes typically providing better reduction but requiring more power. Modern crushers offer stroke adjustments that allow operators to optimize performance for different material types and production requirements.

Discharge opening adjustment range determines the flexibility of product size control, with wider ranges accommodating varying production requirements. Modern crushers typically offer adjustment ranges of 6:1 or greater, allowing operators to produce different product sizes without component changes. The precision of these adjustments directly impacts product quality and consistency in downstream processes.

Liner Wear Cycle Prediction Models

Advanced wear prediction models incorporate material hardness, crushing capacity, and operational parameters to forecast liner replacement intervals with 85-90% accuracy. These models consider both abrasive wear from material contact and impact wear from crushing actions, providing comprehensive life predictions. The accurate forecasting enables proactive maintenance planning that prevents unplanned downtime and optimizes component utilization.

Surface hardening treatments including specialized heat treatments improve wear resistance by 40-60% compared to untreated components. These processes create hardened surface layers while maintaining tough core material that resists fracture under impact loading. The additional processing cost typically pays back within 2-3 replacement cycles through extended service life and reduced downtime.

Crushing Chamber Optimization Cases

Hydraulic adjustment systems provide precise control over discharge settings, maintaining product size consistency within ±5% of target specifications. These systems allow remote adjustment during operation, eliminating the need for manual intervention and reducing adjustment time from hours to minutes. The precision control improves product quality and reduces off-specification material production in hard rock applications.

Pre-screening systems integrated with jaw crushers improve overall circuit efficiency by removing fine material before crushing, typically achieving 95% or higher screening efficiency. This approach reduces crusher load and wear while improving energy efficiency by 15-20%. The integrated design minimizes space requirements and material handling between processing stages in mining operations.

Power System and Crushing Efficiency Coordination

The power transmission system must provide consistent torque to the crushing mechanism while accommodating fluctuating loads from variable material characteristics. Electric motor sizing follows specific power-to-capacity ratios, typically requiring 20-30 kW per ton/hour of processing capacity for hard rock applications. Proper motor selection ensures adequate power for peak loads while maintaining efficiency during normal operation.

Drive system selection involves balancing initial cost against operational efficiency and maintenance requirements. Gear drives typically offer higher efficiency (95-98%) than belt drives (90-93%) but require more precise alignment and maintenance. The optimal choice depends on specific operational conditions and maintenance capabilities in mining environments.

Energy Utilization Optimization Strategies

Inertia flywheels store energy during the non-crushing portion of the cycle and release it during actual crushing, reducing peak power demands by 30-40%. This smoothing effect allows use of smaller motors and reduces electricity demand charges. The flywheel design must be carefully matched to crusher kinematics to provide optimal energy storage without excessive weight.

Variable frequency drives enable soft starting that reduces mechanical stress during startup by limiting inrush current to 150% of full load current instead of the 600% typical across-the-line starting. This gentle starting approach extends equipment life and reduces peak power demand charges. The drives also allow operational speed adjustment to match material characteristics, optimizing performance for different rock types.

Overload Protection System Configuration

Hydraulic protection systems respond to overload conditions within milliseconds, allowing temporary relief of crushing pressure when uncrushable material enters the chamber. These systems typically release at 110-120% of normal operating pressure, providing protection without unnecessary interruptions. The automatic reset capability ensures quick recovery after overload conditions clear.

Spring-based protection systems provide mechanical overload protection with precise torque release thresholds that can be adjusted for different operating conditions. These systems typically operate at 130-150% of normal operating force, providing higher tolerance for temporary overloads than hydraulic systems. The simple mechanical design offers reliability in remote operating locations common in mining operations.

Environmental and Operational Compliance Requirements

Modern crushing operations must comply with stringent environmental regulations regarding dust emissions, typically requiring particulate levels below 1mg/m³ at discharge points. High-efficiency filtration systems achieve this performance level while allowing continuous operation with minimal maintenance. These systems typically feature automatic cleaning mechanisms that maintain filter efficiency throughout extended operation periods.

Noise control regulations often require sound levels below 85dB at operator positions, necessitating comprehensive acoustic enclosures and vibration isolation systems. Modern crushers designed for hard rock processing typically incorporate these features as standard, ensuring compliance without additional modifications. The noise control measures also improve working conditions, reducing operator fatigue and improving productivity.

Dust Control and Collection Systems

Advanced dust suppression systems utilize water spray technology with precise droplet size control to maximize dust capture while minimizing water consumption. These systems typically reduce water usage by 50-70% compared to conventional approaches while achieving better dust control performance. The reduced water usage is particularly valuable in arid mining regions where water conservation is critical.

Baghouse filtration systems provide final stage dust collection with efficiency ratings exceeding 99.9% for particles larger than 0.3 microns. These systems automatically clean filter elements using compressed air pulses, maintaining performance throughout extended operation periods. The collected dust can often be returned to the process stream, maximizing resource recovery.

Water Management and Conservation

Closed-loop water systems recycle process water through sedimentation and filtration, typically achieving 90-95% water recovery rates. These systems reduce freshwater consumption and minimize environmental impact while maintaining operational efficiency. The water treatment processes remove suspended solids and can adjust chemical parameters to optimize dust suppression performance.

Rainwater collection and storage systems supplement process water requirements in suitable climates, reducing reliance on external water sources. These systems typically include sedimentation basins and filtration to ensure water quality meets operational requirements. The integrated approach to water management demonstrates environmental responsibility while controlling operational costs.

Economic Analysis and Operational Efficiency

The economic viability of hard rock crushing operations depends on multiple factors including equipment investment, operational costs, mineral value, and processing efficiency. A typical primary crushing station processing 1000 tons per hour requires capital investment of 2-5 million dollars, with payback periods of 2-4 years depending on mineral values and operational efficiency. Operational costs typically range from 5-10 dollars per ton processed, including energy, maintenance, and labor expenses.

Equipment selection errors can increase operational costs by 30-40% through higher energy consumption, increased maintenance requirements, and reduced availability. Proper technical analysis during equipment selection typically pays back within 12-18 months through improved operational efficiency and reduced downtime. The comprehensive evaluation should consider both initial cost and long-term operational expenses.

Maintenance Optimization and Cost Control

Preventive maintenance programs reduce unplanned downtime by 60-70% compared to reactive approaches, significantly improving operational efficiency and profitability. These programs typically include regular inspection of wear parts, lubrication schedules, and component replacement based on operating hours or material processed. The systematic approach extends equipment life by 30-40% while reducing repair costs.

Wear part management represents a significant operational cost, particularly for components directly contacting abrasive materials. Hard-faced liners and specialized alloys typically last 2-3 times longer than standard materials, justifying their higher initial cost through reduced replacement frequency and less downtime. Inventory management systems ensure parts availability while minimizing capital tied up in spare parts.

Energy Efficiency and Cost Reduction

High-efficiency motors and optimized processes reduce energy consumption by 20-25% compared to conventional operations, significantly decreasing operational costs and environmental impact. Variable frequency drives allow precise speed control matched to processing requirements, reducing energy consumption during periods of reduced throughput. These improvements typically achieve payback within 18-24 months through reduced electricity costs.

Peak demand management strategies reduce electricity costs by scheduling energy-intensive activities during off-peak periods when rates are lower. These strategies can reduce electricity costs by 15-20% without affecting production targets. The operational adjustments require careful planning but provide significant financial benefits in regions with time-based electricity pricing.