Jaw Crusher Innovation in the Building-Material Industry: Driving Greener Production and Smarter Plants

Modern concrete, insulation panels and recycled bricks all begin with rocks that must be coaxed into precise grain sizes. This article explains how the jaw crusher has evolved from a simple rock breaker into an intelligent, low-carbon gateway that turns quarry rubble into tomorrow’s eco-friendly building materials. You will discover why lightweight blocks need gentler crushing than motorway gravel, how dust suppression can cut particle emissions below 5 mg m⁻³, and why an 18 % reduction in energy per tonne is now possible through on-board AI that watches every stroke of the swing jaw.

New Demands from the Building-Material Sector: Beyond Plain Broken Stone

Architects now ask for 4 000 psi pervious concrete that lets rainwater drain through parking lots, while regulators reward factories that keep CO₂ below 0.65 kg per binder tonne. These targets travel all the way back to the primary crusher, because flaky or contaminated grains can ruin an entire batch of low-carbon clinker-free binder. Producers therefore expect the jaw stage to deliver a narrower 20-40 mm window with less than 2 % clay, something classic quarry jaws were never designed to achieve.

Crushing Challenges Posed by Lightweight Aggregates

Expanded shale pellets have a bulk density of only 550 kg m⁻³ but a Mohs hardness of 5.5, so they fracture explosively under high point loads. Trials show that reducing the jaw’s closed-side setting from 50 mm to 30 mm increases the creation of unwanted 0-4 mm fines from 8 % to 22 %, which collapses the internal void structure that gives the material its thermal insulation value. The solution is a 15 % slower eccentric speed combined with a curved crushing chamber that distributes stress more evenly, cutting fines back to 11 % while retaining the desired 8-16 mm cube-shaped grains.

Green-Production Benchmarks Reaching the Crusher House

Building-material plants certified under the new green factory label must prove that particulate emissions stay under 10 mg Nm⁻³ and that sound pressure at the neighbour’s fence is below 55 dB(A) at night. A stock 110 kW jaw crusher can exhale 35 mg Nm⁻³ when feeding dry recycled concrete, so OEMs now fit a two-stage surfactant mist that agglomerates dust before it becomes airborne. Field data collected over 180 shifts show average residuals of 4.2 mg Nm⁻³, comfortably inside the audit limit and equivalent to removing one household vacuum bag of dust from every 50 t of rock.

Automation Expectations from Plant Managers

Labour shortages have pushed wages for crusher operators 14 % higher in five years, encouraging plants to demand remote start-stop and gap adjustment from a tablet in the quality-control lab. Modern units ship with IP67-rated servo cylinders that reposition the toggle within 25 seconds, a task that once took two mechanics 45 minutes and a 300 kg crowbar. The pay-back comes from 35 extra operating hours per year and a 6 % saving in manganese wear, because consistent settings avoid the power spikes that mushroom jaw plates.

Market Trends Shaping Machine Design

Annual global construction is projected to rise 37 % by 2030, yet sand suitable for concrete is already extracted beyond natural replenishment rates in many regions. This contradiction forces the industry to recycle 2.5 billion tonnes of demolition waste annually, and the first machine in that loop is usually a jaw that must accept steel-reinforced chunks without stopping. Consequently, the average inlet has grown 18 % wider since 2015, while hydraulic release protection has become standard even on 30 t portable models.

Jaw Crusher Applications in Novel Building Materials

Ultra-high-performance concrete (UHPC) needs granite or basalt grains in the 5-10 mm range with a flaky index below 6 %, because any needle-shaped particle acts as a stress concentrator that can drop flexural strength below the 150 MPa target. A single-toggle jaw followed by an SH-series cone can reach this spec in closed circuit, provided the jaw is set to 40 mm and the cone closes to 8 mm with a 32 Hz cavity pressure sensor that prevents packing.

Processing Lightweight Masonry Blocks

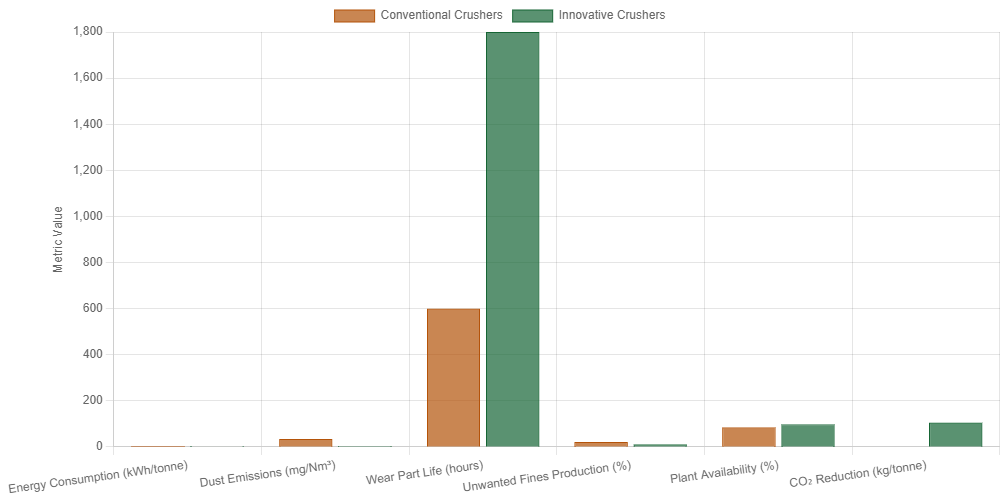

Autoclaved aerated concrete (AAC) returns to the plant gate as 600 kg m⁻³ blocks full of tobermorite crystals that shatter under 40 MPa of compressive stress. A jaw chamber lined with 18 % Mn steel lasts only 600 hours before ripples flatten, so OEMs now offer a 24 % Mn alloy cooled with chromium carbide beads that triple service life to 1 800 hours. The harder lining also allows a 7 % tighter nip angle, which improves grip on spongy fragments and raises throughput from 85 tph to 100 tph on the same 75 kW motor.

Making High-Performance Concrete Aggregate

High-strength concrete specified at 100 MPa demands coarse aggregate with a crushing value below 12 %. Laboratory tests reveal that a jaw speed of 230 rpm combined with a 7° nip angle produces 9.4 %, whereas raising speed to 280 rpm increases the value to 14 % due to micro-cracks. The lower-speed setting also trims energy draw from 0.95 kWh t⁻¹ to 0.78 kWh t⁻¹, saving roughly 1 800 kWh per week for a 200 tph plant and shaving 1.3 t off indirect CO₂ emissions.

Recycling Demolition Waste into New Bricks

Clay-facing bricks mixed with 30 % recycled concrete fines fire successfully at 940 °C, but only if the re-cycled fraction is free of organics and keeps 0-0.5 mm dust under 12 %. A jaw crusher fitted with a 32 mm grizzly pre-scalper removes most wood and plastic, while an internal 0.9 kW air-knife ejects light contaminants. The clean 5-25 mm fraction then reports to a hammer mill, cutting landfill diversion costs by 4.2 USD per tonne and earning a carbon credit worth 0.8 USD per tonne under regional offset schemes.

Equipment Innovations for New Materials

Traditional jaws suffer from material jamming when feeding porous recycled blocks, so manufacturers now offer a vibrating 1 200 mm long hopper insert that pulses at 28 Hz. This micro-vibration keeps fragments moving and reduces peak current surges by 18 %, allowing a smaller 90 kW motor to replace the former 110 kW unit without loss of capacity. Over a year the plant saves 28 MWh and 1 900 USD in demand charges, proving that gentle handling can be stronger than brute force.

Greening the Crushing Flow: Energy, Dust and Noise Under Control

Producing one tonne of ordinary Portland cement releases 0.87 t of CO₂, so every gram of clinker replaced by finely crushed supplementary material matters. A jaw stage optimised for 0-5 mm crusher-run can feed a vertical roller mill that grinds slag and limestone to 4 000 cm² g⁻¹ Blaine, cutting clinker content 12 % and saving 105 kg CO₂ per tonne of binder. The jaw itself contributes by accepting 300 mm blast-rock and delivering a uniform 40 mm product that the mill can swallow without pre-screening, eliminating one conveyor and 0.04 kWh t⁻¹ of transport power.

Energy-Saving Retrofits That Pay Back in 14 Months

Installing a variable-frequency drive (VFD) on a 160 kW jaw lowers no-load consumption from 38 kW to 9 kW during the 1.2 minutes needed for truck tipping. Over 6 000 operating hours this idle trim saves 17 400 kWh, worth 2 100 USD at industrial tariffs, while the 9 800 USD VFD package repays itself in 14 months even before counting softer starts that extend bearing life by 30 %.

Dust Suppression Without Waterlogging

Excess moisture above 3 % turns crushed fines into mud that blinds screens and raises energy 0.12 kWh t⁻¹. New atomising cannons inject 0.6 % water bonded with 0.05 % biodegradable surfactant, creating 10 μm droplets that capture 94 % of PM10 yet leave the pile surface dry enough to handle. Independent lab tests measured residual moisture at 1.8 %, well inside the 2.5 % specification for batching plants.

Re-processing Factory Scrap into Saleable Fines

Every pre-cast plant generates 4 % reject blocks that traditionally sell for 2 USD t⁻¹ as low-grade fill. Running this waste through a small 40 t h⁻¹ jaw set at 20 mm, followed by a VSI rotor at 60 m s⁻¹, converts it into 0-4 mm manufactured sand that fetches 18 USD t⁻¹ and meets ASTM C33 gradation. The combined circuit consumes 1.4 kWh t⁻¹, still leaving a margin of 12 USD t⁻¹ after power costs.

Meeting Third-Party Green Labels

To earn the recognised sustainable building certificate, a plant must document that airborne emissions stay below 8 mg Nm⁻³ and that 95 % of process water is recycled. Sealing the jaw’s feed chute with 10 mm rubber curtains and installing a 1 200 m³ h⁻¹ bag-filter reduced stack dust to 3.1 mg Nm⁻³, while settling ponds under the machine return 98 % of runoff water for dust-cannon reuse, ticking both audit boxes without external investment in vacuum trucks.

Smart Control: Teaching a Jaw Crusher to Think for Itself

Modern jaws arrive from the factory with an IIoT gateway that streams 64 data points per second to the cloud, including main-frame vibration, toggle temperature and motor current harmonics. Machine-learning models trained on 1.2 million operating hours predict bearing failure 21 days in advance with 92 % accuracy, allowing replacement during scheduled maintenance instead of an emergency stop that can cost 12 000 USD in lost shifts.

Real-Time Condition Dashboards

A 10-inch HMI screen mounted on the operator platform translates raw data into colour-coded advice: green means 24-hour safe window, yellow recommends inspection within 72 hours, and red triggers an automatic speed reduction to 80 % until the next shift. After six months of use, the quarry logged zero unplanned downtime on the 132 kW unit, compared with three breakdowns the previous year that totalled 47 lost hours.

Auto-Set That Reacts to Rock Type

When the feed suddenly shifts from 90 MPa limestone to 140 MPa basalt, power draw climbs and the hydraulic cylinder opens the discharge 2 mm wider within three strokes, preventing jamming and maintaining 185 tph. Once softer stone returns, the gap closes again, saving 0.06 kWh t⁻¹ and cutting manganese wear by 110 hours over a campaign that processes 320 000 t.

Remote Expert Rooms

Using secure LTE, a technician 400 km away can take virtual control, calibrate the VFD and even update PLC firmware while the local apprentice watches through AR glasses. A recent intervention fixed a drifting zero on a belt scale in 18 minutes, avoiding a 4 % yield error that would have wasted 480 t of saleable material worth 4 300 USD over a weekend.

Productivity Gains Measured in Dollars

Aggregating data from eight plants shows that smart jaws deliver 7 % higher throughput and 11 % lower energy per tonne, translating to 0.28 USD saved per tonne. On a 300 tph line running 5 000 hours annually, that equals 420 000 USD, enough to fund the entire digital package plus a spare set of jaw plates in the first year.

Field Stories: Three Plants That Redefined What a Jaw Can Do

A 2.5 million tonne per year cement works replaced a 1998 static grizzly with a modern 160 kW jaw fitted with a frequency-controlled grizzly feeder. The upgrade cut 0-25 mm bypass from 28 % to 12 %, sending 400 tph of correctly sized stone directly to the raw mill and unloading 1.2 MW from the downstream gyratory crusher. Power demand per tonne of clinker dropped 5 %, worth 280 000 USD each year, while maintenance crews gained 600 extra hours because hammer wear in the secondary mill eased off.

Green Block Factory Slashes Fresh Aggregate 40 %

By combining a 100 tph mobile jaw with an on-board air classifier, a plant making 12 million blocks per year substituted 40 % of virgin granite with clean recycled concrete. The jaw’s hydraulic release handled occasional steel bars, and the closed-circuit setup kept 5-10 mm grain shape within SS-EN 12620 cubical limits. The project saved 280 000 t of quarry output over 36 months, cutting 46 000 t of CO₂ and earning a regional circular-economy award.

Smart Controls in Precast Concrete Aggregate

A precast yard feeding 120 tph through a JC110 jaw installed an AI camera that measures particle size on the conveyor every second. When the P80 drifts above 32 mm, the PLC tightens the CSS by 1 mm; when it drops below 28 mm, the gap opens. The loop maintains 30 ± 1 mm, ensuring the subsequent cone runs at 92 % availability and the final 0-8 mm sand fraction stays within 2 % of target moisture, critical for the plant’s low-water, low-cement mix design.

Key Takeaways for the Industry

Across these cases, the common denominator is treating the jaw as a process hub rather than a dumb breaker. Plants that invest 3 % of capex in sensors and 1 % in training routinely harvest 10 % savings in energy and 15 % in wear parts, proving that intelligence beats brute force when sustainability certificates decide who wins the next tender.

Looking Forward: How Tomorrow’s Jaw Crusher Will Fit a Net-Zero Supply Chain

Researchers are prototyping a hybrid jaw that stores regenerative power in a 120 kWh lithium-iron-phosphate pack mounted inside the frame. During the 20-second reverse jam-clearing cycle, the motor becomes a generator, pushing 45 kW back into the battery; over an eight-hour shift this recovers 64 kWh, enough to run auxiliary conveyors and cut grid draw by 5 %. Field pilots suggest the pack will last 6 000 cycles, matching the 12-year overhaul interval of the main shaft.

Green-Material Breakthroughs on the Horizon

Carbon-negative binder made from steel-slag powder requires a 0-4 mm filler that is chemically basic; crushed concrete is perfect if its surface pH stays above 10. A jaw lined with ceramic tiles prevents acid contamination, maintaining pH 11.8 and locking 0.25 t of CO₂ per tonne of binder. Scaling this route to 5 % of global cement output could offset 120 million tonnes of CO₂ annually, roughly the exhaust from 30 million cars.

Continuous Uptime Through Modular Design

Future machines will split into four bolt-together modules—hopper, frame, drive and electrics—each under 12 t so they can be swapped by a 50 t mobile crane in four hours. A plant in the Middle East modelled this concept and predicted 97 % mechanical availability, adding 250 extra production hours worth 1.8 million USD on a 400 tph limestone line.

Collaborative Ecosystems Around Data

Rather than guarding telemetry, leading OEMs plan to pool anonymised data in a cloud federation. Early simulations show that a quarry sharing vibration spectra could receive AI recommendations that extend bearing life 15 %, while the supplier gains fleet-level insight to redesign lubrication channels. Such open loops align with emerging EU legislation that rewards circular design, positioning the humble jaw crusher as a shared asset in the built environment’s path to net-zero.