Selecting High-Efficiency, Low-Maintenance Jaw Crushers: Maximizing Production Benefits

Choosing the right jaw crusher involves balancing performance efficiency with maintenance requirements to achieve optimal operational economics. This comprehensive guide examines the key characteristics of high-performance crushers while providing practical strategies for minimizing maintenance costs and maximizing long-term productivity. Understanding these factors enables informed decision-making for various industrial applications.

Core Characteristics of High-Efficiency Jaw Crushers

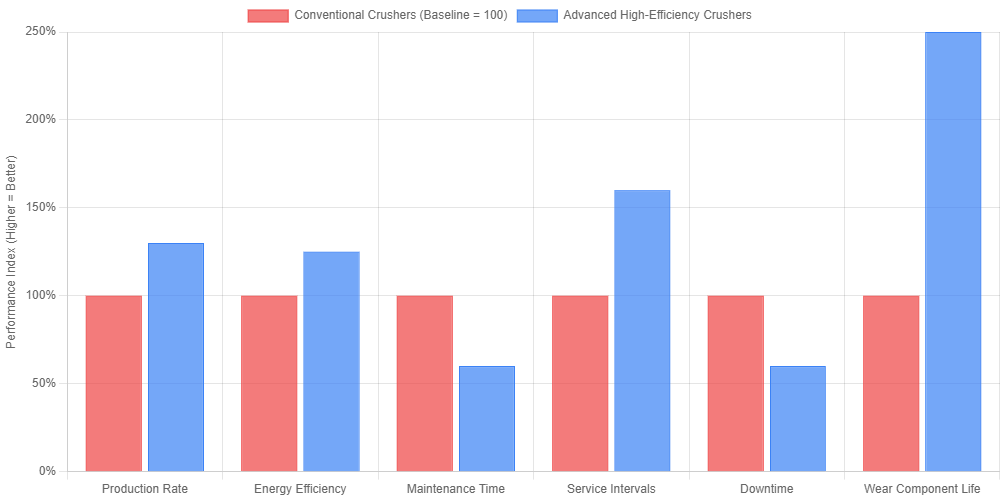

High-efficiency jaw crushers incorporate advanced engineering features that maximize productivity while maintaining energy efficiency. These machines typically achieve 20-30% higher production rates compared to conventional designs while reducing energy consumption by 15-25%. The efficiency improvements stem from optimized kinematics, improved material flow, and advanced control systems that adapt to varying operating conditions.

Modern high-efficiency crushers feature robust construction with precision-machined components that ensure reliable operation under heavy loads. The integration of high-performance motors and efficient power transmission systems minimizes energy losses while delivering consistent crushing performance. These design features collectively contribute to lower operating costs and improved environmental performance through reduced energy consumption.

High-Speed Operation and Crushing Force Design

Advanced jaw crushers utilize optimized eccentric shaft designs that enable higher crushing speeds without compromising reliability. Typical operating speeds range from 250-300 rpm, generating substantial crushing forces while maintaining efficient material processing. The increased speed capabilities allow for higher throughput rates while producing consistent product gradation.

The crushing force generation systems incorporate reinforced components and precision balancing that withstand the dynamic loads associated with high-speed operation. Modern designs achieve crushing forces exceeding 200 tons while maintaining structural integrity and minimizing vibration. This combination of speed and force enables efficient processing of various materials while extending component life.

Intelligent Control Systems: Real-Time Monitoring and Adjustment

Sophisticated control systems continuously monitor operational parameters including power consumption, bearing temperatures, and crushing chamber conditions. These systems automatically adjust operating parameters to maintain optimal performance while preventing damaging conditions. The integration of automated adjustment systems enables real-time optimization of closed-side settings based on material characteristics and production requirements.

Advanced control platforms incorporate predictive algorithms that anticipate maintenance needs and operational issues before they affect performance. These systems typically reduce unplanned downtime by 40-60% while maintaining consistent product quality. The data collected enables continuous improvement through operational analysis and performance optimization.

Optimized Crushing Chamber Structure for Enhanced Efficiency

Modern crushing chamber designs incorporate computational fluid dynamics and finite element analysis to optimize material flow and crushing action. The chamber geometry ensures efficient material reduction while minimizing energy consumption and wear. These optimized designs typically improve crushing efficiency by 15-25% compared to conventional chamber configurations.

The strategic placement of wear protection and optimized kinematics ensure uniform wear distribution across crushing surfaces. This approach extends component life while maintaining consistent product quality throughout the wear cycle. The chamber design also facilitates easier maintenance access and reduces cleaning requirements between material changes.

High-Efficiency Motors and Power Transmission Systems

Premium efficiency motors meeting IE3 or IE4 standards reduce energy consumption by 3-8% compared to standard efficiency models. These motors incorporate advanced materials and design features that minimize energy losses while providing reliable operation under variable load conditions. The improved efficiency significantly reduces operating costs, particularly in continuous operation scenarios.

The power transmission systems utilize precision-engineered components that minimize energy losses through efficient torque transfer. Advanced coupling systems, precision-aligned bearings, and optimized drive arrangements ensure maximum power delivery to the crushing process. These systems typically achieve power transmission efficiencies exceeding 95%, contributing to overall energy efficiency.

Key Selection Factors for Low-Maintenance Jaw Crushers

Selecting jaw crushers with low maintenance requirements involves evaluating multiple design aspects that influence service intervals and repair complexity. Modern low-maintenance designs typically reduce maintenance time by 30-50% compared to conventional crushers while extending service intervals by 40-60%. These improvements significantly impact operational availability and total cost of ownership.

The evaluation of maintenance requirements considers factors including component accessibility, replacement complexity, and service tool requirements. Designs that facilitate quick component replacement and minimize alignment procedures reduce maintenance downtime and labor costs. These features are particularly valuable in remote locations or operations with limited maintenance resources.

Wear-Resistant Materials: Extending Jaw Plate Life

Advanced jaw plate materials incorporating micro-alloying elements and specialized heat treatment processes typically achieve 2-3 times longer service life compared to standard materials. These premium materials maintain their cutting edges longer while resisting deformation under heavy crushing loads. The extended service life reduces replacement frequency and associated downtime.

Material selection considers the specific abrasiveness and impact characteristics of processed materials. For highly abrasive applications, composite materials with ceramic inserts or specialized surface treatments provide exceptional wear resistance. These advanced materials can increase service life by 300-400% in extreme wear conditions, significantly reducing maintenance requirements.

Modular Design: Facilitating Rapid Maintenance and Replacement

Modular construction enables quick replacement of wear components without extensive disassembly. Typical jaw plate replacement times range from 2-4 hours in modular designs compared to 6-8 hours in conventional crushers. This time reduction significantly impacts operational availability and maintenance scheduling.

The modular approach also simplifies inventory management by standardizing components across different crusher sizes and models. This standardization reduces spare parts inventory requirements while ensuring availability when needed. The simplified maintenance procedures enable less experienced personnel to perform routine maintenance tasks safely and efficiently.

Lubrication System Optimization: Reducing Maintenance Frequency

Advanced automatic lubrication systems ensure proper lubrication of all critical components while extending relubrication intervals. These systems typically extend lubrication intervals by 50-100% compared to manual lubrication while improving reliability through consistent lubrication quality. The automated systems also monitor lubrication performance and alert operators to potential issues.

Centralized lubrication points and strategically placed access panels simplify maintenance procedures and reduce lubrication time requirements. The improved lubrication systems contribute to extended bearing life and reduced wear on moving components. These features typically reduce lubrication-related maintenance by 60-70% while improving equipment reliability.

Fault Diagnosis and Early Warning Systems

Integrated monitoring systems continuously track equipment condition and performance parameters, providing early warning of potential issues. Vibration analysis, temperature monitoring, and performance trending enable predictive maintenance approaches that prevent unexpected failures. These systems typically identify developing issues 200-400 operating hours before they cause operational problems.

The diagnostic systems provide clear guidance for maintenance interventions, reducing troubleshooting time and improving repair accuracy. Remote monitoring capabilities enable expert support from equipment manufacturers, ensuring proper maintenance procedures and minimizing errors. These advanced diagnostic capabilities significantly reduce maintenance costs and improve equipment availability.

Balancing Equipment Performance and Maintenance Costs

The optimal balance between performance capabilities and maintenance requirements involves comprehensive economic analysis considering both capital and operational expenditures. High-performance crushers typically command 20-30% higher initial investment but can deliver 40-60% lower operating costs over the equipment lifecycle. This balance requires careful consideration of production requirements, operational conditions, and maintenance capabilities.

Lifecycle cost analysis provides a framework for evaluating the total cost of ownership, including energy consumption, maintenance costs, and production efficiency. This analysis typically reveals that maintenance costs represent 40-60% of total operating costs, highlighting the importance of maintenance-friendly designs. The comprehensive evaluation ensures selection of equipment that delivers the best economic performance for specific operational requirements.

Initial Investment Versus Long-Term Maintenance Costs

The evaluation of capital expenditure against operational costs requires analysis of maintenance requirements, energy consumption, and production efficiency. Premium crushers with advanced features typically demonstrate payback periods of 18-36 months through reduced operating costs and improved productivity. This analysis must consider specific operational conditions and material characteristics.

Long-term maintenance cost projections include component replacement, labor costs, and production losses during maintenance periods. Advanced designs typically reduce these costs by 30-50% through extended service intervals, simplified maintenance procedures, and improved reliability. The comprehensive cost analysis ensures informed investment decisions that maximize long-term economic performance.

Production Benefits from High-Performance Equipment

High-performance crushers deliver increased production capacity and improved product quality that directly impact operational economics. The increased throughput typically ranges from 15-25% compared to standard equipment, enabling higher production volumes without additional capital investment. The improved product quality also enhances downstream processing efficiency and product value.

The consistent performance of advanced crushers maintains production targets despite varying material conditions and operational requirements. This reliability ensures meeting production commitments and maximizing equipment utilization. The production benefits typically justify the higher initial investment through improved operational efficiency and increased revenue generation.

Maintenance Cost Reduction Strategies: Regular Maintenance and Preventive Approaches

Systematic maintenance planning based on equipment monitoring and operational data optimizes maintenance intervals and procedures. Preventive maintenance programs typically reduce maintenance costs by 25-40% compared to reactive approaches while improving equipment availability. The planned maintenance activities minimize production disruptions and extend equipment life.

Condition-based maintenance strategies utilize real-time equipment data to optimize maintenance timing and scope. These approaches typically extend component life by 20-30% while reducing maintenance frequency by 15-25%. The data-driven maintenance optimization ensures resources are deployed where they provide maximum benefit.

Performance Monitoring and Adjustment: Ensuring Optimal Operation

Continuous performance monitoring enables real-time optimization of operational parameters to maintain peak efficiency. The monitoring systems track production capacity, energy consumption, and product quality, providing data for operational adjustments. This continuous optimization typically improves overall efficiency by 8-12% while reducing operating costs.

Automated adjustment systems maintain optimal performance despite changing material characteristics and operating conditions. These systems adapt crushing parameters to maintain product quality while minimizing energy consumption and wear. The automated optimization reduces operator intervention requirements while ensuring consistent performance.

Energy Efficiency Ratio Evaluation for Jaw Crushers

Energy efficiency evaluation provides critical insights into operational economics and environmental performance. Modern jaw crushers typically achieve specific energy consumption of 0.8-1.2 kWh per ton of processed material, representing significant improvements over previous generations. This efficiency directly impacts operating costs and environmental footprint.

The evaluation of energy efficiency considers multiple factors including motor efficiency, power transmission losses, and crushing process efficiency. Advanced monitoring systems provide detailed energy consumption data that enables optimization and identifies improvement opportunities. This comprehensive approach ensures optimal energy utilization throughout the equipment lifecycle.

Energy Consumption Monitoring and Analysis Tools

Advanced energy monitoring systems provide detailed insights into power consumption patterns and efficiency trends. These systems typically identify energy saving opportunities of 10-20% through operational optimization and equipment adjustments. The continuous monitoring ensures optimal energy utilization and identifies performance degradation.

Energy analysis tools correlate power consumption with production output and material characteristics, enabling efficiency optimization. These tools typically identify optimal operating parameters that minimize energy consumption while maintaining production requirements. The data-driven approach ensures continuous improvement in energy efficiency.

Energy Efficiency Improvement Technologies: Variable Frequency Drives and High-Efficiency Motors

Variable frequency drives optimize motor operation by matching speed to load requirements, typically reducing energy consumption by 15-25%. These systems also provide soft-start capabilities that reduce mechanical stress and electrical demand during startup. The improved control enhances overall system efficiency and reliability.

Premium efficiency motors incorporating advanced materials and design features reduce energy losses by 3-8% compared to standard efficiency models. These motors maintain high efficiency across a wide load range, ensuring optimal performance under varying operating conditions. The combination of efficient motors and advanced control maximizes energy efficiency.

Relationship Between Energy Efficiency and Production Costs

Energy consumption typically represents 40-60% of total operating costs for jaw crushers, making efficiency improvements particularly valuable. Each 10% improvement in energy efficiency reduces operating costs by 4-6%, providing significant economic benefits. This relationship emphasizes the importance of energy efficiency in equipment selection and operation.

The economic analysis of energy efficiency improvements considers both capital investment and operational savings. Typical energy efficiency upgrades demonstrate payback periods of 12-24 months through reduced energy costs. This economic performance makes energy efficiency improvements attractive investments with strong returns.

Energy Management Strategies: Optimizing Operation Timing and Loading

Strategic operation scheduling maximizes energy efficiency by utilizing off-peak electricity rates and optimizing equipment loading. These strategies typically reduce energy costs by 15-25% without affecting production output. The operational optimization also reduces peak demand charges and improves overall energy utilization.

Load management strategies ensure optimal equipment loading that maximizes energy efficiency while maintaining production requirements. These approaches typically improve energy efficiency by 8-12% through better load matching and reduced idle operation. The comprehensive energy management ensures optimal economic and environmental performance.

User Case Studies: Practical Applications of High-Efficiency, Low-Maintenance Solutions

Real-world applications demonstrate the practical benefits of selecting appropriate jaw crushers based on specific operational requirements. These case studies provide valuable insights into actual performance, maintenance requirements, and economic benefits. The analysis of successful applications helps guide equipment selection and operational practices.

The case studies cover various industries and applications, highlighting different aspects of performance and maintenance optimization. Each case provides specific data on performance improvements, cost reductions, and operational benefits. This practical information helps validate theoretical considerations and provides guidance for similar applications.

Case Study 1: Successful Equipment Selection in Mining Operations

A large mining operation implemented high-efficiency jaw crushers with advanced automation features, achieving 22% increased throughput while reducing energy consumption by 18%. The installation reduced maintenance requirements by 35% through improved wear protection and automated lubrication systems. The comprehensive approach delivered payback within 24 months through operational improvements.

The operation documented specific performance metrics including reduced downtime, lower maintenance costs, and improved product quality. These improvements directly contributed to increased production capacity and reduced operating costs. The case study provides valuable insights for similar mining applications considering equipment upgrades.

Case Study 2: Long-Term Benefit Analysis in Construction Materials Industry

A construction materials producer documented five years of operational data showing 40% reduction in maintenance costs and 25% improvement in energy efficiency. The advanced jaw crushers maintained consistent performance throughout the period while requiring minimal major repairs. The long-term analysis demonstrated significant economic benefits from the equipment investment.

The analysis included detailed cost tracking and performance monitoring that validated the economic benefits. The operation achieved improved product consistency and reduced environmental impact through lower energy consumption. The comprehensive documentation provides compelling evidence for the economic benefits of advanced crushing technology.

Case Study 3: Efficient Crushing Solutions in Road Construction

A road construction project utilized mobile jaw crushers with advanced efficiency features to process various materials on-site. The operation achieved 30% faster processing times and 20% lower fuel consumption compared to conventional equipment. The mobility and efficiency combination enabled cost-effective material processing directly at the construction site.

The project documented specific benefits including reduced transportation requirements, improved material quality, and lower environmental impact. The efficient operation contributed to project schedule adherence and cost control. The case study demonstrates the value of advanced crushing technology in construction applications.

Case Summary: Key Success Factors and Lessons Learned

The analysis of multiple case studies reveals common success factors including proper equipment selection, comprehensive maintenance planning, and continuous performance optimization. These factors consistently contribute to successful outcomes across different applications and industries. The lessons learned provide valuable guidance for future equipment selection and operation.

The successful applications demonstrate the importance of considering both technical performance and economic factors in equipment selection. The comprehensive approach ensures optimal results that meet operational requirements while maximizing economic benefits. These insights help guide decision-making for similar applications and operational scenarios.

Future Trends: Smart and Automated Jaw Crusher Development

The future of jaw crusher technology focuses on increased automation, improved efficiency, and enhanced connectivity. These developments aim to further reduce operational costs while improving performance and reliability. The integration of advanced technologies transforms crushers into intelligent systems that optimize their own operation and maintenance.

Emerging technologies including artificial intelligence, machine learning, and advanced sensors enable new levels of performance optimization and predictive maintenance. These technologies provide unprecedented insights into equipment condition and performance, enabling proactive maintenance and continuous improvement. The ongoing technological advancement ensures continued improvement in crushing technology.

Application Prospects of Intelligent Control Systems

Advanced control systems incorporating artificial intelligence and machine learning algorithms enable autonomous optimization of crushing parameters. These systems continuously adapt to changing material characteristics and operational requirements, maintaining optimal performance without operator intervention. The intelligent controls typically improve efficiency by 15-25% while reducing operator workload.

The integration of smart adjustment systems with overall process control enables comprehensive optimization of crushing operations. These systems coordinate with upstream and downstream equipment to maximize overall system efficiency. The advanced control capabilities represent the future of crushing technology and operational management.

Automated Maintenance and Remote Monitoring Technologies

Remote monitoring systems enable continuous equipment supervision from anywhere in the world, providing real-time insights into performance and condition. These systems typically reduce response times for maintenance issues by 60-80% while improving repair accuracy. The remote capabilities also enable expert support without requiring physical presence.

Automated maintenance systems perform routine maintenance tasks without human intervention, reducing labor requirements and improving consistency. These systems typically increase maintenance efficiency by 40-60% while ensuring proper procedures are followed. The automation of maintenance activities represents a significant advancement in equipment management.

Role of Artificial Intelligence in Crushing Optimization

Artificial intelligence algorithms analyze operational data to identify optimization opportunities and predict maintenance needs. These systems typically identify efficiency improvements of 10-20% through operational adjustments and process optimization. The predictive capabilities enable proactive maintenance that prevents unexpected failures and reduces downtime.

Machine learning systems continuously improve their performance through data analysis and experience, enabling increasingly effective optimization. These systems adapt to specific operational conditions and material characteristics, providing customized optimization for each application. The artificial intelligence capabilities represent the cutting edge of crushing technology development.

Jaw Crusher Innovation from a Sustainable Development Perspective

Sustainable development considerations drive innovation in energy efficiency, material usage, and environmental impact. Modern crushers incorporate recycled materials in construction and design for disassembly and recycling at end of life. These approaches reduce environmental impact throughout the equipment lifecycle while maintaining performance and reliability.

The focus on sustainability also drives development of more efficient processes that reduce energy consumption and environmental impact. These innovations typically improve environmental performance while reducing operating costs, creating economic and environmental benefits. The sustainable development perspective ensures continued improvement in crushing technology that meets future requirements.