Why Impact Crushers are the Superior Choice for Asphalt Millings (RAP) Recycling?

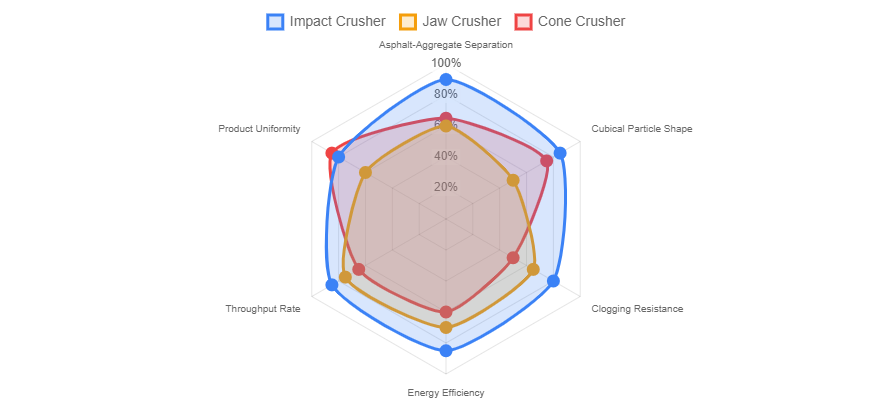

This article delves into the specific reasons why impact crushers have become the preferred machinery for processing Recycled Asphalt Pavement (RAP), highlighting their unique advantages over other crushing technologies like jaw or cone crushers in this critical recycling application.

Understanding the Unique Challenges of Asphalt Millings

Selecting the right equipment begins with a thorough understanding of the material's inherent properties. Asphalt millings present a distinct set of challenges that not every crusher can handle effectively, making material characteristics the first critical consideration.

Recycled Asphalt Pavement possesses a composite structure where aged asphalt binder is firmly attached to aggregate particles.

This unique composition means the crusher must break apart a flexible, sticky matrix rather than just brittle rock, requiring a specific type of fracturing energy.

This combination creates a material with high flexibility and a tendency to stick, leading to potential clogging within machinery.

The tackiness of the asphalt can cause material to build up on conveyor belts, crusher walls, and screens, which can halt production and require labor-intensive cleaning.

The ultimate goal of processing is to produce a clean, well-graded aggregate with a specific particle shape for reuse.

The value of the final product is determined by how well the old asphalt is removed from the original aggregate, leaving a clean, angular particle that can bind effectively with new asphalt cement.

Operators face constant pressure to achieve high processing rates while maintaining strict control over operational expenses.

Economic viability in RAP recycling hinges on processing large volumes of material quickly and with minimal wear part replacement costs, making machine efficiency paramount.

The Perfect Match Between Impact Crushing Principle and RAP Characteristics

The operational mechanics of an impact crusher are uniquely suited to overcome the challenges posed by RAP. Its fundamental design and crushing action provide targeted solutions for breaking down and liberating the valuable aggregate within the asphalt matrix.

A high-speed rotor hurls material against impact plates, effectively breaking apart the asphalt binder.

This kinetic energy impact is far more effective at shattering the brittle asphalt coating and liberating the aggregate than the slow compression force exerted by a jaw crusher.

This violent impact promotes a natural liberation effect, efficiently separating the aggregate from the old asphalt coating.

The high-energy collisions within the crushing chamber ensure a thorough and clean separation, which is essential for producing high-quality recycled aggregate.

The process is selective, maximizing the yield of high-quality, reusable aggregate while minimizing waste.

Impact crushing tends to break the material along its natural grain boundaries, preserving the integrity of the hard aggregate and discarding the unwanted asphalt coating.

Many modern impact crushers feature built-in screening systems, allowing for real-time control over the final product size.

This integrated design, often seen in models like the APPH series, allows for immediate recirculation of oversize material, creating a closed-circuit operation on a single chassis and ensuring precise gradation control.

Unmatched Advantages in Final Product Quality

The quality of the output material is paramount, as it directly influences the performance of the new asphalt mix. The cubical grains produced are highly valued for their ability to interlock, providing superior stability and resistance to deformation under heavy traffic loads.

The impact crushing action naturally produces a high percentage of cubical particles, which enhances the structural integrity of new asphalt.

Cubical particles interlock tightly under compaction, creating a stable skeleton within the asphalt mix that resists rutting and deformation, a common failure mode in roads.

These freshly fractured surfaces are clean and free of excess asphalt, ensuring a strong bond with new binding agents.

A clean aggregate surface is critical for the new liquid asphalt cement to properly adhere, which directly translates to the longevity and durability of the repaved road.

The technology allows for precise control over the particle size distribution, enabling producers to meet stringent grading specifications.

By adjusting the rotor speed, the gap between the blow bars and impact plates, and the type of rotor used, operators can fine-tune the crusher's output to match a specific recipe or project requirement.

A key benefit is the low generation of fine dust, which maximizes the yield of commercially valuable product fractions.

Unlike compression crushers which can create excessive fines through attrition, impact crushers fracture the material cleanly, ensuring more saleable product and less waste.

Specific Designs to Combat Clogging and Adhesion

Manufacturers have developed several innovative features to address the sticky nature of RAP. These design elements are crucial for maintaining continuous operation and preventing costly downtime associated with material build-up and blockages.

Open rotor designs are often employed to prevent material from accumulating and causing imbalances during operation.

An open rotor structure allows smaller, already-sized material to pass through quickly, reducing the residence time of sticky asphalt inside the chamber and minimizing the chance of build-up.

The ability to adjust the rotor speed and the gap between impact elements allows operators to fine-tune the crusher for different material consistencies.

For very tacky RAP, a higher rotor speed and a larger gap might be used to impart more energy for breaking and to reduce the likelihood of plugging the machine.

Special wear materials and designs can generate sufficient heat to reduce the tackiness of the asphalt, mitigating adhesion issues.

The friction generated from crushing can slightly heat the blow bars and impact plates, making the asphalt less sticky and less likely to cling to metal surfaces.

Easy access for maintenance and cleaning is a critical design feature, enabling quick removal of any accumulated material.

Hydraulic opening mechanisms for the crusher housing and easy-access doors are standard on modern machines, allowing for rapid inspection and clearing of any potential clog without the need for major disassembly.

Operational Economy and Return on Investment Analysis

Choosing an impact crusher for RAP recycling is an investment that pays dividends through lower operating costs and higher product value. The economic argument extends beyond the initial purchase price to encompass the total cost of ownership over the machine's lifespan.

A single impact crusher can often perform both crushing and preliminary shaping, reducing system complexity.

This eliminates the need for additional downstream crushing stages, such as a cone crusher for further reduction, simplifying the entire plant layout and reducing capital expenditure.

Lower energy consumption paired with higher throughput rates leads to a reduced cost per ton of processed material.

Impact crushers are generally more energy-efficient for processing non-abrasive materials like RAP compared to compression-based crushers, directly lowering electricity costs.

Reduced need for downstream screening and shaping equipment saves on both investment and footprint.

Because the impact crusher produces a well-shaped product in a single pass, the requirements for subsequent shaping crushers are often minimized or eliminated.

Quick-change wear part designs are instrumental in maximizing machine uptime and productivity.

Modern blow bar retention systems allow for safe and fast replacement, turning a hours-long maintenance task into one that takes minutes, which is crucial for high-volume recycling operations.

Building an Impact Crusher-Centric RAP Recycling Plant

To fully leverage the potential of an impact crusher, it must be integrated into a well-designed system. A holistic plant design ensures that the crusher receives consistent, prepared feed and that the final product is properly sized and classified.

The critical role of front-end pre-screening and magnetic separation cannot be overstated.

A scalping screen removes fine dirt and undersize material before it ever reaches the crusher, while a powerful magnet extracts rebar and other metallic contaminants that could damage the rotor.

The impact crusher is configured as the core crushing unit in the heart of the processing line.

Its position is strategic, taking pre-sized feed from a primary jaw crusher or directly from a screen and transforming it into the final product gradation.

Subsequent screening and size classification processes are designed for efficiency.

After crushing, the material is sent to a series of vibrating screens to be separated into precise product fractions, such as base course or asphalt binder course aggregates.

Dust control and environmental compliance are key considerations in modern plant design.

Enclosing transfer points and utilizing baghouse filter systems are essential for containing dust, protecting the environment, and ensuring the operation meets all regulatory standards.