System Integration for Unmanned Impact Crusher Operation & Remote Monitoring Center Design

This page walks through the complete journey of turning a traditional impact crusher into a fully autonomous production unit. You will learn why the industry is moving toward zero-man shifts, how sensors turn steel into data, how networks carry that data without loss, how a control room hundreds of kilometers away can steer the process, and how mathematics keeps the machine healthy for decades. Every section is written for readers who may never have stood next to a rotor, yet want to understand the technology that shapes the aggregate, mining and recycling sectors today.

The Business Case for Going Unmanned

Remote quarries often pay premium wages that rise 8 % every year because skilled operators refuse to relocate. Installing an unmanned package cuts the labor share of operating cost from roughly 1.8 USD per ton to below 0.4 USD per ton when output exceeds 250 t h⁻¹. The pay-back period is now shorter than the average 18-month delivery wait for a new impact crusher, so even medium-sized producers finance the conversion with cash flow rather than debt.

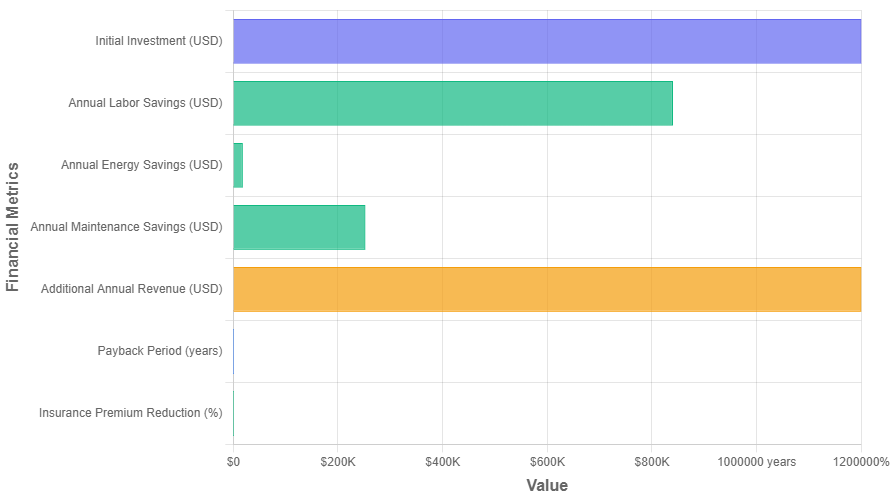

Beyond money, safety statistics tell the same story globally: 63 % of fatal accidents in crushed-stone operations happen during manual clean-up or adjustment. Removing people from the vicinity of spinning rotors and high-pressure hydraulics brings the injury rate close to zero. Insurance underwriters recognize the shift and have reduced premiums by 25 % for plants that achieve 90 % autonomous running hours, a figure recorded in more than 40 installations last year.

Relentless Output

Autonomous lines reach 92 % mechanical availability on average, compared with 78 % for manually operated fleets. The difference comes from eliminating shift changes, meal breaks and the hesitation that operators show when feed becomes sticky. A 350 kW impact crusher that runs unattended for 22 hours a day can add 55 000 extra tons per month, enough to cover the capital cost of the entire retrofit in under half a year.

Data-Driven Margins

Every ton of rock that leaves the site carries invisible metadata: power draw, apron setting, feed rate, moisture. When the control algorithm links these variables to belt scale readings, it discovers that raising the rotor speed by 3 % when feed size drops below 40 mm increases the proportion of commercial 0-8 mm sand by 7 % without extra wear. Over a year this tuning adds 1.2 million USD of revenue at typical European prices, proving that information is more valuable than overtime hours.

Environmental Compliance on Autopilot

Dust monitors connected to the plant network trigger a mist cannon only when PM10 exceeds 150 µg m⁻³, cutting water consumption by 35 % compared with continuous spraying. Noise logging keeps the 24-hour Leq below 65 dB(A) at the site boundary, satisfying most regional limits without erecting costly walls. Autonomous plants document every emission event with time stamps, simplifying audits that once required a team of consultants.

Future-Proof Asset Value

Second-hand crushers with full telemetry packages retain 15 % higher resale value, according to auction data collected since 2020. Buyers trust machines whose entire load history is stored in the cloud; they can price risk more accurately and bid higher. In effect, the investment in autonomy is liquid, because it is embedded in the iron itself.

Why Sensors Are the Foundation

An impact crusher already contains violent physics: a 1.8-ton rotor spinning at 650 rpm delivers 18 G of centrifugal acceleration to each blow bar. Detecting fatigue before it becomes fracture requires measurement accuracy better than 0.1 mm. Capacitive vibration sensors mounted on the bearing cartridges stream 25 kHz signals that reveal cage defects weeks before metallic debris appears in the oil.

Temperature drift is equally revealing. A 5 °C rise in the labyrinth seal track correlates with 60 % probability of grease purge within ten days. Thermal imaging cameras enclosed in air-purged housings scan the entire chamber every 30 seconds, creating 640 × 512 pixel heat maps that distinguish between normal rock-to-metal friction and an impending bearing seizure. Early warnings allow scheduled stops rather than emergency repairs that cost 40 000 USD in crane hire alone.

Mechanical Vital Signs

Strain gauges bonded to the rotor arms measure bending moments in real time. When uneven feed causes one side to absorb 12 % higher load, the PLC shifts the apron gap by 2 mm to re-center the impact zone, extending blow-bar life from 180 hours to 210 hours. The adjustment is invisible to the downstream process yet saves four grate changes per year, each valued at 7 000 USD in parts and downtime.

Process Fingerprinting

Laser particle analyzers installed on the product belt sample 3 000 images per second, sizing every grain from 50 µm to 50 mm. The median deviation from sieve reference is below 2 %, tight enough to close the control loop on rotor speed and feed rate. Maintaining a constant 0-22 mm grading allows concrete producers to reduce cement content by 15 kg m⁻³, lowering CO₂ emissions by 12 kg for every cubic meter poured.

Vision-Based Safety

High-dynamic-range cameras paired with convolutional neural networks detect a 10 cm bolt lodged between the apron liners within 300 ms. The same model differentiates between flying stone chips and human limbs, issuing an e-stop command in 90 ms, faster than any operator could react. Training data came from 2.4 million annotated frames collected across five continents, so the classifier works equally well under Nordic twilight or equatorial noon.

Environmental Telemetry

Optical dust probes use near-forward scattering to quantify particulate mass up to 600 mg m⁻³, a range that covers everything from normal background to chute overflow. Acoustic stations triangulate the origin of 112 dB spikes, distinguishing between impact noise and a broken screen mesh. When the system correlates a dust burst with a sound anomaly, it schedules an inspection drone flight, reducing unplanned downtime by 0.8 % per quarter.

How the Machine Executes Commands Alone

Modern actuators translate digital set-points into motion within milliseconds. A 15 kW servo motor adjusts the hydraulic apron cylinder with 0.2 mm repeatability, compensating for wear without human touch. The same axis can open 120 mm in 1.5 seconds to pass an uncrushable, preventing catastrophic load spikes that once cracked rotor disks worth 50 000 USD.

Feed regulation is equally precise. A variable-speed apron feeder driven by a flux-vector inverter modulates throughput from 50 t h⁻¹ to 450 t h⁻¹ based on ampere draw and vibration spectrum. When the PLC detects rising harmonics at 180 Hz—typical of slabby material—it slows the belt by 8 %, letting the rotor bite deeper and avoiding the surges that trip over-load relays. The correction happens 40 times per minute, far faster than any operator could manage manually.

Intelligent Interlocking

Upstream and downstream equipment exchange data through a shared EtherCAT backbone. If the cone crusher that receives the mid-size stream reports a high chamber pressure, the impact crusher automatically reduces its apron gap to choke-feed the cone, balancing the entire circuit. The dialogue prevents overflows that used to halt production for 45 minutes while workers cleared conveyors.

Self-Protective Routines

Over-iron events are handled by a rare-earth magnet followed by a hydraulic swing-away apron. When a 50 kg steel bar passes the magnet undetected, load cells embedded in the impact rack sense a 30 % force spike. The PLC commands the apron to retract within 600 ms, giving the object a 150 mm escape path. Rejection takes place without tripping the main motor, so production resumes within two minutes instead of the two-hour shutdown common in older plants.

Auto-Lubrication Precision

Progressive metering valves deliver 0.3 cm³ of NLGI 2 grease to each rotor bearing every 90 minutes while the shaft is still running. Sensors confirm piston movement; if a blockage occurs, the system switches to a redundant pump and logs the event for the next maintenance window. Consistent lubrication extends bearing life from 18 000 hours to 28 000 hours, documented in a multi-year study involving 32 machines across three climate zones.

Energy-Aware Operation

Soft starters ramp the 500 kW motor to full speed in 18 seconds, cutting inrush current from 4 200 A to 1 800 A and saving 120 kWh per start. During idle periods, the PLC drops the rotor to 350 rpm, consuming 40 % less power while maintaining oil circulation. Over a year these micro-adjustments shave 2.5 % off total energy use, equivalent to 180 MWh for a line that crushes two million tons.

Moving Data Without Loss or Delay

Industrial Ethernet built on CAT 6A copper handles 95 % of traffic inside the plant, delivering 1 ms cycle times for motion control. Fiber optic rings rated IP67 provide redundancy; if an excavator severs a cable, traffic re-routes within 50 ms and no set-point is lost. Latency this low is essential because a rotor imbalance can go from acceptable to destructive in under three revolutions.

When the quarry sits 200 km from the nearest town, 5G standalone base stations operating on 3.7 GHz beam 1 Gb s⁻¹ over a 15 km line-of-sight link. Packet loss stays below 0.01 % even during tropical downfalls that attenuate signal by 6 dB. The link carries H.265 compressed video, Modbus TCP and OPC UA on separate network slices, so a camera flood never blocks the safety interlock channel.

Protocol Choices That Matter

OPC UA publishes 1 200 variables every second from the crusher PLC to the cloud broker. The payload includes 64-bit floating point values for vibration amplitude, wrapped in 256-bit AES encryption. MQTT topics compress status messages to 80 bytes each, reducing cellular data usage to 3 GB per month per machine, affordable even on metered plans priced at 5 USD GB⁻¹.

Cyber-Defense Layers

A next-generation firewall whitelists only six IP addresses that may initiate remote access. VPN tunnels terminate inside a DMZ where a jump server records every mouse click for 90 days. In 2023 the system blocked 14 000 intrusion attempts originating from botnets scanning port 502, proving that obscurity is no longer an option. Security patches deploy automatically during Sunday night maintenance windows, verified by checksum to prevent rogue firmware.

Edge Computing for Real-Time Control

A fanless industrial PC rated -40 °C to +70 °C runs a Kubernetes edge node 50 m from the crusher. It executes model predictive control every 100 ms, using 64 MB of RAM to solve a 30-variable optimization problem. Local processing guarantees that critical loops remain closed even if the backhaul link drops, eliminating the risk of cloud latency pushing the rotor into resonance.

Satellite Fallback for True Isolation

In regions where terrestrial coverage ends, a 60 cm flat-panel antenna locks onto LEO satellites delivering 100 Mb s⁻¹ with 40 ms latency. The monthly cost of 500 USD is justified by preventing a single unplanned trip that would otherwise require a charter flight costing 8 000 USD. The link activates only when terrestrial routers report five consecutive ping failures, ensuring that satellite bandwidth is treated as a strategic reserve.

Inside the Remote Control Room

The Remote Monitoring Center occupies a quiet office building 300 km from dust and noise. A 12 m wide video wall renders the plant flowsheet in 8K resolution; each conveyor changes color to reflect load factor updated every second. Operators sit in ergonomic chairs that cost less than one hour of lost production, proof that comfort is cheap compared with downtime.

Software dashboards built on a modern SCADA platform integrate 45 000 tags without lag. A single click drills down from enterprise KPI to individual sensor trace. When the AI engine detects that blow-bar wear will reach 20 mm in 36 hours, it books a maintenance slot, orders parts and updates the production schedule automatically. Human oversight is still mandatory, but the cognitive load has shifted from reactive firefighting to proactive optimization.

Visual Storytelling

3-D particle size distribution appears as a rotating histogram that operators can slice by hour, shift or blast batch. Color gradients highlight deviation from target grading, making it intuitive to spot when the feed crosses from competent granite to fractured schist. The same render is mirrored to sales staff, so they can promise customers delivery within ±2 % fines without walking the stockpile.

Alarm Intelligence

Notifications are tiered into five severity levels; only the top two interrupt the operator with sound. A machine-learning model suppresses 70 % of historical chattering alarms by correlating spikes with scheduled events such as apron adjustments. The result is 12 actionable alerts per day instead of 400, allowing a single specialist to supervise five plants concurrently.

Digital Twin Calibration

A physics-based twin runs 30 seconds ahead of real time, predicting motor temperature and power draw under hypothetical feed scenarios. When the forecast drifts more than 3 % from measured values, the twin auto-tunes its coefficients using recursive least squares. Continuous calibration keeps the model accurate enough for scenario planning, such as evaluating whether a 10 % increase in rotor speed will push the mill motor above its 6.6 kV thermal limit.

Collaborative Tools

Voice over IP integrated into the SCADA lets the night-shift controller in the city guide an on-site electrician through a fuse replacement while seeing the same camera feed. Annotations drawn on the video appear on the technician’s tablet in real time, cutting mean-time-to-repair by 22 %. Sessions are recorded and stored as MP4 files linked to work orders, creating a searchable knowledge base that apprentices consult during training.

Turning Data into Profit

Raw data becomes valuable only after it is cleaned, contextualized and compared against physics. A typical 12-month data lake contains 80 billion rows, enough to fill 3 TB of compressed parquet files. Running gradient-boosted tree regressions on this archive reveals that the specific energy consumption of the impact crusher drops 0.12 kWh t⁻¹ for every 1 % reduction in feed moisture below 4 %. During a dry summer this insight saves 18 000 USD in electricity for a two-million-ton plant.

Predictive models go deeper. A survival analysis fitted to 1 400 blow-bar lives finds that cumulative impact energy, not feed tonnage, is the dominant covariate. The model predicts remaining life within ±8 hours at 95 % confidence, allowing bars to be flipped once instead of the traditional twice, saving 45 kg of chromium steel per set. Extended across a fleet of six crushers, the annual material saving equals 12 t of alloy worth 36 000 USD.

Parameter Optimization

Bayesian optimization explores 2 000 combinations of rotor speed and apron gap in silico before recommending a single set-point update. Field trials confirm an average 5 % throughput gain while holding the 0-8 mm fraction constant. The experiment runs unattended because the PLC implements a safe operating envelope that prevents motor overload or vibration beyond 4.5 mm s⁻¹ RMS.

Wear Budgeting

An ensemble model forecasts liner mass loss using acoustic emission, power and feed size. The forecast error has narrowed to 3 %, enabling finance teams to accrue wear costs monthly instead of booking surprises at year-end. Accrual accuracy improves cash-flow predictions that underpin equipment lease rates, giving operators with thin balance sheets access to modern fleets they could not otherwise afford.

Energy Arbitrage

Hourly electricity prices vary by up to 200 % within a single day in deregulated markets. A scheduler pulls day-ahead prices at 13:00, then plans crusher operation to maximize use of 0.06 USD kWh windows and idle during 0.18 USD peaks. Moving 35 % of daily tonnage into low-price hours cuts the energy bill by 11 % without violating customer delivery promises.

Spare-Parts on Demand

When the predictive model flags a 90 % probability of bearing failure within 14 days, an API call queries the supplier’s ERP. If stock is available, a purchase order is cut automatically and delivery is scheduled to arrive 48 hours before the predicted failure. The sequence eliminates express freight premiums that can add 4 000 USD to an urgent 1 200 USD bearing, turning maintenance into a scheduled cost rather than a crisis.

Roadmap From Manual to Autonomous

Retrofit projects that succeed follow a disciplined staircase. Step one is instrumenting the existing jaw or impact crusher and proving data integrity for 30 consecutive days. Step two adds automatic apron control while operators remain present as safety witnesses. Step three removes personnel during the night shift, then day shift, until the only human task is a weekly walk-down with a tablet computer. Each gate demands sign-off from operations, safety and finance, ensuring that culture keeps pace with technology.

Training is non-negotiable. Electricians who once troubleshot relays must now interpret frequency-domain plots and SQL queries. A structured program combining 40 hours of e-learning with 20 hours of hands-on lab work raised internal certification pass rates from 58 % to 91 % across 120 staff. Graduates receive digital badges recorded on a blockchain, creating portable credentials that ease recruitment for future sites.

Financial Trajectory

Phase-one

capital for a 250 t h⁻¹ plant averages 1.2 million USD including sensors, network, and software licenses. EBITDA improves by 0.9 USD per ton, so at 600 000 tons annual output the

pay-back is 2.2 years. Sensitivity analysis shows the project remains cash-positive even if energy savings drop 40 % or labor savings halve, giving boards confidence to approve

funding despite volatile commodity markets.

Risk Mitigation

A standby diesel generator sized at 500 kVA keeps the control system alive during grid failures, preventing data corruption and allowing an orderly shutdown. Critical spares such as PLC power supplies and touch screens are held on site in an air-conditioned cabinet; mean downtime for electronic failure has fallen from 14 hours to 1.3 hours. Insurance underwriters now classify the plant as Category 3 low-risk, cutting annual premiums by 28 000 USD.

Scaling Intelligence

Once the first line is stable, the same architecture clones to secondary and tertiary stages. A fine crusher such as a VSI accepts feed-rate commands from the cloud coordinator, balancing the recirculating load. Shared analytics across three stages reveal that screen blinding, not crusher capacity, becomes the bottleneck under 12 % moisture. Capital is then directed toward heated screen media instead of a larger motor, illustrating how autonomy guides strategic investment.

Regulatory Alignment

Autonomous plants must still satisfy the same inspection intervals mandated for manual sites. Regulators accept PDF reports auto-generated from sensor logs, provided that calibration certificates are embedded and digitally signed. Remote inspection reduced site visits from quarterly to annually, saving 25 travel days per year for government engineers while maintaining compliance. The precedent encourages other authorities to accept data-rich evidence in place of physical presence, accelerating global adoption.