Complete Guide to Rust Prevention Maintenance for Impact Crushers in Humid Regions: Best Practices and Compliance Strategies

Impact crushers operating in humid environments face significant challenges from accelerated corrosion that can compromise structural integrity and operational efficiency. This comprehensive guide examines the scientific principles and practical methodologies for protecting these critical machines from the damaging effects of moisture, salt exposure, and environmental contaminants. Through systematic approaches encompassing material selection, protective coatings, operational modifications, and maintenance protocols, operators can significantly extend equipment service life while reducing maintenance costs. The following sections provide detailed technical guidance based on industry standards and proven engineering practices for combating corrosion in challenging environmental conditions.

Analysis of Corrosion Mechanisms in Humid Environments

Humid conditions create ideal environments for electrochemical corrosion processes that attack metal components of impact crushers. When relative humidity exceeds 60%, thin layers of moisture form on metal surfaces, enabling electrochemical reactions that deteriorate structural materials. The presence of oxygen and electrolytes accelerates these reactions, particularly in coastal areas where salt deposits provide highly conductive pathways for corrosion currents. Understanding these fundamental mechanisms is essential for developing effective protection strategies that address the root causes rather than merely treating the symptoms of corrosion damage.

Relationship Between Relative Humidity and Electrochemical Corrosion

The correlation between atmospheric humidity and corrosion rates follows well-established scientific principles that guide protection strategies. When relative humidity surpasses 60%, moisture films become continuous enough to support sustained electrochemical reactions on steel surfaces. At 80% humidity, corrosion rates can increase by 300% compared to dry conditions, with temperature further accelerating these processes. The critical humidity level varies slightly depending on surface contaminants, with salt particles reducing the threshold to as low as 40% relative humidity. Monitoring and controlling environmental conditions around crusher installations helps maintain humidity below these critical thresholds, significantly reducing corrosion progression.

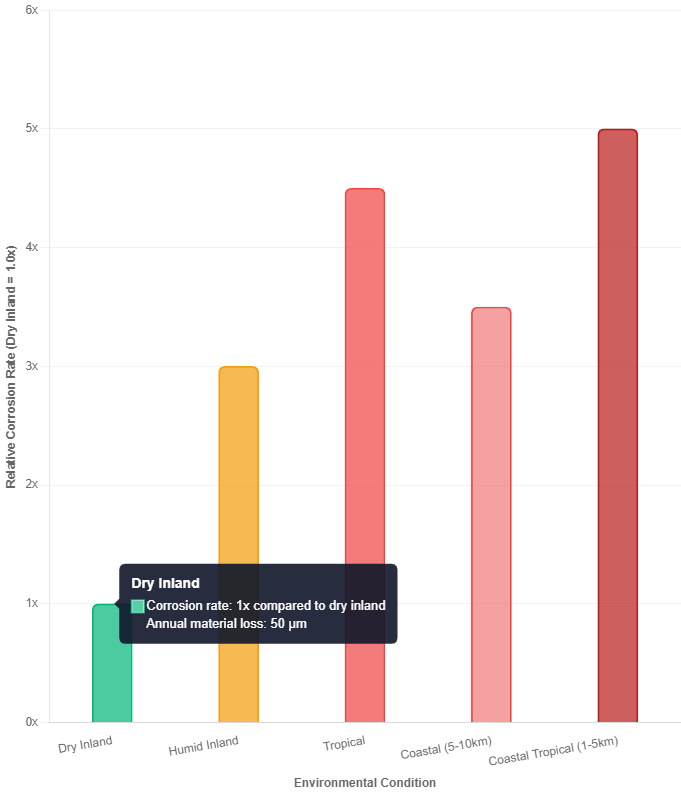

Accelerated Corrosion Effects from Salt Deposition in Coastal Areas

Coastal operations experience dramatically accelerated corrosion due to salt deposition from marine environments. Salt particles, primarily sodium chloride, dissolve in surface moisture to form highly conductive electrolytes that facilitate rapid metal deterioration. Studies indicate that corrosion rates in coastal environments can be 3-5 times higher than inland locations at equivalent humidity levels. The mechanism involves chloride ions penetrating protective oxide layers, creating localized pitting that progresses to structural weakening. Regular washing to remove salt accumulation combined with specialized coating systems provides essential protection for crushers operating within 5 kilometers of coastlines.

Microbiologically Influenced Corrosion in Hot-Humid Conditions

Microbiological activity represents a significant corrosion factor in hot, humid environments where temperatures exceed 25°C and humidity remains above 70%. Bacteria colonies, particularly sulfate-reducing bacteria and acid-producing bacteria, create localized corrosive environments that accelerate metal degradation. These microorganisms produce metabolic byproducts including hydrogen sulfide and organic acids that attack metal surfaces and protective coatings. The problem is particularly prevalent in areas with organic material accumulation or stagnant water. Biocide treatments and regular cleaning protocols help control microbiologically influenced corrosion, preserving equipment integrity in tropical operating conditions.

Preventive Rust Protection Materials and Coating System Selection

Selecting appropriate protective materials and coating systems forms the foundation of effective corrosion prevention for impact crushers operating in humid environments. Modern coating technologies provide multi-layer protection through synergistic combinations of barrier protection, cathodic protection, and chemical resistance. The selection process must consider environmental conditions, operational temperatures, mechanical wear factors, and maintenance accessibility. Proper surface preparation and application techniques significantly influence coating performance, with inadequate preparation reducing protection effectiveness by up to 80% regardless of coating quality.

Comparison of Stainless Steel and Galvanized Component Applications

Stainless steel and galvanized components offer different advantages for various crusher applications in corrosive environments. Stainless steel, particularly grades 316 and 2205, provides excellent corrosion resistance through chromium content that forms passive protective oxide layers. These materials are ideal for high-wear components and areas requiring frequent cleaning. Galvanized steel offers cost-effective protection through zinc sacrificial layers that provide cathodic protection to underlying steel. Hot-dip galvanizing typically provides 50-100 years of protection in rural environments, though this reduces to 20-50 years in coastal locations. The selection depends on specific component requirements, with stainless steel preferred for critical structural elements and galvanizing adequate for secondary components.

Synergistic Protection Mechanism of Zinc-Rich Epoxy Primers and Polyurethane Topcoats

Multi-layer coating systems combining zinc-rich epoxy primers with polyurethane topcoats provide comprehensive protection through multiple mechanisms. The zinc-rich primer offers cathodic protection, sacrificing zinc particles to protect the underlying steel even if the coating is damaged. Epoxy resins provide excellent adhesion and barrier properties, while polyurethane topcoats deliver superior UV resistance and durability against abrasion. This combination typically provides 15-25 years of protection in harsh industrial environments when properly applied to adequately prepared surfaces. The system's effectiveness has been validated through extensive testing including 5,000-hour salt spray tests and weathering simulations equivalent to 20 years of outdoor exposure.

Performance Validation of Nano-Ceramic Coatings in High-Temperature Humid Conditions

Nano-ceramic coatings represent advanced protection technology particularly suited for high-temperature, high-humidity environments where traditional coatings may degrade. These coatings incorporate ceramic nanoparticles that create dense, impermeable barriers with exceptional thermal stability and chemical resistance. Testing demonstrates that nano-ceramic coatings maintain integrity at temperatures up to 400°C while providing corrosion protection equivalent to three times the thickness of conventional epoxy systems. Their hydrophobic properties cause water to bead and run off, reducing moisture contact time and minimizing corrosion initiation. Although approximately 30-40% more expensive than premium conventional coatings, their extended service life and reduced maintenance requirements provide excellent long-term value for crushers operating in extreme conditions.

Specialized Maintenance Strategies for Critical Components

Critical crusher components require targeted protection strategies addressing their specific vulnerability to corrosion in humid environments. The rotor assembly, bearing housings, fastening systems, and hydraulic components each present unique challenges that demand customized solutions. Regular inspection protocols focused on these high-risk areas enable early detection of corrosion initiation, allowing intervention before significant damage occurs. Preventive maintenance schedules should prioritize these components based on their criticality and vulnerability, with protection measures integrated into standard operating procedures.

Sealing Enhancement and Drainage Optimization for Rotor Bearing Housings

Rotor bearing housings represent particularly vulnerable points due to their exposure to both environmental moisture and operational water ingress. Enhanced sealing systems incorporating multiple lip seals, labyrinth passages, and positive-pressure air purging prevent moisture intrusion into bearing chambers. Drainage channels designed with minimum 3% slope ensure complete water runoff, while weep holes positioned at lowest points prevent accumulation. The application of waterproof greases with corrosion inhibitors provides additional internal protection, with re-greasing schedules adjusted for humid conditions. These measures collectively reduce bearing failures by up to 70% in high-humidity operations, significantly improving equipment reliability.

Dacromet Coating Process for Hammer Fixing Bolts

Hammer fixing bolts experience severe corrosion challenges due to their exposure to abrasive materials and moisture. Dacromet coating provides exceptional protection through a zinc-aluminum flake coating process that offers both barrier and cathodic protection. The coating withstands temperatures up to 300°C without degradation, maintaining protection through thermal cycling. Application involves a multi-stage process including cleaning, coating application, curing, and quality verification, resulting in a thin but highly effective protective layer. Bolts treated with Dacromet demonstrate 5-7 times longer service life in humid conditions compared to standard galvanized fasteners, significantly reducing maintenance downtime and replacement costs.

Corrosion-Resistant Alloy Overlay Technology for Crushing Chamber Liners

Crushing chamber liners endure both severe abrasion and corrosive conditions, particularly when processing moist materials in humid environments. Wear-resistant alloy overlays applied through automated welding processes create protective surfaces with both hardness and corrosion resistance. These overlays typically incorporate chromium, nickel, and molybdenum alloys that form stable passive layers while maintaining impact resistance. The process involves applying 3-5mm thick layers to critical wear areas, extending liner life by 40-60% in corrosive applications. Regular inspection and localized reapplication of overlay material maintain protection throughout the liner's service life, optimizing performance between replacement intervals.

Operational Corrosion Control Techniques

Active corrosion control during crusher operation represents a critical aspect of comprehensive protection strategies in humid environments. These techniques complement passive protection methods like coatings and material selection, providing dynamic response to changing conditions. Operational measures include environmental control, chemical treatment, and procedural modifications that reduce corrosion initiation and progression. Implementation requires integration with normal operating procedures and staff training to ensure consistent application and monitoring of effectiveness.

Cathodic Protection System Design for Crusher Frames

Cathodic protection systems provide active corrosion control for crusher frames and other large structural components. Impressed current systems using inert anodes and regulated DC power sources maintain structural steel at protective electrical potentials between -0.85V and -1.1V relative to copper-copper sulfate reference electrodes. These systems are particularly effective for protecting internal surfaces and hard-to-coat areas where traditional coatings may be impractical. Modern systems incorporate automatic potential monitoring and adjustment, maintaining optimal protection levels despite changing environmental conditions. Properly designed cathodic protection can extend structural life by 20-30 years in highly corrosive environments, providing excellent return on investment through reduced maintenance and extended equipment service life.

Integrated Corrosion Inhibitor Addition and Water System Management

Water systems used for dust suppression and equipment cleaning can introduce significant corrosion risks if not properly managed. Corrosion inhibitor addition systems automatically dose treatment chemicals into water supplies, forming protective films on metal surfaces and neutralizing corrosive elements. These systems typically utilize filming amines, oxygen scavengers, or pH control agents tailored to specific water chemistry. Integration with water quality monitoring ensures optimal treatment levels, with automatic adjustment based on flow rates and contamination levels. Proper implementation reduces corrosion rates in water-exposed areas by 70-90%, significantly extending component life while maintaining operational efficiency.

Nitrogen Purging Process for Equipment During Shutdown Periods

Extended shutdown periods present particular corrosion risks as equipment remains stationary in humid conditions. Nitrogen purging displaces oxygen and moisture from internal spaces, creating inert environments that prevent corrosion initiation. The process involves connecting nitrogen sources to equipment enclosures and maintaining slight positive pressure (0.5-1.0 psi) throughout the shutdown period. Oxygen sensors verify maintenance of inert conditions, with automatic nitrogen supplementation triggered if oxygen levels exceed 1%. This method provides superior protection compared to desiccants alone, particularly for complex internal spaces where moisture trapping can occur. Implementation during planned shutdowns of two weeks or longer significantly reduces internal corrosion, particularly in electrical components and precision mechanisms.

Storage and Long-Term Shutdown Maintenance Protocols

Proper storage procedures during extended shutdown periods prevent corrosion damage that often exceeds operational wear. Purpose-built storage facilities with environmental control provide ideal conditions for equipment preservation. For field storage, comprehensive protective measures including encapsulation, desiccant systems, and periodic maintenance prevent deterioration. Documentation and regular inspection ensure maintained protection throughout storage periods, enabling rapid return to service when needed.

Temperature and Humidity Management Standards for Climate-Controlled Storage

Climate-controlled storage facilities maintain optimal preservation conditions through precise environmental management. Standards specify maximum relative humidity of 60% with temperature maintained between 10°C and 25°C to prevent condensation while minimizing thermal cycling. Advanced systems incorporate humidity sensors, automated dehumidification, and temperature control with ±5% stability. Air filtration removes particulate contaminants that could initiate corrosion, while positive pressure prevents infiltration of unconditioned air. These facilities typically achieve corrosion rates less than 10% of those in uncontrolled environments, preserving equipment in near-original condition for extended periods.

Combined Application of VCI Paper and Desiccant Systems

Volatile Corrosion Inhibitor (VCI) paper and desiccant systems provide complementary protection for equipment in storage. VCI papers release protective vapors that form molecular layers on metal surfaces, preventing corrosion initiation without requiring direct contact. Desiccants control humidity within enclosed spaces, typically maintaining levels below 40% relative humidity. The combination provides comprehensive protection, with VCI addressing exposed surfaces and desiccants controlling overall humidity. Calculation guidelines specify desiccant quantities based on enclosure volume and expected storage duration, typically 1kg per cubic meter for six-month protection. Regular inspection and replacement ensure maintained effectiveness throughout storage periods.

Industry Standards and Compliance Management

Adherence to international standards ensures comprehensive corrosion protection through proven methodologies and quality assurance. These standards provide frameworks for material selection, coating specification, application procedures, and maintenance protocols. Compliance documentation facilitates equipment certification and insurance requirements while ensuring consistent protection levels. Regular audit and verification processes maintain standards implementation throughout equipment life cycles.

Coating Selection Guidelines According to ISO 12944-2018 Corrosion Protection Standards

ISO 12944-2018 provides comprehensive guidelines for corrosion protection coating selection based on environmental categories and required durability. The standard categorizes environments from C1 (very low corrosivity) to C5 (very high corrosivity), with specific coating system recommendations for each category. For impact crushers in humid environments, typically C4 or C5 categories apply, requiring coating systems with minimum total dry film thickness of 240-320μm and specific composition requirements. The standard specifies surface preparation standards, application methods, and inspection criteria to ensure proper implementation. Compliance with these guidelines typically ensures 15-25 years of protection before major maintenance, providing predictable lifecycle costs and performance.

Digital Management of Maintenance Records Through CMMS Integration

Computerized Maintenance Management System (CMMS) integration enables comprehensive tracking of corrosion protection activities and performance. These systems document coating applications, inspections, maintenance activities, and environmental conditions, creating complete corrosion management histories. Advanced systems incorporate predictive algorithms that forecast maintenance needs based on historical data and current conditions. Integration with inventory management ensures availability of necessary materials for scheduled maintenance, while mobile access enables real-time data recording during field inspections. Implementation typically reduces unplanned maintenance by 40-60% while extending intervals between major refurbishments, optimizing both protection effectiveness and resource allocation.

Engineering Case Studies and Experience Summary

Practical implementation examples demonstrate the effectiveness of comprehensive corrosion protection strategies in various challenging environments. These case studies provide valuable insights into real-world performance, challenges, and solutions that can inform future projects. Analysis of both successful implementations and less effective approaches helps refine best practices and avoid common pitfalls. The collective experience continues to drive innovation and improvement in corrosion protection methodologies.

Nanocoating Application Results in Tropical Rainforest Project

A major quarry operation in a tropical rainforest environment implemented nano-ceramic coatings on their impact crushers to address severe corrosion issues. Previous conventional coating systems required complete reapplication every 12-18 months due to rapid deterioration. The nano-ceramic coating application, while 35% more expensive initially, demonstrated exceptional durability in the constant high-humidity conditions. After 36 months of operation, the coating maintained 95% integrity with only minor touch-ups required in high-wear areas. The operation achieved 60% reduction in annual maintenance costs and eliminated unplanned downtime related to corrosion damage, demonstrating the long-term value of advanced coating technologies in extreme environments.

Cost-Benefit Analysis of Comprehensive Corrosion Protection in Tropical Regions

Economic analysis of comprehensive corrosion protection programs demonstrates significant financial benefits despite higher initial investments. A detailed study comparing minimal protection versus comprehensive programs showed that while comprehensive programs required 2-3 times higher initial investment, they reduced annual maintenance costs by 40-60% and extended equipment service life by 8-12 years. The net present value analysis demonstrated 25-35% improvement over 15-year equipment life cycles, with payback periods of 2-3 years for the additional investment. These economic benefits combined with improved reliability and reduced downtime make comprehensive corrosion protection programs highly attractive for operations in humid tropical regions.