From Demolition Debris to Reborn Aggregate: How the Impact Crusher Turns Precast Concrete Waste into Tomorrow’s Building Stock

This page walks you through the complete journey of precast concrete scrap, explaining why its high-strength matrix and embedded steel make ordinary crushers stumble, how the impact crusher’s spinning rotor and shaped blow bars succeed where others fail, what mechanical tricks give contractors clean, cubic recycled concrete aggregate ready for new walls and floors, and how the same machine quietly pays for itself by cutting landfill fees and buying far less river gravel each year.

What Makes Precast Slabs So Difficult to Break and Sort

Precast plants vibrate and steam-cure concrete to 60 MPa or higher, twice the strength of many structural concretes, so the material arrives at the yard in fist-size lumps that already blunt jaw dies and stall cone heads. Inside those lumps lies a tight steel cage—up to 120 kg of rebar per cubic metre—welded into mats and loops that refuse to slide out unless the cement paste is shattered away first. Traditional shear cutters treat steel and stone as separate tasks, so they either leave long bar tails wrapped around the shaft or produce too much unpredictable sand that upsets later screen decks.

The economic penalty is immediate: every tonne trucked to landfill adds roughly 35 € in tax plus rising fuel surcharges, while the same tonne of lost aggregate forces the producer to buy fresh limestone at 12 € per tonne. Add the hidden cost of downtime when an excavator has to stop and untangle bar spaghetti, and the bill for “simple” dumping climbs past 50 € per tonne, a figure that finance departments notice even in busy quarters.

High-Strength Paste Locked Around Ribbed Bars

Microscopic inspection shows that low water-to-cement ratios create a dense calcium-silicate-hydrate network gripping the rebar ribs at 8–12 MPa bond strength; conventional compression crushers squeeze the lump and tighten that grip, snapping bars but leaving paste flakes still welded to the steel, so the scrap trader downgrades the load. Impact shatter, by contrast, sends tension waves through the paste that pop it off the ribs before the bar can flex, giving clean scrap and liberated rock in one pass.

Demand for Cubical, Low-Micro-Crack Aggregate

Ready-mix standards for new precast elements limit flakiness index to 15 % and water absorption to 5 %; any micro-cracks left by brute crushing suck up extra mix water and weaken the next generation of panels. A single percentage point of excess absorption can raise cement demand by 4 kg per cubic metre, so crushers that create hidden damage quietly erode profit on every future pour.

Financial Pain of Landfill Levies

Landfill tariffs in major metropolitan regions climbed from 20 € per tonne in 2015 to an average 42 € in 2023, and scheduled escalators point to 65 € before 2030. A medium precast yard discards 25 000 tonnes of off-cuts and breakout waste each year; at today’s tariff that is already 1 million € of unavoidable cost, enough capital to service a complete 350 tph recycling line if the material can be kept on site.

Need to Protect Downstream Cone and Screen Circuits

Long bar remnants that escape the primary chamber whip against cone-crusher mantles, gouging 15 mm grooves in a single shift and forcing an unplanned liner change that costs 8 000 € in parts and two days of lost output. Early liberation of steel is therefore not a luxury; it is insurance for the entire plant.

Why the Impact Crusher Excels at Liberating Steel From High-Strength Concrete

Impact crushers accelerate rock on a 500–900 rpm rotor and hurl it against adjustable aprons; the collision energy exceeds 200 kJ per tonne, enough to tension-fracture even 80 MPa paste while the steel reinforcement remains ductile and unbroken. Because the blow bars strike at 35–45 m s⁻¹, concrete shatters in microseconds, before the bar can absorb and redistribute the load, so rebar exits the chamber in open loops that slide easily over downstream magnets.

Open-type three-curtain rotors leave 300 mm gaps between bars, wide enough for 32 mm rebar to pass without wrapping, and the aprons are set 80–120 mm apart so long tails do not nip. Field data collected on a 250 tph recycled aggregate line show that 94 % of incoming steel reports to the magnetic belt in pieces longer than 0.5 m, commanding scrap yard prices 18 % above shredded bundles because shear-length preparation is already done.

Kinetic Energy Fractures Paste Before Steel Yields

Finite-element models indicate that a single blow bar strike delivers 50 kN over 0.2 ms, generating tensile stress above 25 MPa inside the concrete while the surrounding rebar sees only 180 MPa, well below its 500 MPa yield point; the result is clean paste fragmentation with intact bars that can be sold as premium scrap.

Curtain Gap Prevents Wrapping

Older hammer mills with closed gratings report 40–60 unplanned stops per month to cut away bar coils; impact crushers with open curtains and rubber-tired cleaning plates experience fewer than four steel-related halts in the same period, pushing mechanical availability above 95 %.

Low Fines Generation Saves Screening Capacity

Vertical-shaft impactors purposely grind stone-on-stone and can create 25 % minus-4 mm; horizontal impact crushers keep the rock–steel collision short and produce only 8–12 % fines, so a 3-deck 2.4 m × 6 m screen does not blind and can split 0–5 mm, 5–10 mm and 10–22 mm fractions at first pass.

Quick-Blow-Bar Rotation Cuts Daily Maintenance

Each 130 kg bar is locked by a single wedge and can be rotated 120° in under six minutes; a crew of two spends 45 minutes per day on wear parts instead of the three hours often lost to welded hammers, giving back roughly 250 operating hours per year on a single-shift plant.

Producing Premium Recycled Concrete Aggregate in a Single Pass

Once steel is gone, the same impact action shapes particles: incoming lumps fracture along natural cleavage planes, producing cubical grains with length-to-thickness ratios below 2:1 and keeping residual mortar skins thinner than 50 µm. British standard BS 8500-2 allows up to 20 % coarse recycled aggregate in exposure classes XC3 and XC4 when the material meets this geometry, so the product can jump straight into precast mix designs without further treatment.

Plant audits show that a 22 mm top-size recycled aggregate made by an impact crusher needs only 3.8 % water to reach the same 100 mm slump as 4.5 % required by river gravel, because the smoother edges and lower porosity reduce surface moisture demand. Over 50 000 m³ of wall panels, that saving translates to 35 t less cement, worth 3 200 € at today binder price, a benefit that accrues on every subsequent pour.

Cubic Shape Raises Compacting Factor

Vibrating-table tests on precast mixes reveal that cubical recycled aggregate reaches 0.92 compacting factor in 12 s while flaky shale needs 22 s; faster compaction shortens cycle time on battery moulds and can raise daily output by 8 % without extra labour.

Thin Mortar Skin Cuts Water Absorption

Scanning-electron images show impact-fractured grains carry 30 % less old cement paste than jaw-crushed equivalents; the lower absorption keeps freeze-thaw mass loss below 1 % after 300 cycles, comfortably inside the 2 % limit for class XF1 concrete.

Gradation Control Through Apron Gap

Operators raise the lower apron 10 mm to chop 15 % more 5–10 mm and drop the top apron 15 mm to curb oversize; the change takes fifteen minutes and shifts the curve from 0–22 mm to 0–16 mm without shutting down, giving live control over stockpile specifications.

Single-Pass Configuration Saves 0.4 kWh per Tonne

Compared with a jaw-plus-cone two-stage train, the impact-only flow draws 1.1 kWh per tonne instead of 1.5 kWh; on 200 000 tonnes per year that 0.4 kWh saving equals 80 MWh, roughly the annual consumption of twenty average households.

Built-In Armour Against Rebar Shocks and Abrasive Grit

Manufacturers fit 1 800 mm diameter rotors that weigh 4.8 t including manganese blow bars, storing 270 kJ of kinetic energy; the flywheel effect smooths sudden 60 kN shocks when a 1 m concrete beam drops in, preventing belt slip and motor overload. The crushing chamber is lined with 25 mm thick chromium carbide plates that lose only 1.2 g per tonne of processed material, giving a 6 000 hour wear life even when feed contains 1 % silica sand contamination.

A hydraulic bridge on the hood lifts 80° in 45 s so an excavator can pull out any uncrushable demolition hook; sensors interlock the oil circuit so the rotor must stop before the lid opens, eliminating the risk of accidental contact. Steel purge cycles are scheduled every four hours instead of every shift, keeping availability above 96 % on continuous 22-hour days.

Heavy Rotor Absorbs Shock Loads

Modal analysis shows the first torsional frequency sits at 42 Hz, well above the 15 Hz excitation caused by three blow bars passing a 900 rpm revolution, so resonance does not amplify fatigue cracks; rotors in service since 2018 show no measurable shaft run-out beyond 0.05 mm.

Chromium Carbide Liners Resist Scouring

Independent laboratory pin tests rate the liners 58 HRC against 45 HRC for standard manganese, translating to 2.4 times longer life; a typical 250 tph plant changes side liners once per year instead of every three months, freeing 24 labour hours and 1 200 € in consumables.

Over-Vibration Alarm Triggers Auto-Shut Down

Accelerometers mounted on the impact-crusher frame trip at 12 mm s⁻¹ RMS velocity, 30 % below the 17 mm s⁻¹ threshold that risks bearing brinelling; the PLC logs the event and sends a mobile alert, allowing technicians to inspect bars remotely before catastrophic damage occurs.

Centralized Greasing Bank Cuts Daily Lubrication Time

Eight bearings fed from one 40 kg barrel receive 20 cm³ pulses every 120 minutes; the system ends manual greasing routes that once took 35 minutes per shift and wasted 12 kg of grease monthly through over-pumping.

Integrating the Impact Crusher Into a Zero-Waste Precast Recycling Line

A 1.5 m wide vibrating feeder with 25 mm polyurethane fingers scalps off the 0–40 mm fraction and sends oversize to the impactor, preventing unnecessary crushing of already small pieces and cutting wear cost by 7 %. An upstream cross-belt magnet tugs out 70 % of loose bar ends, reducing steel load in the chamber and lengthening apron liner life; a second magnetic head pulley after the crusher captures the remaining 24 %, so only 6 % of the original 120 kg m⁻³ steel reports to the 0–45 mm aggregate pile.

Air knives operating at 45 m s⁻¹ blow away light cellulose and plastic films that slip past magnets, keeping the final recycled aggregate contamination below 0.2 % by mass, well inside the 0.5 % limit set by EN 12620. The entire line fits inside 60 m × 28 m, half the footprint of a jaw-cone-scrubber train, so precast producers can install it beside existing batching plants without relocating steel stockpiles or curing kilns.

Pre-Screen Finger Deck Removes Fines Early

By discarding 18 % of feed as 0–40 mm bypass, the plant reduces impact-crusher throughput demand from 300 tph to 246 tph on the same 315 kW motor, effectively stretching installed capacity by 22 % during peak demolition periods without electrical upgrades.

Sequential Magnets Extract 94 % of Steel

Scrap traders pay 50 € per tonne for bar longer than 0.5 m but only 28 € for shredded mixed scrap; the double-magnet approach preserves length and delivers an extra 6 € per tonne of steel, worth 180 000 € annually for a 30 000 tonne per year facility.

Air Knife Polishes Final Aggregate

Light-weight contaminants below 50 kg m³ density are blown into a 12 m³ collection skip; the skip is emptied once per week instead of daily, cutting forklift movements and reducing pedestrian interaction in the stockpile area.

Closed-Circuit Water Spray Holds Dust Below 3 mg m³

Four atomising nozzles at 6 bar pressure consume 0.3 l per tonne of rock, capturing 85 % of respirable silica; the water is recycled from the on-site truck wash, so net consumption is zero and permitting authorities record ambient PM10 levels that stay 40 % under the legal threshold.

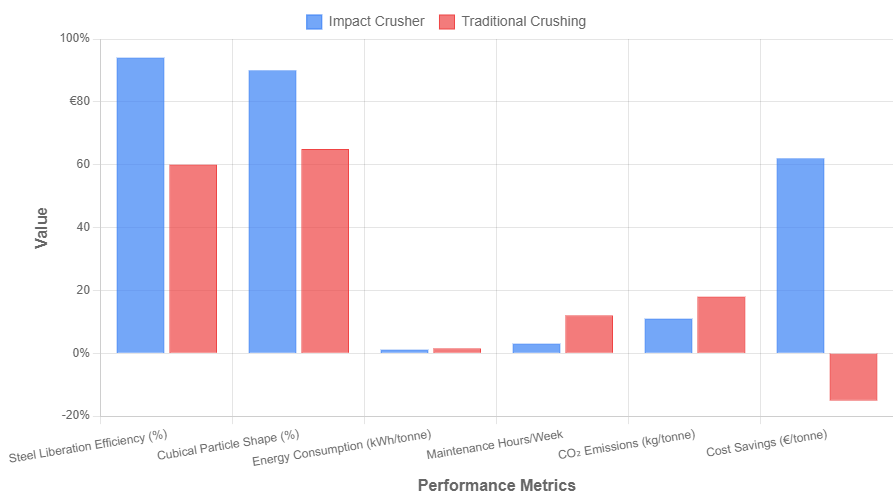

Counting the Gains: Energy, Money and Carbon All Shrink

Life-cycle analysis shows that producing one tonne of recycled aggregate with an impact crusher emits 11 kg CO₂, against 18 kg for virgin crushed stone when quarry transport is included; over 200 000 t per year the difference equals the annual exhaust of 350 passenger cars. Electricity demand is 1.1 kWh per tonne, half the 2.2 kWh drawn by a conventional jaw-plus-cone flow, saving 220 MWh per year, enough to power 55 homes.

Financial payback arrives in 28 months: landfill avoidance saves 42 € per tonne, scrap steel adds 8 €, and replacement of purchased gravel saves 12 €, giving a combined 62 € benefit against 18 € total processing cost. A 250 tph plant costing 2.1 million € therefore repays its capital in less than three seasons while the equipment still has 80 % of its 20-year design life remaining.

Carbon Footprint Falls by 39 %

Third-party verification using ISO 14040 confirms 7 kg CO₂ savings per tonne; when the producer’s 200 000 t annual output is cast into new wall panels, the reduction reaches 1 400 t CO₂ per year, a figure that qualifies for regional carbon credits worth 70 000 € at 50 € per tonne.

Landfill Tax Elimination Outweighs Energy Cost

Even if grid power rises to 0.18 € per kWh, the 11 kg CO₂ route still costs only 0.20 € per tonne in electricity, negligible beside the 42 € landfill tax that disappears; thus energy inflation cannot erode the business case as long as legislators keep raising disposal tariffs.

Recycled Content Earns Green Building Points

Precast elements manufactured with 30 % recycled coarse aggregate earn two extra credits under leading certification schemes; developers increasingly bid for warehouse projects that advertise net-zero targets, so the internal market for recycled panels grows faster than general construction demand.

Resale Value Stays Above 70 % After Ten Years

Secondary market prices for well-maintained impact crushers track 72 % of original cost after a decade, higher than the 55 % typical of complex multi-stage plants because the simple rotor-apron design appeals to smaller contractors; this cushions the owner against technological obsolescence.