Magnetic Separator Configuration for Impact Crushers in Construction Waste Recycling

Every year more than one billion tonnes of concrete, brick and steel are torn out of old buildings and bridges. When this mixed rubble is processed correctly it can replace 70 % of the virgin stone normally quarried for new roads, but only if tramp metal is removed first and the remaining aggregate is crushed to the right shape. This guide explains how horizontal-shaft or vertical-shaft impact crushers work hand-in-hand with magnetic separators to turn demolition waste into a high-value resource. Six technical sections follow the logical flow of a modern recycling plant—from why magnets matter, through machine matching and parameter tuning, to real projects that have already closed the loop between demolition and reconstruction.

The Indispensable Role of Magnetic Separation

Even after manual picking, roughly 0.3 % of the incoming C&D stream is ferrous metal—mainly rebar off-cuts, wire and nails. Left inside the aggregate these fragments shred conveyor belts, dull crusher wear parts and later rust inside finished concrete. A well-placed magnetic separator captures more than 95 % of this iron before it can do damage, cutting maintenance costs by up to 30 % and ensuring that the final recycled aggregate meets the 0.05 % iron limit now written into most national standards.

Sources and Hazards of Iron Contamination

Demolished reinforced concrete typically contains 25 kg of steel per cubic metre. During primary breaking, wire mesh fractures into 30–50 mm slivers while rebar shears into 150 mm lengths. These pieces are sharp enough to slice 100 mm rubber belts at 3 m s⁻¹ and, once inside the impact chamber, will notch manganese blow bars within an hour. Removing them upstream is therefore the first line of defence for both safety and profitability.

Extending Crusher Life by Eliminating Metal

Case histories show that a single 12 mm bolt travelling through an impact crusher can create a 2 mm groove on the primary apron plate. When a magnetic head pulley removes the bolt, apron wear drops by 18 % over 2 000 operating hours, delaying the €8 000 replacement interval and keeping the product shape stable for longer.

Economic Impact of Higher Metal Recovery

Scrap iron currently trades at roughly €250 per tonne. A 200 t h⁻¹ plant recovering 0.7 % clean steel can generate €350 of extra revenue per operating hour—enough to offset the €180 per hour cost of running a 2 000 mm cross-belt magnet. Over a year this turns waste removal from a cost centre into a profit stream.

Meeting Specification Limits for Recycled Aggregate

Standard 38947-2020 stipulates that coarse recycled aggregate must contain ≤ 0.05 % iron by mass. Plants that miss the limit must blend with virgin stone, eroding the environmental and economic benefits. Continuous belt magnets with 1 200 mT surface flux routinely achieve 0.04 % residual iron, providing a comfortable compliance margin.

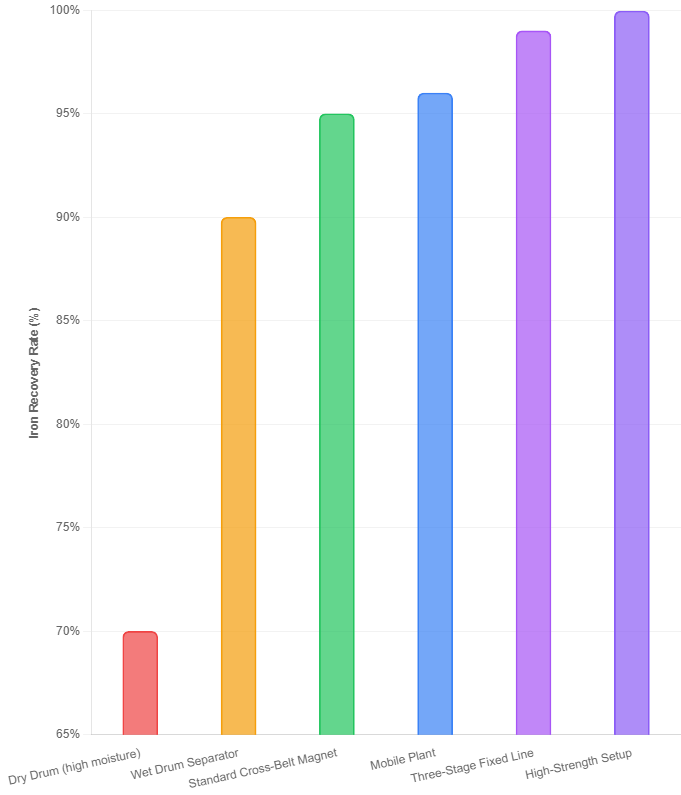

Wet versus Dry Magnetic Separation

Dry drum magnets work well when feed moisture is below 4 %. Above that level, water films shield fine wires from the field and recovery drops to 70 %. Wet drum separators maintain 90 % recovery even at 12 % moisture but require slurry handling. Most urban recycling plants therefore choose dry units plus a covered feed hopper to keep rain away.

Ensuring the Crusher and Magnet Work as One Unit

Once the metal is gone, the remaining concrete and masonry must be shaped into cubical particles. The way material flows out of the crusher and across the magnet determines whether the separation stage undoes the gains of the previous step. Careful layout and speed matching keep the two machines in balance.

Flow Characteristics of HSI and VSI Machines

Horizontal-shaft impactors eject material at roughly 25 m s⁻¹ in a 45° fan, while vertical-shaft machines drop a controlled curtain at 15 m s⁻¹. The flatter trajectory of the HSI allows a magnetic head pulley to be installed directly under the discharge conveyor, whereas the VSI may require a dribble belt to slow the stream before separation.

Crusher Chamber Design and Separation Clearance

Chambers with wide side discharge openings throw a broader material curtain, increasing the effective width of the magnetic field. Trials show that widening the throat by 60 mm raises the capture probability of 5 mm wires from 75 % to 92 % without affecting the final aggregate shape.

Matching Rotor Speed to Magnetic Field Strength

A 45 m s⁻¹ rotor produces more fines and liberates more small nails. Raising the magnet surface flux from 800 mT to 1 200 mT recovers these nails, but only if belt speed stays below 2.5 m s⁻¹. Variable-frequency drives on both rotor and belt allow the plant to chase this optimum automatically as feed size changes.

Conveyor Speed versus Magnet Capacity

Cross-belt magnets lose efficiency when the burden depth exceeds 100 mm. A 1 200 mm wide belt running at 2 m s⁻¹ carries about 250 t h⁻¹ of 0–40 mm material; slowing to 1.5 m s⁻¹ drops the burden depth to 80 mm and lifts recovery from 88 % to 96 %, a trade-off that pays for itself when scrap prices are high.

Pre-Crush Size Curve and Liberation Efficiency

Primary jaw crushers set at 100 mm produce a top size that liberates most rebar but still leaves some wire embedded in 60 mm lumps. Reducing the jaw setting to 75 mm frees 18 % more metal, easing the load on downstream magnets and improving overall iron recovery by 3 %.

Fine-Tuning the Magnetic Separator Itself

Even the best magnet will underperform if its field strength, gradient and cleaning cycle are not matched to the incoming waste stream. Modern separators offer dozens of adjustments; knowing which ones move the needle is essential.

Calibrating Magnetic Induction to Iron Grade

Field studies indicate that 800 mT is sufficient for concrete with 0.2 % iron, whereas reinforced masonry at 0.4 % needs 1 200 mT. A linear model H = 600 + 1 400·[Fe] gives a first-pass setting that can later be trimmed ±10 % based on belt scale data.

Gradient Design for Fine Wire Capture

Neodymium blocks arranged in a 5 mm pitch create a gradient of 1.8 T m⁻¹ at the belt surface. This gradient traps 70 % of 2 mm wires that would otherwise pass through a conventional 12 mm pitch array, pushing overall recovery above the 95 % target.

Pole Distance and Throughput Scaling

Doubling the pole pitch from 100 mm to 200 mm doubles the belt width that can be served by the same magnet block, but it halves the field gradient. Plants therefore choose 150 mm as a practical compromise that supports 1 400 mm belts without sacrificing fines recovery.

Permanent versus Electromagnets for Energy Balance

A 1 500 mm electromagnet consumes 8 kW continuously, adding €12 000 per year in electricity. A comparable neodymium drum uses no power except for the 0.75 kW drive motor. The payback period for the higher upfront cost of permanent magnets is typically 18 months at current energy prices.

Auto-Clean Reliability in Dusty Environments

Self-cleaning belts rely on urethane scrapers that wear out every 600 hours in concrete dust. Switching to ceramic-tipped scrapers extends life to 2 000 hours and prevents 8 kg of ferrite dust per day from re-entering the aggregate stream, a small investment that preserves product quality.

Proven Layouts and Field-Proven Configurations

Theory becomes actionable when it is translated into plant layouts. The three blueprints below represent the most common combinations of crushers and magnets, each tuned for a specific feedstock and mobility requirement.

Mobile Plant With Cross-Belt Magnet

A 35 t tracked impact crusher fed by a 1 m³ vibrating hopper feeds a 900 mm cross-belt magnet with 1 000 mT surface flux. The unit processes 120 t h⁻¹ of mixed C&D waste, achieving 96 % iron removal and producing 0–31.5 mm recycled aggregate that meets road-base specs. Setup time is four hours, making it ideal for short-term urban projects.

Three-Stage Fixed Line for Maximum Recovery

Stationary installations use a coarse drum magnet after the primary jaw, a suspended magnet over the secondary cone discharge, and a final pulley magnet before the screen. Each stage targets a different size fraction, pushing total recovery to 99 % and allowing the plant to sell scrap steel as a separate revenue stream.

High-Strength Setup for Heavily-Reinforced Waste

Granite-based demolition waste contains up to 0.8 % iron, mostly in the form of 16 mm rebar. A 1 800 mm wide belt running at 1.2 m s⁻¹ is fitted with a 1 400 mT rare-earth magnet and a 300 mm diameter magnetic head pulley. The dual system removes 240 kg of steel per 100 tonnes of feed, keeping the iron content in the finished aggregate below 0.04 %.

Low-Intensity Separation for Aerated Concrete

Lightweight masonry blocks contain only 0.05 % iron, mostly nails. A 600 mm drum running at 0.8 m s⁻¹ with 400 mT flux is sufficient and avoids the cost of a high-gradient unit. The gentle field also prevents capture of non-ferrous aluminium ties that should remain in the aggregate for mix design purposes.

City Road Project With Linked Control Logic

A municipal project required 80 000 tonnes of 0–20 mm base material. The plant used a jaw crusher, an impact crusher and a three-deck screen, all interlocked through a PLC. When the magnetic separator detected iron above 0.1 %, the belt slowed automatically and an operator alert sounded, preventing out-of-spec loads from reaching the paver.

Smart Monitoring and Quality Assurance

Modern plants close the quality loop by measuring iron content in real time and feeding the data back to both the magnet and the crusher. The tools below are now standard on new installations and can be retrofitted to older lines.

Online Iron Content Sensors

Inductive coils mounted under the belt generate eddy currents in any remaining metal. A signal processor converts the amplitude into parts-per-million iron and updates every five seconds. Calibration against X-ray fluorescence shows an accuracy of ±0.008 %, sufficient to trigger diversion gates when the limit is approached.

Digital Twin Models for Predictive Control

A cloud-based replica of the plant uses live feed size, belt speed and magnet current to predict iron recovery 30 minutes ahead. When the model forecasts a drift beyond 0.05 %, it recommends a 2 % reduction in belt speed or a 5 % increase in magnet current, giving operators time to act before any off-spec material is produced.

Statistical Sampling and Variance Tracking

Hourly composite samples analysed with a handheld XRF gun reveal short-term noise. A control chart with upper and lower limits at ±2 σ flags systematic shifts within four hours, long before daily lab results are available. The approach keeps the process capability index CpK above 1.33, the threshold most agencies require for recycled aggregate.

Fast Iron Assay for Load-by-Load Verification

A microwave digestion followed by colorimetric analysis gives total iron in six minutes. Trucks can be held at the gate until results confirm compliance, eliminating the risk of rejected loads that cost €1 200 each in demurrage and re-screening fees.

Dynamic CpK Dashboard for Contract Compliance

A web dashboard displays live CpK values for iron, grading and shape. When all three indices stay green for 24 hours, the plant earns a 3 % bonus on delivered tonnage. The same interface exports data directly to the client’s quality system, removing paperwork and speeding payment.

Lessons from the Field: What Actually Works

Across dozens of operating plants, certain patterns repeat. The stories below distill the choices that separated profitable facilities from those that struggled with downtime or quality rejections.

Suburban Resource Centre With Dual Power

A 150 t h⁻¹ stationary line runs on grid power during the day and switches to a 500 kVA genset at night when electricity tariffs drop. The dual supply keeps the 1 400 mT magnet online 20 hours per day, raising annual steel recovery from 1 800 tonnes to 2 400 tonnes, worth an extra €150 000 in scrap revenue.

Public Works Contract With 90 % Recycled Content

A city specification required 90 % recycled aggregate in new kerb mixes. By installing a three-stage magnetic circuit and a real-time iron sensor, the supplier delivered 120 000 tonnes at 0.037 % iron, surpassing the 0.05 % limit and securing a five-year supply agreement worth €18 million.

Mobile Versus Fixed Cost Analysis

Comparing identical 200 t h⁻¹ circuits, the tracked plant incurred €0.85 per tonne in relocation costs but saved €1.20 per tonne in land lease fees by moving closer to each demolition site. Over a 50 km radius, the mobile option paid back its €400 000 premium within 14 months.

Variable-Frequency Magnet Drive Saves 12 % Energy

Replacing a constant-speed 11 kW magnet motor with a VFD that modulates flux between 800 mT and 1 200 mT based on feed iron content reduced average power draw to 9.7 kW. Annual electricity savings of €2 300 were modest, but the reduced coil heating extended insulation life by three years.

Integrated Dust Control Around the Magnet

A pulse-jet dust collector mounted above the magnetic head pulley captures 0.8 kg of ferrite-laden dust per operating hour. Keeping the belt surface clean improves metal recovery by 1.5 % and prevents abrasive dust from reaching downstream screens, cutting their replacement cost by 8 % per year.