Analysis of Key Selection Points for Impact Crushers in Different Application Scenarios

This comprehensive guide examines the critical factors for selecting impact crushers across various industrial applications, focusing on how different operational environments demand specific machine characteristics and configurations. Impact crushers utilize high-speed impact forces to fracture materials through rapid collision between the incoming feed and rotating hammers or blow bars, making them particularly suitable for materials with medium hardness and good brittleness characteristics. We will explore the specific requirements for mining operations, construction waste recycling, and aggregate production, detailing how each application demands unique combinations of durability, flexibility, and efficiency from these versatile crushing machines.

Impact Crusher Selection for Mining Applications

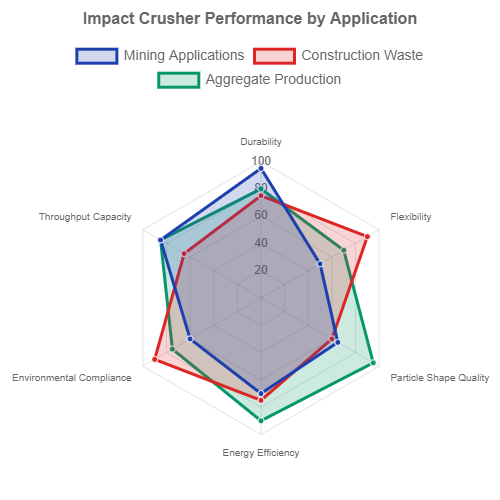

Mining operations present some of the most demanding conditions for impact crushers, requiring robust equipment capable of processing hard, abrasive ores while withstanding harsh environmental challenges. The selection process for mining applications must prioritize durability and reliability above all other considerations, as equipment failures in remote mining locations can result in substantial production losses and expensive repair operations. Impact crushers in mining must be engineered to handle the extreme mechanical stresses generated when fracturing hard rock formations while maintaining operational efficiency throughout extended production cycles.

Beyond mere hardness considerations, mining impact crushers must accommodate variable feed conditions, from large blocky ore directly from the blast site to more consistent feed from primary crushers. The machines selected must integrate seamlessly into complex mineral processing circuits, often operating in tandem with screening equipment and conveying systems. Environmental factors including dust, moisture, temperature extremes, and remote locations further complicate equipment selection, making comprehensive evaluation of all operational parameters essential for successful implementation in mining scenarios.

Technical Requirements for Hard Ore Crushing

Processing hard ores such as granite, basalt, and iron ore demands impact crushers with exceptional impact energy transfer capabilities and superior wear resistance. These materials typically have compressive strengths exceeding 150 MPa and high abrasiveness indices, requiring crushers with massive rotors capable of storing and transferring substantial kinetic energy to the feed material. The combination of high impact forces and exceptional wear resistance represents the fundamental engineering challenge for crusher manufacturers serving the mining sector.

The crushing chamber design must optimize material trajectory and impact angles to maximize size reduction efficiency while minimizing wear component stress. Modern mining impact crushers often feature multi-stage crushing zones within a single rotor system, allowing progressive reduction of hard ores through successive impact events. These advanced rotor designs incorporate specialized wear protection systems and often utilize tungsten carbide inserts in critical wear areas to extend operational life between maintenance intervals. The selection of appropriate blow bar geometry and metallurgy becomes particularly critical when processing highly abrasive ores that can rapidly degrade conventional manganese steel components.

Adaptability to Harsh Mining Environments

Mining environments present numerous challenges beyond the mechanical demands of ore crushing, including excessive dust generation, temperature extremes, vibration, and potential exposure to moisture. Impact crushers designed for mining applications must incorporate comprehensive environmental protection systems to ensure reliable operation under these adverse conditions. Dust represents a particular concern in mining operations, both for equipment protection and regulatory compliance, making integrated dust suppression or collection systems an essential selection criterion.

Equipment stability and vibration resistance become critical considerations in mining applications where crushers must operate on potentially unstable ground or in areas with significant vibration from other mining activities. Modern mining impact crushers feature reinforced frames and specialized mounting systems designed to absorb operational vibrations and maintain alignment under full load conditions. Weather protection systems, including enhanced sealing of bearings and electrical components, prevent contamination from dust and moisture that could otherwise lead to premature component failure. These environmental adaptations significantly contribute to the overall reliability and longevity of impact crushers in demanding mining applications.

Key Selection Points for Construction Waste Processing Applications

Construction and demolition waste recycling presents unique challenges for impact crusher selection, primarily due to the highly variable and often contaminated nature of the feed material. Unlike uniform natural aggregates, construction waste contains mixed materials including concrete, bricks, wood, metals, and occasional contaminants that require flexible processing solutions. Impact crushers for this application must balance robust construction with operational flexibility, enabling processors to handle constantly changing feed composition while maintaining production efficiency and end product quality.

The selection process for construction waste recycling must consider not only the crusher's mechanical capabilities but also its integration with various separation and sorting technologies that typically accompany recycling operations. Modern recycling plants often employ complex material flow systems incorporating magnetic separators, air classifiers, and manual sorting stations, requiring impact crushers that can function effectively within these integrated systems. Additionally, urban and semi-urban locations common to recycling operations impose noise and dust emission requirements that significantly influence equipment selection and necessary auxiliary systems.

Flexibility for Mixed Waste Processing

The heterogeneous nature of construction and demolition waste demands impact crushers with exceptional processing flexibility, capable of handling materials with varying hardness, size, and composition without operational interruptions. Modern impact crushers designed for recycling applications feature adjustable rotor speeds and impact configurations that can be modified to optimize performance for different material types encountered throughout a processing shift. This adaptability ensures consistent product quality despite variations in feed material characteristics that would challenge less flexible crushing technologies.

Advanced impact crushers for recycling incorporate intelligent control systems that automatically adjust operational parameters based on feed conditions and crusher loading. These systems monitor power consumption, vibration levels, and throughput rates to optimize crushing performance while protecting the equipment from damage caused by uncrushable objects. Many models include hydraulic adjustment mechanisms for the impact aprons and grinding path, allowing operators to fine-tune the crushing process for different material types and desired product specifications. This operational flexibility proves essential for recycling operations processing highly variable construction and demolition waste streams.

Equipment Configuration for Environmental Compliance

Construction waste recycling operations frequently occur in urban or semi-urban locations where environmental regulations impose strict limits on noise and dust emissions. Impact crusher selection for these applications must include comprehensive environmental control systems that minimize the operation's community impact while maintaining processing efficiency. Modern crushers designed for urban recycling applications incorporate numerous noise reduction technologies including acoustic enclosures, vibration isolation mounts, and sound-attenuating materials that reduce operational noise levels by 10-15 dB compared to conventional designs.

Dust control represents another critical consideration for urban recycling operations, requiring integrated dust suppression or collection systems that prevent particulate matter from escaping the processing area. Many impact crushers designed for construction waste applications feature water spray systems that suppress dust at key transfer points while advanced models may include complete encapsulation and negative pressure systems with baghouse filters for maximum dust control. These environmental considerations often dictate the overall equipment configuration and significantly influence the operational cost structure of recycling facilities operating in environmentally sensitive locations.

Selecting Impact Crushers for Aggregate Production Applications

Aggregate production for construction materials represents the most traditional application for impact crushers, focusing on producing high-quality crushed stone, sand, and gravel meeting strict specifications for various construction applications. In this sector, impact crushers are particularly valued for their ability to produce well-shaped, cubical aggregate products with minimal flaky or elongated particles that compromise the quality of concrete and asphalt mixtures. The selection process for aggregate production emphasizes product quality consistency, operational efficiency, and production cost control across high-volume operations.

Modern aggregate operations require impact crushers that integrate seamlessly with complex processing plants including multiple crushing stages, screening operations, and material handling systems. The selected equipment must demonstrate reliability under continuous operation while maintaining precise control over product gradation and particle shape characteristics. Additionally, economic considerations including energy efficiency, wear part consumption, and maintenance requirements significantly influence equipment selection decisions in the highly competitive aggregate production industry where profit margins depend on optimizing every aspect of the production process.

Technical Specifications for High-Quality Aggregate Production

Producing premium quality aggregates requires impact crushers capable of delivering consistent particle shape characteristics and precise size control throughout extended production runs. Modern impact crushers achieve superior particle shape through optimized rotor designs that create multiple impact events within the crushing chamber, ensuring thorough fracturing of aggregate particles along natural cleavage lines. This results in the cubical product shape preferred for concrete and asphalt applications where angular, well-proportioned particles provide better mechanical interlock and require less cementitious material for binding.

Advanced impact crushers for aggregate production incorporate sophisticated adjustment systems that maintain consistent product gradation despite variations in feed material characteristics. These systems often include hydraulic adjustment of the impact aprons and grinding path, allowing operators to fine-tune the crushing chamber geometry to achieve specific product specifications. Many modern models feature computer-controlled adjustment systems that can automatically compensate for wear component degradation, maintaining consistent product quality throughout the wear life of crushing components. This level of control proves essential for aggregate producers supplying specification-grade materials to the construction industry.

Efficiency and Cost Optimization in Aggregate Production

Economic considerations heavily influence impact crusher selection for aggregate production, where high-volume operations magnify the financial impact of efficiency differences between equipment options. Modern impact crushers designed for aggregate applications prioritize energy efficiency through optimized rotor designs that maximize energy transfer to the feed material, reducing power consumption per ton of processed aggregate. These efficiency improvements directly translate to lower operating costs and reduced environmental impact through decreased energy consumption.

Maintenance cost control represents another critical economic factor in crusher selection, with advanced designs featuring quick-wear component change-out systems that minimize downtime during maintenance operations. Many impact crushers now incorporate rotor and wear part designs that extend operational life between maintenance intervals, reducing both part replacement costs and production losses during maintenance shutdowns. Additionally, remote monitoring capabilities allow maintenance planning based on actual equipment condition rather than fixed schedules, further optimizing maintenance efficiency and reducing operational costs in high-volume aggregate production facilities.