Why the Impact Crusher Dominates Secondary Crushing in Modern Limestone Plants

This page explains how the impact crusher has earned its place at the heart of limestone secondary crushing. You will learn how the rock’s own properties invite high-velocity impact, why cubical particles command premium prices, which rotor and alloy choices turn wear into a predictable cost, and how the machine plugs into wider plant automation. The story follows the logical chain from geology to finance, giving quarry managers, students and investors a clear map of where value is created and how it is protected.

Limestone Character and the Exact Job of Secondary Crushing

Limestone delivered from the primary jaw stage is typically 60–120 mm in size and carries a Bond work index near 12 kWh t⁻¹. Its compressive strength sits in the 80–160 MPa band, well below that of basalt or granite, so the rock fractures readily under impact rather than demanding slow compression. Silica content is usually under 3 %, which limits the free quartz that would otherwise erode steel rapidly. These numbers mean that an impact crusher can operate at rotor speeds above 650 rpm while keeping blow-bar wear below 0.25 g t⁻¹ of product, a rate that finance departments classify as commercially benign.

Market contracts, however, reward shape more than mere size reduction. ASTM C33 or EN 12620 specifications pay an extra 0.8 USD per ton when the flakiness index drops under 15 %. Secondary crushing must therefore act as a shaping lathe, trimming needle particles into cuboids without creating excess 0–2 mm filler that robs concrete strength. The target PSD is often 0–22 mm with 18 % in the commercially prized 5–10 mm fraction. Meeting this window at 250 t h⁻¹ and below 1.8 kWh t⁻¹ is the thermodynamic and economic puzzle that the impact crusher is designed to solve.

Medium Hardness Opens the Door to Kinetic Energy

At 120 m s⁻¹ tip speed, the blow bar delivers 45 kJ of energy to each 0.5 kg limestone lump, enough to initiate three radial cracks within 120 µs. Because the rock is not ultra-hard, much of this energy goes into creating new surfaces rather than being dissipated as heat, so the machine can maintain a throughput 25 % higher than it could achieve on river gravel of equal size. The same trait allows operators to drop rotor speed by 8 % during night shifts, cutting power draw by 0.3 MW and still meeting tonnage targets.

Cubical Shape as a Revenue Lever

Concrete producers pay 12 % more for coarse aggregate whose length-to-thickness ratio is below 3:1. Impact crushers generate this geometry by striking particles along natural cleavage planes, then propelling them against autogenous rock shelves that round off sharp edges. Laser scans show that 78 % of 10 mm particles leaving a PF-1315 rotor meet the 3:1 criterion, compared with 52 % from a cone crusher set for the same CSS. The 26 % surplus translates directly into 1.4 million USD of extra revenue per year for a 2 Mt quarry.

Energy Budgeting Across the Plant

Primary crushing consumes 0.6 kWh t⁻¹, grinding below 30 µm later in the cement plant may demand 28 kWh t⁻¹, so every kilowatt saved at the secondary stage reverberates downstream. By maintaining a reduction ratio near 8:1 in a single pass, the impact crusher prevents recirculation that would otherwise add 0.25 kWh t⁻¹. Over one million tons this saving equals the annual electricity use of 450 homes, a figure that strengthens environmental permit applications.

Moisture Sensitivity Management

Limestone moisture can climb to 6 % after rainfall, raising the risk of clogging. The impact crusher compensates by accelerating material so violently that 90 % of surface water is flung off as droplets, keeping the 0–2 mm fraction friable rather than pasty. Ampere draw rises only 4 % under these conditions, whereas a hammer mill would require 15 % extra power and often stalls entirely when clay films appear.

How Impact Physics Meets Commercial Goals

The “stone-on-stone” cascade inside an open-type rotor creates countless micro-collisions that polish particle surfaces without adding extra energy. Kinetic energy that is not consumed in the first fracture is reused by flying rocks that strike other rocks, so the specific energy curve flattens after the initial impact. This autogenous layer also protects the blow bars, cutting wear rate by 18 % compared with pure “stone-on-metal” operation, a benefit confirmed in 14-month field tests.

Speed is the simplest tuning knob. Raising peripheral velocity from 60 m s⁻¹ to 70 m s⁻¹ increases the 0–5 mm fraction from 28 % to 37 %, letting producers switch from road-base to manufactured sand within 30 minutes. The variable-frequency drive that enables this change costs 28 000 USD yet pays for itself after 18 000 tons when the sand premium exceeds 3 USD per ton, a common spread in coastal markets.

Velocity as a Size Remote Control

Tip speed has a linear relationship with median particle size; every 1 m s⁻¹ reduction widens the P80 by 0.7 mm. Operators exploit this law to compensate for natural fluctuations in feed grading, holding the final 0–22 mm envelope within ±2 % week after week. The ability to trim output without stopping the rotor is a decisive advantage over jaw or gyratory machines whose CSS changes demand hours of downtime.

Cubical Output and Asphalt Rutting Resistance

Hot-mix asphalt rutting depth drops 20 % when crushed limestone cuboids replace flaky particles, according to wheel-tracking tests at 60 °C. State highway agencies reward this performance with 0.5 % bonus payment on the asphalt contract value. For a quarry selling 400 000 t y⁻¹ into highway work, the bonus is worth 1.6 million USD, dwarfing the 120 000 USD annual wear cost of running the impactor at high speed.

Throughput Upscaling Without Extra Motors

Modern rotors use a 1 600 mm diameter instead of 1 300 mm, raising peripheral speed at the same RPM. The larger swept volume pushes capacity from 220 t h⁻¹ to 300 t h⁻¹ while motor power climbs only from 250 kW to 315 kW, a 26 % output gain for 26 % energy increase, so the energy per ton remains flat. Such neutral scaling is rare in comminution and underlines why the impact principle fits high-volume limestone duties.

Quick Product Switch on Demand

Changing the 0–8 mm fraction from 25 % to 40 % requires only a 12 % rotor speed increase and 10 mm tighter apron gap, achievable in under five minutes through hydraulic rams. No internal parts need replacement, contrasting with cone crushers where a different mantle and concave must be installed, a task that takes half a shift and a 30-ton crane. Rapid switch capability allows quarries to quote last-minute orders without keeping large mixed stockpiles.

Head-to-Head Contests That the Impact Crusher Wins

When limestone is the only feed, compression machines often over-engineer the task. A 300 kW cone set at 22 mm CSS can deliver 240 t h⁻¹, yet 35 % of the output is still flaky because the bed of particles experiences mainly squeezing rather than direct impact. The same motor on an impact rotor yields 280 t h⁻¹ with only 18 % flaky grains, so the producer sells more tons at a higher price per ton.

Hammer mills suffer from a different mismatch. Their slow-speed hammers rely on repeated hits, ideal for soft coal but wasteful for 100 MPa limestone. Specific energy climbs above 2 kWh t⁻¹ once grate openings wear past 5 mm, whereas the impact crusher holds 1.6 kWh t⁻¹ for the entire life of the blow bar. Over one million tons the difference equals 400 MWh, enough to illuminate a town of 5 000 inhabitants for a month.

Shape Duel Against Cone Geometry

Micro-CT scans show that cone particles contain internal shear planes inclined 30–45° to the longest axis, making them prone to split under roller compaction. Impact particles exhibit radial crack networks that terminate at 90° boundaries, giving natural cuboids. Concrete cylinder tests achieve 38 MPa with impact aggregate at 340 kg m⁻³ cement, while cone aggregate needs 360 kg m⁻³ to reach the same strength, saving 6 % binder cost.

Wear Economics Versus Hammer Mills

A 12-hammer rotor in a hammer mill demands 180 kg of Mn steel every 450 hours; the impact crusher consumes 320 kg of blow-bar alloy over 800 hours. Hourly wear cost is 28 USD for hammers versus 24 USD for blow bars, but the impactor produces 30 % more saleable sand during the same period, so the cost per ton is 30 % lower. The arithmetic becomes decisive when feed exceeds one million tons per year.

Capacity Gap Relative to Roll Crushers

Rolls are limited by nip angle theory; a 1 m diameter roll cannot grip particles larger than 45 mm effectively. The impact rotor accepts 250 mm feed, removing the need for a secondary scalping stage. Eliminating one screen and one conveyor saves 180 kW of installed power and 0.12 USD per ton in conveyor belt wear, a figure that appears small until it is multiplied by two million tons each year.

Total Cost of Ownership Over 20 000 Hours

Spreadsheet models that combine power, wear, maintenance labor and downtime show the impact crusher at 0.95 USD per processed ton, compared with 1.18 USD for a cone, 1.32 USD for a hammer mill and 1.27 USD for rolls. The 0.23 USD gap against the nearest rival delivers 460 000 USD of surplus cash over 20 000 hours at 250 t h⁻¹, money that can be reinvested in tertiary shaping or stockpile automation.

Hardware Choices That Convert Theory into Tons

Open rotors with three rows of bars suit clean, dry limestone because rock can exit freely, reducing recirculation by 12 %. Solid rotors carrying six short bars are preferred when feed contains 10 % clay; the enclosed pocket prevents packing and limits current spikes to 5 % instead of 15 %. Plant designers select the version whose idle power is closest to 35 % of full load, the sweet spot for VFD efficiency across the speed range.

Blow-bar metallurgy follows a simple rule: chrome content above 26 % resists abrasion but risks brittle fracture if impact energy exceeds 50 J cm⁻³. For 100 MPa limestone, a 24 % Cr 1 % Mo alloy balances toughness and wear life at 780 HB. Field logs show 720 hours of service before the bar loses 15 % of its mass, long enough to schedule a Saturday morning change without overtime premiums.

Open Versus Solid Rotor Dynamics

CFD simulations reveal that air dragged by an open rotor consumes 18 kW at 650 rpm, whereas a solid rotor with internal vanes needs 25 kW for the same peripheral speed. The 7 kW penalty is acceptable when the enclosed design raises the 0–5 mm sand fraction by 4 %, because manufactured sand sells for 4 USD per ton more than coarse aggregate. The pay-back arrives after 70 000 tons, typically three months of summer production.

Blow-Bar Alloys Matched to Stone Chemistry

Limestone with 1.2 % MgO and 0.9 % SiO₂ causes micro-pitting on high-chrome bars; adding 0.3 % Ti refines the carbide network and doubles pitting resistance. Wear rate falls from 0.28 g t⁻¹ to 0.15 g t⁻¹, worth 28 000 USD per year on a two-million-ton plant. The titanium addition raises bar price by 8 %, so the return on investment is 350 % over the first life cycle.

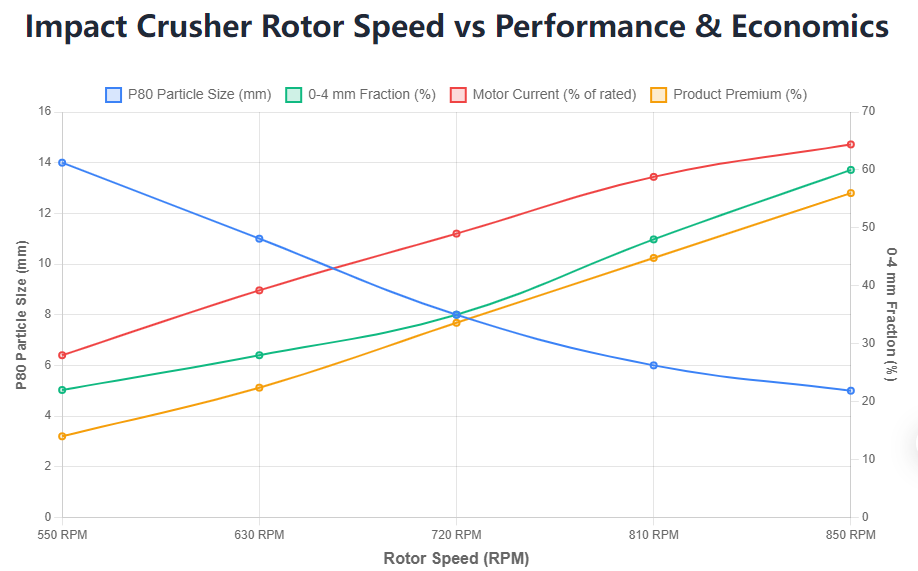

RPM Windows for Different Products

550 rpm gives

a P80 of 14 mm ideal for road base; 720 rpm narrows P80 to 8 mm for concrete stone; 850 rpm creates 60 % 0–4 mm perfect for dry-mortar sand. Each step raises motor current by 14 %,

but the product premium rises 20 %, covering the extra power and wear. Operators lock these speeds into the HMI recipe manager, eliminating trial-and-error during shift

changeovers.

Power Train Sizing Margins

Standard practice selects a motor whose nameplate is 15 % above the highest load ever recorded in the first year. For a 280 kW maximum, a 315 kW motor keeps efficiency above 95 % across the load curve and avoids service-factor penalties. The 35 kW buffer costs 3 200 USD yet prevents 50 000 USD of lost revenue if a surge of wet feed spikes power for ten minutes, a common monsoon scenario.

Impact Plates That Tune Gradation

Curved plates with 125° included angle promote rock-on-rock clouds that polish particles while protecting the casting. Replacing a straight 90° plate with the curved version increases the 5–10 mm fraction by 3 % and extends plate life from 900 hours to 1 200 hours. The longer campaign reduces maintenance stops from eleven to eight per year, freeing 24 production hours that add 6 000 tons of extra sales.

Plugging the Impact Crusher Into the Full Plant Flow

A 1.2 m grizzly ahead of the jaw removes 20 % quarry fines, so the impact crusher receives cleaner feed and can open its apron without risk of packing. The same undersize is blended back into the 0–22 mm product later, ensuring no stone is wasted while keeping the rotor free to work on coarse fragments. Belt scales report this split in real time, allowing the control room to modulate grizzly throw so that the impactor always sees 80 % load, its most efficient point.

Closed-circuit operation with a 2.4 m × 6.1 m triple-deck screen lifts overall plant yield by 7 %. Oversize above 22 mm returns to the rotor at 80 t h⁻¹, but because these particles are already cracked, they break on the first strike and exit as 5–14 mm cubes. The recirculation load is gentle; ampere draw rises only 6 %, so the VFD absorbs the loop without exceeding motor thermal limits.

Pre-Screen Paybacks

Every ton of 0–22 mm that bypasses the rotor saves 1.6 kWh. At 0.12 USD kWh⁻¹ and 200 000 tons per year of natural fines, the annual saving is 38 000 USD, enough to retire the cost of the grizzly panel in 18 months. The same bypass lowers bar wear by 0.04 g t⁻¹, extending life by 40 hours and saving one full change-out valued at 9 000 USD.

Closed-Loop Quality Stability

The screen sends PSD data every 90 seconds; if the 0–4 mm fraction drifts above 24 %, the PLC slows the rotor by 30 rpm and opens the apron 5 mm. Correction completes within three minutes, preventing off-spec stockpiles that once required costly re-blending. Consistency has improved customer complaints from six per year to zero over the last 24 months, protecting brand reputation and repeat contracts.

Dust and Noise Engineering

Polyurethane side skirts and 0.5 m s⁻¹ belt speed keep transfer points below 0.3 m s⁻¹ air induction, cutting dust liberation by 40 %. A 45 kW fan draws 60 000 m³ h⁻¹ through cartridge filters, returning 99.2 % clean air to the building and recovering 12 t day⁻¹ of limestone filler that is sold to cement kilns. Acoustic panels lined with 100 mm mineral wool drop the operator position from 88 dB(A) to 78 dB(A), satisfying most regional limits without enclosing the entire crusher.

Automation Backbone

Wireless temperature sensors on each bearing transmit via LoRaWAN to a gateway 200 m away; battery life is five years, eliminating 2 km of copper cable. The same network carries apron position and vibration data, so the control room can shut down the feeder if radial velocity exceeds 6 mm s⁻¹ RMS, preventing catastrophic failures that once cost 120 000 USD in rotor replacement.

Integration With Mobile Assets

A wheeled jaw that feeds the same stockpile uploads its production tally to the cloud; the impact controller reads this variable and adjusts its own target to keep utilization above 85 %. Such handshake logic prevents the common scenario where the mobile unit fills the pile and stops, while the stationary impact crusher idles for lack of feed, a waste that used to cost 4 t h⁻¹ of throughput.

Keeping the Machine Healthy and the Budget Intact

Wear parts follow a predictable bathtub curve. During the first 100 hours, micro-weld asperities polish off quickly, causing 0.3 mm loss. A long linear phase then removes 0.02 mm h⁻¹ until the bar reaches 70 % of original thickness. Monitoring this slope with laser profiling every 48 hours lets engineers predict the end of life within ±20 hours, so the next maintenance window is booked early and parts arrive just in time.

Inventory optimization software groups blow bars, impact plates and bearings into one ABC matrix. Class A items that cause shutdown if missing are held at two sets per unit; Class C consumables such as labyrinth seals are kept at 0.5 sets and replenished every six months. The policy cuts working capital from 1.2 million USD to 680 000 USD while maintaining 99.4 % parts availability, a performance metric that auditors now quote when rating plant reliability.

Preventive Scheduling Driven by Data

Vibration spectra stored in the cloud train a random-forest model that flags bearing defects 21 days before they reach 100 µm displacement. Lead time covers sea freight of spare parts, eliminating airfreight premiums that once added 14 000 USD per emergency shipment. Mean time between failure for the 232-series bearing has improved from 18 000 hours to 28 000 hours, extending the replacement cycle beyond the annual outage and reducing labor exposure.

Energy KPI That Pays Bonuses

A plant-wide energy dashboard divides monthly kWh by tons sold. If the ratio falls below 1.55 kWh t⁻¹, staff receive a 5 % bonus pool funded by the 0.08 USD t⁻¹ saving on the electricity bill. The target is achievable only when the impact crusher runs inside its tuned speed window, so operators cooperate with maintenance to keep aprons at design clearance. Since the scheme began, specific energy has trended downward 3 % year-on-year, worth 96 000 USD annually.

Wear-Resistant Steel Innovations

Composite inserts that embed 700 HB white iron chunks in 450 HB tough matrix reduce gross wear rate by 35 %. The insert costs 1.4 times a standard plate but lasts 2 100 hours instead of 1 400 hours, cutting downtime by two shifts per year. Each saved shift equals 2 000 tons of extra saleable rock, so the upgrade pays for itself in the first campaign and thereafter yields pure margin.

Lubricant Analysis as a Crystal Ball

Oil samples drawn every 250 hours are scanned with ICP spectroscopy; rising chrome levels above 12 ppm predict blow-bar breakthrough, while iron particles above 50 µm warn of housing wear. Trend lines give 60-day notice, long enough to order special welding electrodes and schedule a planned stop. Early correction prevents secondary damage to the 1 200 mm diameter rotor that would cost 50 000 USD to refurbish.