Complete Guide to Impact Crusher Wear Parts Replacement: Step-by-Step Instructions and Safety Considerations

This comprehensive guide provides detailed information on the replacement of wear parts for impact crushers in industrial operations. Proper maintenance not only ensures optimal equipment performance but also extends the service life of the machinery. The guide covers preparation requirements before replacement, component identification methods, specific replacement procedures, testing protocols, and maintenance strategies. Following these guidelines helps maintain production efficiency and ensure workplace safety.

Importance and Preparation for Replacing Wear Parts of Impact Crushers

Replacing wear parts is a critical step in maintaining crusher performance and preventing unexpected breakdowns. Regular replacement of wear parts not only ensures stable product quality but also reduces long-term maintenance costs. Adequate preparation before replacement can minimize downtime to the greatest extent and guarantee the safety of personnel during maintenance operations.

Preparation involves multiple safety measures and equipment inspections. Before starting work, technicians must confirm that the equipment has been completely shut down and its power supply has been disconnected. At the same time, necessary tools and replacement parts should be prepared in advance to ensure the smooth initiation of the replacement process.

Safety Inspections Before Replacement

The equipment must be completely shut down and thoroughly disconnected from the power source. Implementing lockout-tagout procedures can prevent accidental startup of the equipment during maintenance. In addition, warning signs should be posted around the work area to alert other personnel.

Personal protective equipment is essential, including hard hats, safety goggles, protective gloves, and steel-toed safety shoes. If dust is generated during the operation, respiratory protection equipment must also be provided; when working at height, fall protection equipment must be used.

Preparation of Tools and Materials

Required tools include torque wrenches, hydraulic pullers, and specialized lifting equipment. The specifications of replacement parts must comply with the original equipment manufacturer’s requirements; lubricants and cleaning materials should also be selected according to specific application scenarios.

Materials such as technical manuals and installation guides should be prepared in advance for reference during the operation. Measuring instruments can be used to verify whether components are installed in place and aligned correctly; the load-bearing capacity of lifting equipment must meet the requirements for hoisting heavy components.

Identification and Functional Analysis of Core Wear Parts

Impact crushers contain several core wear parts that require regular replacement. Understanding the function of each component helps technicians conduct standardized maintenance work. Components of different materials and designs play specific roles in the crushing process.

The wear patterns of wear parts can reflect the equipment’s operating status and material characteristics. Through regular inspections, the replacement cycle of wear parts can be predicted, thereby rationally planning maintenance schedules; accurate identification of wear part types also ensures the selection of correct replacement parts.

Function and Wear Patterns of Blow Bars

Blow bars are the main components for impact crushing of materials. They come into direct contact with materials and bear impact wear, so they need to be replaced regularly. Their wear patterns can intuitively reflect material characteristics and the crusher’s operating status.

If asymmetric wear occurs on blow bars, it may indicate an imbalance in the rotor or uneven distribution of feed materials; excessive wear at specific locations suggests problems with material flow. Regular rotation of blow bars can extend their service life and maintain crushing efficiency.

Protective Role of Liner Plates

Liner plates protect the structure of the crushing chamber from direct impact and wear, distributing wear across multiple surfaces to reduce structural damage. When selecting liner plates, appropriate types should be determined based on the abrasiveness and impact characteristics of the materials.

Whether liner plates need to be replaced can be judged by measuring their thickness. Excessive wear of liner plates will lead to reduced crushing efficiency and increased energy consumption; regular inspection of liner plates can prevent major failures and ensure the overall integrity of the equipment.

Maintenance Requirements for Rotor Bearings

Rotor bearings support the entire crushing mechanism and bear significant dynamic loads. Such components require proper lubrication and regular monitoring of their operating status. Once a bearing fails, it may cause severe equipment damage and significantly extend downtime.

Early signs of bearing deterioration can be detected through vibration analysis; monitoring bearing temperature can promptly identify lubrication problems. Regularly adding lubricant to bearings can extend their service life and ensure the reliability of equipment operation.

Detailed Replacement Procedure for Blow Bars

Replacing blow bars requires following a systematic process and standardized operating methods. Operating in accordance with established steps not only ensures correct installation but also guarantees work safety; each step must be performed carefully to avoid equipment damage.

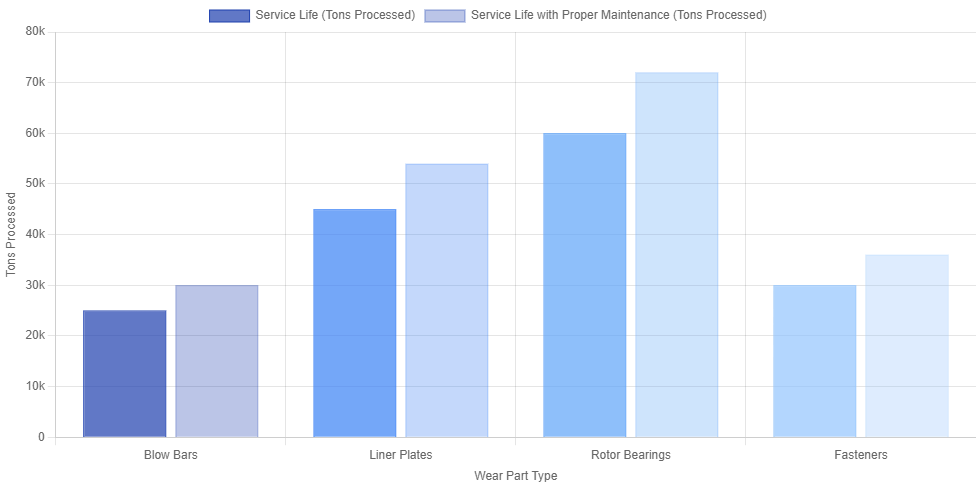

The replacement frequency of blow bars depends on the abrasiveness of the material and the total production volume. For materials with medium abrasiveness, in most production scenarios, blow bars need to be replaced after processing 20,000 to 30,000 tons of material; if processing materials with higher hardness, the service life of blow bars will be significantly shortened.

Power Disconnection and Safety Verification

The key first step is to achieve complete power isolation of the equipment. The main circuit breaker must be locked in the off position, and before starting work, a voltage test is required to confirm that the equipment is in a zero-energy state.

At the same time, mechanical isolation measures must be taken to prevent accidental movement of equipment components and ensure that crusher components do not rotate. Before disassembly, the pressure in the hydraulic system must also be released.

Disassembly and Inspection of Worn Components

Appropriate tools and methods should be used to disassemble fasteners. For rusted bolts, penetrating lubricant can be applied to assist in loosening; when using impact tools, extra care must be taken to avoid damaging threaded holes.

Disassembling components usually requires specialized lifting equipment, and stable support must be provided when removing heavy blow bars. During the disassembly process, adjacent components should also be protected to prevent damage.

Installation and Verification of New Components

The installation surfaces of components must be kept clean and undamaged, and alignment marks should be used to ensure the correct installation orientation of components. When tightening bolts, they should be gradually tightened in the specified sequence.

The bolt torque must comply with the manufacturer’s requirements; the torque for blow bar bolts is usually between 300 and 500 N·m. After installation is completed, a final check is required to ensure that all components are securely fixed. Before restoring power supply, a rotation test must also be conducted to verify that the components can rotate freely.

Testing and Verification After Component Replacement

Testing after component replacement is a critical step to ensure correct installation and the equipment’s readiness for operation. Systematic verification can prevent operational problems or damage to the equipment, and multi-stage testing can fully confirm the crusher’s performance.

Testing procedures must be documented in writing and strictly followed. If any abnormal conditions are found, immediate investigation and resolution are required. Standardized testing can reduce the risk of premature component failure.

No-Load Operation Testing

When starting the equipment for the first time, no materials should be added. Operators need to carefully listen to the equipment’s operating sound to determine whether there are abnormal noises caused by installation issues, and at the same time ensure that vibration values are controlled within the allowable range.

The equipment’s rotation speed should smoothly reach the required operating parameters, and the bearing temperature must stabilize within the normal range. During the testing period, all safety systems must function properly.

Load-Bearing Performance Verification

Materials should be added gradually to monitor the equipment’s performance. The crushing capacity should meet the expected production efficiency, and the product particle size must comply with specification requirements.

The equipment’s energy consumption must be controlled within the normal operating range. If abnormal vibration occurs, it may be caused by component imbalance or installation deviation. During the initial load-bearing operation of the equipment, continuous monitoring is required to promptly detect potential problems.

Common Replacement Problems and Solutions

Various problems may be encountered during the replacement of wear parts, requiring targeted solutions. Understanding common problems helps technicians handle faults efficiently; adequate pre-preparation can avoid most potential problems.

Recording problems and corresponding solutions can form valuable reference materials; sharing experiences can improve the overall efficiency of maintenance work, and continuous improvement can reduce difficulties in future replacement operations.

Component Loosening and Fixing Methods

Improper application of bolt torque is the main cause of fastener loosening. Thread lubricants should be selected according to application requirements, and anti-loosening devices can be used to prevent loosening caused by vibration.

Regular re-tightening of bolts can maintain appropriate tension of fasteners; after the initial operation of the equipment, the bolt torque needs to be verified. Standardized operating procedures can ensure long-term stability of components.

Performance Issues After Replacement

Reduced crushing efficiency is often caused by improper installation. The alignment of components affects crushing performance, and adjustments may be required to achieve the optimal operating state.

Material characteristics have a significant impact on crusher performance. If the feed material changes, adjustments to the equipment’s operating parameters may be necessary. Monitoring can help grasp performance trends and clarify maintenance needs.

Maintenance Recommendations and Methods to Extend Service Life

Proactive maintenance can extend the service life of components and reduce operating costs. Adopting a systematic maintenance approach can prevent unexpected failures and production losses, and continuous attention to the equipment’s status can ensure its reliability.

Maintenance records can provide valuable historical data; through analysis, areas for improvement can be identified and replacement cycles optimized; a comprehensive maintenance plan can ensure long-term stable operation of the equipment.

Regular Inspection and Monitoring

Through regular inspections, signs of wear can be detected before component failure; recording component measurement data can track their deterioration process; with the help of trend analysis, the optimal replacement time can be predicted.

Through visual inspection, surface damage and abnormal wear of components can be identified; non-destructive testing technology can detect internal defects of components; a comprehensive assessment of the equipment’s status provides a basis for timely maintenance work.

Operating Specifications to Extend Service Life

Reasonable control of feed materials can reduce component wear; strictly adhering to the feed size limit can prevent equipment overloading; classifying materials ensures stable equipment operating conditions.

The equipment’s operating parameters must match the material characteristics. For different materials, performance can be optimized by adjusting the rotation speed. Through continuous monitoring, the equipment can maintain efficient operation and the service life of components can be extended.